Princess is one of the cleverer canoe paddlers I've seen - hiding linkspam in a quote.

Hi All Ive lurked on this forum for probably 5 years now. Figured it was time to chime in.

In regards to heat management you need to start thinking outside the box a little more. This technology makes unmakable (made up that word i think) parts possible. So for instance - on the exhaust manifold, you could incorporate small cooling passage or external cooling fins. I can imagine a closed thermal loop cooling system in the header that when heated would push the hot fluid up and out of the header. Cold fluid would flow in to absorb more heat. It would be a passive system that only works when the temp gets to a dangerous level. The system would even continue to work after the car is shut down.

3D printing changes everything. There are even people working on 3D printing of human body tissues.

Roger

By the way, kids....you should really browse though The Thingiverse.

Lots of 3D printed ideas including some automotive stuff (I see a fair amount of missing automotive trim pieces being re-created).

Some other kind of interesting projects seen there:

RTechEd wrote: In regards to heat management you need to start thinking outside the box a little more. This technology makes unmakable (made up that word i think) parts possible. So for instance - on the exhaust manifold, you could incorporate small cooling passage or external cooling fins. I can imagine a closed thermal loop cooling system in the header that when heated would push the hot fluid up and out of the header. Cold fluid would flow in to absorb more heat. It would be a passive system that only works when the temp gets to a dangerous level. The system would even continue to work after the car is shut down.

I recall seeing images from the 50s or 60s of water jacketed turbo exhaust housings.

That said, the trend is trying to keep heat IN the exhaust manifold, not shed it. Thus you get fancy multi-wall headers (Corvette LS1) that have the benefits of tubular headers without the heat loss problems.

And then you have Honda, who is doing an end-run around the problem by just having one exhaust port per cylinder head.

I get what you're saying about being able to do things that would be a bitch and a half to sand- or die-cast, or even lost-foam (can you lost-foam cast iron?), but I think this also illustrates an important point. When people get a new toy, they want to play with it, and 3D printing is a wonderful new toy. But one of the problems of the new-toy effect is losing sight of what the end goal should be.

aeronca65t wrote: By the way, kids....you should really browse though The Thingiverse. Lots of 3D printed ideas including some automotive stuff (I see a fair amount of missing automotive trim pieces being re-created).

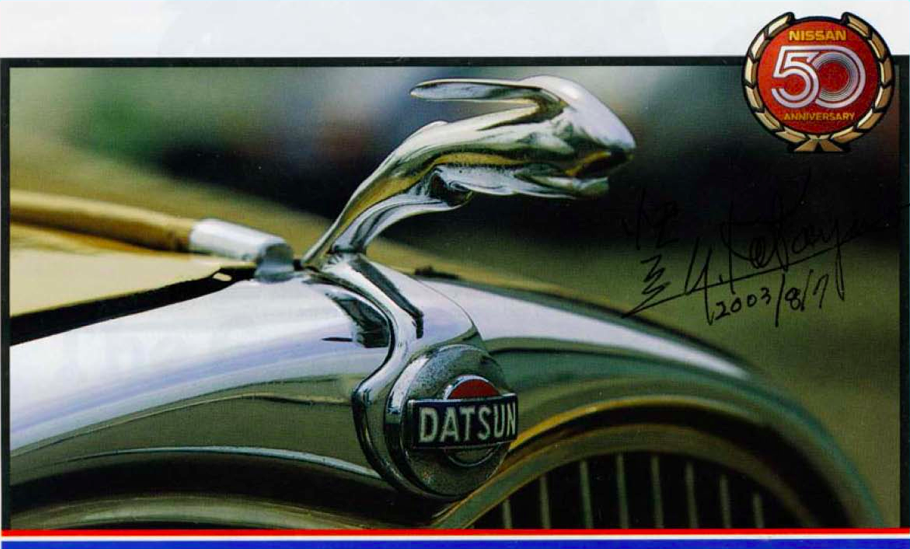

I'd love to have someone print up interior door pulls that look like the left and right halves of the 1930s datsun hare hood ornament.

I'd use them on the interior of my replica

In reply to Knurled:

A lot of engine blocks are cast via lost polystyrene foam, iron included. There's a cool YouTube video somewhere documenting the process used to cast GM 5 cyl canyon/Colorado blocks. Its pretty cool.

In reply to Knurled:

I think there are enough of these toys around that the serious big industrial machines can do serious big industrial stuff. Besides, they'll be able to print a new 3d printer here in a few years. The only problem is that you have to build a bigger printer than the ones you're going to build with the printer ![]()

JoeyM wrote: I'd love to have someone print up interior door pulls that look like the left and right halves of the 1930s datsun hare hood ornament.......

You just need someone (you?) to make a 3D drawing in AutoCad Inventor, SolidWorks, ProE, Google SketchUp Pro, or any other parametric CAD program. Typically the drawing file must be an "STL" format.

If you can't do it locally, you might actually find someone to do it via the Thingiverse link above.

Then sent the file to these guys.

http://i.materialise.com/

In reply to knurled.

I guess what i was really trying to say was that there might be limitations of the 3D printing materials/process if you are doing a direct part replacement but that with an outside the box thinking approach you can use this technology to get some pretty awesome results.

In reply to 4cylndrfury:

The original Saturns employed lost foam for engine components;

The block & head were aluminum, but the crank was cast iron.

This allowed them to employ hollow sections inside the crank to reduce weight and material usage.

The styrofoam cores were created as halves, then glued together with special adhesive.

ISTR that the process was more like investment casting, ie they coated the cores with investment slurry before packing with casting sand. A steam process blew out the foam & adhesive, before pouring.

There used to be some nice detailed web pages (search: foundry, lost foam, Saturn), but seems most of my links are dead now.

Saturn is dead, but the processes they developed and perfected live on at GM, as 4cf pointed out.

Carter

You'll need to log in to post.