Been a while since I've been able to post an update on the car. The car did well at the NCM track after all of the recent upgrades (larger wheels, tires, and brakes). I put them to use at the USCA event that came through town in early June and took seventh place in the GTL (under 3,200 lb class) with the car. The car ahead of me was one a 2,500 pound Camaro with 800 horsepower, and the car who beat it was a Miata with a K-series Honda engine longitudinally mounted sporting 300 wheel horsepower. Needless to say, a pretty fun group of cars and people to run around a track with. Leading up to the event, I didn't have an extreme amount of prep work for the car, or so I thought. I was really waiting for the following items to show up on the proverbial doorstep: an Eastwood fender roller so I could clearance the fenders for the 275mm tires in the front, the Falken Azenis RT615K tires, and the Advan TCIII wheels to get here from Japan by way of California. Everything got here the week of the event so ultimately I found myself in yet another rush before an event. Once everything came in, I was impressed not only with how the new wheels were going to look on the car, but also the sheer amount of additional tire I was going to have to make room for under the front fenders.  IMG_5017 by eric.burnett09, on Flickr

IMG_5017 by eric.burnett09, on Flickr

IMG_5019 by eric.burnett09, on Flickr

IMG_5019 by eric.burnett09, on Flickr

IMG_5023 by eric.burnett09, on Flickr

IMG_5023 by eric.burnett09, on Flickr

IMG_5028 by eric.burnett09, on Flickr

IMG_5028 by eric.burnett09, on Flickr

After getting the tires mounted on the wheels, I brought them over to work and spent some time with the car on a lift getting them under the car to figure out how much pulling I was going to have to do and how large of a spacer I was going to need (ended up using a 10mm and installing the Nismo extended wheel studs I have had sitting around that I scored from Enjuku Racing). It's important to remember here that these fenders are pretty thin and that no two pieces of metal want to be pulled the same way. The clearance has to come from somewhere, so it'll be pulled from the base or the sides of the fender, and it's a mystery how that's going to make the rest of the fenders look until you're finished. Thankfully, this car is meant to be put to use, rather than just look nice, so I'm not greatly concerned about the end result as long as I can drive the track with no rubbing. That being said, they didn't look bad when I was finished.  IMG_5055 by eric.burnett09, on Flickr

IMG_5055 by eric.burnett09, on Flickr

IMG_5056 by eric.burnett09, on Flickr

IMG_5056 by eric.burnett09, on Flickr

IMG_5058 by eric.burnett09, on Flickr

IMG_5058 by eric.burnett09, on Flickr  IMG_5044 by eric.burnett09, on Flickr

IMG_5044 by eric.burnett09, on Flickr

IMG_5042 by eric.burnett09, on Flickr

IMG_5042 by eric.burnett09, on Flickr

IMG_8760 by eric.burnett09, on Flickr

IMG_8760 by eric.burnett09, on Flickr

After the car was all dialed in and the fenders were pulled, I tested it lock to lock and then took it down the street to fill up at a nearby Shell and grab a soda and study the cars new look.

IMG_5065 by eric.burnett09, on Flickr

IMG_5065 by eric.burnett09, on Flickr

I had the following alignment specs set on the car at the recommendation of a couple of friends that have these cars and drive them competitively here and there: Front: -2.25 degrees of camber, 6 degrees of caster, 0'' toe Rear: -1.5 degrees camber, 1/8'' toe-in total, .25 on each side Once I got the car back from that I spent the night before the event doing a bunch of little stuff, like swapping out the antifreeze for distilled water, ensuring wiring was thoroughly zip-tied out of the way of heat sources, fuel lines tight, harnesses secure, Go Pro installed, mandatory event stickers installed, crappy yellow headlights polished.

IMG_5076 by eric.burnett09, on Flickr

IMG_5076 by eric.burnett09, on Flickr

IMG_5079 by eric.burnett09, on Flickr

IMG_5079 by eric.burnett09, on Flickr

Once that was all done the car was up in the air from the coolant swap and I went to let it down. Pushed the lever to release the stops and it pushed completely down and didn't release the stop on the other post. Spent the next 45 minutes taking the covers off one of the other lifts in the shop to see how it should work. Ended up establishing the cable had slipped through on the other side and we had to manually release it and put a "do not use" sign on it until it could be fixed the following week. Went to bed at around 2 a.m.....

IMG_5062 by eric.burnett09, on Flickr

IMG_5062 by eric.burnett09, on Flickr

On to the event: Got out to the event by 7 a.m. wondering how in the world I was going to be able to focus on less than five hours of sleep and got setup with my father.

IMG_5093 by eric.burnett09, on Flickr

IMG_5093 by eric.burnett09, on Flickr

Drivers meeting:  IMG_5085 by eric.burnett09, on Flickr

IMG_5085 by eric.burnett09, on Flickr

The Speed Stop Challenge was first for my run group. It was set up differently than most that I've been involved with through work before. It used part of the slalom portion of the NCM track. I wasn't as quick as I wanted to be on this as I think the car needs a smaller bore master cylinder as there isn't a ton of pedal modulation available with the 1 1/16'' Z32 master. No ABS was interesting to get used to with the setup also. At least the rear brakes weren't locking up before the fronts. I had purchased some stock Z32 rear pads in case that ended up being the case, but thankfully I didn't have to.

