So I pulled the connectors off to make sure I ordered the correct ones and decided to save a few bucks and order them the flange gasket and some other stuff (my whole fleet is in need of spark plugs) off Rock Auto.

Then I realized decided to replace the transfer case seals since I have this apart but I forgot to put t-case seals on the order and had to create a new order for seals.

Just now, checking my email, I realized I'm missing one of the odd seals between the trans/t-case and have to make a 3rd order since I apparently can't figure out how to add to an order.

At this point, paying shipping for 3 separate orders I'm not saving enough to really be worth waiting for parts with a dead vehicle in the driveway. (or unplanned dead vehicle anyway)

I'm suddenly remembering why I usually just get odd seals like these from the dealership 5 minutes away.

I had a bunch of packages come in today so I spent the evening pulling the t-case (again) and replacing all the seals. Actually, I think I spent more time cleaning it than anything else, but I digress.

I did buy a $4 wrench to cut up to get 2 bolts on the top of the trans/t-case union that have to be removed with a box end. I only had enough space for those two that I couldn't even use a 12pt box end without flipping it after every stroke and of course they wouldn't spin in by hand. A stubby combo would have been perfect, but I don't have any, yet*, so...

That new box end half is just Smart.  I actually saved time going to the store, realizing I left my wallet at home, going back, and cutting up the wrench vs the maddeningly interminable tedium that was 12° of wrench swing.

I actually saved time going to the store, realizing I left my wallet at home, going back, and cutting up the wrench vs the maddeningly interminable tedium that was 12° of wrench swing.

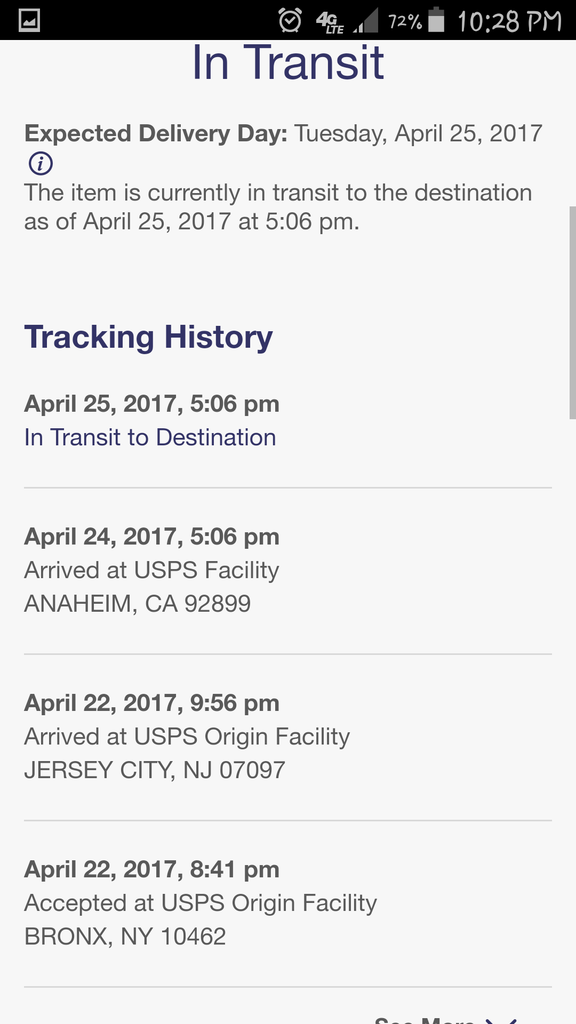

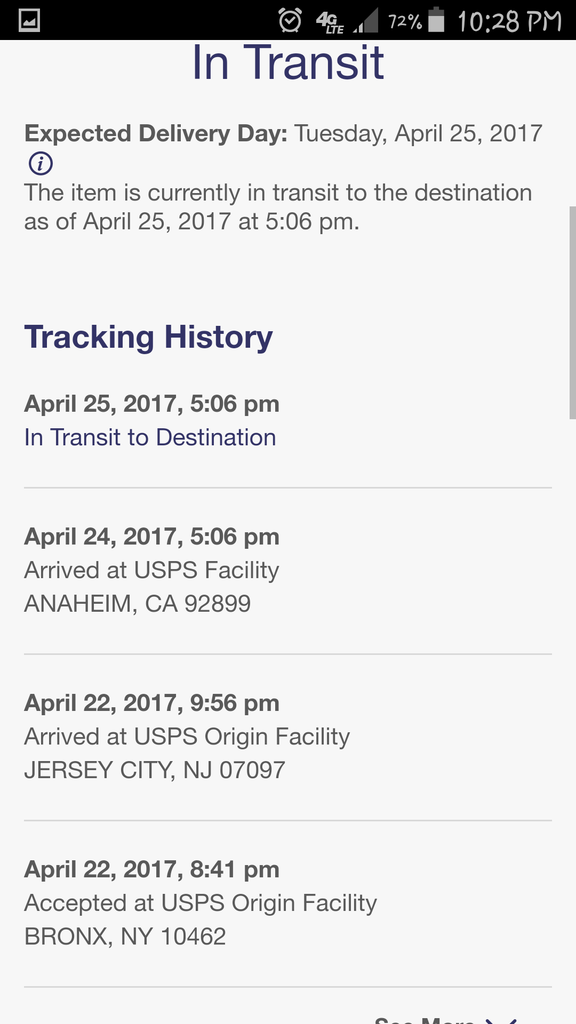

I'm still waiting on the new cooling line connectors which need to go on before I can put the exhaust and cross member back in. They were supposed to come today as well so I checked the tracking and...

