I really want to get down to Barber sometime soon. I went to school in Huntsville and have lotsa friends down that way. One is an instructor there at Barber and I think helps run some of the TAC autocrosses.

I really want to get down to Barber sometime soon. I went to school in Huntsville and have lotsa friends down that way. One is an instructor there at Barber and I think helps run some of the TAC autocrosses.

BradLTL said:In reply to Ian F :

It was this thread that I used to help make my decision: https://www.northamericanmotoring.com/forums/drivetrain-cooper-s/287613-m7-speed-crank-pulley.html

Basically, M7 set themselves up to be flamed and no one could establish a case of a real world issue. Maybe that’s just my wishful thinking. I don’t have any loyalty to M7, if I have an issue you’ll all know about it.

So, here I am... eating my words.

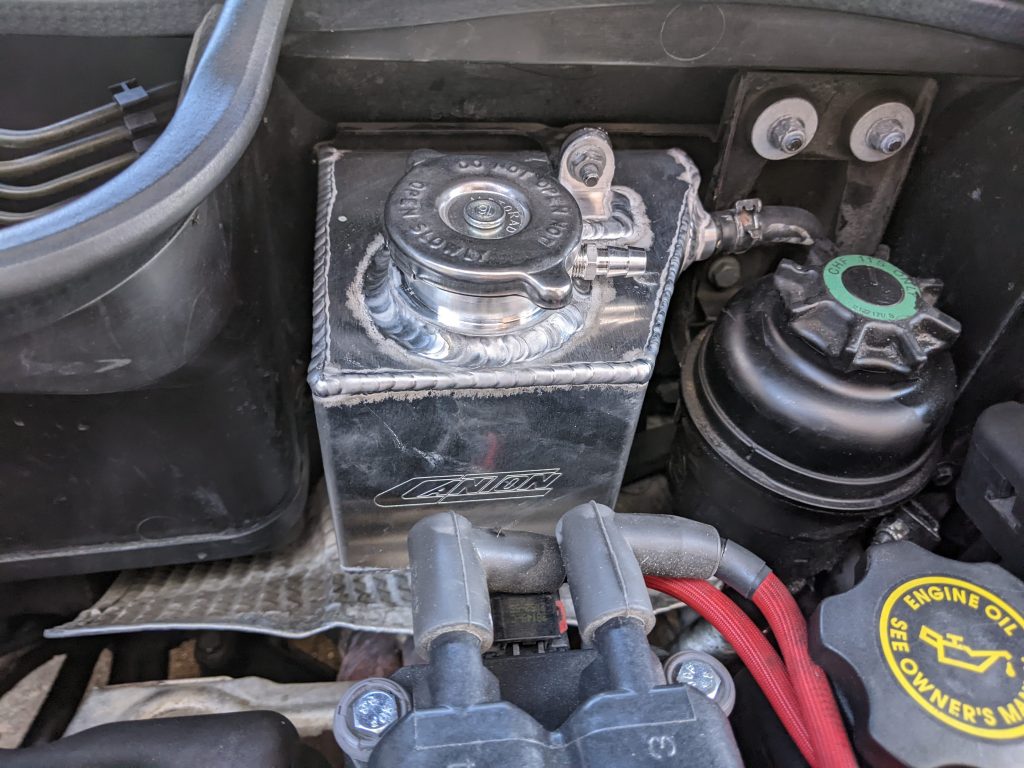

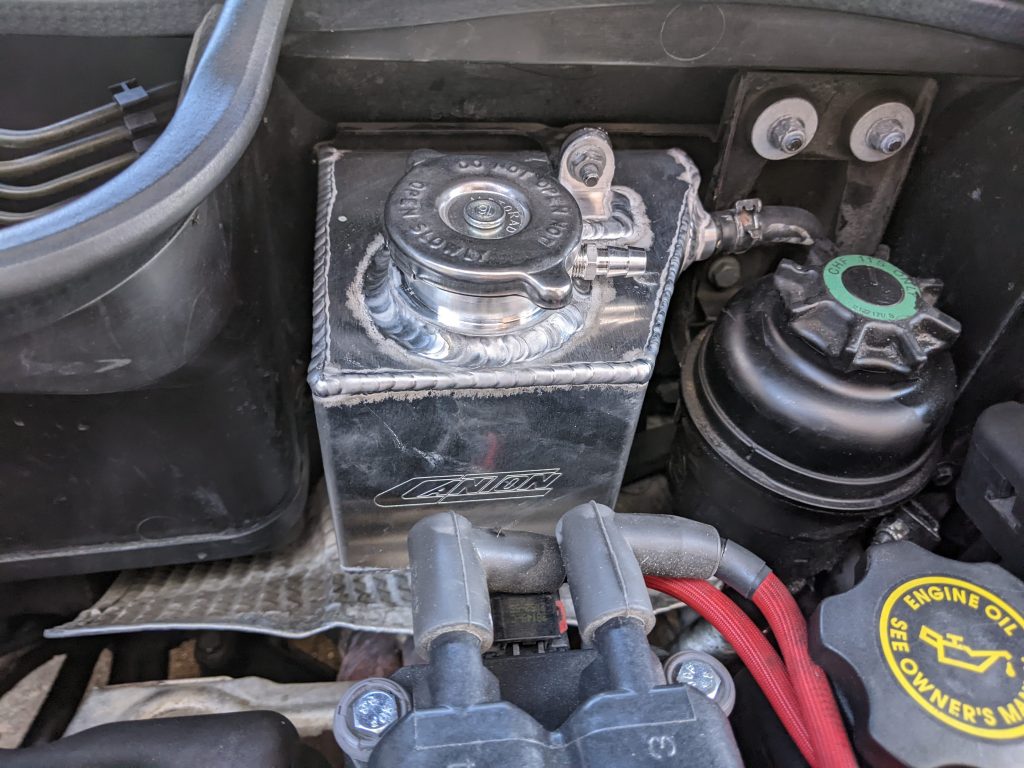

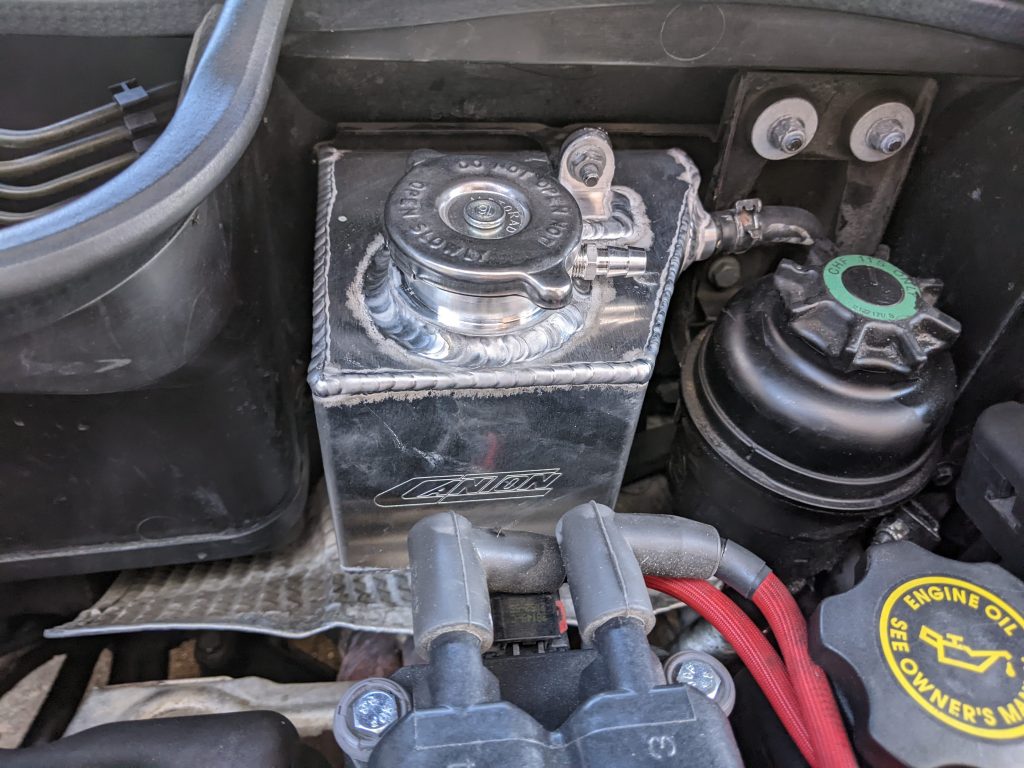

Thankfully, my Mini wasn't damaged. As Way was going through my car, we had discussed swapping to an ATi crank pulley for reliability reasons. He dug in and found that I have been dodging bullets for awhile. Way's opinion is that the M7 pulleys were machined incorrectly and that was causing some strange alignment and forces on/caused by the belt. One pulley was pulling the belt out, the other pulling in. This caused fraying on the edge of the belt and caused the SC pulley to rub on the super charger body. Way confirmed there wasn't any issues with the shaft. Needless to say, both pulleys are in the bin now.

Friday made the trek over to Atlanta to reclaim the Mini. After an extended wait, the coil-overs finally came in and were installed. The last item was the trailer hitch. The one in stock was for a different model, so it was a last minute order. But FINALLY… it’s done?

First of all, really appreciate Way and the team at Way Motor Works. They really worked with me as a partner on this part of the project. Way and I talked for a couple weeks before doing any work (or spending any money) on the goals and budget. We refined the list of parts and work that needed to be done. Then as the work was being done, I would get calls when they saw something that should be addressed while they were doing the work. Just in the course of doing the work list, they found a couple gaskets, a hose, and a shifter cable that needed to be replaced. Any of those items failing would have ruined our OLOA event.

Here’s what all was on the invoice from Way:

So, you know not much, really. I’ll censor the price tags to protect the innocent, but will share some pictures of what you can see:

