Wow, this car is functional art. How much of your budget is is welding wire/sticks?

This is really a pro level build on a diy budget.

Do you guys have any non challenge builds going on, or are they all former challenge cars that have a bit more into them now that the budget constraints are gone? What's the fastest/quickest car you've built?

In reply to Run_Away :

Weld wire isn't too bad. I buy in the largest quantity I can because it is cheaper that way.

Thanks for the kind words.

We have a couple non challenge cars. Most of them are challenge cars though.

Our fastest build would be my dad's 1954 Studebaker. It has gone 179mph.

Quickest would be my dad's roadster he built over 10 years ago. It went mid 9s. My dad would know the exact number. I don't have any pictures of that one.

You can see a lot of our builds here: https://www.paccracing.com/new-page/

Day 100 - December 16, 2017

Made lower intercooler mounts. Began making shroud between radiator and intercooler. Continued making mounts for front end.

I've been wondering why you don't see more big turbo cars running diesel truck intercoolers.

I know air volume is an issue, but are other concerns?

Crackers said:

I've been wondering why you don't see more big turbo cars running diesel truck intercoolers.

I know air volume is an issue, but are other concerns?

The ballance of diminishing returns. At the risk of getting long winded....

A 11.90 second car has a 9.71#/HP ratio. A 10.90 car is 7.30 #/HP. 9.90 is 5.32#/HP. 8.90 is 3.79#/HP. Long story short - you have to make crazy power or be crazy light to go fast. Aside from the budget restraint, we make all our decisions based on whether we can beat/meet 5#/HP. We scrape undercoating and weigh it in HP. We drill holes and count them in HP. We go to extremes to eliminate weight. Don't beat the horse....unload the wagon.

While installing too big a part on a slower car (11 seconds and slower) has less detrimental impact on performance, adding too big to a fast car is very "expensive" when it has to be accelerated. If you have a 30 pound IC and piping package in a 11.90 car, anything over 3.1 net HP gain is going to move the car quicker. On an 8.90 second car you use 7.91 HP to move the IC and anymore gain moves the car quicker. Not a big deal on IC choice - go as big as you can. Packaging is the greater restraint. The temperature drop and associated power gain far outweigh the weight penalty when you use a bigger IC.

OTOH turbos are heavy. We have two 70MM, one is 56# (truck) and the other 25# (aftermarket). The truck turbo takes 6HP more just to move it when compared to the aftermarket piece and it has higher discharge temps because it is not in the higher efficiency area on the map. Performance wise, it is expensive on a race car but the compromise is livable on a Challenge budget.

At the end of the day we look to find (80) places to remove 1 oz (a 1 HP equivalent), and we are always trying to right size the major parts.

wheels777 said:

Don't beat the horse....unload the wagon.

there's a certain irony that that was typed into the internet... I'm not sure what... but I know it's there

