This got kind of long, apologies in advance.

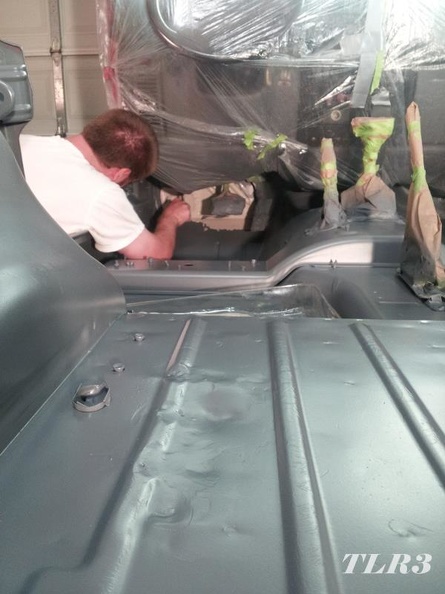

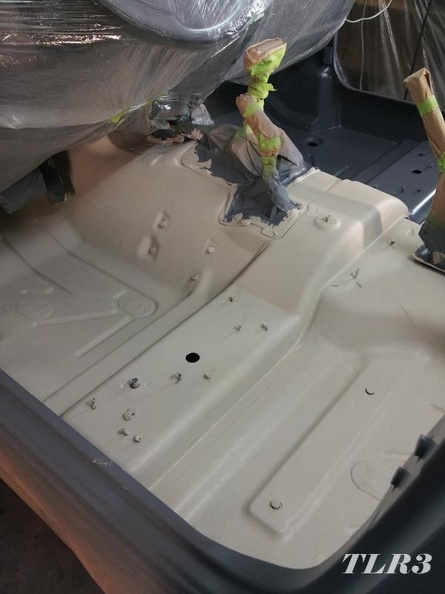

Late on the third day after priming, I finally sprayed bed liner. Remember that I only had 4 days to work with the epoxy primer before it had to be sanded. Since there wasn't a lot of epoxy primer still exposed, most was covered with HNR, I went ahead and did a quick rubbing with some 120 grit and roughed up it's surface just in case. I also wiped down the still primed areas with some denatured alcohol since they were all areas I had been leaning up against, and dripping sweat on.

I thoroughly vacuumed the entire tub again with the Shop Vac, and then I was basically ready to go.

Before I mixed up any of the liner, I applied the Adhesion Promoter to the entire tub of the Jeep. The Adhesion Promoter's spray bottle basically sucks. You can adjust the nozzle to go from a large spray to a stream, there's no real mist option. Needless to say I went through the Adhesion Promoter relatively quickly, I managed to spray some on the entire tub, but had absolutely zero Adhesion Promoter left by the time the entire tub was covered, some places were coated thicker than others while attempting to adjust the nozzle.

During my correspondence with Dana at Al's, he suggested mixing and applying half of the product at a time. This is excellent advice that I neglected to take. With out really thinking about what I was doing, after I got Component B shaken up to my satisfaction, I opened the lid and proceeded to dump its entire contents into the Component A container.  What did I just do?!?!? At that point I was committed, so I went ahead and made the entire gallon.

What did I just do?!?!? At that point I was committed, so I went ahead and made the entire gallon.

I soon figured out why Dana recommended to only mix half of the batch at a time. If you mix the entire contents you wind up with roughly a gallon of product, and you have a gun that holds roughly a gallon of material in its hopper. The top of the hopper is open, not sealed. So, open top hopper, filled to the brim, 1 gallon of heavy bed liner, plus the weight of the gun, regulator, and hose, doesn't take a rocket surgeon to figure out what's going to happen.

At least it's easy to peel off a dirty concrete floor once it has hardened.

Sadly that wasn't the only spill, however the silver lining was that the other spill was in the tub where I was going to spray liner anyway. Spread with a roller, and topped with more product out of the texture gun you can't tell where it was spilled.

No point crying over spilled milk... I mean bed liner, so then I proceeded to spray the liner onto a big card board box, adjust the air pressure, and gun settings, get a feel for the gun, and achieve a texture I was happy with. I had already selected the smallest tip that came with the texture gun, three different sizes are provided with the gun.

