Edit: Brainfart, judging by the date on the bad motor starter cap of AUG 17 1945, this is actually more of a very late WW2/Very early postwar period drill press. If a mod gets bored, feel free to fix it.

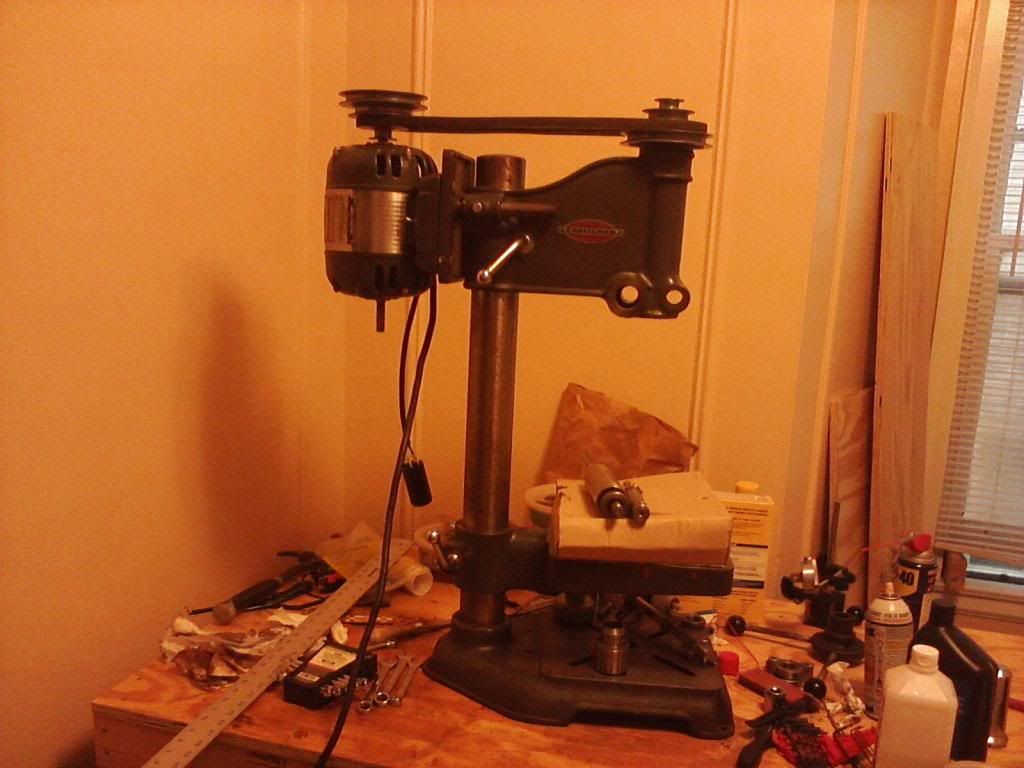

I spotted this on CL for $100, kinda thought about it, then emailed the guy and he immediately dropped to $50 without asking as a "get it out of here" move. I fell for it and now its in my dining room(I'm in an apartment currently). Everything that needs to be tight is still very tight and besides the quill lock bolt its all there, that red tag is the factory lubrication tag. I don't think its seen much use.

