I drew, in green, the existing bar and then an arrow showing where it could go.

And the light bulb comes on! ![]() I'll have to look at that tonight, but I think my engine would need to go up another inch or so to clear the 1.5" tubing that I think this structure demands. Also I couldn't go quite that far in at the back because I need a point outside of the ends of the engine and transmission to join the side panel to the floor.

I'll have to look at that tonight, but I think my engine would need to go up another inch or so to clear the 1.5" tubing that I think this structure demands. Also I couldn't go quite that far in at the back because I need a point outside of the ends of the engine and transmission to join the side panel to the floor.

Sorry about that. I usually see this thread at work and can't spend a ton of time on it. Rest assured that you're doing a great job and it's awfully impressive. My proposed idea would make it a trapezoid as viewed from the rear, a look I kind of like. I am not sure what you're planning on for bodywork back there, and that matters.

Keep it up, no matter which direction!

No need to be sorry, I have trouble understanding without pictures some times! ![]()

I agree the trapezoid would be a cool look. I will have to see if I have the room.

I don't think I have room to move the lower tubes in any farther.

I have it as far over as I can and still allow the engine to be removed from the bottom. There is actually plenty of room on the engine side, but none on the transmission side. The trapizoid would have mirrored the shape of the frot too...

Some Junkyard engineering yielded some solutions for my alternator and engine torque mount. A 4 cyl Dodge Stratus gave up its alternator mount, alternator, front engine mount bracket and block/bell housing bracket. Both the alternator mount and the block to bell housing bracket needed some clearancing with the die grinder to fit. The alternator is a very tight fit against the SRT-4 intake manifold. I will either try to find a smaller alternator, or possibly make my own mounts that locate the alternator lower to help the CG.

I am thinking of using one of the "dog bones" from the SRT-4 in conjunction with the stratus torque mount bracket as shown in the picture above. The Stratus also had a rear torque mount just behind the axle, but it isn't compatible with my transmission and I am thinking about not running a rear torque mount. My thinking is that the rear torque mount, being right next to the axle does not do much. The torque reaction of the drivetrain is centered on the axle, and to hold the engine in place against this torque you would want your mount to be as far from the axle as possible to provide the most torque resistance with the least force. The front mount is as far as possible from the axle.

Progress has been a bit slow lately because I need to make decisions on the Rear end styling and the rear torque mount. I am leaning towards Plan B for the rear end. I need to do some more thinking on if the rear torque mount is needed, and if so how to build it without making it a pain to remove the engine.

Yesterday I cleaned up the junkyard parts and got started on the front torque mount attachment to the frame.

I will also be running some tubing from this bracket to the diagonals on the roll cage.

Any additional narrowing of the rear width of the tail's taper would be giving up diffuser area anyhow, no?

Spectacular work! I'm enjoying this thread an awful lot...

If you need room to extend the diffuser, perhaps you could rotate the rear mount around and mount in tension instead of compression? That way you could open the area below the axles (unless you can't alter that lower bar the mount is tacked to now.

The mount pictured above is the front mount. I am liking the bobble mount idea from the other thread for the rear mount. The tubes under the axles are needed to keep the rear suspension where it needs to be and to attach the flat floor to. The axles are going to need to be removed to pull the engine.

I finished up the engine torque mount last night, but am holding off welding it in because there have been some concerns about the design on another forum. I have started a separate discussion here to critique my design: http://grassrootsmotorsports.com/forum/grm/learn-me-fwd-engine-mounts/79415/page1/#post1450594

I don't know a lot about FWD mounts, but I do understand the physics involved, I think. That mount looks fine, but honestly I would do the opposite. Instead of bracing your lower mount attachment point with two tubes connecting to the "V", why not invert the mount, and make the same tubes make the V, which would end at the mount rather than the lower tube?

That doesn't sound easy to understand. hang on.

In reply to tuna55:

That would also work, would be lighter, but to get the correct angle on the mount the triangulation tubes would have to extend back into the engine compartment under the intake and would likely trap the engine.