Day 101 - December 9, 2017

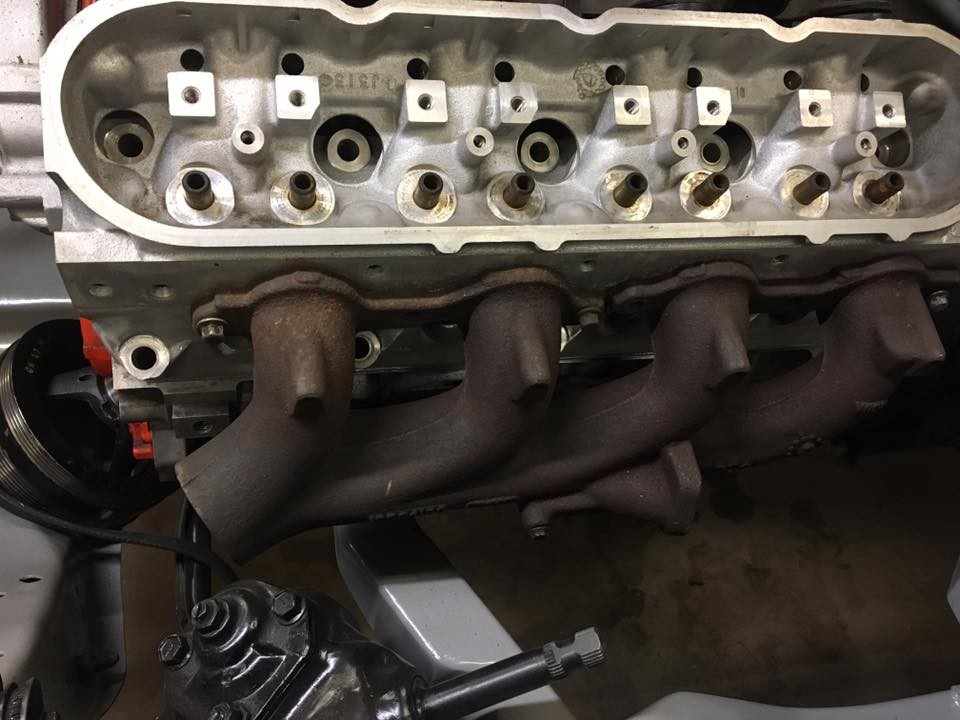

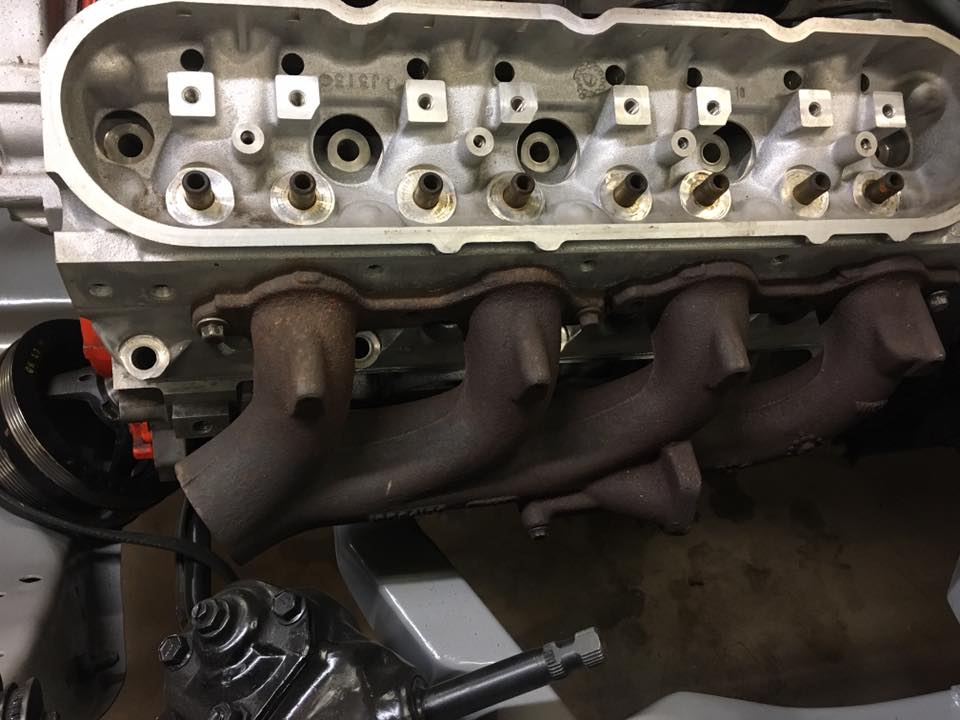

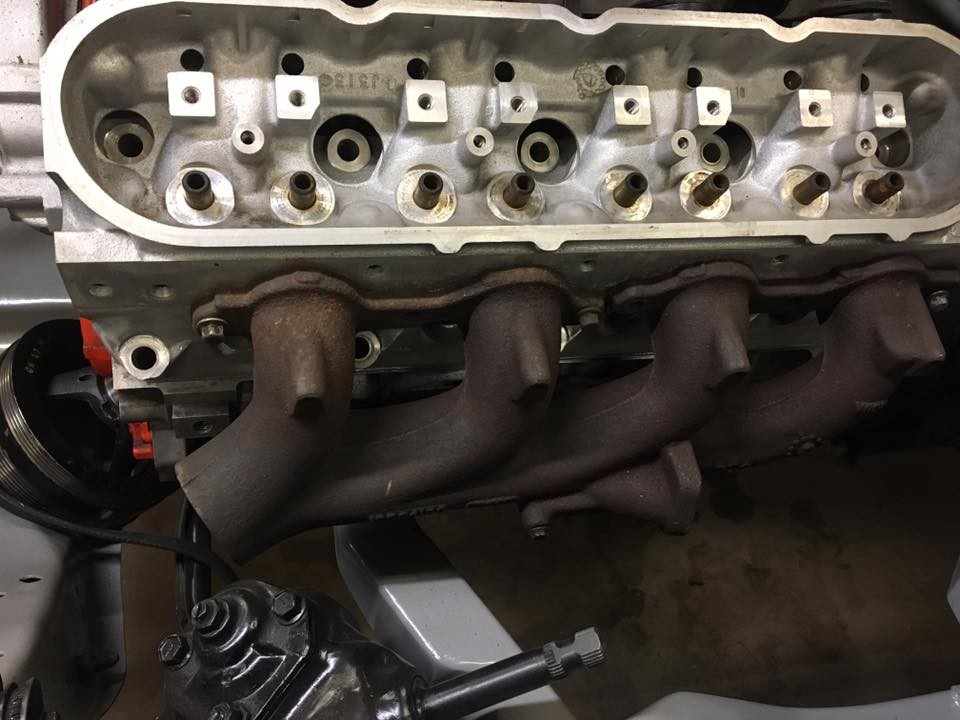

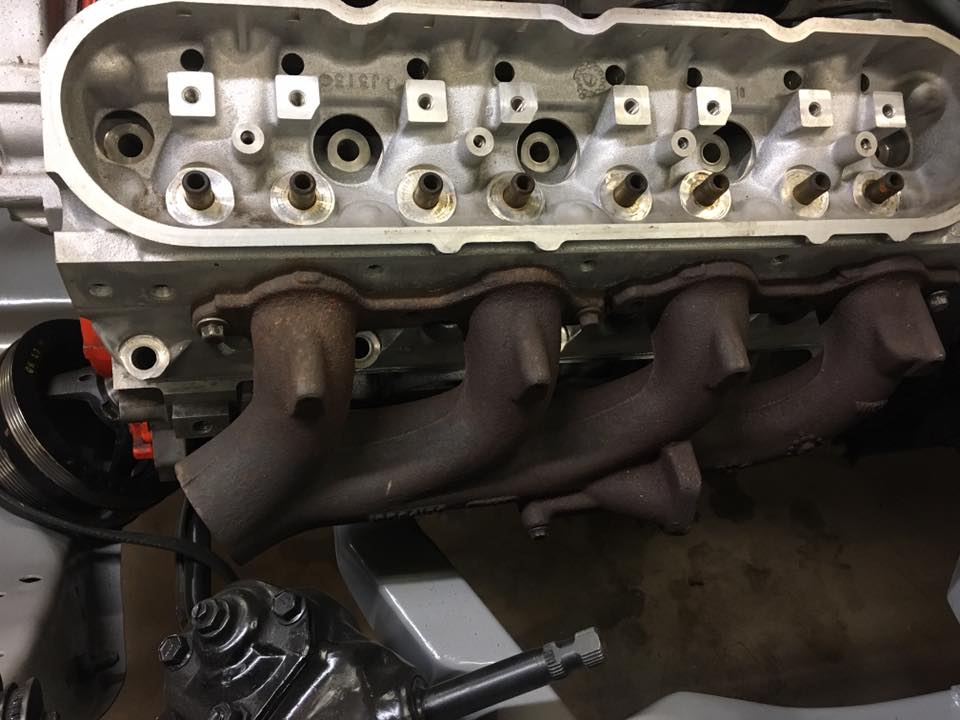

Made lower radiator mounts. Began to lighten manifold. Removed 1 pound 1.6 oz (0.2 HP).

I wonder how many negative horsepowers you have added to all the nooks and crannies in the shop in the form of grinder dust.

Also, can't believe there was a whole pound of excess weight on that manifold. Nothing gets past you guys!

maschinenbau said:

I wonder how many negative horsepowers you have added to all the nooks and crannies in the shop in the form of grinder dust.

Also, can't believe there was a whole pound of excess weight on that manifold. Nothing gets past you guys!

they're way more grinder happy than me, and i sweep up pounds at a time. i should post a couple pictures of details on my Datsun, that Andrew initially built for land speed racing in the mid 2000's before it was sent to rot under a tree in southern ohio prior to my purchase. It definitely defines a quote from him somewhere that read along the lines of "saw blades and drill bits aren't part of the budget." Front bumper has 60+ holes and the battery tray has 80+ - between his initial stuff and me adding more the car has upwards of 350 lightening holes in it. I'm really enjoying the details of the sunbird because I have been to their place a few times and seen different projects in different stages of build. It's much like my place except they have more room under cover and I don't have a vertical mill...yet. He's also at the point where his boys can do stuff with him other than play with transformers in the shop. I'm looking forward to the day where i can say "Colin, weld this" and he does it.

