Disclaimer: I wasn't sure where to put this thread. It's Grassrootsian, to be sure, but also relevant to classic motoring and racing. So if anyone up high feels it should be moved, please do so. Furthermore, I am not a professional welder, a professional mechanic, or known for particularly good hygiene (just ask my wife). As a result, do not attempt this yourself, unless you're as stubborn and committed to taking the hard way about any project as I am.

Background: I've owned my 1964 Chevrolet Corvair for about 9 years now. I drove it home from California to Maryland, and it's been a good little summertime cruiser. It's also taken many long trips, most of which have involved some sort of along-the-way repair, but none of which left me stranded.

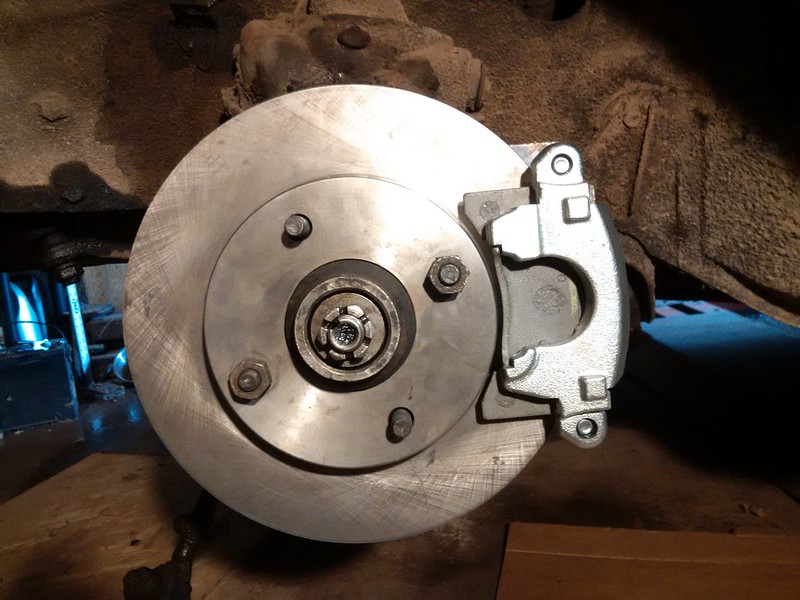

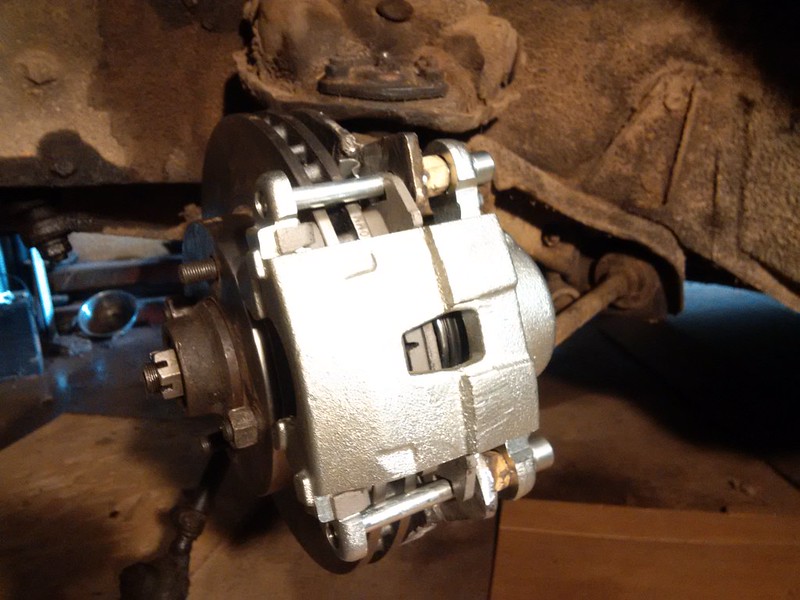

However, one very glaring weak point for the Corvair is that of many older cars: the brakes. I've worked on them, adjusted them, and tried all sorts of magic, but the car just never really stopped well. One wheel would lock up, or it would pull, or they would fade. And on a swing-axle car with a rear-weight bias, the last thing you want to worry about is your brakes. Trust me, there's a lot more you need to focus on.

After one particularly harrowing sideways slide, I took the car off the road and made up my mind that I would not drive it again until the brakes were completely fixed. That was, unfortunately, about 2 years ago. This spring, though, I finally got a plan together and started work. A little spoiler: it's done, but I wanted to do a write-up on it here, both for future reference for myself, and for the benefit of others who may also be struggling with the brakes on their Early (1960-1964) Corvairs.

Naturally, if you own a late model (65-69) 'Vair, none of this matters. You can simply bolt on some parts sourced from the later GM parts bin and have disc brakes in a weekend. But the early cars have always had their share of "uniqueness"...