Currently no engine mount on the rear, but it was suggested in the discussion linked above to use something like this:

Well that's true, there would be no way to keep the force normal to the mount, but I am not sure that's totally crucial if you have a rear mount.

I recommend a rear mount, then, either way. Otherwise I would expect to see either your side mounts fail prematurely or excess movement in the back of the engine. In the car, I presume that's handled by the transmission mount instead. Can you run a stock transmission mount back there, or am I missing something?

In reply to bgkast:

There's a couple of rear mounts available here that you could potentially adapt to your purposes: http://polybushings.com/pages/moparmounts.html

Johnny is in Coos Bay and builds all the products himself and has a ton of Turbo-Dodges, he loves to talk about weird turbo-dodge projects and could probably bring a couple to Portland for you to look at before buying.

tuna55 wrote: Well that's true, there would be no way to keep the force normal to the mount, but I am not sure that's totally crucial if you have a rear mount.

This sounds right to me. While the torque being applied to the engine/trans unit is through the axles, the axles don't locate anything, so the rotation of the engine/trans unit will be reacted through the front mount and lateral mounts right now.

While I believe it does make some difference where the axles are on the unit, you still can't react the torque between only the output shafts and the front mount. Another shot at visualization: If the front mount weren't there, what would the engine/trans rotate around? The lateral mounts, not the output shafts.

I think that actually the alignment of the front mount might be at right angles to a line between the side mounts and front mount, rather than between the outputs and front mount.

I guess you are correct, since the axles are not fixed the engine will tend to rotate around the side mounts.

bgkast wrote: I guess you are correct, since the axles are not fixed the engine will tend to rotate around the side mounts.

That's closer to correct. Of course, when you add in the mount we're discussing, and the compliances of all of the bushings, the centroid becomes much less trivial to locate. Essentially, it will rotate about something, and it likely isn't constant, so just brace it against whatever you have and stop worrying about right angles so much. I'd hang that mount from the upper bar and then add a mount on the other end if the transmission doesn't already have something similar.

Just me, though, and I've never built anything like this.

Yeah, the rotation axis is what I was having a hard wrapping my head around.

I guess the question now is will I have an issue using a link on the front and rear ans relying on the main left and right mounts solely to hold the engine in place fore/aft and up/ down.

bgkast wrote: Yeah, the rotation axis is what I was having a hard wrapping my head around. I guess the question now is will I have an issue using a link on the front and rear ans relying on the main left and right mounts solely to hold the engine in place fore/aft and up/ down.

How does the transmission mount in that car?

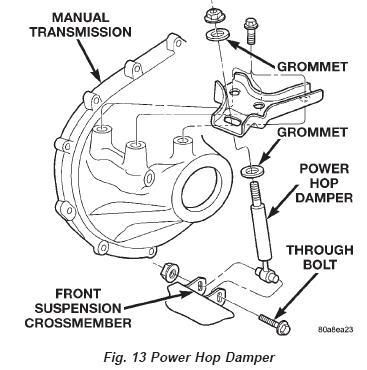

It the 1st gen neon with the Power Hop Damper (that is a sweet name btw) the engine mounts with left and right mounts like my engine, plus this in the front.

My brake and clutch pedals arrived yesterday, so I started mocking them up. They are about an inch too high still in the picture.

I also finally made a decision on how to finish of the rear structure of the car and built it.

This may seem like a fairly simple task, but for some reason it has been a huge mental barrier. With that out of the way I can start to fully weld the chassis. I plan to start with welds on vertical surfaces, then move to horizontal welds before flipping the chassis and welding the previously upside-down joints.

Not a whole lot of progress today. I went to the junkyard and swapped the stratus alternator I got last weekend for a 1st gen neon one. Success! The neon alternator on the stratus bracket fits perfectly on the SRT engine. I also grabbed a power hop damper and bracket.

I spent the rest of the afternoon cleaning up huge piles of grinding dust, vacuuming the build table and then started cleaning joints for final welding.

You'll need to log in to post.