does it have steel liners ? or a coating on the bore ?

VERY interesting engine design! Fully open deck, cam bearing caps, bolt-in lifter housings, dual rocker shafts, and those pushrod angles! A lot of weird stuff going on here. Surprised they didn't try to shove the starter in that valley while they're at it.

maschinenbau - weird rocker angles too

californiamilleghia - full on steel liners - I believe that is where the mass comes from... besides the steel crank

more to come......

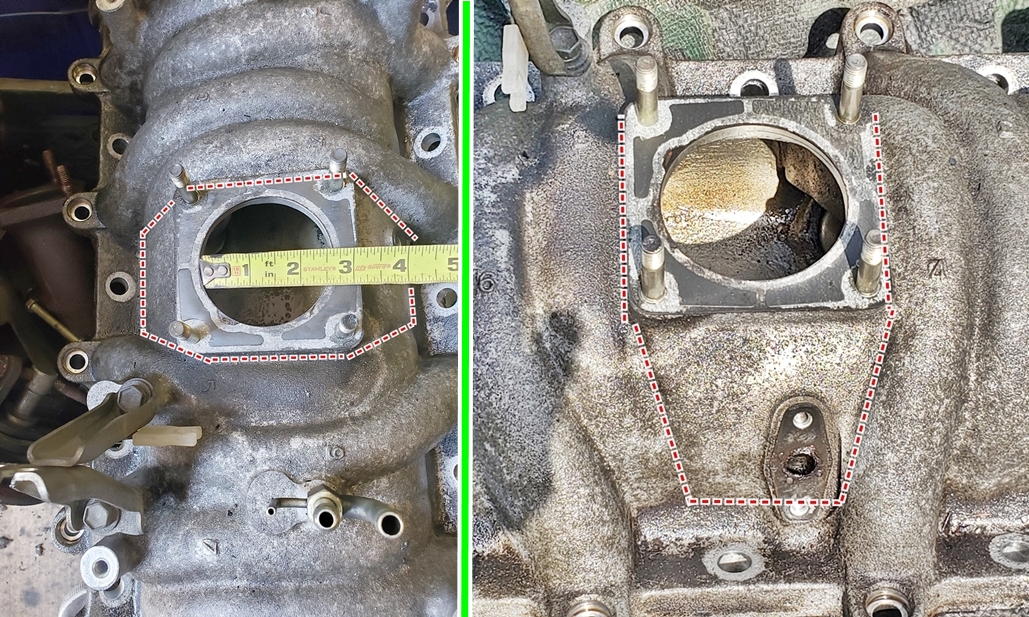

For your intake manifold thinking, the manifold to head angle looks similar to the 1UZ engines (15 degrees from square). The port shapes and injector placement are similar as well. You may be able to modify a 1UZ manifold to get something of a starting point. I am sure the bore spacing is different, but it may be worth checking out/cutting up a much more sacrificial manifold.

stafford1500 said:For your intake manifold thinking, the manifold to head angle looks similar to the 1UZ engines (15 degrees from square). The port shapes and injector placement are similar as well. You may be able to modify a 1UZ manifold to get something of a starting point. I am sure the bore spacing is different, but it may be worth checking out/cutting up a much more sacrificial manifold.

![]()

I've done a bit more digging into the manifold... It MAY actually be satisfactory for my goals! The design isn't quite as restrictive as I first thought. While the current T/B is small, the manifold actually isn't! The design uses shaped runners that pick up from the central plenum - that much I posted before... but having removed the T/B, a LOT more becomes evident..... the whole center section can easily be modified. One suggestion was to run a Mustang 75mm throttle body, another was to re-work the center section to accept a smaller twin T/B assembly

As to volume... if it needs more... I can have the intake runners Extrude Hone-d

As an internet keyboard jockey engine expert, I say: Intake swaps on mostly stock engines are highly overrated. Especially 4.0 liter limo engines at 8.6:1 CR that peak at 4400 rpm.

Very quickly you can lose intake charge velocity by hogging out the runners then you have a dog below 3500 rpm. And big intakes do you no good without the heads, cam and exhaust work to support it. there's various flow measurement home made instruments out there with a shop vac and U-tube (on you tube lol) that you could calculate theoretical CFM at various port vacuum measurements.

Extrude hone is probably the most sensible way to gain some flow without grinding through a port wall or making matters worse.

That intake kinda looks like an LS1

Carry on Sir! what a great project engine.

