Hey everybody. This year I'm making the leap to road course events with this Corolla I've been working on for the last few years. I'd been autocrossing in my MR2 Supercharged for 10 year or so, but I went full track-toy with this car, and would love to get input from you guys (and gals) on what I've done so far, as well as things to aim for in the future of the project. I welcome any constructive criticism on making this thing more reliable and safer for trackcross/HPDE events. Thanks for reading!

June 2017

I recently finally sold my 1986 Cressida wagon, not due to any fault of the car, but just due to lost interest. As much as I liked that car it just didn't have that spark for me any longer. I realized as cool as the wagon was, I wasn't driving it often enough, and didn't enjoy the car as much as I used to. After riding with some friends in their Miatas as VIR, I realized I had to get on track. I have too much emotional attachment with my MR2 to flog it on a road course, what I really need is a normally aspirated light weight car that I can be confident in flogging - both mechanically, and with regards to my own personal driving skill (or lack thereof). As it just so happens, a friend of mine recently moved and was unable to bring his 1987 Corolla FX16 GTS with him, and it had just sat at his place of employment for over a year. He offered me what I think was a good price, and I brought the little 'Rolla home with the intention of making it a track car.

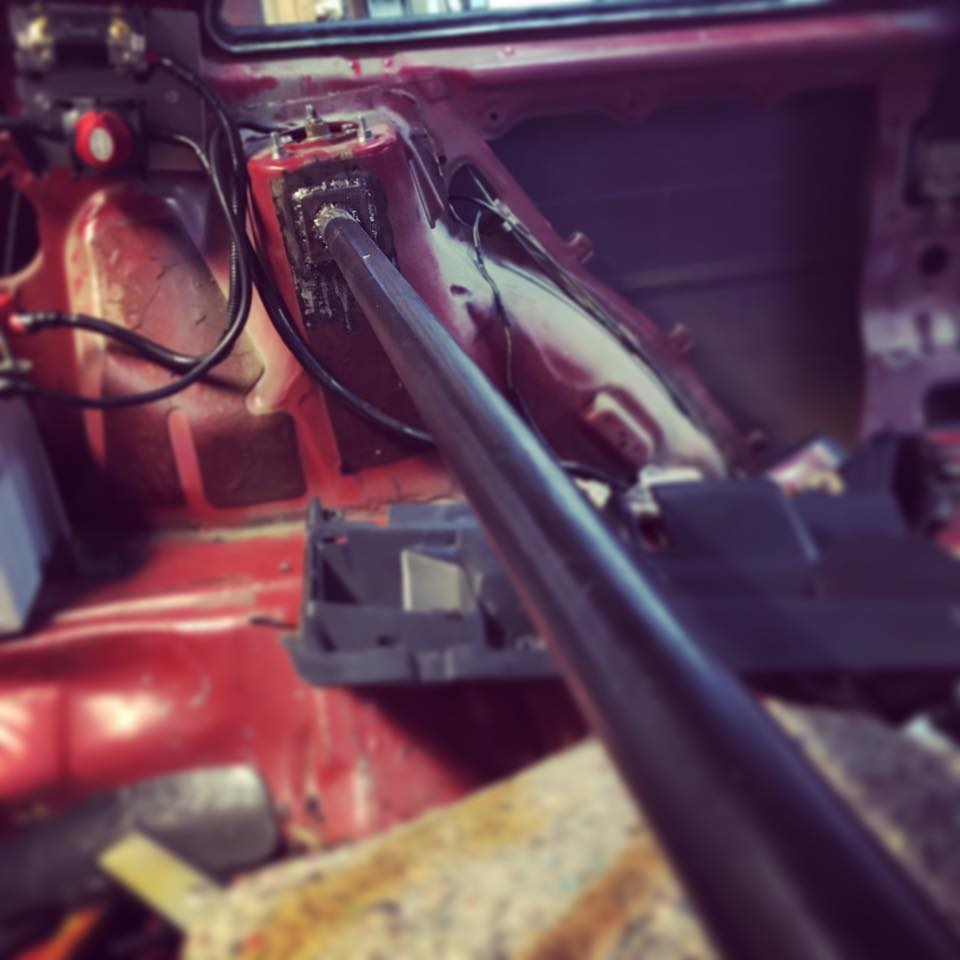

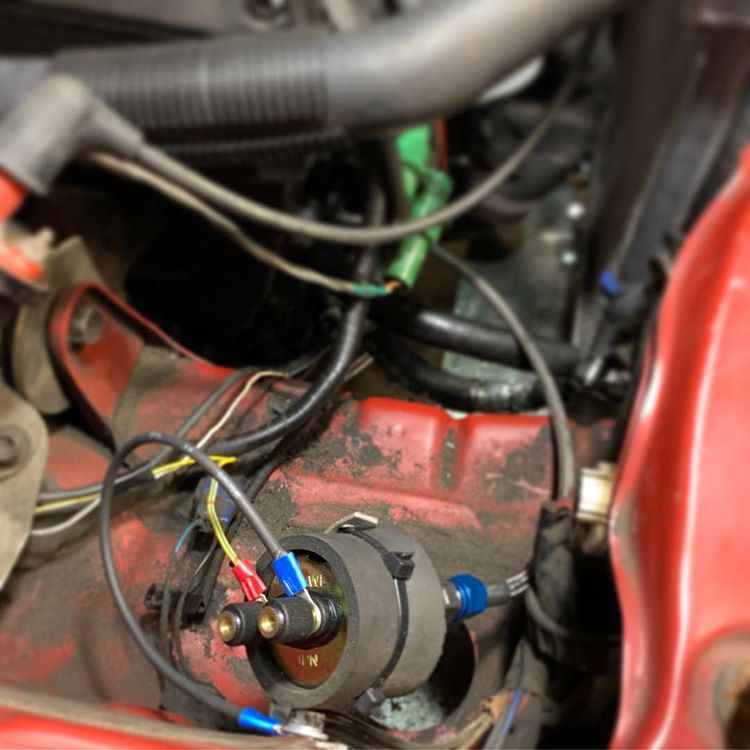

When I went to pick the car up, it started right up when jumped, and drove onto the trailer under its own power. However when I got home, the car would just crank and crank without starting. It was then pushed into the garage so I could start tearing into it. The first step was a new battery so I didn't have to jump it every time. The previous owner had already relocated the battery to the trunk/hatch area, so I replaced the (very dead) group 35 battery with a new group 51R for a little weight savings. I also refined the relocation by adding corrugated plastic sheathing over the power wire to protect it, as well as adding a cutoff switch and a 150A fuse, mounted to a panel I made out of totally-not-a-stop-sign.

