Spent about 5 hours tearing my wife's FJ cruiser apart to get to the (maybe) bad knock sensor. I need to get another one and then put it back together. Lots of nuts and bolts sitting in nice little piles. I'm always more nervous putting things back together. Taking stuff APART is easy.

DrBoost

UltimaDork

9/13/14 8:01 p.m.

I'm the opposite. Taking stuff apart is when rusty bolts break or strip.

Texas. No rust. That part is pretty awesome.

Beware the leftover parts!

You might try a piece of cardboard. I poke the bolts through the cardboard in the same pattern as on the car and write the description and torque on the cardboard with a sharpie.

In reply to Ojala:

Nice tech tip! I poke bolts in cardboard, but mostly just to hit the heads with spray paint.

mndsm

MegaDork

9/13/14 8:48 p.m.

Ojala wrote:

You might try a piece of cardboard. I poke the bolts through the cardboard in the same pattern as on the car and write the description and torque on the cardboard with a sharpie.

That is hella smart. go put that in tips like..now.

mndsm wrote:

Ojala wrote:

You might try a piece of cardboard. I poke the bolts through the cardboard in the same pattern as on the car and write the description and torque on the cardboard with a sharpie.

That is hella smart. go put that in tips like..now.

I've done that before and it works as well as you'd hope. It's a good tip. This time I thought I wouldn't have too many so I used my magnetic tray and created nice little piles corresponing to particular parts. It's not as good as the cardboard.

In reply to mazdeuce:

I put a long bolt into a short hole one time and cost myself a case. So ever since then I am very careful to put the exact right bolts back into the right hole. I just put the torque on the cardboard because i can eyeball wrench sizes but I can't remember torque values or steps since I use a lot of aftermarket studs that use different torque from stock.

i always try to put bolts back into the holes they came out of if i know it's going to be apart for more than a few hours..

wbjones

UltimaDork

9/14/14 3:52 a.m.

It took me 4 hours to get fenders off a YJ Jeep. 30 minutes to put new ones back on. Rust.

Just in case it was keeping anyone up at night, I put it all back together this morning. All of the bolts went back in the holes. All of the hoses and plugs back on. No codes no leaks. I am tentatively calling it a success. $800 in labor saved!

Ojala wrote:

You might try a piece of cardboard. I poke the bolts through the cardboard in the same pattern as on the car and write the description and torque on the cardboard with a sharpie.

I first did this when modding my dads moped. 14 bolts and 13 different sizes. Now I do this all the time when the bolt are different sizes. some times i'll even draw a basic shape of the part to know where the bolts go and i can grab them without even looking, makes assembly faster. my biggest issue is running out of spare card board to draw on and poke holes in.

1988RedT2 wrote:

Beware the leftover parts!

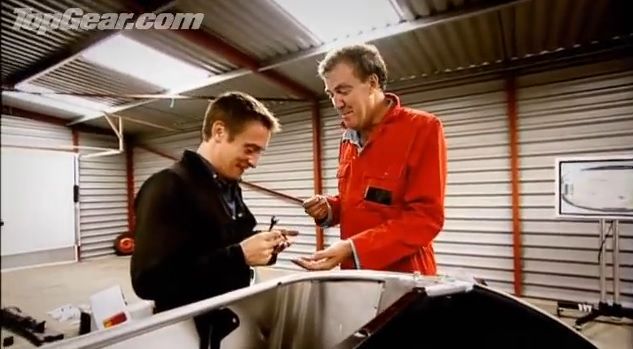

^ This reminded me of this, from the Top Gear Build-A-Caterham-at-the-track-before-the-Stig-drives-one-to-the-track episode:

"But Jeremy, this is all really important stuff."

"But Jeremy, this is all really important stuff."

"But Jeremy, this is all really important stuff."

"But Jeremy, this is all really important stuff."