I'm in Texas...

This is why I buy local.

Oh well... This will give me time to figure out how to straighten the bent exhaust flanges. They're, no E36 M3, like 3/8" plate, but they're bent enough the two have an 1/8" gap in the middle and won't seal. How does that even happen?! I'm thinking some time with a torch, some clamps and judicious use of some 5/8" scrap plate and a few spacers will remedy the situation.

*After today's wrenching dramatics I decided the time has long passed for me to pony up and get a good set of stubbies, so I pulled out my wallet and I have a new Craftsman stubby wrench set coming. Sears had just sent me an email this morning to tell me I had an extra $8 worth of rewards points until May. If I hadn't forgotten my Sears password and hadn't had to access my junk email I'd have never known, yay me!

The moral of the story here is: Check your email, it's time to buy more tools.

Just wonderin' could those two bolts have been reached with an extra long 3/8" extension(2') and a universal? This setup has worked for me when pulling the 5 speed, but then again I'm not fighting a T/case..

That won't work here. Here's a random Google image of the adapter/trans mount.

The top two on this side are what I'm after. Literally the only thing that fits is a standard box end. There's barely enough space between the flanges to fit the bolt into. I don't think you can even get a ratcheting box end on there. (Not that I have any of those either.)

Yeah, fortunately it's already done as I think I'm as likely to set the thing on fire as I am to do this again any time soon.

I want to work on the bed while I'm waiting on parts, but I don't want to have to pull the thing off jack stands to level it only to jack it back up to get the exhaust back under it.

Speaking of exhaust, it looks like the flange was probably warped when it was welded to the cat. I don't think any amount of heating/clamping/hammering is going to get it right, so I'm just going to fill the void with the welder and grind it flat-ish today then set it aside.

Then after that and connectors I just need new u-joints and a few gallons of ATF to get it on the road again.

The danger with ratcheting box-ends and spaces like that is that it's possible to get it stuck. They don't reverse without flipping over, so if you back the bolt out far enough there's not enough clearance to remove it and you also can't put the bolt back in.

I really hadn't thought about that before. I imagine that scenario would pretty well make me lose my E36 M3.

I'm starting to second guess if I really want a set or not. Or laying down some serious coin for some reversible ones from Matco or Snap-On. (I may or may not have looked into ratcheting wrenches yesterday while I was shopping)

So I did some welding.

This welding wire I'm using probably needs to be thrown out. Porosity like MF. It was on clearance locally for $7 for 2# rolls and the first roll I bought was fantastic so I bought the rest they had but the rest of this stuff is super finicky and garbage. I might keep it for sheet metal sculpture stuff, but I don't trust it for structural welds.

Grinding, filing, more welding, more filing and BAM! It's within 1/64" and should be fine with the gasket and maybe a little high-temp RTV.

That's really all I can do until I either get parts, or get it back on the ground, or start more projects. So I'm going to let it sit until I get parts.

Crackers....as they say in these parts....'that dog'll hunt' great work!

Crackers wrote:

I really hadn't thought about that before. I imagine that scenario would pretty well make me lose my E36 M3.

I'm starting to second guess if I really want a set or not. Or laying down some serious coin for some reversible ones from Matco or Snap-On. (I may or may not have looked into ratcheting wrenches yesterday while I was shopping)

FWIW I picked up a cheap set with switches for direction several years back. I don't remember where I found them, but it was either one of the big box stores, or Advance/Autozone. They've held up fine to my amateur wrenching.

The reversible ones usually don't have as fine a ratchet mechanism. I have a set of the non-reversible GearWrench ones, and they're awesome. You just need to keep in mind that if you're going to use one in a confined space to stop every couple turns and make sure you're not running dangerously low on space for getting it out.

In reply to 759NRNG:

Thank you sir! I may have done that before.

In reply to Pete Gossett:

I actually quite like the Duralast tools at AZ. I have a combo wrench set and a 1/4" ratchet that have pretty much been my default since I bought them as emergency spares 10 years ago. I use them a lot too.

I had originally bought them as a set I wasn't going to be worried about cutting or heating/bending for situations like yesterday, but when it finally came down to it I couldn't do it. LOL

In reply to codrus:

I'm seriously considering the GearWrench 32pc kit. At $75 it seems like a hell of a deal if they're genuinely capable of ratcheting at 5°.