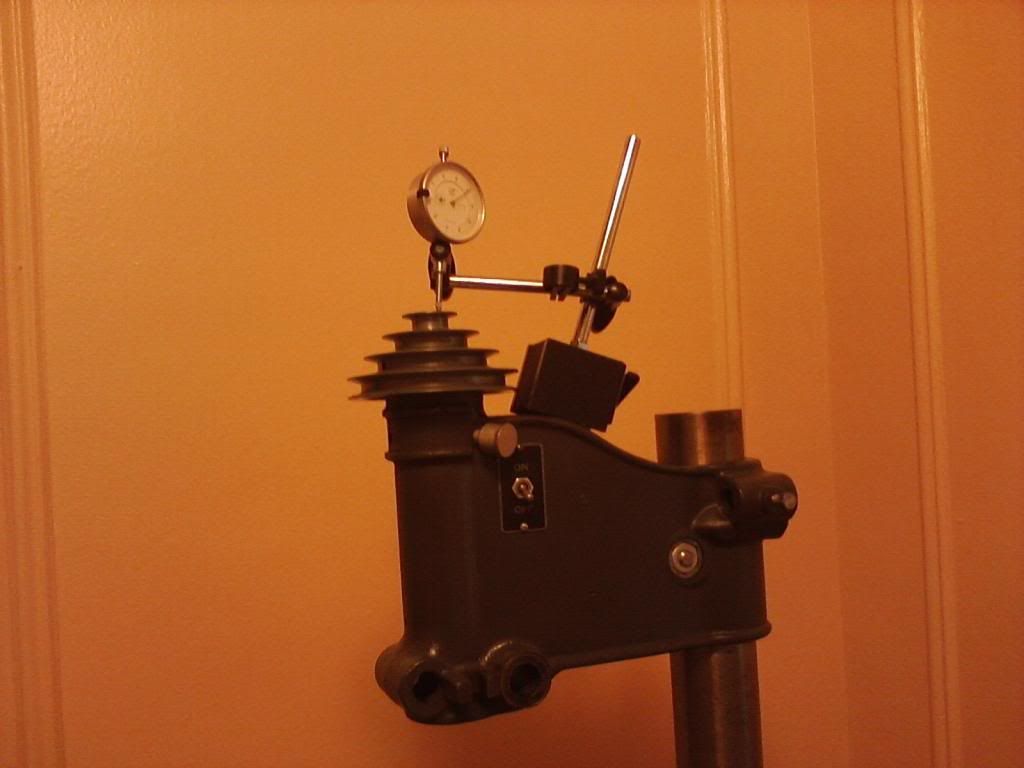

For those unfamiliar the 101 in the model number indicates this was built by the Atlas Press Co. in Kalamazoo MI, the same that made all those great lathes. Crafstsman back then meant the best Sears had to offer, and it shows. This is an extremely well built drill press, the spindle rides on 2 ball bearings, and the spindle is floating, the driven pulley rides on its own set of 2 ball bearings, pre WW2, these would have been SKF bearings. I can run the quill all the way down and don't feel any play in it unless I really lean on it. It still has the original Jacobs chuck. It has to weight AT LEAST 150 lbs. I think this one was made in late 1945. Going by the 1942 Sears catalog featuring a similar model, inflation adjusted it cost about $1200 with the optional 1/2 HP ball bearing motor.

And in my dining room, check out the stalled coffee table project in the background.

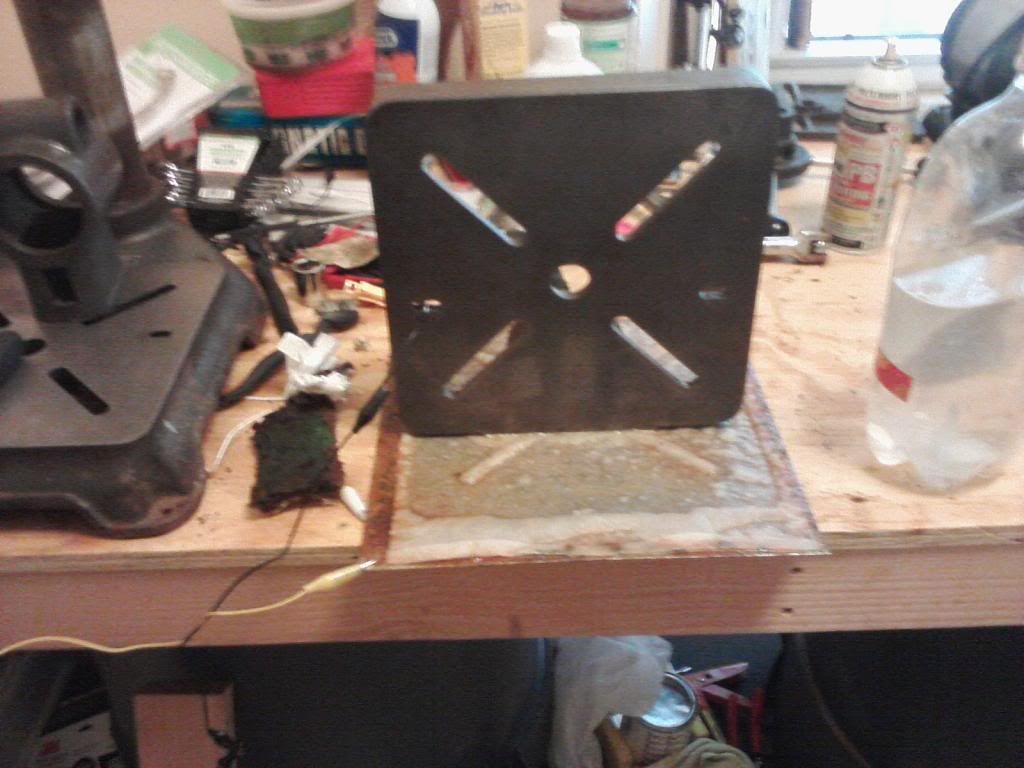

Plan is to get the motor working, tear everything down and clean and lubricate, then put it to work. Most of the paint is still there, so it should clean up nicely. I want this to end up looking like it would have if it were properly cared for its whole life.

Should you want to ask the question "Aren't you kinda crazy for having a drill press in an apartment?" Have you ever had the freedom to drill a hole in something WHENEVER you want to? It's awesome.