1972 Celica FB! + 244 hemi = mini Boss ,Japanese style....

In reply to Agent98 :

You may not have seen his work yet, but this is oldeskewltoy, our resident head porting and flow wizard. If there's anyone who make this engine breathe, it's him for sure. I'm excited to see what you do with this.

Agent98 said:As an internet keyboard jockey engine expert, I say: Intake swaps on mostly stock engines are highly overrated. Especially 4.0 liter limo engines at 8.6:1 CR that peak at 4400 rpm.

Very quickly you can lose intake charge velocity by hogging out the runners then you have a dog below 3500 rpm. And big intakes do you no good without the heads, cam and exhaust work to support it. there's various flow measurement home made instruments out there with a shop vac and U-tube (on you tube lol) that you could calculate theoretical CFM at various port vacuum measurements.

Extrude hone is probably the most sensible way to gain some flow without grinding through a port wall or making matters worse.

That intake kinda looks like an LS1

Carry on Sir! what a great project engine.

1972 Celica FB! + 244 hemi = mini Boss ,Japanese style....

![]()

As I do a great deal of headwork, I have my own flowbench, so I can actually do the testing. There is a great deal of similarities to Toyota's 4 cylinder "T" engine series. The T engines use the same size valves, and the same diameter pistons, the V8 uses a bit more stroke. My plan DEPENDS on if it remains N/A, or I decide to boost it... and THAT decision has yet to be made...........

This whole project is about owning a "Hemi".... and what would be better???... a blown Hemi??? Now with that said, I don't want a Funny car, or Pro-Stock type hood scoop blocking vision, nor do I want a rumbling monster(idle, or WOT, nothing else) - I do intend to use this in something (still undecided). I'm also not a fan of turbo chargers, my preference on a V8 would be a supercharger.

1972 Celica wasn't available in fastback, that body style was 1976-1977 (at least in the USA). And that would be the ideal car for this, but finding one with full interior is almost as hard as finding this engine was........

In reply to oldeskewltoy :

An Eaton supercharger would definitely work better for street use than a pair of T2’s turbochargers. While the pair of T2’s would likely make more ultimate power.

EBay, made in China T2’s turbo’s when last checked prices were like $130 each add the waste gate and you’re at less than $500 for a pair.

However I’ve seen used M90’s sell for $2-300. Both would need additional funds on drive and mounting / or tubing/ intercoolers etc.

The Supercharger would have to go on top of the engine in order to get the shortest straightest intake path while the Turbo’s can pretty well be mounted in a lot of spaces giving you a lower Hood height.

With regard lowback seat and high backed racing seat. Since this is intended to be mainly street driven let that guild your choice. I’d go low back and a padded headrest on the rollbar

11.4" flywheel, inside a 14.5" bell housing......

Gaskets (intake, head, exhaust, and oil pan) have been sent on to Cometic.....

so, while waiting to hear back on the gaskets....

