Replaced the original front Carrera shocks with new QA1 shocks. These are coil-overs.

I really like them. But then the factory stock ones were installed in late 1990, so were pretty old.

Issue with the rear shocks. I did have them rebuilt but within a very short time they "blew" out. Stock factory shocks should be correct for the car BUT!

Tested and measured compressed length, extended length and at ride stance. OOPS!

Only 1-1/2" of travel tip the shock bottoms out. Seem this car was set lower than the other Consulier's for the photo shoot and left that way.

So I have three options the way I see it.

1 raise the car an inch

2 fab a way to move the shock so it has more travel without full compression

3 get shorter shocks

Looks like QA1 sells that same shock but an inch shorter compressed and 2 inches shorter extended. P/N 7543

I'd try that if you can give up the 2 inches of droop travel.

http://www.qa1.net/qa1_motorsports/circle-track/shocks/twin-tube/75-series-steel-chrome-plated-shock.html

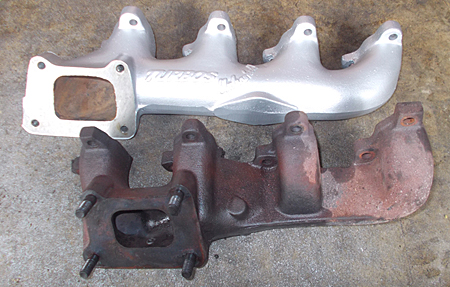

Bought the QA1's and have them installed. Look right! I have yet to test drive it. BECAUSE....I took the intake, exhaust manifold and turbo off. Will post in a day or two of whats going to replace the stock parts.

The rear shocks were replaced with QA1 coil-over shocks. I made a mistake of not checking free length and they bottmed out. This car was lower than the other Consulier GTP's, leaving only 1-1/2 inches before they hit. Bought shorter, adjustable shocks that should work better with the lowered suspension.

I could have had the Bilstein shocks fixed and changed mounting points but I wanted to try the QA1's.

These were purchased from Summit,

part number HAL-DS401.

The new manifold moves the turbo in a position that's about 3 inches to the left of stock. This test fit shows it fits and does not hit the frame at all. New turbo is a Garret Super 70, with a 3 inch swing valve. (the turbo's exit)

Next step is to install/test fit the new oil and water lines that feed the turbo.

Took a 555 transaxle I had to a friend for inspection and freshening up (bearings, syncro's, etc).

Also going to add: Case drain plug eavy duty chrome-moly bearing support plate Quaife limited slip

NOT going to install it right now, just want it ready "in case".

I know that won't happen but this is my insurance. Otherwise it will be installed next winter.

That is some turbo Mopar porn right there! I have been trying to source a 555 or hybrid here in FL to replace the 525 in my Charger but they have all but disappeared from CL.

Worked on the install of the exhaust header and new intake today. Would have been easier to take the head off and install them and put the head back on. But I didn't do it that way. The lower part of the intake is on and the TU header is bolted up. Nuts are not quite tight enough yet.

This is a shot during intake testing. To get the nuts tight, I need a different 10mm wrench, something with more angle on the head. Not sure if something like that is made. If not I will be cutting and welding to make one.

Shot from below with both intake and header installed.

Here is some more shots while in progress. Taping vacuum fitting holes, inside of intake (needs cleaned) and attached the top to the bottom of the intake.

The one photo from the under side showing the cast header also. Its a super 70 turbo. Also braided fuel and water lines to the turbo.

Inside the intake.

Did you keep the Bilsteins? They are practically infinitely rebuildable and revalvable, and almost every part interchanges between Bilsteins with the same piston diameter (46 or 36 mm). They cost ~$4 to rebuild once you have the tools. Add $5 for the valve to convert them to takeaparts if they aren't already.

Got it running pretty well. Had trouble with the 10 ft long throttle cable. Day after it was done, took a road trip. It lasted two weeks, 5400 miles and 15 states. The destination was a Turbo-Dodge convention about 80 miles this side of Chicago. On the way back made a detour to Denver, Phoenix, Los Angeles and then back to Oregon. Had one breakdown, it was only the coil. $14 later and was on the road.

Took the turbo off yet again. Sending it back to get it fixed. They "clipped" it when I did not want or ask for it. Also need to fix the oil control for the pvc, as when I corner sharp it smokes. Also an axle boot is tore, so getting that fixed.

Then...next time I am in Portland, I might stop by. I do NEED to get some Grassroots Magazine stickers on it!

You'll need to log in to post.