Initial impressions were very limited to a 2.5 hour interstate cruise home. The car is definitely more stiff, but generally not too bad. The bigger sharp dips are where you really notice how stiffly sprung the car is now. Power is roughly the same as before, maybe slightly less. I think Way would argue this one with me, but we didn’t do before/after dynos so we’ll never know for sure. Any which way, not enough to worry about.

The biggest change is the clutch. Going from a worn stock clutch to a new racing(ish) clutch is quite a change. The pedal feels about the same. It’s not overly heavy and the pick up point is in about the same spot. The difference is in the grab. The OS Giken clutch grabs immediately and holds. You have to be ready with the throttle and ready to go, there’s no slipping this clutch.

The ride home was uneventful, except the price of gas. Now it’s the time to finish setting up the car and starting to dial it in for One Lap of America.

Seeing this really makes me miss my 2006 Cooper S. I sold it after 5 years and 40k miles. It was a really fun car, but bone stock. The stock suspension on R53s was quite stiff. I imagine yours is now really firm, but having quality shocks can make that livable. It will be interesting to see how it handles now.

I'm going to get the seat and roll bar in it and then try and get it to little 'dega to start dialing it in this month.

Less than a month away from the start of One Lap of America 2022... and we still aren't officially in the event. We've moved up a good bit on the wait-list, but as of today we are still #29. I really need some people to finalize their decisions because this waiting game is putting us in a bind on logistics.

There's still a number of larger expenses to go (not counting the remainder of the entry fee): a trailer, a 5th wheel and a set of tires for the event, the roll bar, and some smaller odds and ends. I'm going to do the roll bar, but am going to wait on the rest until we are confirmed.

There isn't an immediate need for a trailer outside of this event, so that will have to wait. Roughly $1,000 to build a custom trailer isn't a necessary expense... yet.

Tires become the real challenge. The plan all along was to purchase tires and have them installed at TireRack the day before the event. That would provide the most life in the tires through the event. The issue is supply chain and availability. I don't want to purchase tires and have them sit in South Bend if we are not in the event. So, I can't order them until we are confirmed. That means we might not be able to run our preference of tire, and have to settle for the tires that are in stock. Here's the list.

Our preference would be the Yokohama Advan A052s. However, they are on back order. After that I think it is the Continental ExtremeContact Force, and the Falken RT660s.