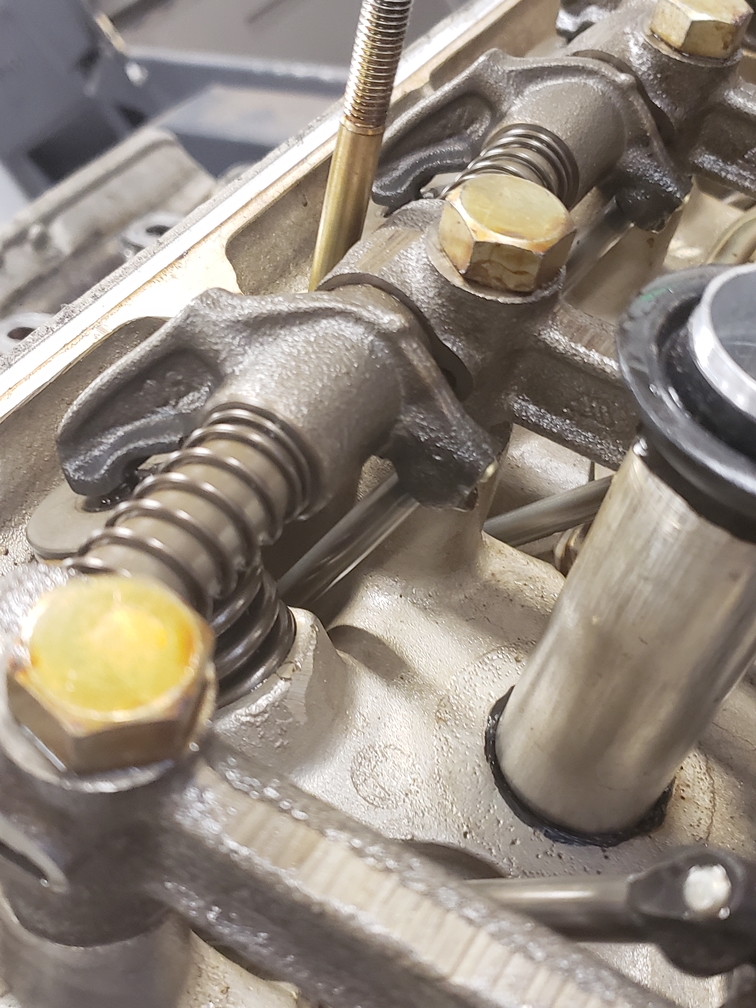

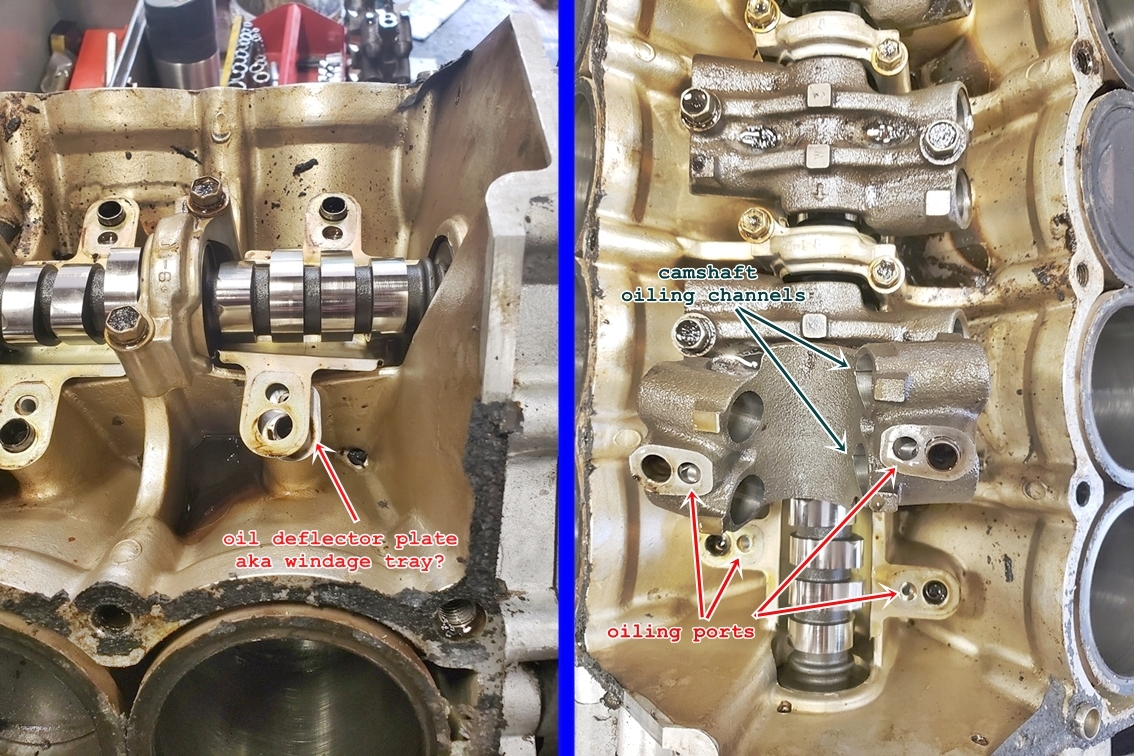

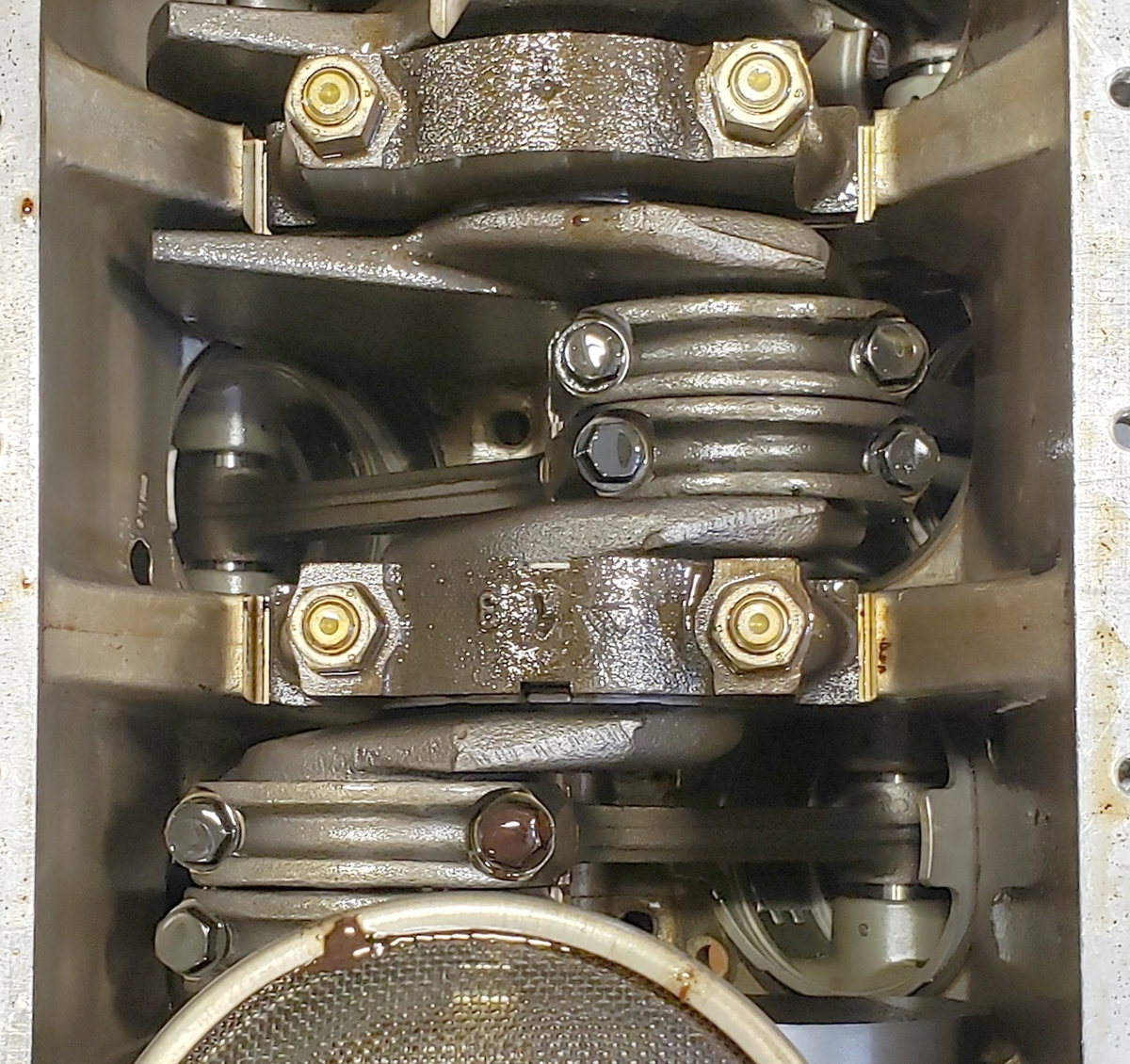

oiling for the cam lobes, and lifters. Interesting "windage tray" for the camshaft, and note the machined-in channels to direct oil @ the camshaft. Additionally note the structure - from the cam cap bolts holes are along the same rib as the head bolt holes.

Main studs.... full counter weighted crank, and "giraffe" aka diesel type connecting rods.

more to come....

In reply to oldeskewltoy :

What's the purpose for that offset in the rod like that? Offsetting stress on the rod bolts and trusting that the shear force won't matter because the crank is in the way?

In reply to Sk1dmark :

Usually it is done for assembly reasons. Subaru does it on the Fx engines so you can get to the rod bolts with an assembled case (no more assembling the rods to the crank, then assembling the case halves, then putting the pistons in with a hole in the side of the cylinder for wristpin access)

Ferrari alo did it on their early engines because the bores were too small to pass a perpendicularly split rod through. 1500-2000cc V12s have tiny cylinders!

You can fit a larger crank pin diameter (rod big-end diameter) with angle-split rods given the same bore diameter. Perpindicular-split rods will be wider for the same crank pin size because the rod cap bolts are way off to the side.

Diesels do it to maximize crank pin size (and therefore strength/durability/wear of the crankshaft and rod bearings) while still being able to pull pistons out the top for service.

