Keith Tanner said:

In reply to Curtis73 (Forum Supporter) :

I would have thought the LS7 would have the answers for a high RPM valvetrain. Besides, those failures don't usually take out the entire engine the way a rod does :)

It's fun doing the math on loads on the rods as RPM goes up. It's exponential.

Not valvetrain explosion, just getting the valves to not float with all the inertia of the pushrod architecture.

Keith Tanner said:

In reply to Curtis73 (Forum Supporter) :

I would have thought the LS7 would have the answers for a high RPM valvetrain. Besides, those failures don't usually take out the entire engine the way a rod does :)

It's fun doing the math on loads on the rods as RPM goes up. It's exponential.

Our engines we run in our Champcar can handle 8500rpm easy. They make 180ish WHP from 5000-8500rpm but because of endurance racing, I have the rev limiter set at 7300. Anyways the point is, valvetrain failure is an easy fix sometimes. Nothing Fs stuff up like a rod joining the SpaceX program when it decides to yeet itself out of the car on the backstretch at Sebring at 7000rpm

In reply to DirtyBird222 :

Exactly.

Anyhow, if I wanted to make a high RPM LS I'd start by looking at what the GM engineers did to the LS7 because they had to make those engines last longer than a YouTube video. But if I was looking for cheap and reliable speed, I'd be bolting in an engine with a bunch more displacement and leaving it as stock as possible. Which is exactly what I did.

That modified 5.3 never lived up to all the promises and it was as expensive as a crate LS3. But at least it was slower, more work and didn't have a warranty!

Here's a 6.2 with a 4.8 crank. It's says 4.2 that's a typo. Gets to 349 inches.

Why do you need to spin to 8k? Just to say you can? I'm guilty of having these same thoughts and a semi-serious plan for making them happen in the past. I used to like the 4.8 crank thinking but it's really hard to make compression with a 4.8 crank unless you are in the LS3 or LS7 bore neighborhood. I've said this before in a similar thread, the LS7 has the longest (4") stroke of any factory offered LS engine and the highest factory redline.

My suggestion from having a cammed 5.3 in a light car is an off the shelf cam and pac 1218/1219 (depending on cam lift) valve springs and stock lifters. This combo will hold up just fine to 7500rpm and depending on cam selection can make power all the way up there too. Summit Pro LS series cams are a great starting point, I had a SUM-8708 in my L33 before 300k miles and oiling issues took that engine out.

dyintorace said:

I'm perhaps the least qualified to speak on the topic, but isn't one way to do it by "de-stroking" the 5.3 with a 4.8 crank?

This is called a 4.8, they share the same block and bore size. Pre 05 iron block 5.3 engines had dished pistons that was the only difference besides the crank and cam.

Keith Tanner said:

Sell 5.3, buy 6.0, use tork instead of RPM. That'll cost you less than trying to make the 5.3 outperform a bigger engine.

I've had a built up 5.3, a mostly stock 5.7 and a 6.2 that's bone stock other than the ASA cam. The 5.3 and 6.2 were in the same car, the 5.7 was in a different car that weighs about the same. The car is much faster with the 6.2. It was the gap in performance between the 5.3 and the 5.7 that made me change it out. The big engine was worth something like 18 mph down the straight at High Plains.

The nice thing about the LS engines is that they're all the same size, so a displacement increase is a simple thing. About the only caveat is the number of teeth on the reluctor wheel, that's determined by your engine management. And you can swap those.

This is the approach I would recommend. I've driven a dozen LS-powered cars in various states of tune and none of them really liked to rev, even if they could. They always seem lazy to pick up rpm, but the lump of instant torque throughout the powerband makes the cars fast anyway.

You have something there. I expect the engineers wanted good fuel mileage over power and the size of the valves/ ports / head design/ were geared in that direction.

The Jaguar V12 is exactly that. When built as a race motor it made 519 horsepower out of 5 liters back in the 1960's

In production where its ultimate goal was luxury sedans it made only 260 hp out of 5.3 liters. Clear up through 1992 That's an engine that really was design for torque.

The crankshaft weighs 78.8 pounds and the confides have almost a pound apiece in extra ballast to ensure there is no engine noise.

Just start watching Calvin's videos. They have already done a 4.8 crank in a 6.0 block. It made over 1000 wheel horsepower with a turbo.

z31maniac said:

Making anything spin to 8k regularly that didn't come from the factory that way isn't going to be cheap.

Hi there!

(factory-parts redline: 6500-7000)

Especially still making power up there.