It's not all doom and gloom. There have been some updates on the car development side of things. The most important bit was that the seat came and I was able to get it installed. We went with the Corbeau FX1 and matching bracket for our Mini. Installation had a few small bumps, these were do to the seat bracket design.

The bracket design basically captures the bolt that holds it to the floor. Makes it near impossible to get the bolts back in. So, I engineered a solution. I cut a notch that provided the needed clearance to get the bolts in properly.

The only other complaint is that I wish the rails were 1/2 to 3/4s of an inch further towards the middle of the car. The shoulder of the seat hits the door, there's more room towards the middle of the car that should minimize that. I may come back to this and modify the bracket at some point.

The Mini is also going to become part truck. The Trailer hitch came in and I did a test fit. I'm going to have to get under the car to get it fully installed. I also need to wire up the connector for the trailer lights and a new reverse light.

The other major work effort that is immediately on my plate is getting the suspension completely setup and dialed in. I've got a bit of analysis paralysis on this effort though. It's a big effort and one that I don't have any first hand experience (in the real world) at performing. I'm trying to convince a friend that they really want to help me get it setup, just to have that more experienced set of eyes guiding the process and making sure I don't make significant mistakes. I have all the tools ready with an alignment kit, and a nice set of scales.

Lastly, was able to finally install the Ultra-gauge. It's a simple and effective tool to provide information that is not readily available on the gauges in the Mini. It also has the ability to alert on specific conditions reported (e.g. high engine temps). For the price, I can't imagine you could be the value. It was $80 with a $7 mount. I had a 3D printed mount for it, but there was some design issues on it and it was just easier to buy the official mount versus design and print my own. Maybe that is a project for another day.

So, we keep waiting and working. Based on some personal things that are going on, we've set our cut off date to be April 18th. If we have not been officially confirmed to the event by then, we are going to withdraw until next year. That would really suck but that is the reality of things as they are today. We moved up 7 spaces two days ago, but none yesterday. Right now I think we are right on the line if we will be in the event or not. Stay tuned.

Car looks great! I think the seat mount points are just ever so slightly off-center on these cars. I have the same problem with the door card making contact with my seat on the drivers side, no issue passenger. The door card self-clearanced but I don't love the slight indentation left on the card and seat. Very minor, and no noises, but also no issue passenger side.

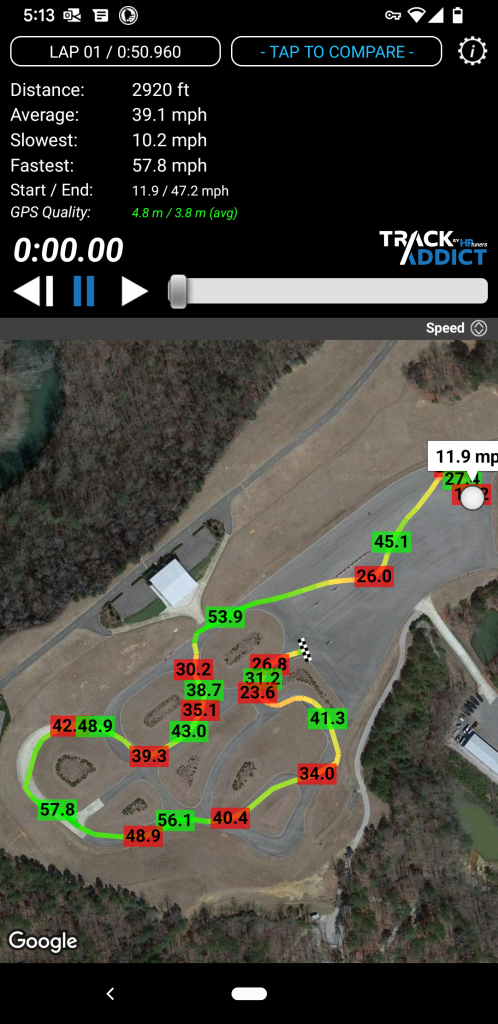

Well, it was more testing the tuning comes later. Good news is that we’ve moved up about halfway through the wait-list. Bad news is there’s still a good ways to go. We are currently sitting at #23.

This event was much more about learning how the Mini handles with all the changes and updates. With a redone suspension and drive train, the car is literally going to drive like a new car. Initial impressions are that the car is a ton faster, and much easier to drive faster.

The LSD made the first impression. That was mostly because the first turn on the course setup was a 1st gear hairpin into a fairly long straight. Ideally suited for unloading a tire and spinning it. As soon as I was on the exit of the turn, I would hammer down the gas and the car did not complain one bit. It just started accelerating, no spinning of tires. There was another section at the end of the course with a 4 corner S (left, left, right, right complex) that was a slow 2nd gear corner. Again, hammer down on exit, where previously the inside tire would have spun the car just pulled to the finish of the course. Overall, very happy with how the LSD performed.