They're especially appealing as they can be exchanged under warranty at Sears like the Craftsman stuff.

Crackers wrote:

In reply to codrus:

I'm seriously considering the GearWrench 32pc kit. At $75 it seems like a hell of a deal if they're genuinely capable of ratcheting at 5°.

They're especially appealing as they can be exchanged under warranty at Sears like the Craftsman stuff.

If you can find a Sears -- the ones around here have all closed.

I'm very happy with my GearWrench ratcheting wrenches. In fact, I've actually switched to using GearWrench as my default tool brand instead of Craftsman (see previous comment about Sears). I haven't measured the swing, plus mine are several years old, and I think they've revised them since then. They work very well though.

So I'm just going to watch this happen since Rusty Plow truck is a 1500 and I can see through it's bed. Then I'll just copy you

Great work so far.

The I've been trying to justify spending the coin for a set of SK XFrames which are 1.7 degree swing, six point, and have a stupidly strong ratcheting mechanism but now that it has been brought up they're flip over to reverse.

So, apparently the primary leak point WAS NOT the rear main!

Despite the fact that oil was dripping exclusively from the hole in the flywheel cover, and the fact that the rear main seal crumbled when it came out, it continues to drip, only this time from somewhere near the oil filter.

Someone please stop me before I hurt myself...

callin' rinn n' stimpie to the front desk ASAP!!!!

The two positive things about this are;

1) It's no longer falling apart.

2) It has no audible exhaust leaks for the first time since I bought it 7 years ago!

I had to walk away from it before I lost my temper and did something I'd regret, but tomorrow I'll probably end up pulling and resealing the oil cooler adapter as it's really the only other thing in the area capable of leaking oil.

OK, it's all buttoned up. No engine or transfer case leaks. The oil cooler adapter was definitely leaking. I feel like such an idiot. The rear main was definitely leaking though as the inside of the flywheel cover was caked in thick old oil. I think the most frustrating this about all this is the motor needs to come out, probably next year sometime as it recently started having oil pressure issues at OT at idle that I "resolved" with 20w-50 on the last oil change. I'm hoping to do a 5.3 swap to get rid of that stupid vortec spider injector thing and avoid having to deal with a rebuild etc.

Anyhow, the trans pan now appears to be leaking a little. Not entirely sure that's it, or that it wasn't leaking before since it was also covered in oil, but unless it starts leaking faster I'm punting it for another time. I'm so sick of being under this thing, and I hate ATF. I seem to lack whatever skill is necessary to not spill it all the berkeley over EVERYTHING!

I'm probably gonna take a break from it for a while. This whole endeavor is approaching $600 with the jack and all, and I don't want to think about it for a while.

Having a running-driving truck that I can't really use has been bugging me, so today I swapped out the plugs and cleaned up the cap/rotor. The cap/rotor really should be replaced, but they're +/-$50, it's running fine, and it cleaned up well.

Tomorrow I'm going to work on the fuel filler, and at least get it mounted so I can put fuel in it. I'm still debating between an exposed cap, or reusing the old fuel door hinge, so I'll probably hedge and make a pocket for an exposed cap with provision for adding a door later.

If that goes smoothly (LMAO, right?!) I'll try to get the rest of the mounts welded in and maybe cut the skirts for the wheel openings. Once that stuff is done I can start thinking about paint.

Even with all that done, I still need to think about the most efficient way to bolt down the wood deck. So far the prevailing idea involves bolting the wood to a bit of angle iron, then bolting the angle iron to the cross members. That way most of the drilling can be done on a drill press to maximize drill bit life. But I likely won't get that far until next month as I'm going on vacation at the end of the month and I'm having to shuffle a ton of stuff around to make time for it.

Did I just read the word 'SKIRTS' ? yea maybe on a '57 el Cameo, but on tow pig err 'Sheila' ????

She may never make a silk purse, but she can still dress like a lady!

In truck terms, this is called a skirted flatbed. I've always intended to add a skirt/fender/filler panel around the wheel openings. It looks very unfinished in its current state, even if you over look the obvious unfinished-ness of it.

I didn't get nearly as much done as I had hoped I would. I got a late start and have a dislocated finger that proved to be a sizable obstacle.

But, I cut a big ugly hole.

And made some modern art.

I had hit them with some phosphoric acid before that picture since it will be easier to deal with the rust before it's welded up.

Assembly and install will go pretty quick now that all the parts are made.

I decided I'm not going to try and repurpose the factory door hardware, but I'm not going to leave the cap exposed either.

I'm going to make the door and hinge as a separate assembly that can be installed later. That way I won't have to figure out the details now and risk stalling out again.

With that, I hope to be ready to roll on some bed liner this weekend.

sorry bro, went to the first page and saw the voids at the rear tires (skirts).

Lockin' hatch on the gas cap?

I might've missed it but is this pig swilling good ol petrol or the coal rollers choice of fuel... aka diesel?

![]()