It is time to upgrade my drill press game (I currently have the cheapest benchtop version from HF, and it might even be a bad one of those - the runout is insane).

I'd love to buy something that will last essentially forever. I'd love to buy something used, but I don't want a 'project'. I guess I don't mind a little cleaning or lubing, but I really would want to pay a bit more to avoid getting a unit that immediately needs to be rebuilt. I'm probably looking at floorstanding. I technically have 220 in my shop but not really where I want the drill press. 110v is preferred. I definitely can't do 3 phase.

Should I buy used? or should I get something new?

What should I be looking for? Features? Brands? Where to shop?

How much is reasonable for me to expect to pay?

Finally, should I just get a mill instead?

Robbie (Forum Supporter) said:

Finally, should I just get a mill instead?

Probably not, but it's what I opened this thread to write....

Tom Suddard said:

Robbie (Forum Supporter) said:

Finally, should I just get a mill instead?

Probably not, but it's what I opened this thread to write....

As a recent mill user/owner. I'm now in the market for a drill press too. Drilling holes on the mill is way slower than a drill press for normal flat stock and drill bit changes due to not having the built in safe through hole to not hit your table

I think I'd be watching CL and FB marketplace for something solid. Not necessarily from an "old==good" mindset, but just because the used discount will make something closer to industrial strength feasible.

I have a Ryobi bench-top I got nearly 20 years ago and it... makes holes. Well enough that I'm looking at a chuck upgrade Trent recommended. But if it so much as hiccuped I'd probably replace it with a nicer/heavier used drill press.

TheTallOne17 said:

Tom Suddard said:

Robbie (Forum Supporter) said:

Finally, should I just get a mill instead?

Probably not, but it's what I opened this thread to write....

As a recent mill user/owner. I'm now in the market for a drill press too. Drilling holes on the mill is way slower than a drill press for normal flat stock and drill bit changes due to not having the built in safe through hole to not hit your table

Yeah, good point. I still keep my old Delta drill press around for exactly that reason.

Not sure of your budget or size requirements, but Jet makes pretty good stuff.

I've had a 17" floor model for ~25 years or so.

Other than replacing the cheap chuck with a 5/8" Jacobs, I haven't had to do anything to it.

I've also got their 6" jointer and 14" bandsaw. All good stuff.

Mr_Asa

UltimaDork

1/18/23 11:47 a.m.

If you're concerned about runout on a drill press... doesn't that mean you need a mill for proper tolerance?

My thoughts on it at least.

Interesting spindle difference between a drill press and a mill. Drill presses are designed to take axial load (thrust). The tool geometry is what keeps the hole straight. A mill is designed to take radial and axial load, that is why you can cut a hole with a center cutting end mill.

Not really pertinent to anything other than the run out comment but interesting. If you have a good center punch the drill should follow the spot.

Mr_Asa said:

If you're concerned about runout on a drill press... doesn't that mean you need a mill for proper tolerance?

My thoughts on it at least.

Or more likely he will need to reseat the chuck in the Morse taper on the spindle OR replace the chuck itself.

I have one of these. Bought off craigslist for $700. It does the minimal amount of milling I need to do and is an outstanding drill press. I've been pretty happy with it.

In reply to Robbie (Forum Supporter) :

It really depends on your standards. 40 + years ago I bought a made in Taiwan cheap drill press ( new) It's worked flawlessly since.

For real accuracy I used my belt driven vertical mill made sometime in the late 1800's.

But I've done a lot on my Drill press such as fly cut pistons for valve relief, Gently milled aluminum bungs in a Vice I slid across the surface. To ensure they were completely straight.

Chamfered brass throw-out bearings. And a few other light duty tasks. The art of such abuse is how light a pass and well lubricated things are. ( oh and really sharp cutting edges)

Trent

PowerDork

1/18/23 12:53 p.m.

At some point during your search someone is going to recommend, or you will come across one of those 1940's through 1960's Craftsman drill presses made by King Seeley. They are nicely made, really cool looking and something you should totally avoid.

The spindle speeds are way too high to use with any drill bit over 1/4" in steel. They never have the rack and pinion option so adjusting the height of the table is a pain and will likely need a complete overhaul

This is coming from a person who has had four. They are just terrible for a modern workshop, but man they look cool.