11406910_10102131860132412_8943413141550516104_n by eric.burnett09, on Flickr

11406910_10102131860132412_8943413141550516104_n by eric.burnett09, on Flickr

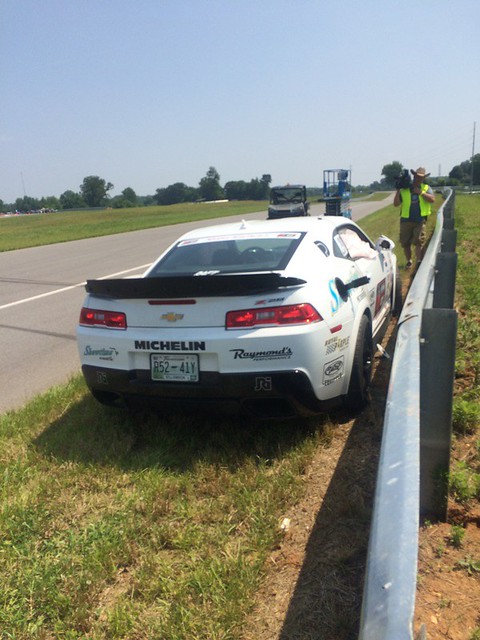

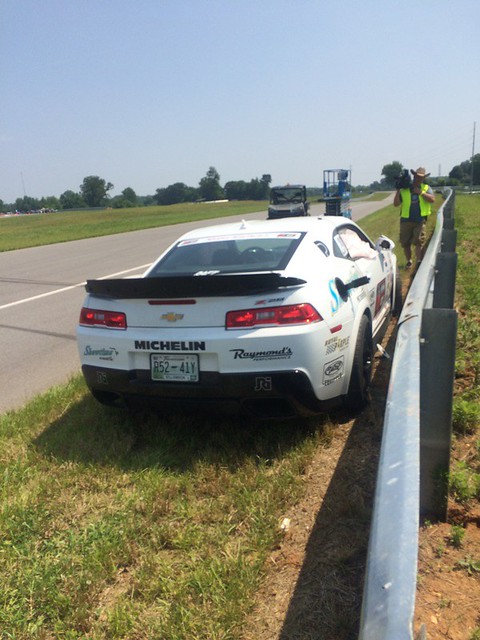

After I finished a few runs on the Speed Stop, I went back to my pit to check tire pressures and heard the horrific THWACK! of a car smacking the K-rail. I ran back over to see one of the Showtime Z/28 had lost traction in one of the corners and had slid cross track and slid up against the barrier. They are team players and were able to get spare suspension parts on and pull the fender out and continue running the event.

IMG_5091 by eric.burnett09, on Flickr

IMG_5091 by eric.burnett09, on Flickr

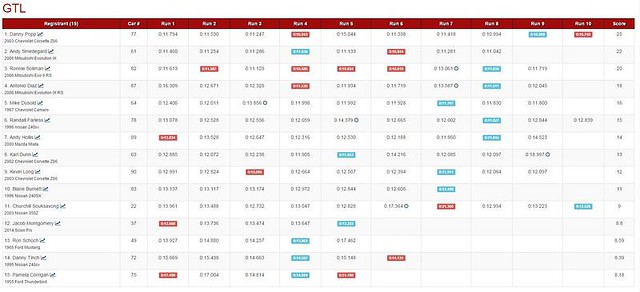

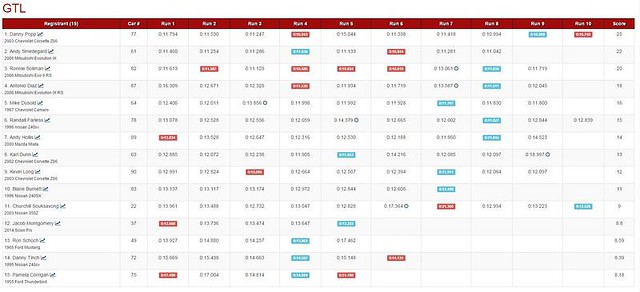

Ended up finishing that portion of the event with best of 12.499 from start to finish. Good enough for 10th out of the 15 in the class that participated in the Speed Stop. Definitely room to improve, but glad to have better performing brakes than at my last track day.

