Ouch.

But I'm very glad to see you persist with this one. I really think you're on to something, and while there will certainly be more trials and troubles ahead, the end result is going to be something that supersedes being expressed by its numbers alone.

ive gotta say, your attitude and preserverance are inspiration to me. i walked away after fighting a pitman arm tonight. you blew a motor for no apparent reason, and said "berkeley it. lets go big or go home."

and the way you wrote it up says that you had a good peace of mind about it, and a good outlook on the whole deal. im sure cussing was involved, as it was a significant investment, but i didnt sense the dejectedness, anger, and frustration i see so many times when something like this happens.

keep it up, man. and thank you.

michael

sorry to hear about the troubles. that thing sure sounded high strung on the video. sometimes all thats left to do is jump back in the ring for another round. Keep at it man, any chance those cam sprockets never got torqued after flipping them around? I only ask because it sounds like something I might do

petegossett wrote:

Ouch.

But I'm *very* glad to see you persist with this one. I really think you're on to something, and while there will certainly be more trials and troubles ahead, the end result is going to be something that supersedes being expressed by its numbers alone.

Here's hoping.  Sure has been a lot of money to throw at a "hunch" in terms of a formula to make a dent in SMF.

Sure has been a lot of money to throw at a "hunch" in terms of a formula to make a dent in SMF.

Dusterbd13 wrote:

ive gotta say, your attitude and preserverance are inspiration to me. i walked away after fighting a pitman arm tonight. you blew a motor for no apparent reason, and said "berkeley it. lets go big or go home."

and the way you wrote it up says that you had a good peace of mind about it, and a good outlook on the whole deal. im sure cussing was involved, as it was a significant investment, but i didnt sense the dejectedness, anger, and frustration i see so many times when something like this happens.

keep it up, man. and thank you.

michael

If this car were harder to work on at this point, i'd probably pack it in. But there's been so much stuff removed, there's so much space, and there's a pretty minimal wiring harness. Plus having all -AN stuff and no stupid clamps. And the fact that i put this car together from the ground up, i can have this motor out in an hour tops. Once new motor is assembled, i can have it in the car and running within 3 hours maximum.

I had the motor in and out of the car no less than 5 times when i was test fitting, so i've got this down to a science.

But yes, there was lots of cussing.

Going with the "go big or go home" plan makes more sense than it might seem on the surface. I already had the rods/pistons/fasteners/bearings. (Though we'll see if the bearings are the right size.) Really the only further costs i'm getting hit with are:

1) Machine shop costs for boring and hot tanking the new block

2) Machine shop costs for assembling the new bottom end (if i don't do it myself)

3) Charges from Delta cams to copy the front two cams to put in the new heads

4) New timing set

5) New water pump (in case the old one doesn't work on the new block.)

6) Fluids

7) S2000 injectors. (The Gixxers aren't going to handle the new power)

8) POSSIBLY a stronger clutch, but i'll figure that out if it turns out to be a problem.

I'm borrowing these heads from my buddy. (indymx6 on here) I'll be building my own set using the 01-02 626 heads from the block i'm going to use over the winter. His heads a nice, and better than what i was using, but not quite good enough for my "end game."

Selling my old bottom end will cover the machine shop costs, maybe plus some. I'm looking at well less than a grand out of pocket to do all this.

2K4Kcsq wrote:

sorry to hear about the troubles. that thing sure sounded high strung on the video. sometimes all thats left to do is jump back in the ring for another round. Keep at it man, any chance those cam sprockets never got torqued after flipping them around? I only ask because it sounds like something I might do

Heh, yeah it was high strung as hell! I'll have a better camera next time it starts so you can really hear it.

The cam sprockets were torqued down, i made sure of that.

It's just one of those things. I'm sure there's a reason why it happened, and it may very well have been something that i did wrong. There's just no real way to find a concrete answer with looking at what got damaged.

pres589

SuperDork

4/10/13 10:18 a.m.

So the cam seized in the head after it started to warm up? What are the bearing clearances (I know there aren't bearing shells in the head for the cam to run in, so journal to saddle clearance?) on the cams? The lobes still look good, friction surfaces look good?

I'd really want to know what happened to that camshaft before putting more time / money / etc into another similar setup.

Were you expecting this thing to be high-strung? I didn't catch the video yet.

Damn. Best of luck on the next engine. You're a much better gearhead than me. I had troubles very similar to what you're experiencing and after the 12th or 13th kick in the junk I said berkeley it and gave the car away.

My hat is off to you and I'm rooting for you!

pres589 wrote:

So the cam seized in the head after it started to warm up? What are the bearing clearances (I know there aren't bearing shells in the head for the cam to run in, so journal to saddle clearance?) on the cams? The lobes still look good, friction surfaces look good?

I'd really want to know what happened to that camshaft before putting more time / money / etc into another similar setup.

Were you expecting this thing to be high-strung? I didn't catch the video yet.

I made it to 133 degrees water temp when it died. Don't know the clearances, haven't popped the valve covers off yet. I'm taking the cams out this evening so i'll know what the cams look like at least. Journal clearances should be stock. They were stock heads and that portion of the cams wasn't touched.

There is no way at all to figure out exactly what happened because of the things that broke. The best i can do is give an "either this or this happened" scenario.

I was expecting it to be pretty high strung. It's a rev-happy motor to begin with. After a 9lb flywheel, lighter clutch, ITBs, those cams, and no accessories to drive other than alternator and water pump... it was only going to be revvier.

Motor i'm working on now will be more so. Another two points of compression, ported heads, slightly lighter valvetrain, and i'm going to clean up the inside of the throttles a bit.

In the picture where you show the pin ripped out of the cam, why does it look like the upper and lower saddles do not align?