TheV8Kid said:

Day 100 - December 16, 2017

Made lower intercooler mounts. Began making shroud between radiator and intercooler. Continued making mounts for front en

Beautiful work as always, Nelsons. I'm trying to get my mind around the tube/washer/ bent bit of mount situation here. My guess is that it is tight with the front closed, and they rotate to a looser (laterally) orientation when opened. In short, it looks like you have a tilting front end that also has a separate hood for more basic maintenance, but will come off for more in- depth stuff, ala Binky, only not powered.

Apologies if my wording is unclear. I had quite a time trying to phrase what I hope is an intelligent question. Thank you in advance. This whole build thread is schooling me on tons of stuff.

In reply to wheelsmithy :

It is not a tilt front end. The washer is a guide. Drop it on the rail, slide it back, and the registers keep it centered. the picture you copied is the right side. There is an identical reversed set up on the left.

In reply to wheelsmithy :

I like the way you're thinking, but your guess is wrong. The idea is you set the front end down on the lower register which sticks out further, then simply push back and it will center the front end using the upper register. If we were to make the upper register straight, it would be harder slide into place. By putting at an angle it provides more surface area to slot it into place.

This front end will be strictly a walk off front end. What you will see on a lot of tilt front ends is they will have 2 piece fenders in the back so that the front end can tilt easily without getting caught on stuff. We would prefer not do this to our front end. See pic below.

In the case of project Binky, they did it a little different and made a slider and pin register. This is heavy, but a more elegant solution. Tons of different ways to do the same thing.

We prefer walk off front ends, because they are off and out of the way when you need to work. Also they tend to be lighter, and don't get caught in the wind as easily. The only bad thing is you need two people to remove them.

In reply to wheels777 :

Wow the discussion on saving weight versus adding horsepower and the effect it has on faster cars was really enlightening. Like, one of the most insightful things I’ve read on car building in a while. No wonder you guys are so fast!

In reply to Patrick :

You did a good job with the Datsun. Glad to see it being used and enjoyed. Having more than one person working at a time makes a big difference!

dculberson said:

In reply to wheels777 :

Wow the discussion on saving weight versus adding horsepower and the effect it has on faster cars was really enlightening. Like, one of the most insightful things I’ve read on car building in a while. No wonder you guys are so fast!

We're nothing if we aren't helping others to realize their own goals. Information is gold.

FWIW, our heaviest Challenge car was 2727 with driver and fully loaded. We are hoping that this Nova is going to be light.

Is that the Colin Chapman mantra of "add lightness"?

FIYAPOWA said:

Is that the Colin Chapman mantra of "add lightness"?

Adding lightness was coined over 55 years ago. Unfortunately, I have no idea who Colin Chapman is. But I am confident he probably used the same dynamic, physical and engineering principles that every racer applies. I've been directly involved in racing for 40 years and weight consciousness has always been part of the sport.

Colin Chapman was the founder of lotus and is credited with creating the phrase "adding lightness" about 50+ years ago now.

I appreciate the discussion on hp vs weight. It is gonna make me look at my chumpcar a bit differently, that's for sure!

