As those who have been to an SCCA Solo National event know, the first time you attend one of these events you're blind to the caliber of drivers they draw, and promptly think you can walk out with a trophy (or at least I am arrogant enough to believe that I could). I have fallen victim to this situation in the past two trips out of Lincoln. I continually fell into a trap involving an uncompetitive car (wrong tires, not fully prepped, etc.) and disappointment at Nationals. Well, I have finally come to the conclusion that I ought to rule out the car in my list of racer excuses. That transpired into a 1989 Honda CRX Si built for STS. This car has a history as an autocross car, as can be seen here. However, a car that was nationally competitive 6 years ago does not mean much if it hasn't been maintained. Thankfully, this car seemed to be pretty well maintained, however after passing through a few sets of hands over the last 6 years means it probably is not well prepped.

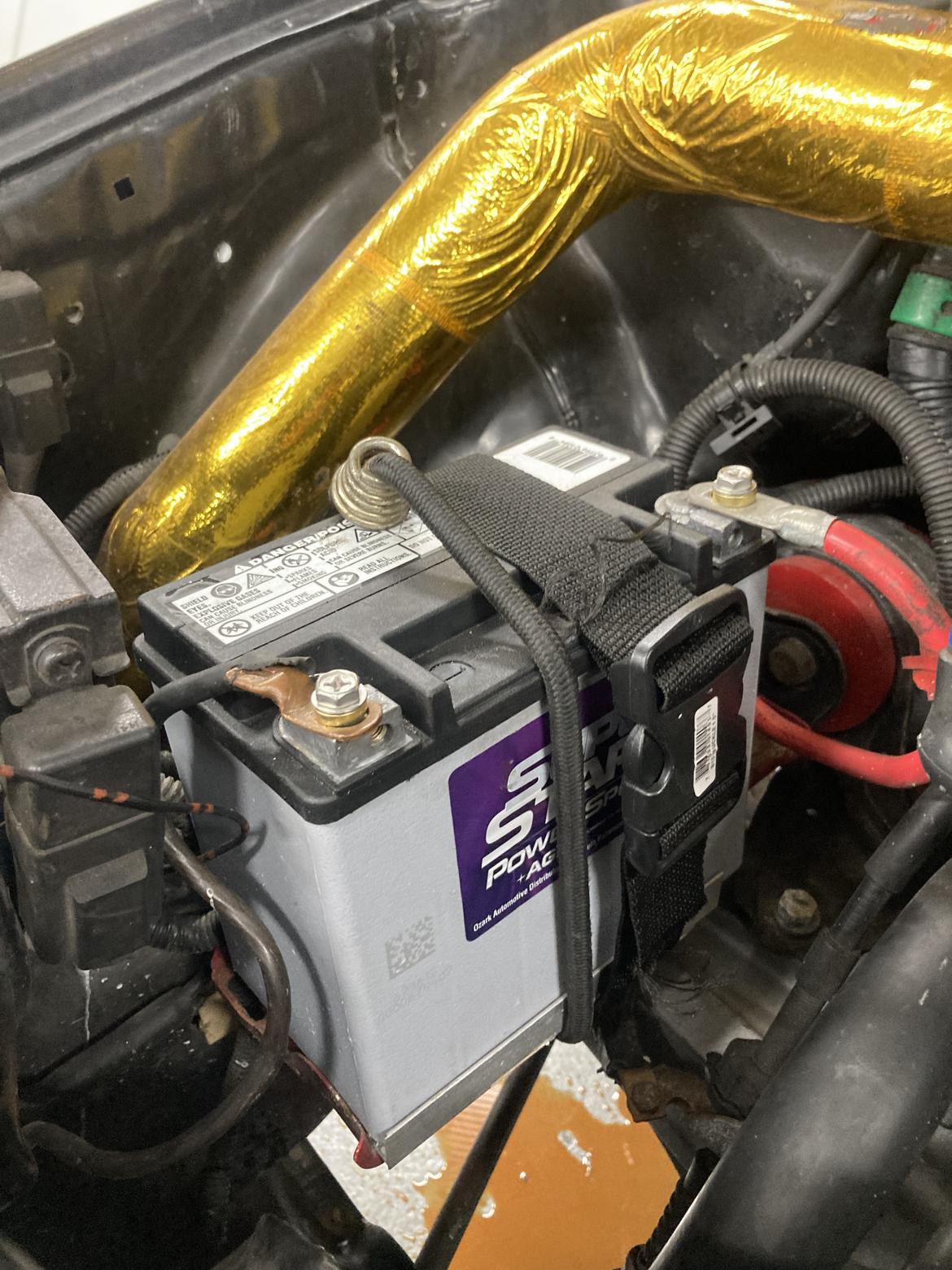

After picking this car up, I promptly decided to sign up for an autocross at Grissom two weeks out, because, why not? It runs and drives. So I put it on the lift, figuring it needed a good prep. My hypothesis was not wrong. After working through all of the suspension components, and engine bay I had determined a couple things. This car had a lot of loose fasteners probably due to poly bushings and engine mounts, and the battery "mount" was atrocious(I mean seriously, it is not that hard to mount a battery), new tires, there was no cold air intake mount, and it needed the brakes bled, badly.

This photo shows a bold that holds load from the lower kingpin being held on by maybe 3 threads.

The brake fluid that came out after the first purge of the system

The first fabrication project on this car that was required was a fix for the battery mount, I decided that a bungee cord and a cheap plastic strap would not do.

The replacement was made with just a simple aluminum strap that would secure it to the mount. I did this pretty quickly, and it is not very serviceable, so I figure that is something to fix in the future.

I also flushed the cooling system, as I couldn't tell if it was filled with water or coolant, and living in Michigan, I figured it was worth it to drain the system to know it won't freeze if the car is out in cold weather.

After the car was prepped, I took it out to a divisional event at Grissom. The first day I ended up 4th on pax, beating someone who trophied this past year in ES, which gave me some confidence in this car. The second day did not go quite as well, the tires were corded as the previous owner street drove the car with the aggressive alignment, resulting in crazy camber wear. I think I ended up 14th on pax. Being a college student, I decided to hit the books for a while before touching the car again. However, with Thanksgiving Break this past weekend, I decided it was the perfect time to get back under the hood, with the intention of fixing some slight frame rail rust.