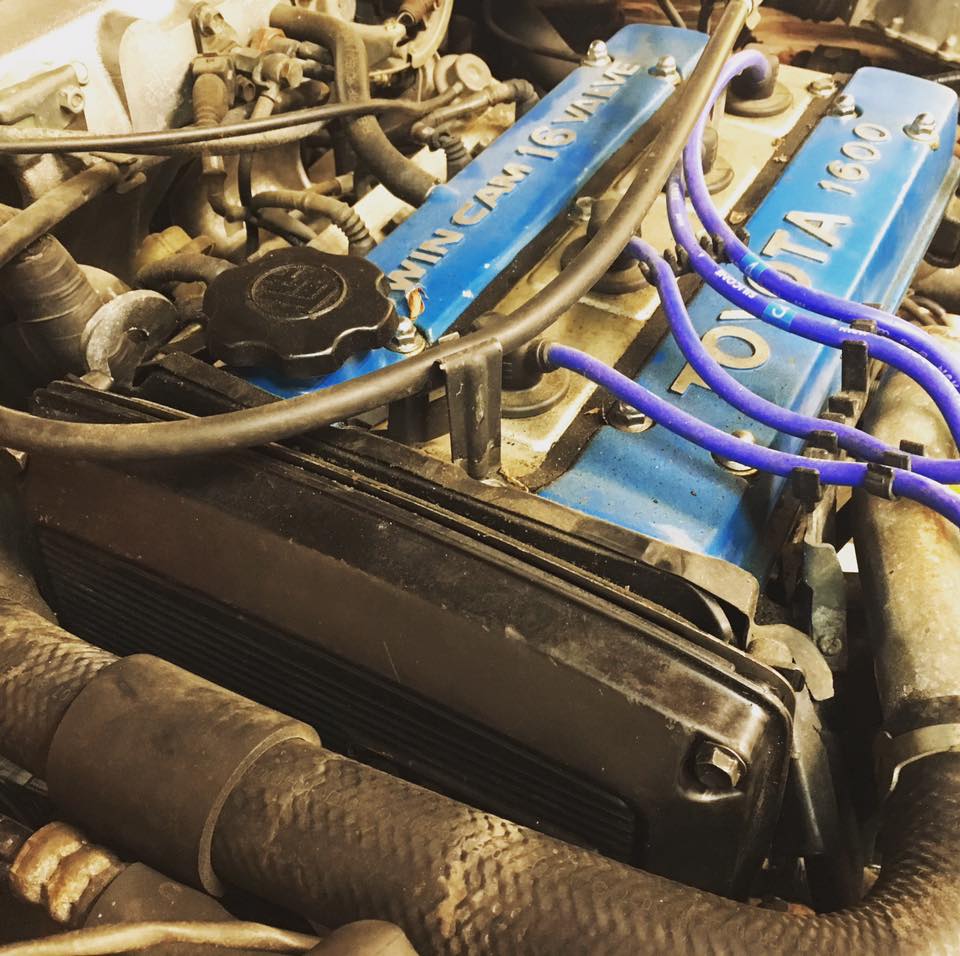

The first thing I had noticed when I opened the hood was the intake duct from the airbox was wrapped with duct tape and possibly a huge vacuum leak. The previous owner had left an intake pipe from a Jeep or something in the car, so I chopped that up and welded it back together to fit.

Considering it was my first attempt at welding, I don't think it looks too terrible. I did do a couple extra passes to make sure it's air tight.

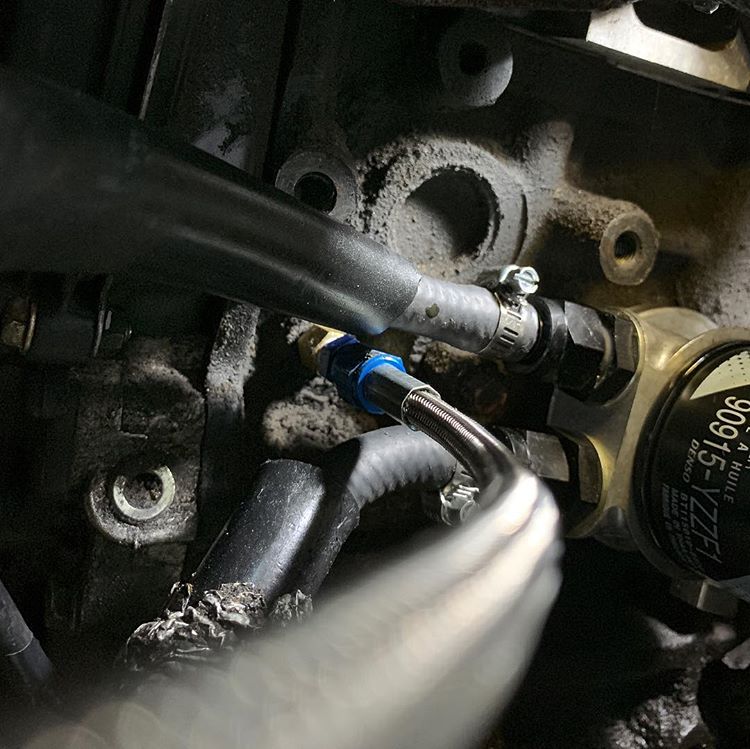

I also had to add a barb for some vacuum lines. A quick coat of paint later and it was installed in the car. However it still wouldn't start. At this point I had a feeling it was a fuel issue, so I loosened the fuel line fitting at the cold start injector and cranked the car again. Some fuel came out, but it didn't seem like the pressure was quite where it should be. The big thing I notice though was the fuel smelled like paint thinner. I ordered a new Denso fuel pump, and with the help of some friends, spent a Saturday dropping the tank.

Once the bad fuel was removed, new pump installed, and fresh gas poured in, the car started right up. Now that the car was running, I could start thinking about some weight reduction modifications. The rear half of the interior came out pretty quickly, as well as the spare tire. I also removed the rear wiper arm and motor, partially for weight savings, and partially because it's ugly as hell.