In reply to NOHOME:

That's just the angle of the pic and some slight excess rtv. I noticed that too and double checked today. DEFINITELY not the problem.

now im interested. im thinking hydrolock.....

Dusterbd13 wrote:

now im interested. im thinking hydrolock.....

Kinda hard to hydrolock a motor that's never been running outside of a garage.

Drum roll PLEASE!!!!

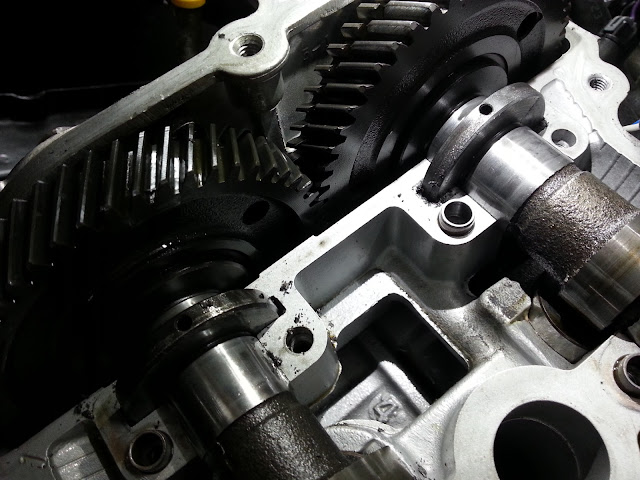

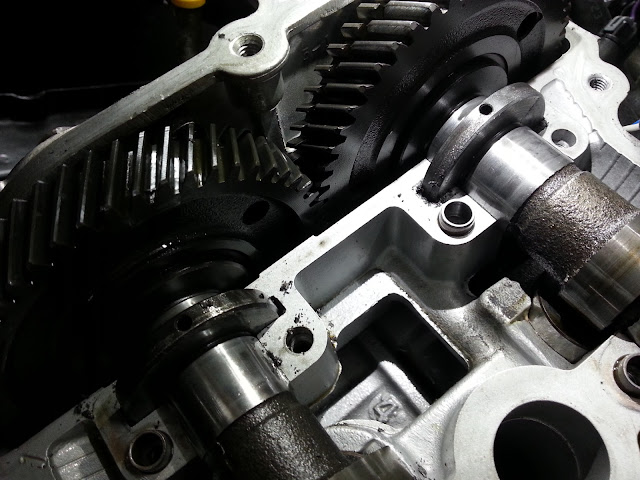

I took off the front valve cover to see:

THIS.

You can also see on the other end that something isn't quite right.

Oh. Oh my.

I uh. Uhhhhh.... WUT.

The other end.

Here's a crack running down the front cam where the locator pin was. This was NOT the offending cam. The back cam is what caused all the problems, and the cams are meshed together with a friction gear.

Money shots of offending cam.

FUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUU.

After really looking at what the built motor would cost me, and the amount of work it was going to take, i'm going to take a big gamble at this point and see if i can use my current bottom end.

When i drained the oil i didn't see any sparkles. I'm going to flush it 2-3 times with cheap oil and drag a magnet across the pan and see what i can come up with.

I'll know for sure if that's going to be possible by this weekend. If it is, then i'm just waiting on my copied cams to come back and i can have new heads on this thing and ready to rock in about 3-4 hours of work. Already ordered a new timing set.

I don't really want to mess with the built motor unless i can do ALL of it at once, and not mess around with stand-in heads on my built bottom end. No sense in rushing that whole thing, i'd rather do it on my terms. I'm 99% sure this bottom end is ok to use. It looks like from the damage and how it all went down that once this cam heated up enough to do what it did, it happened almost instantly. This isn't the sort of thing that goes on for awhile. This was a "one second it was running, next second it wasn't" kind of thing.

Oh, and yes, i DO know why this happened. This will not be an issue on the next set of heads.

was there any oil flow at all up top? =/

That IS some epic carnage. Very impressive.

Wow... awsome carnage... so why did it happen?? its obviously an oilling issue... were the cams not lubed well enough in assembly lube before install?? how are the back cams?? Or did you find a oil feed problem??

Not an oiling issue.

Cam cap order is supposed to be 1 2 3 4 5 6 7 8 not 1 2 3 4 5 7 6 8.

Buddy put them on in wrong order.

Well so yeah it's an oiling issue caused by bad clearances. But there was nothing wrong with the oiling system itself.

damn......

i think that carnage needs to go in the car craft blown up parts of the month section

dang. it hurts looking at those pics but i guess it's a small win just solving the mystery. I know you'll make it right man. keep at it, those honda's won't even know what hit em when this thing hits the track!

In reply to Swank Force One:

Damn that sucks... I guess after the timing belt mix up and now this your buddy has been demoted to pizza duties... :)

pres589

SuperDork

4/11/13 8:57 a.m.

Is this the same buddy that was doing your remote battery relocation work?

I was doing the battery relocation work, but using that horrible berkeleying cable that he recommended.

Honestly, i was present when the cams and caps were installed, but i kindof just stayed out of the way and let the experts handle it. I blame me for not checking everything closely and asking questions.

But yes. Unfortunately it seems that the two major things to go wrong were not things that i did. (Timing and now this) Lesson learned. I do the important things myself now, even if it's on a motor that i'm not intimately familiar with. Not doing it myself has cost me a pretty significant chunk of money at this point. Two extra tows @ $150 a pop. A set of brand new fresh heads @ $270 just in machine work, a timing set @ $100-$150, and now to have these cams copied will probably run me $300-$350.

About $1000 total. E36 M3 happens, i'm not mad at anyone, i know when the cams and caps were installed, it was super late at night and everyone was tired. Smart thing to do would have been to call it a night and then me do it myself.