You don't necessarily want to make power up there. Maybe you just want to not have to shift but you still want to gear it well enough to have serious oomph coming off the corner. Maybe you want to continue being able to compete after you lose 2nd or 3rd gear (or both) again.

If anything you want to make sure peak power happens well before max revs, in any car, so that your engine speed before and after a shift brackets peak power (ideally, horsepower is the same before and after a shift). This maximizes torque at the driveshaft.

I artifically limit power in the engine above by dumping 20-25% excess fuel over 9000 so it doesn't slam into the hard rev limit. It still does, just not as violently.

Thank you all for a fantastic discussion that led me to where i needed to be, not where i wanted to go.

My brain stuck on a specific rear gear, trans and tire diameter. Therefore, the need for more rpm.

However, more torque, less gear and rpm gets me the same thing for way cheaper and more reliable. I honestly hadn't thought of that due to target fixation.

Application is my nascar hybrid with a wide ratio saginaw four speed. Hence some of the oddities.

Milled heads, decent cam and valve springs, 7k tops. Easy button, going from the 3.50 gears to 3.20s

In reply to Dusterbd13-michael :

Now's a bad time to point out that there are people running stock 5.3 rotating assemblies to 8800 in drag racing.

Bottom end is good. The money for RPM goes into the valvetrain, and gets really expensive and maintenance-intensive quickly, especially when you can't access it for inspection by just popping the valve covers and intake manifold off.

In reply to Pete. (l33t FS) :

What's the weakest link in the valvetrain? Valve float?

In reply to dannyp84 :

Not on a rotary :)

It's going to depend on the engine. On an LS, you've got pushrods and lifters and rockers and valves and springs and it's all hopping around like crazy. On a Miata, you've got springs and valves and lifters. Lot easier to rev the nuts off those, and what happens first is valve float followed by a collapsed lifter (based on my personal testing). I suspect too many rpm on an LS would show up in valve float, followed by pushrods once you install better springs. This is a pretty well-trodden path, because people get the "8000 rpm LS!" itch fairly regularly and there is a trail of broken parts to show the way.

But it's so easy to just install more displacement instead :)

The pushrods seem to be okay, but the rockers hate life. You'll be wanting a solid roller, which is better for higher RPM at the expense of beating up the rockers and the rollers (and the out of controllers). Depending on Factors, you might be in there a lot. I had some customers who needed replacement lifters and/or rockers every 3k or so. Check lash often and tear things down for inspection when one of them opens up all of a sudden.

I worked with someone who wanted to build a 9000 capable engine, IIRC he was looking at shaft rockers that ran about $3k plus all the other expenses. He opted to tone the engine specs down a bit, which is probably sufficient for a 6l engine in an NB.

Opti

SuperDork

1/26/23 8:46 p.m.

Ive seen a bunch of 7500 rpm, Ive also seen a bunch of explosions at near stock revs. If I was going to do this cheaply, Id have to be completely okay with it letting go, Id call one of the LS cam grinders and have them spec me a cam and springs. Id spend a bunch of money on lifters (ive seen the LS7 stuff okay at 7500 and Ive seen them explode a bunch lately so who knows), stronger push rods, and at a minimum a fulcrum upgrade on the rockers. Ive seen a bunch of rockers spit all their needle bearings at much lower revs.

Id look for a set of LS6 243s for the lighter valves. I think the LS6 valves went out of production about 10 years ago, but IIRC they are about 20 grams lighter. If I had a good machine shop, Id try to just find the valves and have them stuck in the 5.3 heads. I think they both have a 1.55 exhaust but the LS6 should be a 2.0 and the 5.3 is like a 1.89 on the intake.

The only thing Id even remotely care about on the bottom end would be an oil pump and a better timing setup.

Id run it until it explodes but wouldnt be surprised if it did. Ive seen much milder stuff survive, but ive also seen the opposite. Most of my experience is around drag racing and street stuff, so its a different use case.

Much easier path at 7-7500 rpms.

Opti said:

Ive seen a bunch of 7500 rpm, Ive also seen a bunch of explosions at near stock revs. If I was going to do this cheaply, Id have to be completely okay with it letting go, Id call one of the LS cam grinders and have them spec me a cam and springs. Id spend a bunch of money on lifters (ive seen the LS7 stuff okay at 7500 and Ive seen them explode a bunch lately so who knows), stronger push rods, and at a minimum a fulcrum upgrade on the rockers. Ive seen a bunch of rockers spit all their needle bearings at much lower revs.