Being a front-heavy car, I want to remove as much weight up there as possible. On my MR2, I replaced the heavy cast iron exhaust manifold with a stock 20v 4A-GE part, so I wanted to do the same on this car. The 20v manifold is tubular steel so it weighs less, can be heat wrapped, and flows a little better. However unlike the MR2, the FX's starter is on the exhaust side of the engine, which means more extensive modification of the manifold is required. That will be covered in future posts, as I am currently waiting on parts.

While the exhaust was off, I went ahead and removed the EGR. Just say "no" to higher underhood temperatures, carbon buildup inside your intake, and extra weight, folks.

Also included in the car was the original front grille, which really ties the looks of the front end together. However that had to be removed again so I could start removing AC components.

An anonymous local dumpster kindly donated a few large alumacore signs for future aero projects. Alumacore basically consists of two thin layers of aluminum sandwiching a layer of rubber or plastic between them. It's not the lightest thing ever, but it's very rigid for how thin it is, and is a great cheap material to make splitters and other aero parts from.

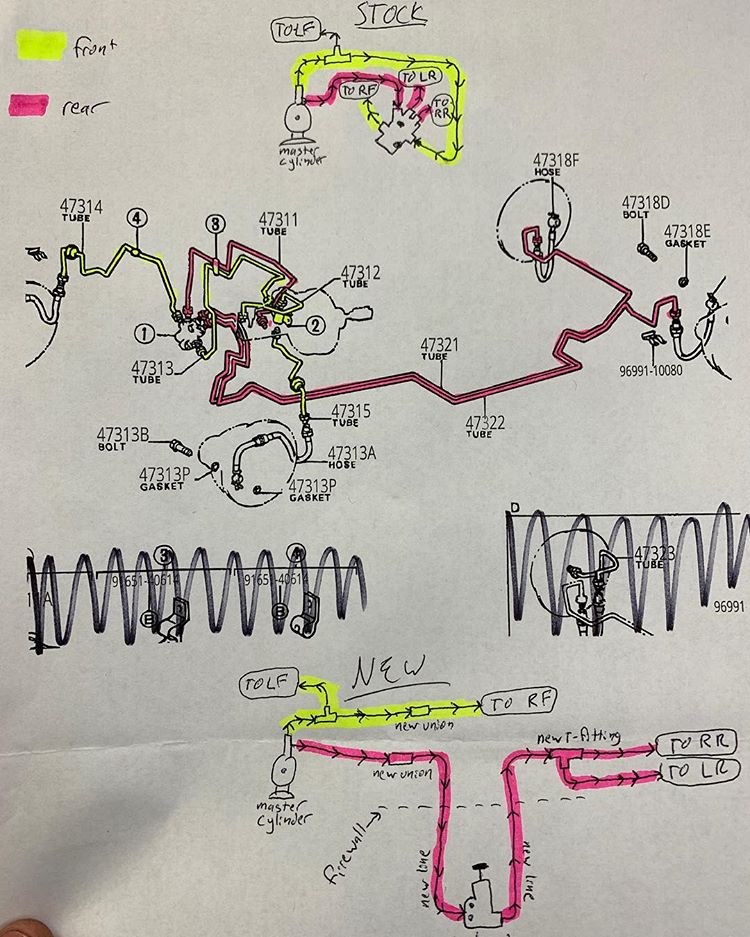