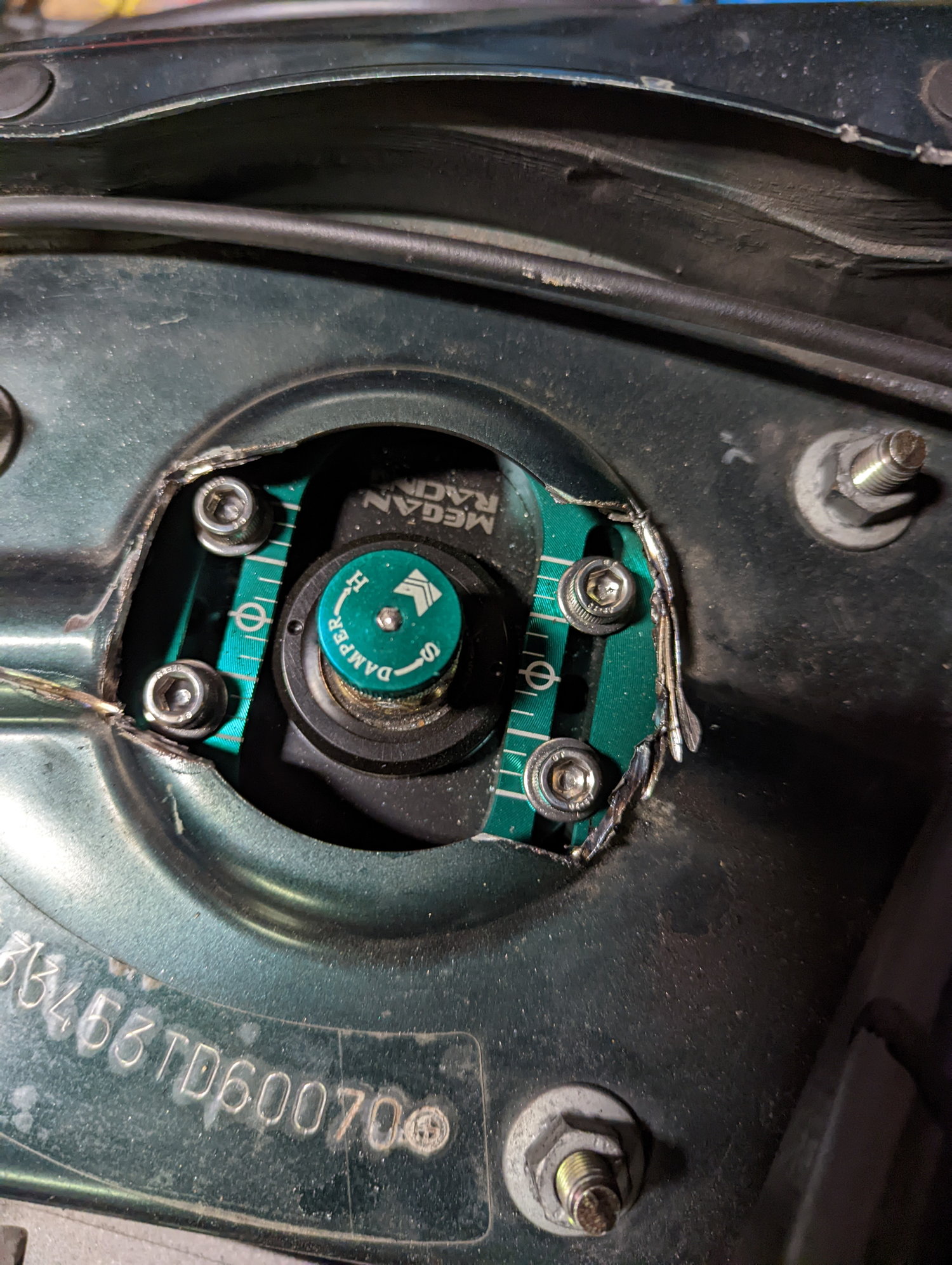

The coilovers (and sway bar, control arms, and bushings) were the other major area of unknown. My fear was that adding and stiffening the suspension would cause the car to become twitchy under hard braking. The car would get a little nervous in those conditions, it never felt uncontrollable. And honestly, it was more predictable than on the stock suspension. With the lowered ride height and increased stiffness all the way around, it was much easier to understand how the tires were coping with the demands being placed on them. I was able to use more of the tires ability in both braking and turning. It was a dramatic difference even without running the slicks. The car just felt fast, and managed hard braking and change of direction significantly better than stock. There was a high speed section that required a small, but quick left to right to left. In a couple runs, I noticed that I picked up a small bounce on the rear end going through that series. I should note that the coilovers are running right in the middle of the range for stiffness and the car hasn’t been fully dialed in with an alignment and corner balancing yet. Very positive start here though.

A few other odds and ends…

The seat was fine. While driving, I really didn’t notice it much. I didn’t feel like I was significantly better or worse for it. I don’t have the full harness in yet, so I was still using the factory belts. I did not have a sore spot on my leg from bracing myself while racing, so maybe it was doing more than I realized. I’ll reevaluate it after the full harness is installed.

The UltraGauge did everything it was expected to do exactly as expected. The mount held well, and the placement was perfectly visible in both day and night (well early morning, but dark). What I found in watching the readings is the engine temps pick up a good bit when sitting still. In the drive thru getting breakfast and coffee, the engine temp went from about 170 to 210. The factory gauge just showed the needle right in the middle with no fluctuations at all. I’d probably be happier not knowing, but I think the visibility is ultimately a good thing for managing the car and performance.

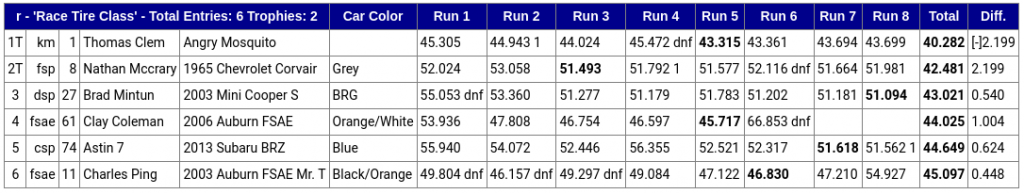

While results weren’t the goal of the day, I’m pretty happy with how it ended up. I didn’t technically win the class, but classing for the Mini is weird with the SCCA these days. I’m not sure how a car competes with a shifter kart and a couple Formula SAE cars, but whatever. For the event (and to be more like One Lap of America) I ran my worn Dunlop D3s, everyone else in class was actually on their slicks. Despite that I put in the fastest RAW time for cars in the class. PAX is just an argument waiting to happen, so we’ll leave that one alone.

One of the few things to go wrong on the car during the event was my mount and the app I use to record the runs. It started with me forgetting to setup the track during the morning walk, so I missed the morning runs. I set it up during the lunch break and was prepared to capture the runs in the afternoon. I’m guessing the app lost permissions to the camera because it did not record any video. I also only managed to capture 2 runs. On the 3rd run the mount popped off the window and feel to the floor board. That was basically the end of that. Here’s the 2 runs it did capture:

No Lap of America 2022

Sad trombone noises play...

10 days until the start of the One Lap of America event. We had climbed up the order from 46th, to 29th, to 21st, and finally to 14th on the wait-list. Looking at the remaining entries, I only counted maybe 7 that were questionable or incomplete. I talked with Brock and he didn't have any good news either. The entrants didn't have the attrition of the last few events. That's good for OLOA, but wasn't great for our entry.