You can infer the crankshaft on this engine is probably relatively strong for it's bore size. A good way to double-check is compare the ratio of rod big-end diameter to bore diameter. Compare that ratio to other engines. I bet that ratio is higher than most gas V8s of this displacement. Obviously there are many many other factors to crankshaft/rod strength, but that's a big one.

In reply to maschinenbau :

Or maybe Toyota wanted to make it easy to tighten all the caps on the assembly line. That does look a lot more pleasant to work on than, say, a small block Chevy. You could probably access all bolts without having to move the crank.

Wasn't this Toyota's first non-inline engine?

In reply to Knurled. :

Perhaps! Looks like you can pop all the rod caps off in one shot. The angle split also helps assembly when you have deep block skirts, which are also good for block strength. Very cool engine.

I love this thread/forum. I've been a Toyota fanboy my whole life and yet I knew nothing about the 5V other than its existence, now I'm learning fun details about them and general knowledge to boot! Thanks for the info guys!

In reply to Knurled. :

Close, but no cigar. The U-series of engines were flat twins that beat the V-series by several years. The U was introduced in 1961, and powered the Sports 800, the Toyota Sports car that introduced the concept of the Targa top to the world before....(gasp!)...Porsche! ![]()

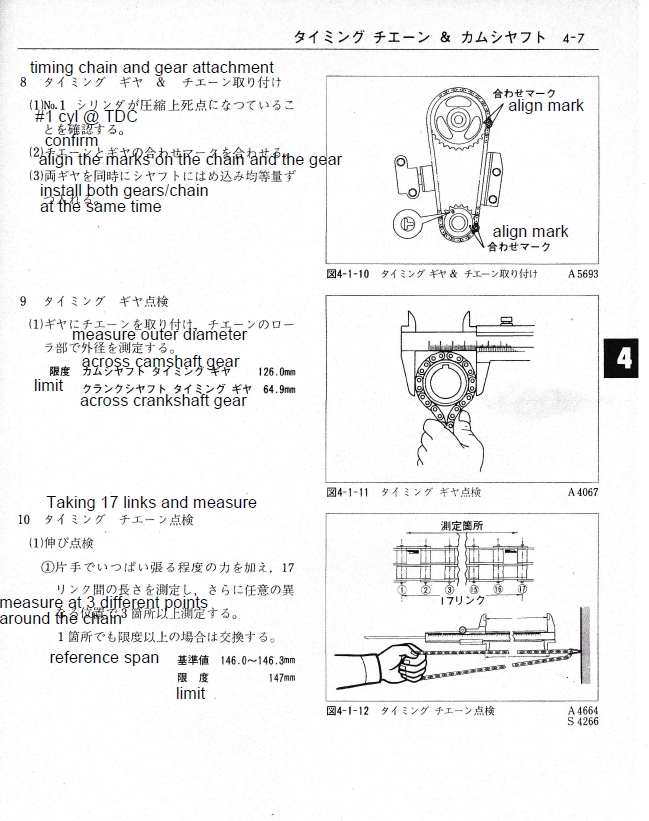

so spent a few hours with "Bixby" today... While it worked... I had to adjust how I did it... because "Bixby" couldn't seem to handle whole pages.....