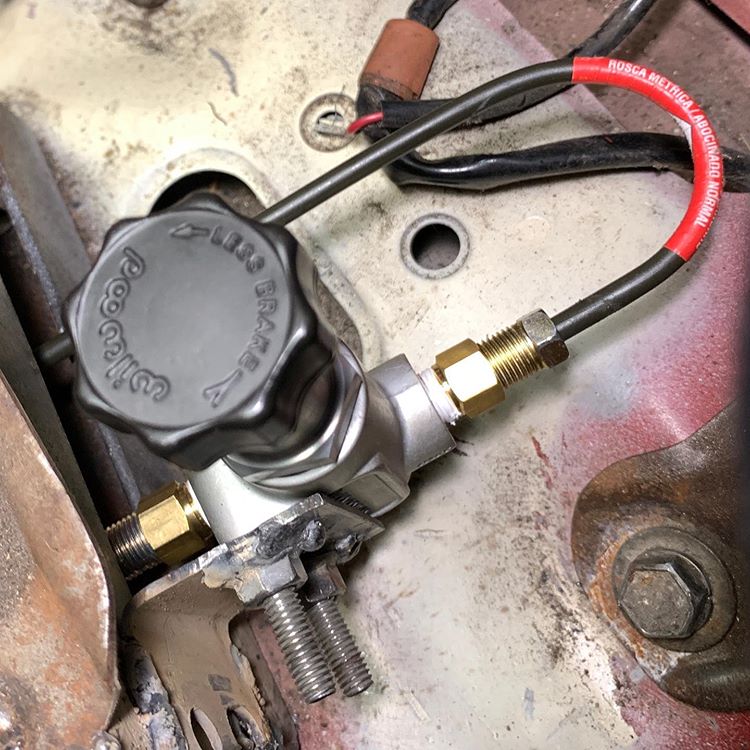

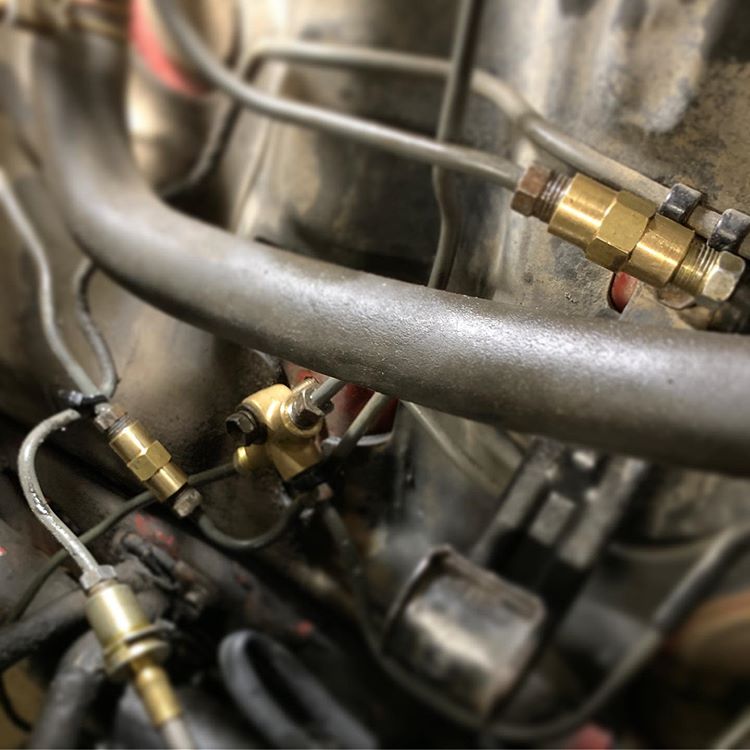

Next on the list of stuff to be upgraded was the brake system and shifter. The aftermarket for the FX16 is basically nonexistent so I spent a lot of time cross-referencing part numbers to see what parts from other cars would fit. I discovered that the front brakes are identical to 85-86 MR2s, which means 87-89 MR2 front brakes are a bolt-on upgrade. Unfortunately the guy I ordered calipers from sent me the wrong ones, so I'm currently waiting on the correct caliper brackets to come in. The upgrade is really in the rotors, as the calipers and pads are the same, you just need the correct brackets to accommodate the larger MR2 rotors. For pads, I discovered that rear pads for a Celica All-Trac are the same, so Porterfield HP R4S pads were selected front and rear, and Motul 600*F synthetic fluid will be going in. I've had great luck with those on my MR2 in the past.

AW11 MR2 stainless lines, Celica All-Trac rear pads, new stock rotors, and Motul 600* fluid should work great for a rear brake setup. Also note in this picture that the rear struts have been replaced with KYB's. This will make building my own coilovers much more difficult for the rear. I'll cross that bridge later.