Al's directions say to set the air pressure at 35 psi (I think I'll have to double check that), I saw a youtube video recommending 50 psi, so I started at 50 and worked my way down. I settled on 30 psi to achieve the results and texture I wanted. I couldn't tell you where the knob on the gun was turned to, you'll just have to practice on your own. I have a double filter, and regulator, and a manual hose reel mounted on my garage wall, I typically leave the wall regulator set at 90 psi, and I used a HF mini regulator attached to the texture gun to adjust the air pressure for at the gun.

My first time ever spraying bed liner was eventful, I've already covered spilling the stuff. I had a real bug issue when spraying the primer, and I didn't want that problem again, so I kept the garage door closed to spray the liner. No air flow and it was HOT, I was soaking wet with sweat, and could hardly see for the stinging sweat in my eyes. You kind of need to be able to see when spraying bed liner.

I mentioned earlier how my air compressor wouldn't be up to the task of continuous texture gun use, so I had a "brilliant" idea: Hey, I've got a little Porter Cable pancake compressor, why don't I just hook it into the manifold on my Speedaire, that ought to help some, right?

As it turns out the Porter Cable has a higher shut off pressure than I have my Speedaire set for, so basically the Porter Cable keeps on running. Any guesses what happens in you garage when you're not only running two air compressors basically continuous, but also a 500 watt shop light, and its 96° outside? This doesn't take a rocket surgeon either, threw a breaker.  Great! Where's the breaker box in this house, in the garage like a normal person would have? Nope, it's outside, other end of the house. I've got bed liner all over me, I can't go through the house, I must open the garage door, and run outside around the house and flip the breaker back on.

Great! Where's the breaker box in this house, in the garage like a normal person would have? Nope, it's outside, other end of the house. I've got bed liner all over me, I can't go through the house, I must open the garage door, and run outside around the house and flip the breaker back on.

I must say the look on the faces of the neighbor kids when they saw me running out of the garage, mask on, covered in gray stuff, and soaking wet was kind of priceless. I'm sure they thought, "we better get the hell out of here, that meth lab is about to blow."

So I turned the Porter Cable off, got the power back on, and got back to the garage to finish up. It wasn't long before I started getting real inconsistent texture from my gun. Pressure was fine, compressor was going, what could be the problem? I look in the hopper, there's still quite a bit of material in the hopper, I noticed it was much more viscous than it was when I started spraying, it had started to harden already.

I was not a happy camper. Al's advertise this stuff as having a 20 minute pot life, I might have gotten 12 minutes of actual sprayable material before it became too thick. I could still spray it out of the gun, but it was very inconsistent and was making a much coarser texture than what I wanted, so I quit. I had a little over a pint of product left in the hopper.

Between what I spilled, test spraying, and what hardened in the hopper, I lost at least a quart (1/4) of my liner. I didn't have near the coverage that I wanted on Muffin either. There were thin spots and off angles that you could still see HNR through a light coating of bed liner. I was not a happy but I didn't have time to sulk.

I knew how hot it was going to be so I thought shorts and a tee shirt were a good idea. I was wrong. I had bed liner all over my arms and legs. As I mentioned earlier, SWMBO had to give me a sponge bath with denatured alcohol, not fun. I then quickly hopped in the shower, and scrubbed. Thankfully I didn't get any on or near my hootus.

You're supposed to remove any masking about as soon as you finish spraying the bed liner so that you can have a defined line between bed liner and paint, and so the bed liner doesn't permanently glue your masking tape in place. So as soon as I got out of the shower I rushed back out to the garage and began unmasking Muffin.

This was not a good night, I was not happy with my initial results, nor how much product I wasted, but at this point there wasn't much else I could do. I had thankfully covered all of the areas that were still just primer sufficiently, so I was no longer worrying about the 4 day top coat window, or having to sand around/through any bed liner. Before I went to bed that night I got on Amazon and ordered another 1 gallon gray Al's Liner kit, Prime 2 day delivery.

Additionally, keeping the garage door closed made the entire house stink, so SWMBO wasn't happy either, if she ain't happy, no ones happy.

![]()

![]()