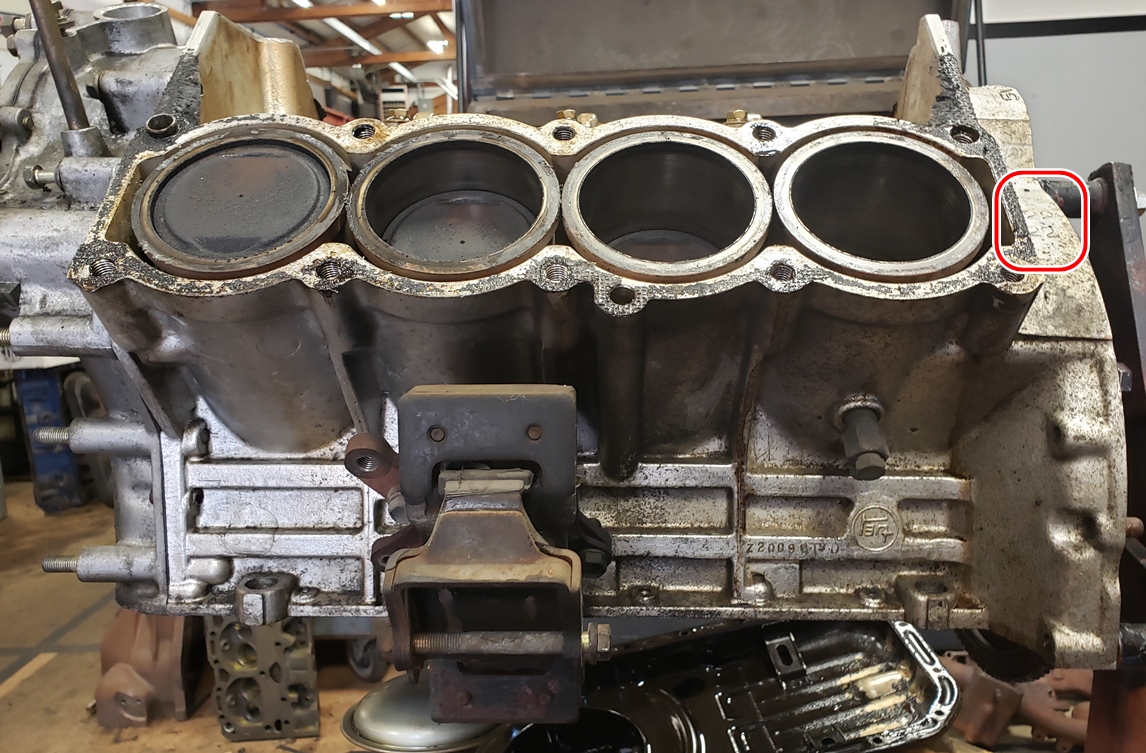

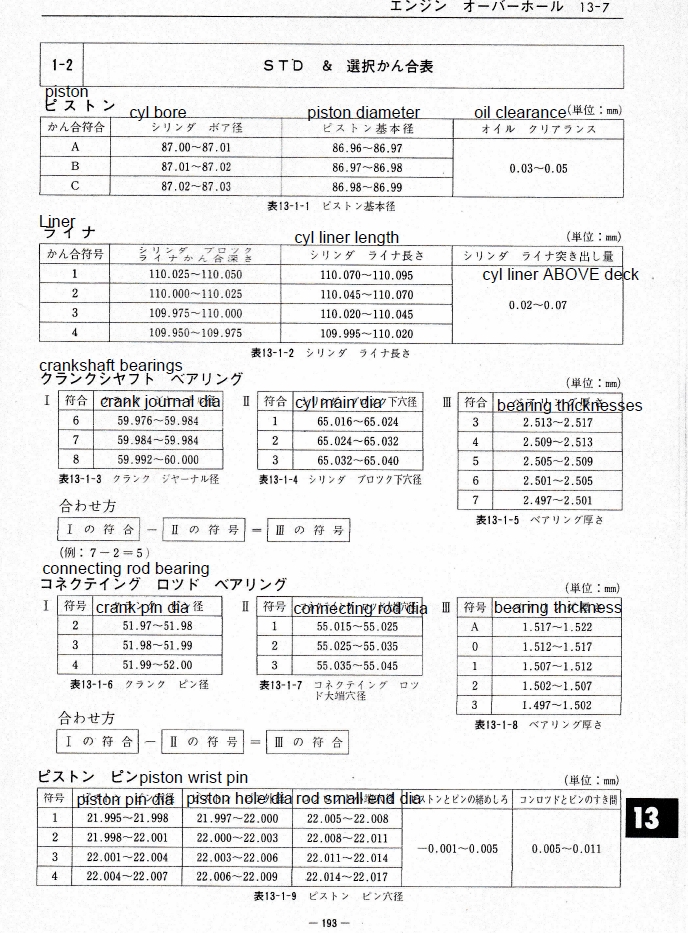

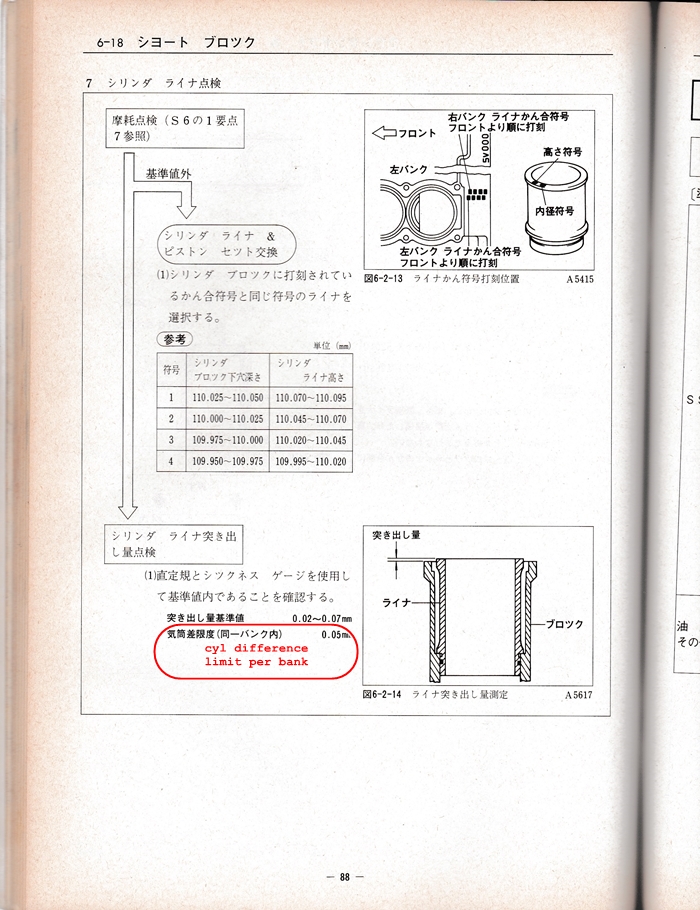

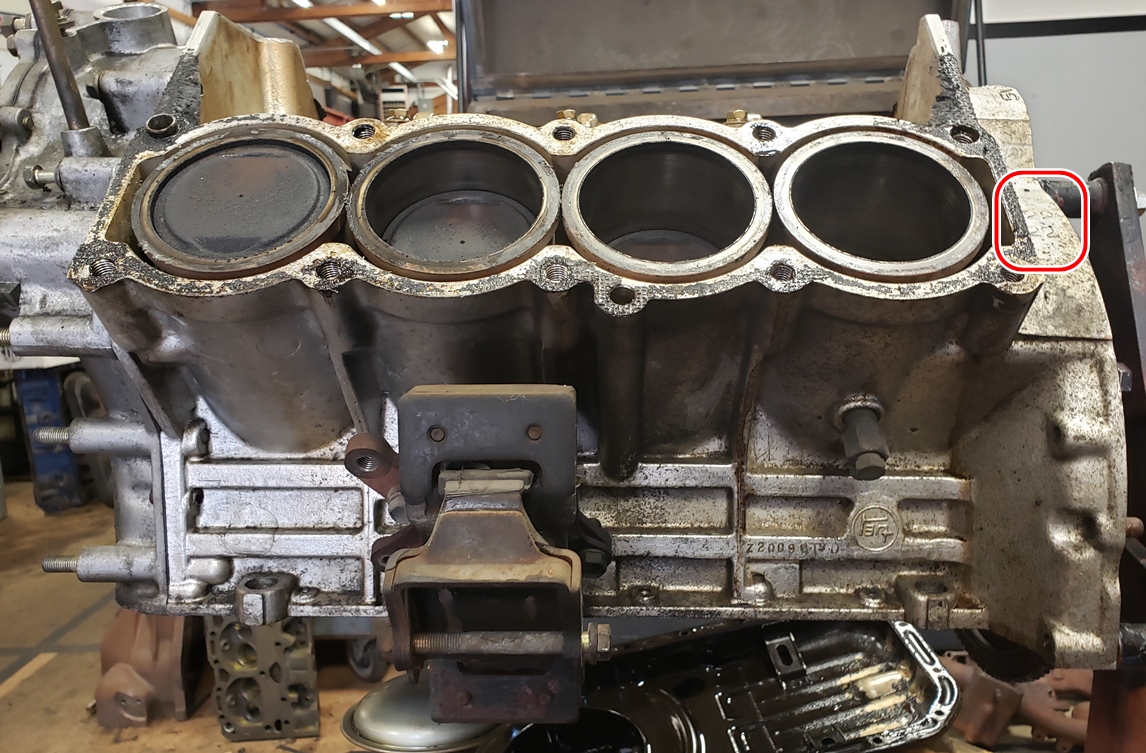

and now this photo makes sense.... the red square shows 8 #2s... and if you read the spec sheet above, all the liners are the same spec length 110.045mm-110.070

I've also been doing some piston searches.... (preliminary as I don't yet have a chamber volume, or a piston dome volume) I've been looking @ Toyota "T" piston types as they are similar...