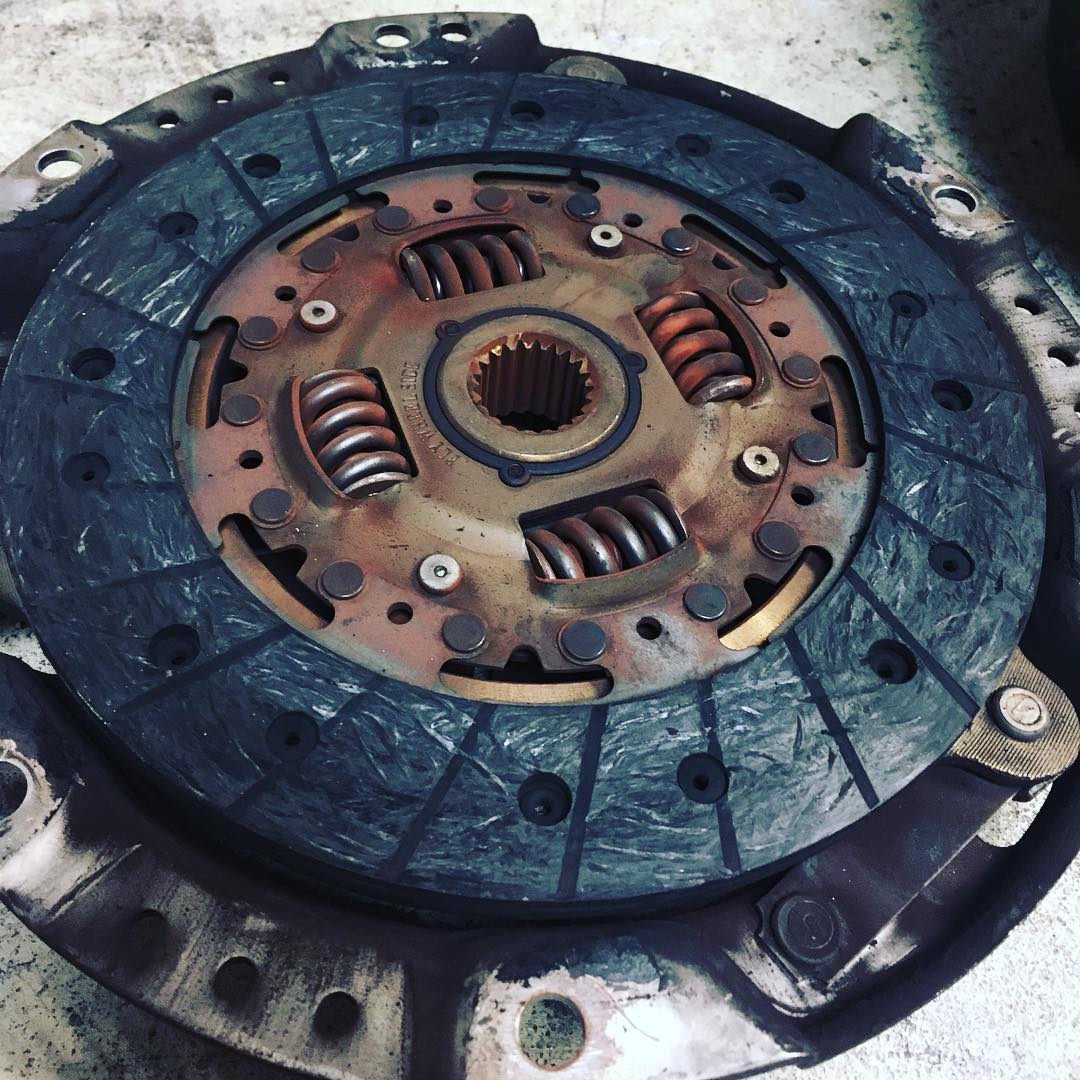

MR2 brass shifter bushings fit great, but are a serious pain to install. AC lines, intake, and charcoal canister all get in the way. It was so much easier on the MR2! I also took the opportunity to grease all the pivot points and rotate the 'little square bushing' where the arms meet for much better shifter feel.