GTL Speed Stop Results by eric.burnett09, on Flickr

GTL Speed Stop Results by eric.burnett09, on Flickr

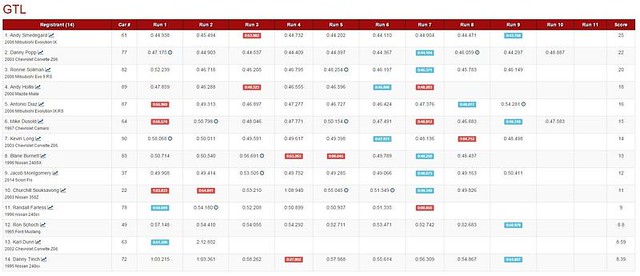

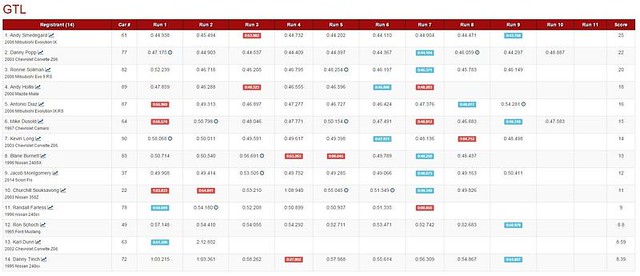

As for the autocross, the car was a totally different animal with the larger contact patches in the front. Took a few runs to get comfortable with having a car that could actually grip in and take weight off of the rear by letting off of the throttle so easily. Had to be much more sensitive with my inputs to the throttle compared to when the 235s were on the front as I was always having to come off throttle to dial out understeer. Now letting off throttle the same amount had a much more grippy effect on the front and I had to dial that back a bit. I left the Sikky sway bar on the softest setting and stiffened up the coilovers a few clicks and that is all I changed on the autocross. The alignment and tire pressure seemed to be working out just fine on the front tires as the wear markings were coming over on the ed of the tire perfectly. I was trying to get the tires down to about 35 psi hot. Stephen Lee, good friend and competitive member of the Kentucky SCCA chapter was on hand and was able to give me a few pointers by riding along throughout the day.

IMG_5095 by eric.burnett09, on Flickr

IMG_5095 by eric.burnett09, on Flickr

11411977_432125190307442_7277678917185462554_o by eric.burnett09, on Flickr

11411977_432125190307442_7277678917185462554_o by eric.burnett09, on Flickr

GTL Autocross Results by eric.burnett09, on Flickr

GTL Autocross Results by eric.burnett09, on Flickr

On to the road course: I've only tracked this car a couple of times. One was on a short course of the track over the winter at what the NCM facility calls a "Track X". The most recent outing for the car on track was at the same facility at NCM but on the Grand Full course. This time we were donig the West course and so I was already familiar with it. The only thing changing was the fact that the car was enjoying newer parts. I was also stoked that the car was keeping up with some of the cars that were in my run group. Granted the car could probably be setup better in the suspension department, but in the GoPro video below I'm actually keeping up with and catching up to a new Z/28! [URL="https://www.youtube.com/watch?v=wrV6id6aVMA"]https://www.youtube.com/watch?v=wrV6id6aVMA[/URL]

GTL Road Course Results by eric.burnett09, on Flickr

GTL Road Course Results by eric.burnett09, on Flickr

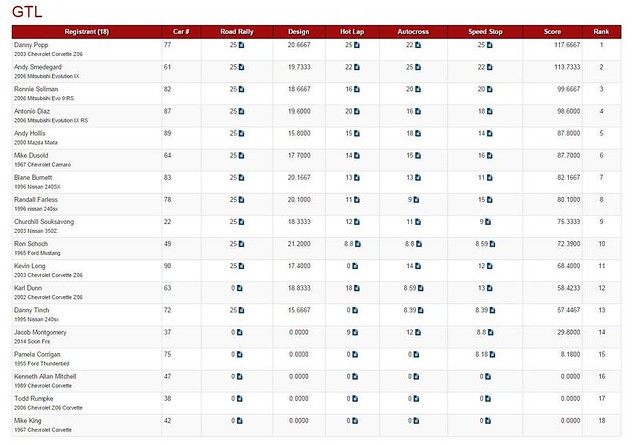

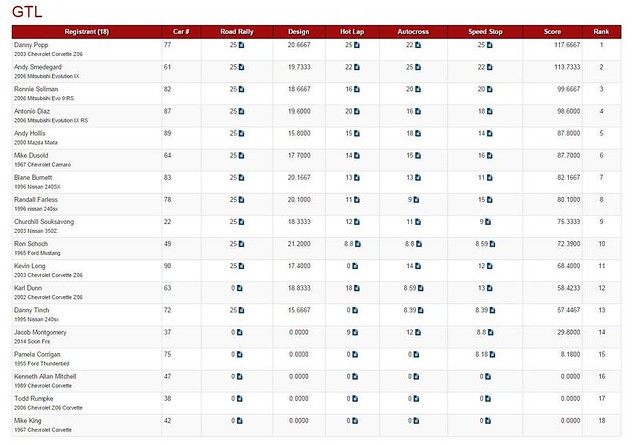

Overall results: Not having a ton of track experience other than a few track days and a couple of schools, I'm pretty stoked the car did as well as it did. I try to be as humble as possible, so I'm sure that it would've been faster with perhaps one of my nissanroadracing.com peers piloting it around or setting it up, but that's the whole point of developing a car over time: to see it progress. 7th place out of 18 registered is a-okay for my first time around. I look forward to seeing what it can do in a year's time at the same event! Thanks for reading! Any constructive criticism is welcome.

GTL Overall Results by eric.burnett09, on Flickr

GTL Overall Results by eric.burnett09, on Flickr