Squish and shave the door felts like this. This is how the factory did it:

I had previously made a fancy speaker holder that would angle a pair of 5-1/4" coax to hopefully improve the soundstage from a center-mount speaker. Sadly, it did not clear the heater controls, or the modifications I did to the ashtray to house the air ride gauges. Grrr. So.... flat panel it is.

I had also added 6 more rows to fit the speakers better than the single opening was:

NOHOME

MegaDork

1/14/23 2:59 p.m.

Congrats. Done about half a dozen rope installs and broke one on the Ford F2. Does not get less scary with experience.

FYI, here in Ontario, IF you can find a guy to install one, they want $500 and no guarantee that they wont break the window. It breaks, they want another $500 and you pay for glass again. Have not found a glass shop that will do this work.

Every local glass shop interrupted my inquiry with "we won't touch it!" right quick; nobody here will do it.

I asked a buddy who runs a custom/hotrod body shop about tips, and he says he sweats bullets doing them, and if it's too curved, after having broken a few $1000 windshields, he has a guy he pays.

Even when I went back to the glass shop with "Hi! You might remember me from such episodes as: 'I'd like a windshield for my '61 Chevy Apache..'," and they were so quick with "we won't touch it!"

SkinnyG (Forum Supporter) said:

Every local glass shop interrupted my inquiry with "we won't touch it!" right quick; nobody here will do it.

I asked a buddy who runs a custom/hotrod body shop about tips, and he says he sweats bullets doing them, and if it's too curved, after having broken a few $1000 windshields, he has a guy he pays.

Even when I went back to the glass shop with "Hi! You might remember me from such episodes as: 'I'd like a windshield for my '61 Chevy Apache..'," and they were so quick with "we won't touch it!"

I read that last paragraph in the Troy McClure voice

I totally used my Troy McClure voice to ask it (grin).

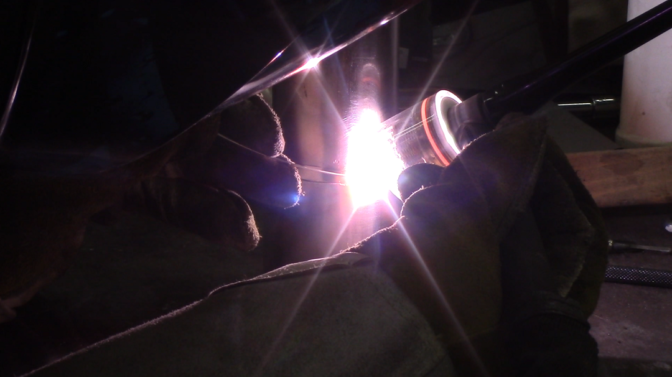

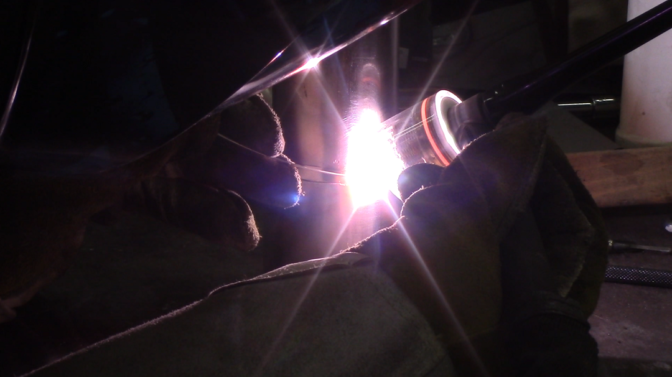

Fuel filler tube fabricated out of stainless. Tank inlet was 2" and the filler neck was 2-1/4." I had bought an exhaust reducer, but it really didn't fit well, so I hand-flared the 2" to match a 2-1/4" section I had laying around. Filler neck uses original (but new) rubber seal.

And we have working headlights!

In reply to SkinnyG (Forum Supporter) :

Cutting down the rolocs when the edge is wasted is brilliant. Props to Carl, I like his style. One tip I hope I remember to take away from this is welding a washer to a non-flat surface to keep the fastener from digging in.

love what you do, and how you explain it. Thanks for documenting this stuff.

so while sat at work ive read all of this over a few days, sat here in the uk wondering why we dont have such cool trucks

My motor vehicle teacher as a duch bag and very non inspiring, you sir are totally inspiring and skinny kids are lucky to have you

rock on Garth

Party on, Wayne.

Air Ride gauges hidden in what used to be the ash tray:

Plus two Viair 400's:

Slow slow progress of late. Bed back on, bumper on, fenders got welting:

Taillights added, wheels on, aired out:

In reply to SkinnyG (Forum Supporter) :

I'm going to need a moment alone

NOHOME

MegaDork

2/26/23 10:21 p.m.

I will admit to being skeptical about the colour choices. But you hit it out of the park in the end.

In reply to NOHOME :

I 100% am with you on this. This truck turned out perfectly!

Thats an amazing truck. Beautiful work!!!

wowzers... I only hope to see this truck in person someday. Just excellent execution all around.

759NRNG

PowerDork

2/27/23 9:29 p.m.

My apologies, these last shots have revealed various modification executions(front/rear bumpers) that I was totally NOT paying attention to. Very well done Teach....and oh I love the rimz.

Absolutely love it! Is this a truck arm rear suspension, or leaf spring? (I'm too lazy to go back in the thread and look)..

I did nothing with the bumpers. The front is original, and the rear is reproduction.

Truck arms.

Front is 73-87 crossmember and arms, modified to fit 88-98 2" dropped spindles, 8600gvw brakes, hydroboost, Fox Body Rack & Pinion steering (zero toe change from 5" ride height to on the ground).

Rear is 9" Ford, TrueTrac, 5x5 axles, Caprice rotors, Z28 calipers, 1350 driveshaft (Bear's Performance, Ontario).

Engine is 6.0L LQ4, ARP head studs, LS9 head gaskets, ring gapped to 22psi boost, VS Racing 7875 Billet turbo

Trans is 4L80E, dual-fed Direct, extra direct clutch, Sonnax overrun clutch valve, FULLY rollerized (not just the rear), other valvebody/oiling improvements.

Haven't been working on the truck at all over spring break. Largely doing things for family.

I did, however, get a pretty thorough clean on, got the '61 over to the hoist, and finally found the top of my work bench.

Moved over to the hoist:

I had installed the press-on door seals by Precision, but had to re-adjust the doors so they could at least close and latch, which left a big honking gap. Yuck. On the 67-72 Chevy Truck forum, there is talk that 8th Gen Civic door seals fit perfect on a 64-66, and CAN fit a 60-63 with an extra section added. The Precision door seals look better, but the doors close with the Honda Civic seals. I'm probably going to be ok with it over time.

Hooked up the shifter.

Poked around in the shop, tidied, and made a list of what I think I need to finish things.

I've been working on SkinnyKid2's first car - a PT Cruiser. I did a timing belt, struts, control arm bushings, an AC Compressor, plugs, and thermostat. I want to rename it the PTSD Cruiser.