So, here we are 10 days from the start and having to bow out (or really just take our name off the wait-list). Without being confirmed, we haven't ordered event tires, we haven't booked hotel rooms, found a trailer, packed, booked a flight for my dad, and there are a couple personal things that need committed scheduling. This was the line in the sand for us, past this it would be hard to put together a good entry.

It's disappointing to not be in the event. A lot of work, sweat, dollars and effort went into trying to make this happen. Trying to find the bright side, none of the effort was wasted, it doesn't expire and we are already planning for next year's One Lap of America event. I'm more connected to the event now so we should be able to put our names on the list and not get stuck in wait-list hell.

I guess now I have a year to finish sorting the car.

With One Lap 2022 in the books, the urgency to get things done has lessened a good bit. Like any good project car, there still are things to be done. There always will be...

The last (or currently last) major component needed was a roll bar. It isn't required by OLOA, but it is an important safety component. This car is a "mullet car" (yep, totally made that up) it's business in the front and party in the back. Meaning, most of the interior is still in the front of the car, the back has been mostly gutted. Wanting to keep the car practical for street driving, means that a full cage wasn't in the plan. That left a few options: something pre-fabbed, a bolt-in bar, or a completely custom bar.

Being tall I have the seat all the way back on the sliders while driving. That doesn't leave much/any room behind the factory seat for a bar, so it was looking like something custom was going to be the answer. Before committing I wanted to get the new seat installed and see what the actual spacing was going to be behind the seat.

http://www.kirkracing.com/index.html

I reached out to Mark Stewart at Kirk Racing and talked through the options. I settled on the bolt-in bar he offered. There ended up being about 2" of space behind the driver seat when in the full back position. That's a enough space for the bar and the bolt-in is a considerable cost saving over a full custom bar.

I dropped the Mini off last week. Mark had the bar built, painted and installed in a couple days. It actually took me longer to go pick up the car than it did for him to install it. The only negative with the bolt-in bar is that where it mounts behind the seats requires removing the factory seat belt anchor. So, without some modifications, the factory 3-point belts can't be used. For the driver's side, I already have the 5-point harness to install. Just need to decide what to do with the passenger side now.

It has been a bit since I've provided an update, but that doesn't mean there hasn't been activity. The reality is, there has been too much activity. With summer ending, family vacations, school starting back, kids testing for a black belt, the world games, learning to weld, non-stop work and conferences... it's really just sapped my desire to sit down at a computer and write.

I guess that's my way of warning you this will be a long post that will wander over a bunch of different updates. Also, if anyone is wondering why Max is leading (winning) the F1 championship... I'm not saying I helped, but I'm also not saying that I didn't. 6.4s to single handily change the tire.

I guess we'll start at the end, the back end... specifically the trailer. It's long been part of the plan to add a trailer to the Mini. First it'll help with track days, getting race wheels/tires to the track, all the extra equipment and tools, etc. Secondly, it would be great for quality of life in One Lap of America 2023. We can't use race specific wheels/tires, but we can carry a lot more gear, snacks, pillows, the essentials. So when Tim (Aircooled at GRM) came through with some friends and family discounts, that immediately became a trailer.

The trailer hitch was already installed on the Mini, we just needed the trailer to pair it with on our adventures. I went with the Harbor Freight 4x6' lightweight trailer. First step was paint to more or less match the car, then on to assembly. Putting the trailer together was straight forward. I focused keeping things aligned, since pre-reading told me that there were some level of tolerances to expect with cheap Chinese steel.

I took my time and it took about an afternoon to get the build complete. I was out of square by 1/16" I called it good enough. I also was not a fan of how they routed the wiring, so I had to drill a few extra holes to clean up the wire routing. Once that was done, I bolted on some good plywood and the front tool box. Four 245 wide tires juuuuuusssst fit. So this layout probably wouldn't work for your Corvette.

Remaining work on the trailer is mostly on the Mini. I have 8 wheel chocks that I'll bolt on the trailer to add some stability to the tires. Those will come off during OLOA and another box will be added for storage.

Moving on to the Mini. I need to wire up the electric harness still. I hate working on wiring, it's like the least satisfactory work effort. Since I removed the reverse light for the trailer hitch, I need to add another to keep the car street legal. This was solved in the cleanest way possible. I sourced a set of R52 taillights. These lights are direct replacements for the units on the R53, but have an integrated reverse light in them. I have two wiring projects that are related, and will tackle them both at the same time: rewiring the taillights, wiring the trailer harness.

Next on the to-do list was getting the suspension fully sorted out and the car balanced. That meant breaking out the scales and alignment kit. I didn't do a great job of getting pictures of the alignment process, but let's say it was less than graceful. We did get to the result we wanted: -1.3 degrees of camber on the front, and -0.9 on the rear.

The coilovers gave me an excellent chance to work on my metal grinding skills. I'm truly a function over form fabricator.