Id look for a set of LS6 243s for the lighter valves. I think the LS6 valves went out of production about 10 years ago, but IIRC they are about 20 grams lighter. If I had a good machine shop, Id try to just find the valves and have them stuck in the 5.3 heads. I think they both have a 1.55 exhaust but the LS6 should be a 2.0 and the 5.3 is like a 1.89 on the intake.

The only thing Id even remotely care about on the bottom end would be an oil pump and a better timing setup.

Id run it until it explodes but wouldnt be surprised if it did. Ive seen much milder stuff survive, but ive also seen the opposite. Most of my experience is around drag racing and street stuff, so its a different use case.

Much easier path at 7-7500 rpms.

Think OBS SWB truck setup for street crusing and drag racing on the cheap..... looking for advice. Go. I don't care about rpm, but want a nice long flat torque curve. I can go with any rearend gears recommended, but want to use a 4 spd E controlled auto built 4L60, 65 or 80E for 2WD application. I also have a nitrous kit so something dead reliable that can take a 100-150 wet shot might be ideal for my applications. I was LOL at the "trucknorris" cam offered.

In reply to AnthonyGS (Forum Supporter) :

The power curves I've seen of turbo cars tend to be pretty decently flat. Unlike NA which tends to have a pretty sharp curve.

In reply to frenchyd :

It's all about tuning. You build the curve you want, within the constraints of physics. If you want a very high specific output on a turbo engine, you're probably going to have give up some of that flat torque curve. On naturally aspirated cars, you have the same limitations - you can get a nice flat curve, but it's going to be thanks to a cam choice that gives up some of the top end. Tech can help with this.

Basically, you can't just say "turbo cars have a flat torque curve and NA don't" because it's a bad generalization.