Day 102 - December 20, 2017

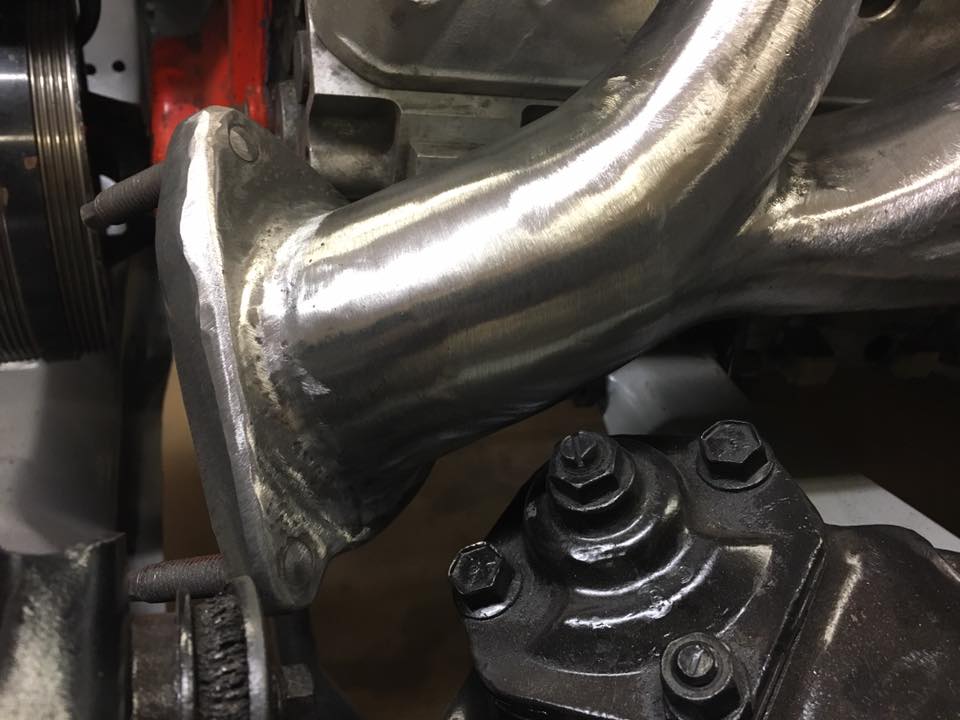

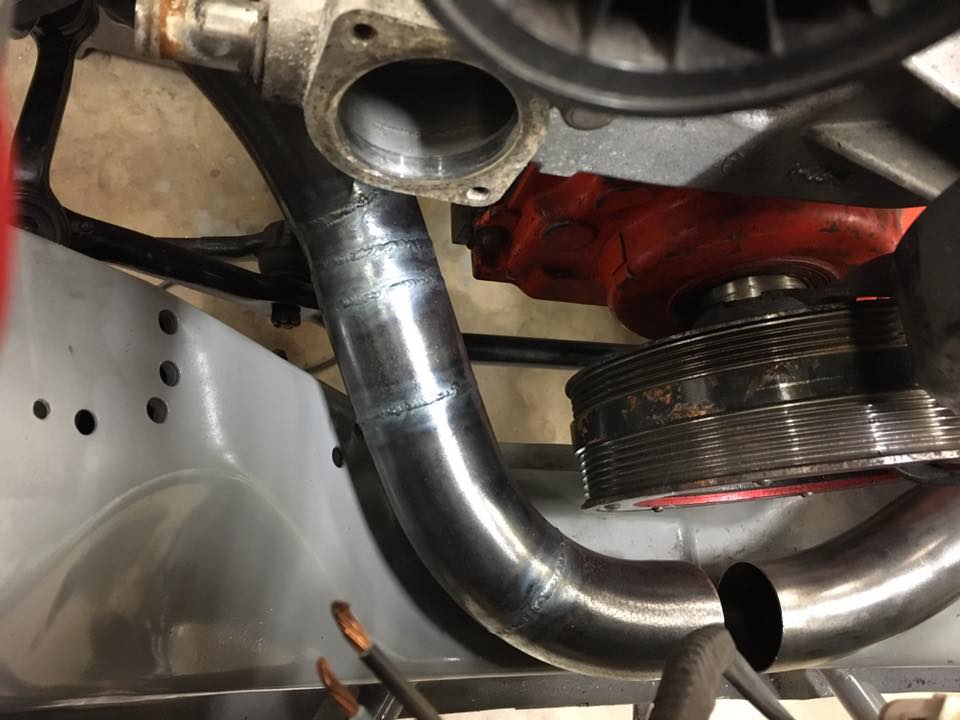

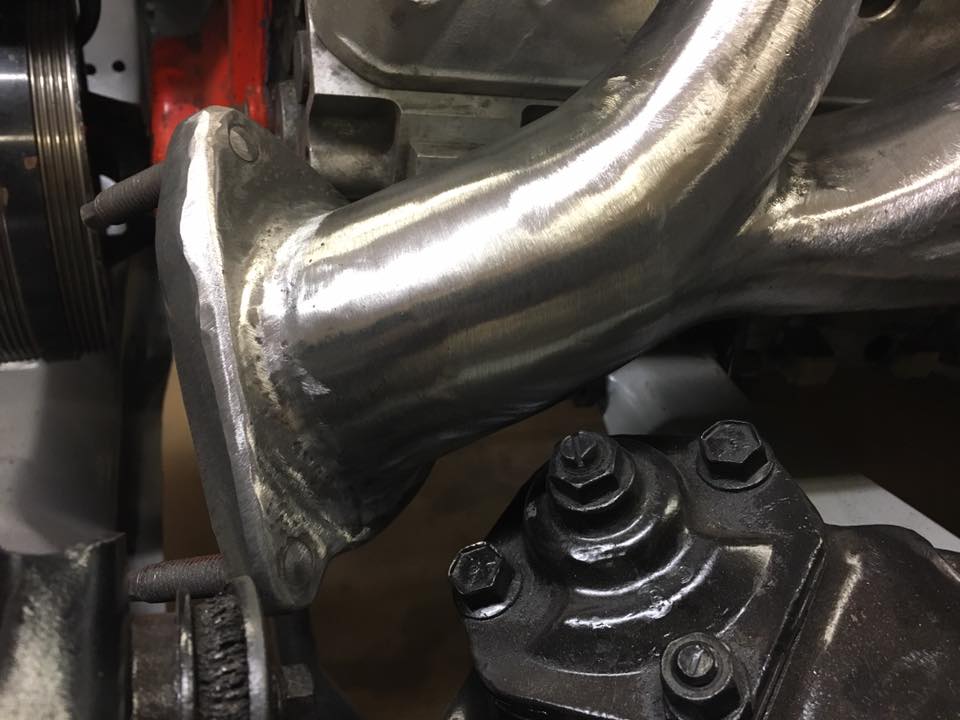

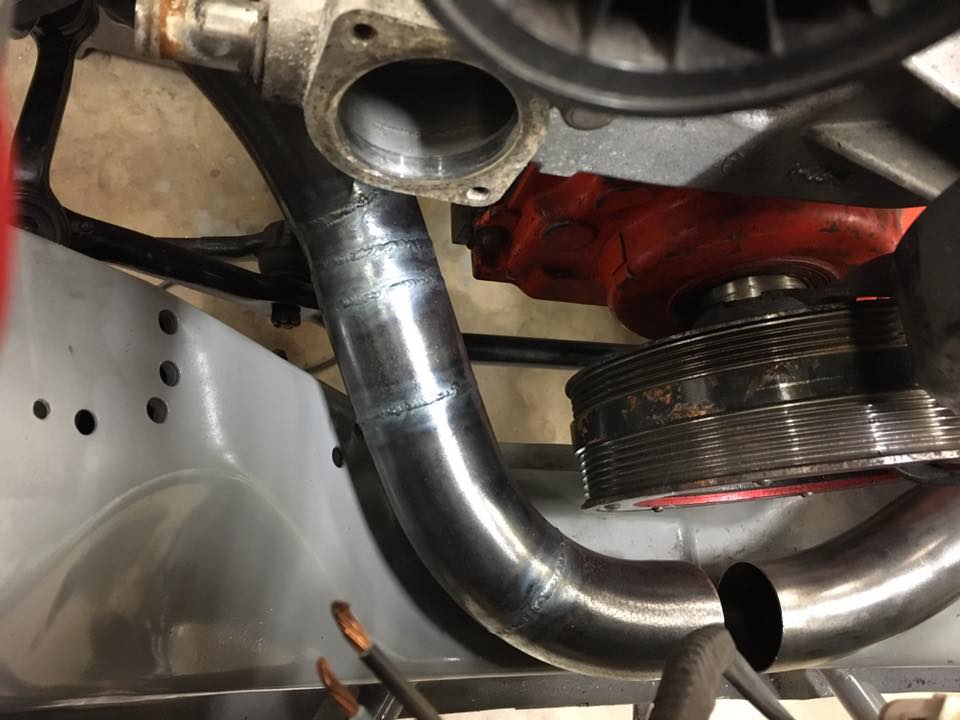

Total manifold weight loss: 1 pound 9.6 oz (0.28 HP). Re-clocked outlet flange on manifold. Began making crossover tube. Continued working on shroud.

Before

After

In reply to wheels777 : Cool, I understand now, and everything (the collective) you say makes sense. My misinterpretation of your awesome work gives me ideas for future projects of my own. In short, I think this thread (not to mention, passing on Darth Nader to a fellow competitor) is the ultimate representation of sportsmanship. You guys are a class act.

Day 103 - December 28, 2017

Continued working on cross over tube and radiator shroud.

Day 104 - December 29, 2017

Mounted fan, and made radiator struts.

After reading the Datsun build thread I’m surprised you are using a turbo. I’d think the weight and cost of the turbo setup would not outweigh the cost benefit of nitrous.

a turbo might be cheaper in the long run from a "whole budget" perspective... especially considering how much testing they do

Andy Neuman said:

After reading the Datsun build thread I’m surprised you are using a turbo. I’d think the weight and cost of the turbo setup would not outweigh the cost benefit of nitrous.

Your recognition to the fact that there were many lessons learned is spot on. However, your expectations and/or interpretations of how we would apply those lessons learned is not.

![]()