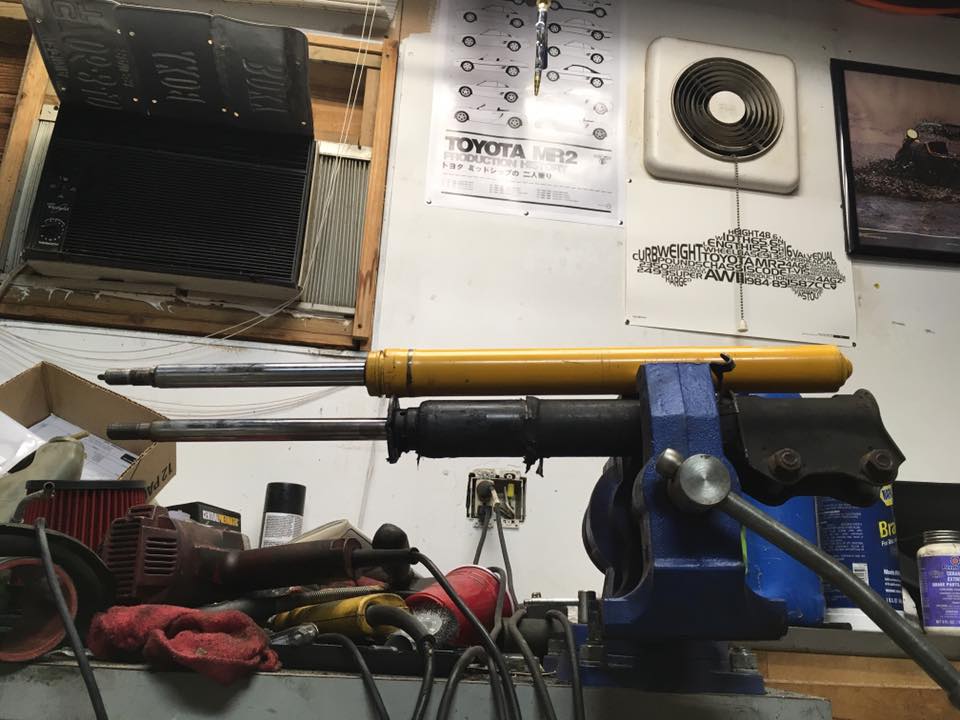

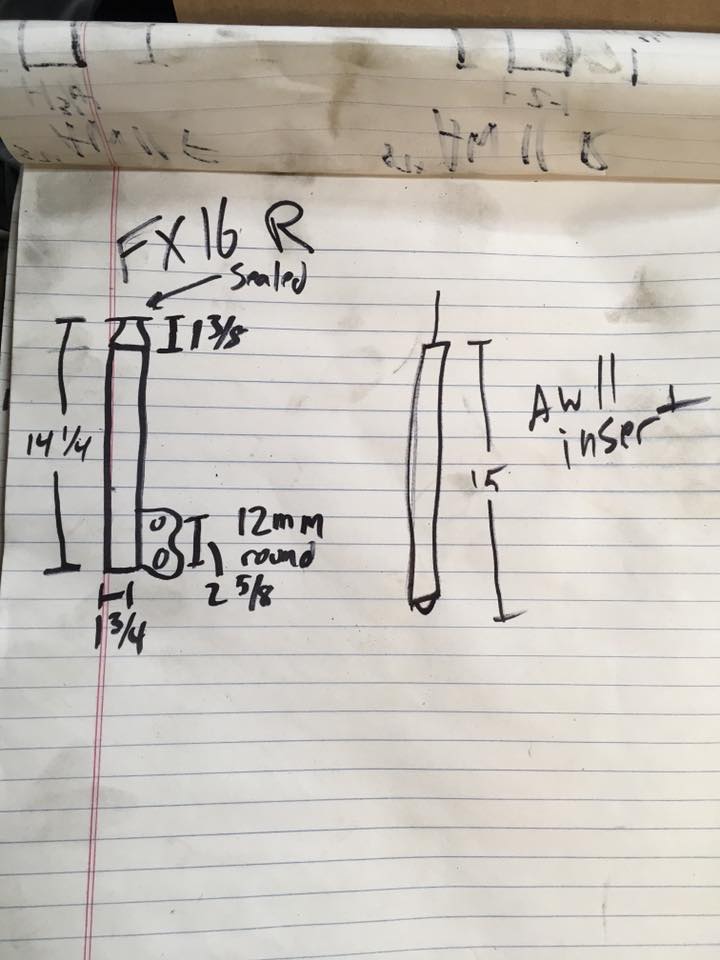

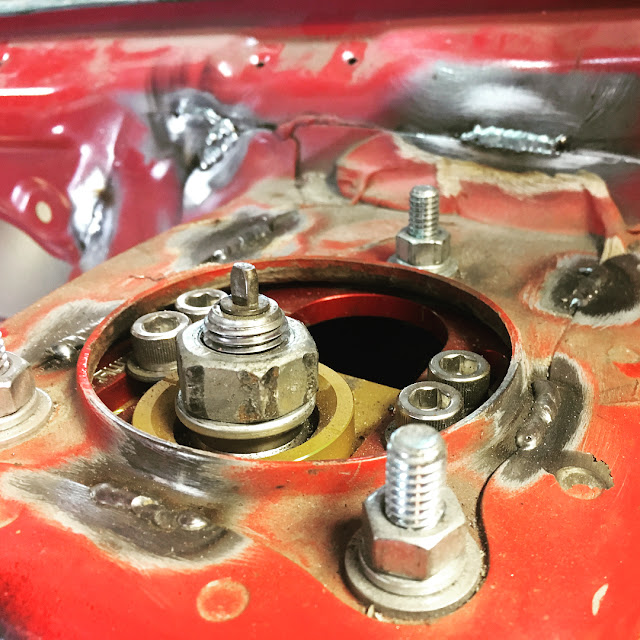

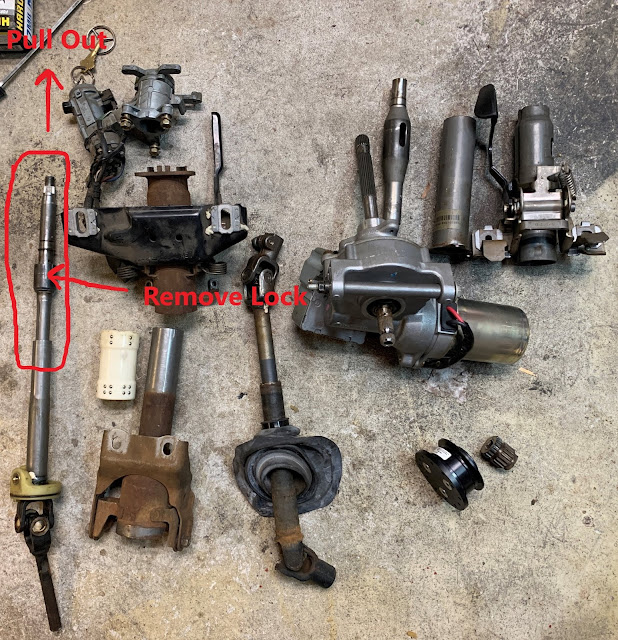

Remember how I said aftermarket support for the FX16 was nonexistant? That includes shocks. Koni no longer makes inserts for the FX so I'll be forced to use parts from other cars. BC makes a set of coilovers, but I've heard that while that brand is perfectly adequate for spirited street driving, something a little more established is better for track duty. That's why I'll be going with a DIY coilover solution using Koni adjustable shocks. I removed one of