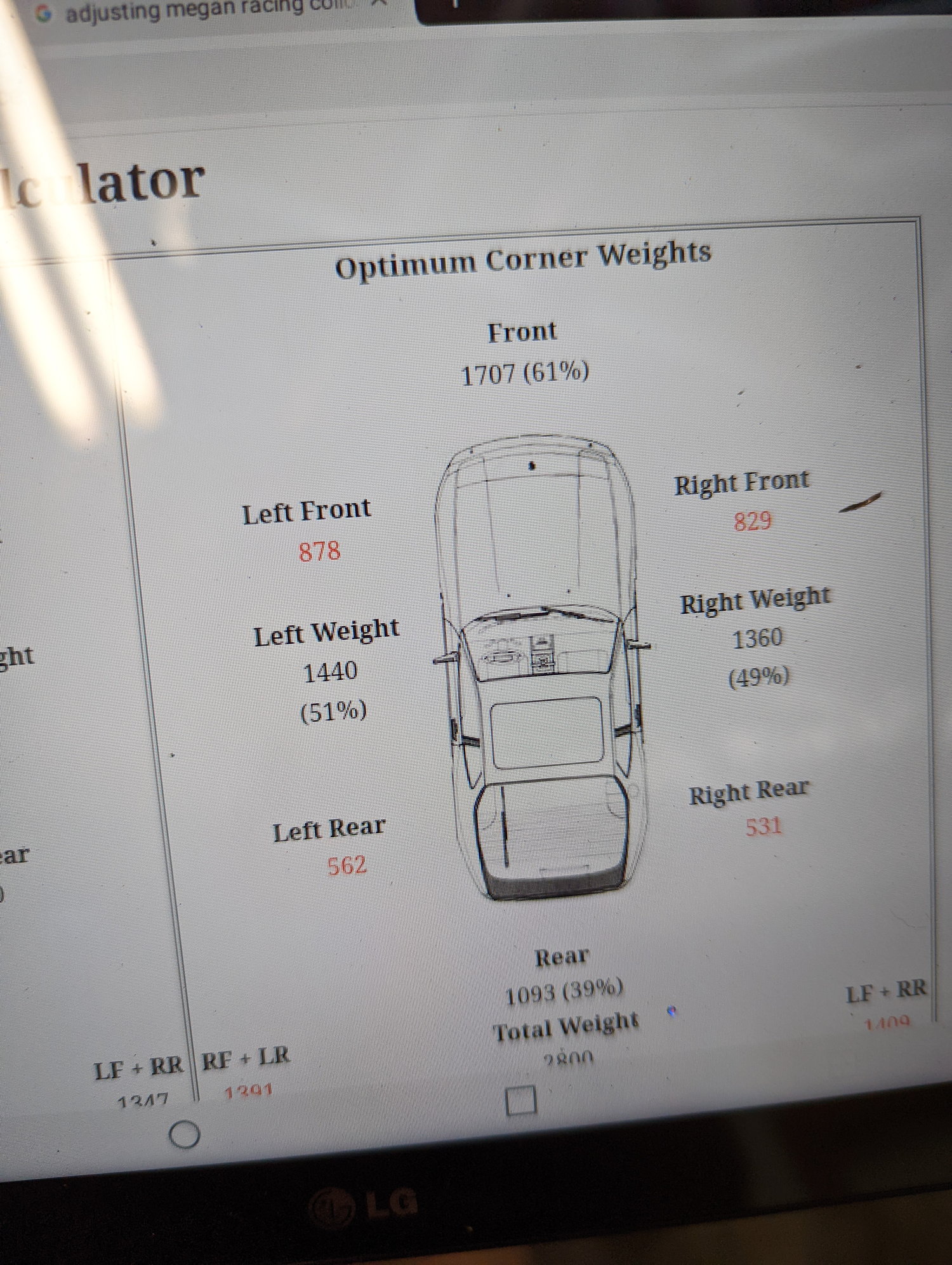

Once the alignment was settled, it was time to start working on the car balance. That started with a trip to my gym to borrow a 150lbs sand bag and a 70lbs dumbbell. That provides roughly 10lbs of clearance to account for shoes/suits/helmets/etc., and being in 2 pieces allowed us to position the weights in places that nearly exactly matched the weights with me in the driver seat.

Now was time to break out the calculators to determine what are target weights for each corner should be, then tweak corners, settle the suspension, and re-weigh. Rinse and repeat until happy. The internet told us the numbers we needed to hit to make our Mini a Porsche 944:

This process took awhile: roll the car off the scales, jack it up, remove a wheel, adjust the coilover the direction we thought it needed to go to make the numbers move, put the wheel back on, bounce the car a bit, roll the car back up the ramps, measure again. Started working on the rear of the car, and then finally to the driver's side front for the final bit. We ended up at a respectable 49.7:50.3% cross weight, with a 61:39% front to rear weight. Total weight with driver and a full(ish) tank of gas ended up being 2798lbs.

The process wasn't without its trials though. We had planned all this activity so that we could get everything setup and that weekend take the car to the local autocross for some shakedown runs. It would also be the first time my Dad got to take the car out in anger to start getting a feel for how it handles. Nothing gets to be easy with this project car (if you've been following along since the brake upgrade you'll understand). We were already strapped a bit for time due to my work schedule, and then a series of severe thunderstorms took an evening away. I left my Dad unattended for a bit to keep making progress. When I came back, he was sitting in a chair drinking water and asked if I could tighten the lug nuts. Being the trusting person that I am, I grabbed the torque wrench and went to work. On the first swing of the wrench...

I'm not going to say I was setup to fail here, but I'm saying that I didn't put a lot of pressure on that stud. This is Friday afternoon, before a Saturday autocross. We had 2 problems: first getting the broken stud out; second getting a replacement. I called everyone locally that I thought might have some studs, and then called everyone they recommended... no luck. So, that's a lost battle.

There wasn't enough of the stud hanging out to be able to get two nuts on and locked together. The next thought was to cut a nut in half. However, if you saw my work with a grinder above, we are only looking at 25-30% chance of success. Looking at those odds and the time it would take, I decided to phone a friend. I called my buddy Alan. He suggested we drive out to his house/shop and then we could weld a nut on the remaining stud and then should be able to get it out. That's what we did, and it worked.

Temporarily we replaced with stud with a log bolt, but that got us going and able to run the autocross.

The autocross went well. The car handled well despite being 95 degrees, humid and having to deal with 2 drivers. It would get warm after a run, but popping the hood and spraying the intercooler would bring the temps down before the next run. We ran the street tires since the trailer isn't all the way done and they don't fit in the hatch with the rollbar installed. The car started out not rotating as much as I would like, and with 2 opinions on what to change to fix it, we didn't really improve it during the morning session. In the afternoon, with the bright sun and temps up the tires got greasy but I took the lead on tweaking the air pressures to get the car's balance where I liked it. The last 2 runs of the day the car really felt good and we both turned our best time. The last run of the day, I was a full second faster than any run prior... right up until I tried to spin out right in front of the finish line. Probably ended up losing 2 seconds righting the car and crossing the line.

https://youtu.be/PdHzC0Tq3nU

Ok , need some help...

Took the Mini out for a track day at Talladega Gran Prix (because I hate tires apparently). Mini ran amazing. Ran down Miatas and a Z06 in both of the first 2 sessions.

After the second 20 minute session, I was talking to some other drivers and noticed a spot under the car. I assumed it was there before and ignored it. When I finished the conversation the one spot had become many. E36M3.