As flat as my current domes are, I doubt I'll need anything radical... no where near this

more to come..... ![]()

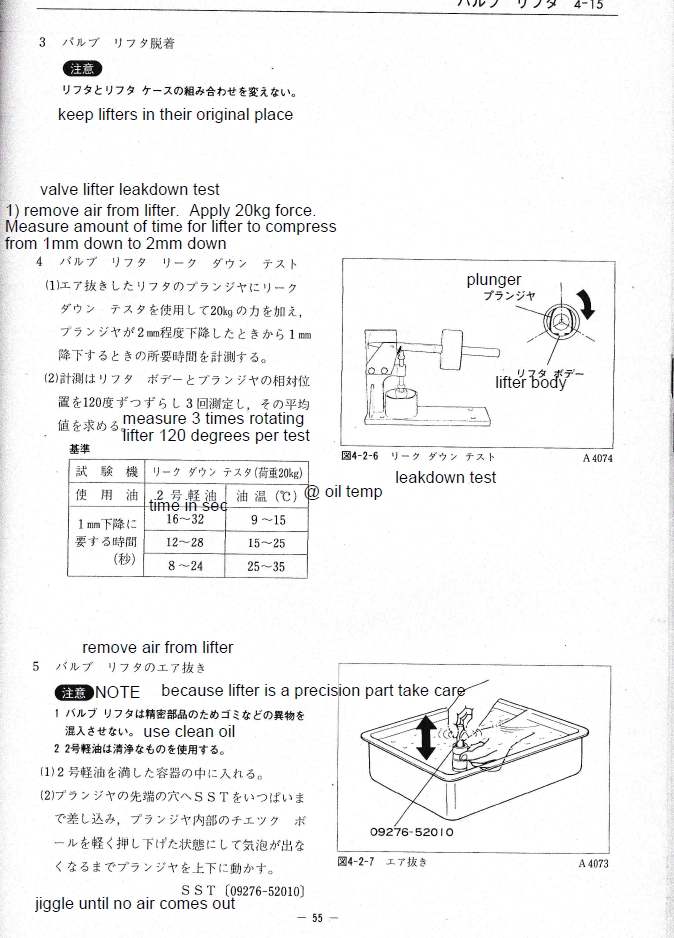

While I'm pretty confident of my translations so far...

I'm feeling uncertain about this one... anyone read (interpret) Japanese??

oldeskewltoy said:so spent a few hours with "Bixby" today... While it worked... I had to adjust how I did it... because "Bixby" couldn't seem to handle whole pages.....

and now this photo makes sense.... the red square shows 8 #2s... and if you read the spec sheet above, all the liners are the same spec length 110.045mm-110.070

I've also been doing some piston searches.... (preliminary as I don't yet have a chamber volume, or a piston dome volume) I've been looking @ Toyota "T" piston types as they are similar...

As flat as my current domes are, I doubt I'll need anything radical... no where near this

more to come.....

Do be careful when putting a dome into a Hemi head.

First you lose the prime advantage of a Hemi head. Which is flame propagation. With the dome you are trying to ignite basically an orange peel shape. Very easy to shroud the flame and lose power.

Second you lose the turbulence generated in a Hemi chamber.

Third instead of having the whole chamber for the fuel/air charge to draw into on valve overlap You only have the narrow area between the top of the Hemi chamber and the dome of the piston.

Increased compression does help but at the cost of those three issues.

That’s where forced induction provides it’s real benefit. The chamber can easily be filled with fuel/air charge yet retain all the benefits of the Hemi chamber.

One final point. Intake valves are bigger than exhaust valves.. any dome will reflect that and the valve relief for the piston will reflect that. The resulting asymmetry in the dome will unequally load one side of the piston. At low piston speeds it’s not an issue but speeds above 3000 FPS will cause issues.

In reply to frenchyd :

There is a good reason hemi heads are not used anymore, and I think you hit all of them.

In reply to Knurled. :

The main reason hemi’s aren’t used anymore is because a 4 valve head flows even more than a 2 valve Hemi head and does it at a lower valve angle which means you can get decent compression without a dome.

Make no mistake, I love a Hemi head. There are work around to the limitations. Look at The latest Cosworth piston for the early Jaguar engine. It deals with all those issues and is remarkably light. Very important for a piston with the 4.17 inch stroke Jaguar has used since the introduction of the XK120 back in 1949.

You'll need to log in to post.