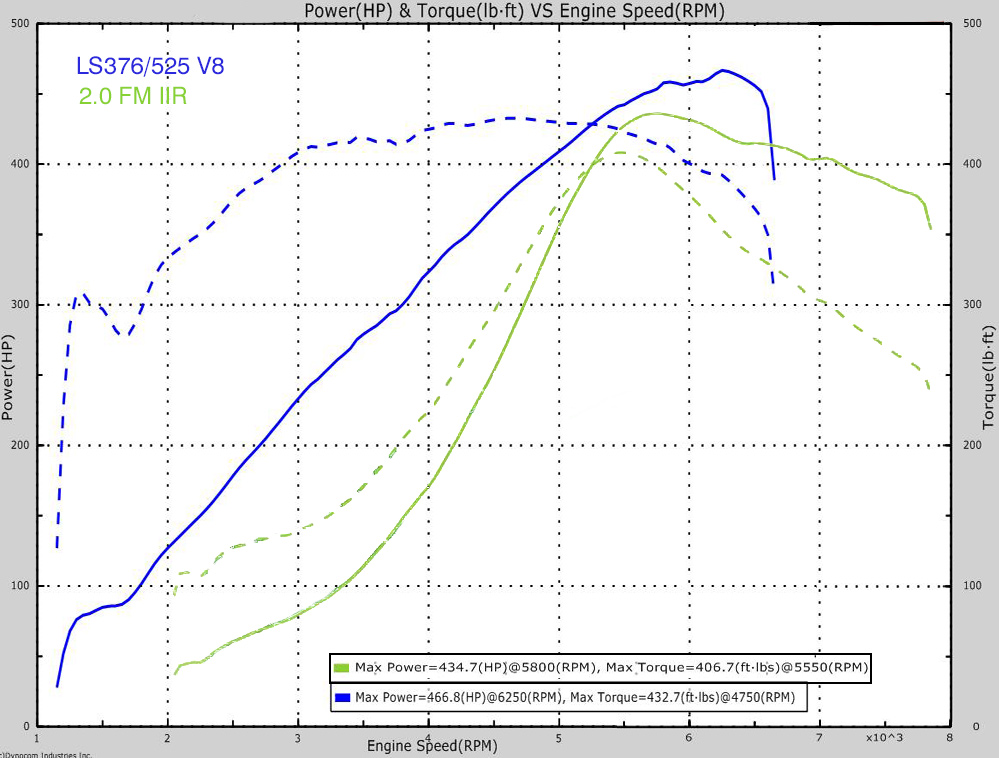

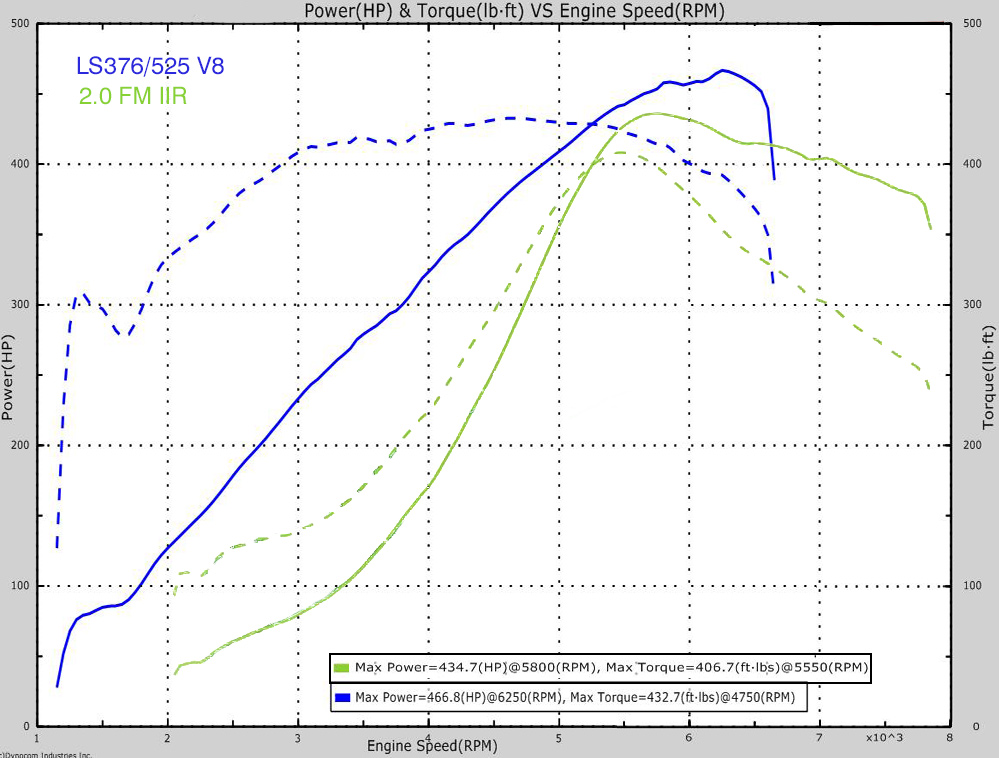

I'll just leave this here :)

Here's another. One's a 2.0 with about $10k worth of high-end internals. The other is a 1.6 with a bolt-on turbo kit. These aren't cherry-picked examples, I owned three out of four of the cars in these charts.

http://www.targamiata.com/images_lrg/Janel%20vs%20Targa.pdf

In reply to Keith Tanner :

Interestingly both engines make peak torque 1000rpm from each other. If one were to only look at where the peak torque figure was, they might make some pretty bad assumptions.

In reply to Pete. (l33t FS) :

Yeah, quoting peak numbers on a dyno chart is a great way to avoid the real story. That's why I keep the V8 vs turbo 2.0 chart around, to illustrate it. I had plans a while back to write a dyno program that would display the area under the curve for a chart. I haven't worked out what the units would be yet :)

In reply to Keith Tanner :

We agree. I should have said low dollar junkyard builds .

You can't change the nature of a horse. Just have to give it good food and healthy exercise .

( like E85 and 30 pounds of boost )

Looking at the chart a little more in depth (and there is only one, the 2.0 vs 1.6 turbo is not showing), it kinda proves my point of redline vs peak power.

Without a gearing calculator in front of me, and making assumptions about the transmissions in use, it looks like the turbo mill will never drop much below 400hp if you shift at redline. The V8, on the other hand, will, assuming that 6500 is the redline. The V8 would be a bit faster if the redline was raised a bit, as it is it looks like it falls down to 350hp after a shift.

Old WRC and even late Group A cars were crazy quick for only 330-350hp or so because they made the power everywhere, so average power per gear was always high. 400 to 550 ft-lb peak tapering down to not very much at the top end because the restrictor limited the power.

2.0 vs 1.6 was a PDF, link added.

Problem is with perfect shift points in my experience is that they're a theoretical concept. The V8 curve gives you room to change your shift points if necessary, due to traffic or a bothersome corner or something. I had a weird problem at one point that only happened at high RPM shifts, so I ended up doing a full session at Laguna Seca with the car in 4th gear. It was still pretty darn quick. The turbo car would have struggled mightily.