I cleaned up and braved a quick drive home. No lights, no warnings, nothing other than leaking oil down the interstate.

I cleaned up the underneath of the car, did an oil change (hoping it was an issue with the filter). When I started it, it still leaked. Best I can tell it is coming from below the filter and towards the middle of the car.

I've got a million pictures trying to see where I can't get my head.. any help?

My R53 had the oil pan gasket and right side engine mount replaced at 30k miles. Both leaked oil around the same area. The leaking mount wetted the body directly under the mount and was partly collapsed. The pan gasket was less obviously leaking.

The internet mechanics on the Mini specific forum have diagnosed it as the oil heat exchanger that is right below the filter. Makes sense from what I can see and is a fairly common issue.

Ending the year with a bang...

...maybe a pop? Or a hiss? Disappointingly, it probably didn't event make a sound.

With the Autocross season winding down, and my consistency not where I thought it was going to be this year, I wasn't overly concerned about end of year standings. So, when the October double-header event came up and I knew I would only be able to do one of the two days, it wasn't that hard of a decision to do something different and head out to Talladega Gran Prix for one of their open track days.

It had been a bit since I'd been out there, but it is a fun track and a great value for the amount of time you get on track. The downside is that it has a bit of a reputation for destroying tires, more on that later.

It was a great day for racing / driving. It started a bit cool in the morning, but the sun felt nice and the day had a near perfect warm up. The event itself was well run, casual, and had the right number of cars per run group for the track. Pretty normal pattern for track events: 3 run groups (beginner, intermediate, and advanced); each group getting 20 minute sessions. 20 minutes is a lot of laps on a track that short.

First session was really getting dialed into the line and remembering the details of the track, and trying to get a feel for the balance of the car. Coming out of the last Autocross event, I felt the front had more to give and increased the stiffness on the fronts a few clicks. Running the Mini through a few high speed corners, the balance felt pretty good. Turn in and mid corner felt great; corner exit had some understeer. I put that down to being FWD and have 61% front weight bias. The tires and LSD made it really manageable, I could control the car and place it exactly where I wanted it to go.

One of my favorite features of the Mini is how unassuming it is when you bring it to a track. Almost 20 years old, most people won't give it a second look in the paddock/grid. Then after a couple sessions, you suddenly have people coming up and questioning what you've done to it, how much power it makes, etc. After the second session where I passed all but 1 car in the run group, I had a few people intrigued by the Mini.

I did have one exciting moment during the second session. I over cooked it going into the last set of corners and the backend of the car started to come around on me. I was able to catch it and only put 2 wheels in the grass, but the extra bump popped open the glove box. So, I had to pull into the pits to close it (couldn't reach with the harness fastened). Other than that, the car was fast and consistent. I was really happy with how the day was going to that point.

After the session was standing around chatting with the other drivers (another driver had followed my lead and over cooked the last corner and had an even more exciting tank slapper). I looked back over at the Mini and then the day took a turn for the worse. There was a small drop of fluid coming from just behind the passenger side front tire. I watched it for a minute, and the small drops kept coming.

That was immediately game over for the track day. I tried to find the source at the track, but climbing under the car and trying to look over the top, there was nothing easily visible. All I could tell was that it was coming from somewhere on the backside of the engine. After some debate on tow vs. drive, I decided to drive it home.

Made it home with no issues. Put the car up on jack stands and started looking around. Decided to do the low hanging fruit first. Went ahead and did an oil change. Draining the oil showed that the leak wasn't terrible and there was plenty in the engine. Also, after completing the change and ensuring that everything was tightened up properly, the leak was still present.

With the car up on jack stands and the wheel off, I could get a bit of a better view. Best guess at the leak was that it was coming from the oil heat exchanger:

I reached out to Way (Way Motorworks) and talked to him about it. He agreed that was the likely source, but recommended that we replace the entire filter housing and not just the heat exchanger. I looked through what it would take to replace it myself and decided that would be a terrible idea.

That meant I needed to find someone that I trusted to work on a track / modified car locally. Enter Corsa Crew:

https://corsacrewrace.com/

I've known Joe for awhile. He and the team provide a number of services, including renting track cars for arrive and drive at a number of tracks. One of the cars he rents is a Mini. Joe was good to handle the fix. I had them flush and change the brake fluid and then had them just look through the car and see if they had other concerns. They did find a soon-to-be issue with the map sensor plug and that was fixed as well.

The Corsa Crew team had the Mini ready to go right when they said they would. Had performed test drives and whip downs and had ensured there were no other leaks when they gave it back to me. I picked it up this last Saturday and it just so happened that there was a HPDE event at Barber's that day. Now, I didn't have time to participate in the HPDE, but they did offer some lunch time parade laps. A good way to put the car through it's paces, and more importantly an opportunity for me to get my son out on the big track!

#TeamRedLineOil

It's great to have the Mini back at home and not leaking oil all over the garage floor. At this point, we're pretty much done for 2022. With the holidays, kids out of school, autocross season over, and it just being cold I'm going into planning and execution for One Lap 2023. Technically, I'm on the wait list again... BUT this time I’m #3 on the list.

As for what little Talladega does for your tires? Well, I’ll leave you with this image of my front right:

In this social media based economy, with these hyper funded and polished influencers driving the content on every platform, the only way to stand out from the crowd is to be your authentic self ... And I am an idiot.

