In reply to SkinnyG (Forum Supporter) :

If I ever take the bed of my C10 back off I'm doing something like this, instead of badly fitting formed hoses. Nice work!

In reply to SkinnyG (Forum Supporter) :

If I ever take the bed of my C10 back off I'm doing something like this, instead of badly fitting formed hoses. Nice work!

Brake Brakes are plumbed from the Wilwood proportioning valve back.

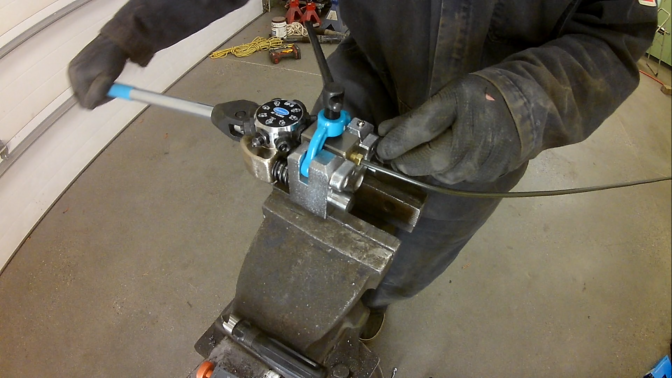

You have GOT to get one of these:

Mine is an Eastwood, but they likely come from the same factory.

I had previously bought one for work off Amazon from "4lifetimelines" for about the same price, fell in love with it, and bought my own.

Fuel and brake line clamps made from some sort of plastic I bought two years ago.

Four large ones, and that one wee one on the right. Air lines and wiring dangling:

In reply to SkinnyG (Forum Supporter) :

i would like to upvote this more than once. i can't wait for first drive video!

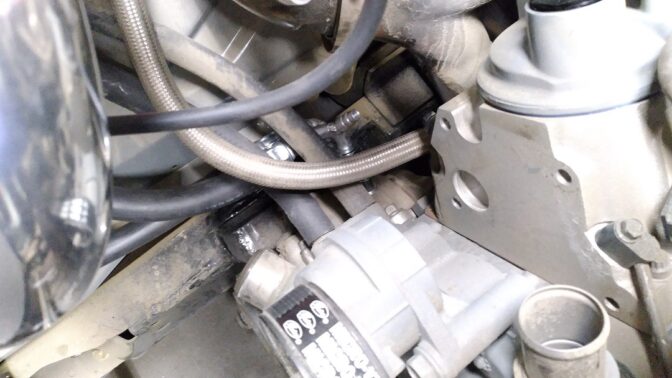

Taking a bit of a break from wiring, I plumbed the trans cooler lines to the rad and external cooler and back, I had to use a compression coupler as I couldn't do it all in one piece:

Then I finished fabricating the A/C lines. Out of the firewall:

Into the compressor. I had to relocate the Low Pressure fitting on this generic hose kit:

Also trial fitting the Methanol Injection tank:

And mounted and plumbed the manual boost controller:

PCM is mounted behind the stereo in the middle of the dash. I made a bracket that works with an under-dash AC bracket I made, all using existing holes.

A/C is all connected, and currently (finally) holding a vacuum (the exceedingly cheap LS AC adapters were pretty junk, and the seals they came with were garbage). Frankly a surprise, since I cut and welded many of the hose ends to have the angle I wanted.

Charged the AC with one can of oil, and what was left of a can of R12a. Haven't checked pressure since. Need to source a low pressure switch. My AC kit(s) came with a trinary switch, which serves as a high and low pressure switch, AND can turn on a fan. The PCM seems to want a HP input and a LP input, and allegedly can control a fan itself. I think it might be better to feed it what it wants.

I started wrapping the down pipe in header wrap, but truthfully I need a whole lot more than the 15' that came with the turbo blanket. On 4" sewer pipe with 1/4" overlap, that only covers about 26" of pipe, and I need a whole lot more than that.

Also mounted the Meth tank and pump and plumbed the nozzle.

What A/C compressor are you using? I'm assuming it's mounted down low (stock location?) since I can't see it in pics. I enjoy seeing your progress!

Header wrap and a turbo blanket. If you've ever done insulation, you know how this feels on your skin. It took a full 50' roll for the down tube.

Ran the wires into the cab, had to cut the factory wiring opening a bit larger. I will likely use one of these split seals.

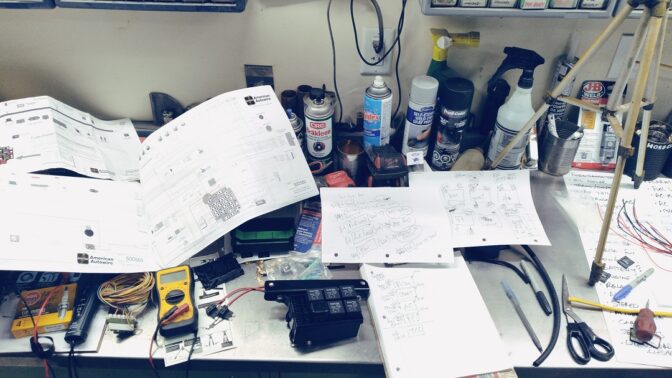

Chugging my way through details of the wiring

I made brackets that will attach to the steering colum bracket mounts, one for a fuse and relay box, and another for the drive-by-wire module.

Also added the OBD2 port, accessible but tucked out of the way.

Wiring wiring wiring.

Finished up wiring the AC system.

Running wires to the starter and alternator.

Wiring the Classic Instruments gauge cluster.

Wiring an alarm system.

Wiring the OBD2 port.

No pictures, because it's just.....

In reply to SkinnyG (Forum Supporter) :

I'm really looking forward to run videos of this thing! Love the build and especially think it's cool considering what you started with -- long bed, rust and all.

Exciting news!

I got the PCM to wake up, and my scan tool works. 5 codes, which are basically that the four O2s and the Evap are not connected.

Now to download the tune with HPTuners.

In reply to SkinnyG (Forum Supporter) :

did you write yourself a note "NO OIL IN ENGINE"?

do you need to?

I have not connected the purple starter solenoid wire yet, and won't until I'm ready.

Interestingly, I cannot run 3-bar on this P59 ECU.

My goal was 22psi boost in this 1960's 2WD pickup with zero traction control and 245 tires.

Oh well.....

Probably for the best.

In reply to SkinnyG (Forum Supporter) :

The GM ECMs are like 80 bucks at the scrapyard here in Ontario. Grab a 411 version and boost it to the moon

NOHOME said:In reply to SkinnyG (Forum Supporter) :

The GM ECMs are like 80 bucks at the scrapyard here in Ontario. Grab a 411 version and boost it to the moon

Except I just spent two HPT credits on this one. I'll be fine for now. It's not like I'm going to hit the ground at 22psi. I have the softest wastegate spring in there and a boost controller, so I can drag out the inevitable a little slower.

Tidying up wiring under the hood and under the dash.

Heat-wrapped and ran the oil pressure and coolant temp wires for the Gauge Cluster.

Wired the courtesy lights.

Wired most of the alarm system, just need to add door pins switches.

Wired the Methanol Injection system, and placed but did not wire the "active" and "low juice" lights.

Wired the linelock. Need to pick a MOMSW. The kit came with one, but I don't want some nasty-butt button on the column shifter. I figure a foot switch would be classier. Do we NEED a light to tell me it's on? I mean, if I'm pressing the button and it's holding, it's probably on.

Need to get a relay for the cooling fan, but all the wires and connectors are now there.

You'll need to log in to post.