The first day with the intention of completing this project, my brother, Jack made a snarky comment on the appearance of the car with its orange accents.

So I decided I would see how it looked if I pulled off some of the wrap, which I found I enjoyed the look of more. Next thing I knew 6 hours had gone by and I hadn't started the project I meant to, but I had pulled off all of the orange wrap. This led me to my next revelation...I will never buy a car covered in stickers, or that's wrapped ever again.

With all of the really important de stickering done, it was finally time to cut the car apart. I am fortunate enough to have access to a lift, and decades of sheet metal fabrication experience through my dad, Carl Heideman.

This is how the frame rail looked before the repair

After cutting back the first layer of sheet metal on the floor, it looked like it would need to be taken further back to get a good spot to weld to (no rust), and to prevent it from rusting again.

This was the first patch, not the prettiest work ever done, but at least only everyone who reads this thread will know about that one. After this first patch was burned in, the second patch was built, burned in, welds were grinded, and it was hit with undercoating.

The wheels that came on the car were 15x7 Enki RPF1's, which are a good looking wheel, but I was looking for a lightweight 15x7.5'' wheel. All of the real competitive guys seem to run the SSR Competition wheels, but due to the fact I am a broke college student, I figured I'd settle for spending far less than a couple thousand bucks for a couple extra pounds. I was able to pick up a set of 949 6UL's from a fellow autocrosser, and found they weighed in at 12 pounds, not too bad in my opinion.

With that done, what I see next in the full preparation of this car is to get the Whitener shocks rebuilt if that's still possible, or replace them with a higher end shock, check the alignment (and try to get some testing in), get some new tires, and maybe put the car on the dyno to check the tune and see how much power the little 1.6 liter engine can make.

Thankfully, apparently the failure was uneventful, as my dad was towing it unloaded at the time of failure. Still pretty creepy though.

Thankfully, apparently the failure was uneventful, as my dad was towing it unloaded at the time of failure. Still pretty creepy though.