the front struts to take measurements and compare with some MR2 parts I had laying around. Left to right, we have AW11 front (modified for coilovers), AW11 87-89 rear, SW20 rear, and finally the FX16 front.

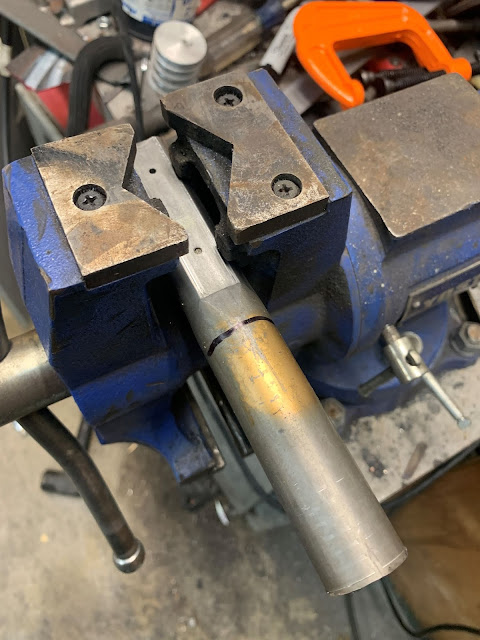

Here are the rough measurements I took. The FX16 front and AW11 rear housings are almost identical, with the AW11 housing being a couple mm longer. The SW20 rear housings are similar, but are a little longer still, and do not have an eccentric upper bolt hole. Another big difference is the MR2 housings have a courser thread for the gland nut, but the FX16's thread is much finer.