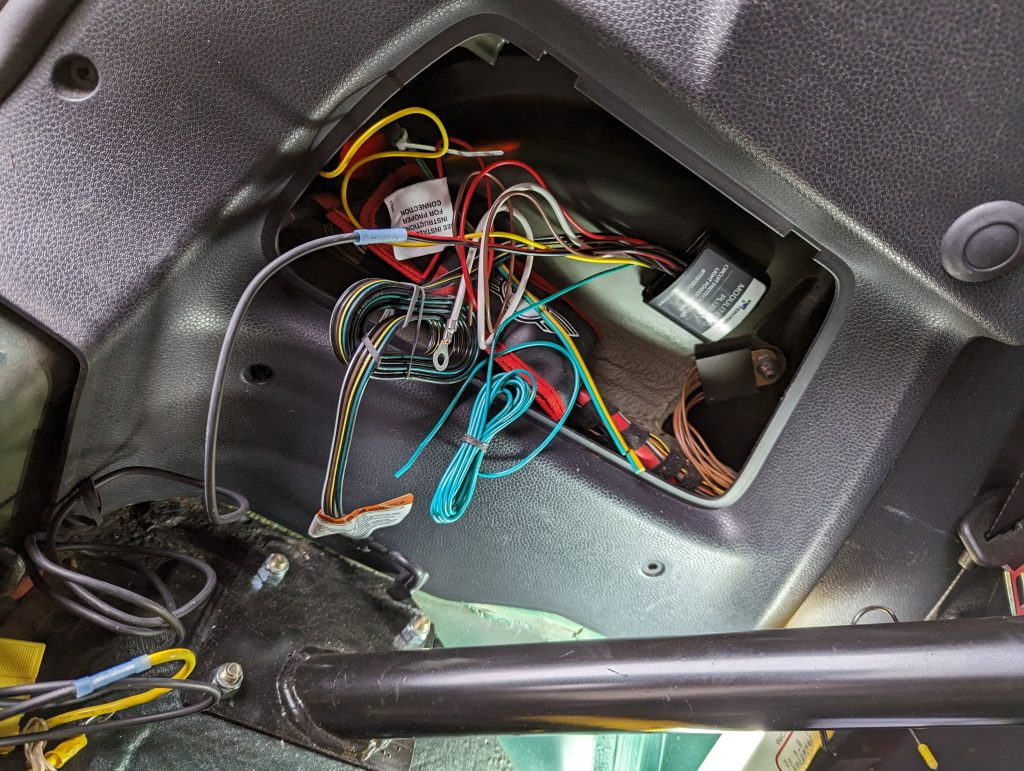

I've been putting off a part of the project I started last summer, I have plenty of excuses if you need any. A critical part of having a trailer is wiring up a harness so that the lights work. Electric work is like my least favorite thing to do, across the spectrum. I don't like installing light fixtures or ceiling fans, connecting wires on computer motherboards, let alone working with the mess of electronics that come on a car. But.. this had to get done.

Now, being a BMW Mini meant this task wasn't straight forward. Honestly, I don't know if it could have been done with simple splicing, but I do know that Outmotoring sells a specific kit to connect a trailer harness to the R53. Being that this kit exists tells me that it solves some issue; I figured best to do it right rather than the pain and suffering on doing wrong and fighting through that to only end up back at this harness kit.

With all of the excuses out of the way, the rain stopping, and having the wiring kit sitting in my office, it was time to suck it up and get it done. Outmotoring was kind enough to send pre-printed instructions, and enough spare wires that you have options on how you want to complete the install. With the back of my Mini already stripped, half the was already done. The rest of the instructions were pretty easy to follow... right up to the point were I had to connect wires. This too, should be a straight forward process, unless you're colorblind. I am and became immediately befuddled trying to discern the difference between the green wire with blue strip and blue wire with brown stripe. Ugh. I called in reinforcements from my wife, who was surprisingly in good spirits helping with a car project. She too thought the wiring offered by BMW was a bit ridiculous. I called out patterns and she carefully picked out the correct wire for me, a few connector snaps later and we were done with that step. I ran the remaining wires, connected everything and then went for the test. Crap... nothing.

It was getting late, dark and I was done with wires for the night.

The next morning I decided to fix / finish it. What was frustrating was that I didn't have any feedback to work from at all. Car lights worked fine, just as before. Trailer was nothing at all. It wasn't that I got wires crossed or anything like that, it was as if there was no power at all getting to the lights. And that's when it hit me, I thought I saw a fuse in the bag of connectors included in the kit. I went digging and sure enough there it was a nice blue fuse in amongst the blue wire connectors. I popped open the little yellow thing connected to the auxiliary power post, and there was a spot for the exact fuse in my hand. Modern technology is amazing.

Connecting up the trailer and testing, this time with power, and everything worked exactly as it should. Outmotoring tried to create an idiot proof kit, I proved them wrong.

With the trailer all ready to go, I loaded it up and took it for a test drive. I even made the rest of the family follow me on the short drive. Not only did I want to make sure the lights worked, I wanted to test the trailer's road manners. The test drive proved that it tracked straight, the wheels were square with no perceivable wobble, and it didn't cause a significant impact on the drivability of the Mini. All good. Ready to go for the Autocross season and One Lap of America 2023

I replaced the oil filter housing on the '02 that I had last summer and it was not fun. Mine was leaking around the oil pressure switch in which there was a small crack in the housing. The coolant lines run through it was well.

First SCCA event of the 2023 year, and a wet one at that. Not heavy rain, but a constant drizzle to light rain, no drying throughout the day.

Full field turnout despite the weather. Didn't start out great. Had an unexpected call from work that kept me up and working until 1am. I didn't get to pack and prepare before the morning of the event. Sleep deprived, I managed to get most of the things. This was the first official use of the trailer. That all went well. Pulled great, lights worked, and importantly nothing feel off.

I did, however, forget my numbers and to charge the batteries for my impact and air pump.

Tape of shame.

The main goal of this event was to validate that the 15x8s and 245 tires wouldn't rub after all the suspension changes. That meant running slicks... in the rain. Not ideal, but I think in the lighter periods we were right on the edge of where they worked.

That's a great picture, but it doesn't actually show how wet it was all day. Despite the start and the weather, the day was fun. Lots of Novice drivers and several offs, but only minor car injuries.

Balancing traction was the game of the day. Managed to spin once as a result of an over aggressive switch back.

Still was pretty fast and had a result...

I might have got an email from someone who might have been named Brock, that might have said I'm confirmed for an event that might start in May.

Brad,

I just joined this forum to say. I love your car, and we are basically twins with different colored hair :P

I have a r53 in BRG with a white top..

Gotta say I love your car, and the things you do with it. I read through 7 pages of forum posts, which for someone like me (short attention span) is hard to do. It is really cool to see your work on your car, I admire it.

Questions for you...

What is the best budget suspension you'd reccomend for a R53? I currently need a new set of shocks and going to do the whole upgrade.

Thanks!

You'll need to log in to post.