In reply to Trent :

What are appropriate spindle speeds for steel? I got a little bench top drill press for a song a little while ago, but as far as I can tell it will only spin down to about 500 RPM.

I'd recommend getting at least a 14", 3/4hp with 12+ speeds with 200-3000 rpm range. Spent a little money and get an import 1/2" keyless chuck with very low runout (> .003" TIR).

I did a lot with a Porter Cable from Lowes after squaring everything and building a belt tensioner. I currently have a like 40" Japanese made press ISJ maybe? $100 on FB market place and it's perfect.

For accuracy you want a mill or mill/drill

Mr_Asa

UltimaDork

1/18/23 1:21 p.m.

stafford1500 said:

Mr_Asa said:

If you're concerned about runout on a drill press... doesn't that mean you need a mill for proper tolerance?

My thoughts on it at least.

Or more likely he will need to reseat the chuck in the Morse taper on the spindle OR replace the chuck itself.

Yeah, you can address the runout and make it better. I was more thinking "if you are worried about runout, you are probably looking for more precision than a drill press can give."

In reply to Mr_Asa :

I wish you could come by and use my machine. Put a small bit in and watch it dance!

As soon as you put some pressure on the bit the whole thing calms down a lot, which to me says there is a lot of slop in some bearing somewhere.

I am confident I can at least match the accuracy of my drill press with a hand drill.

Trent

PowerDork

1/18/23 1:44 p.m.

AMiataCalledSteve said:

In reply to Trent :

What are appropriate spindle speeds for steel? I got a little bench top drill press for a song a little while ago, but as far as I can tell it will only spin down to about 500 RPM.

500 should keep you in the clear for up to 3/4" drills.

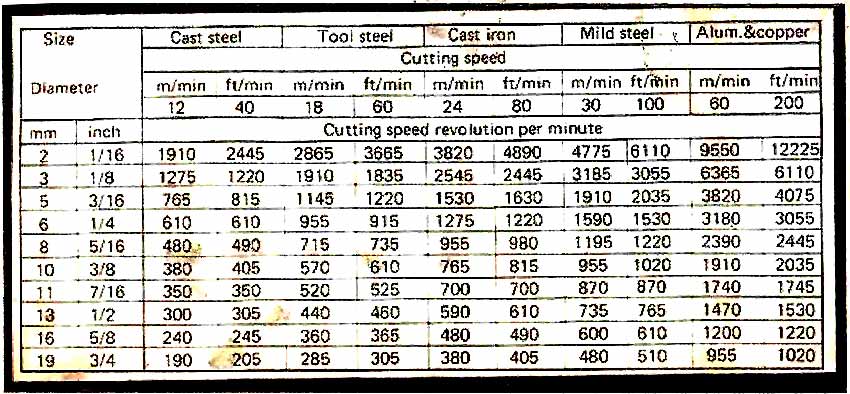

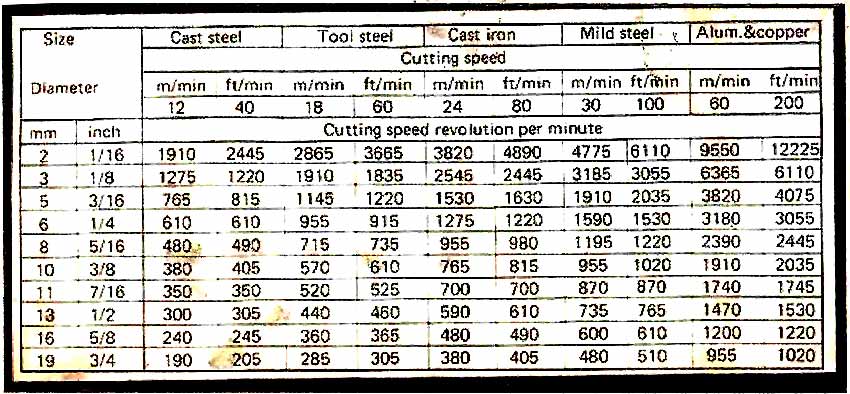

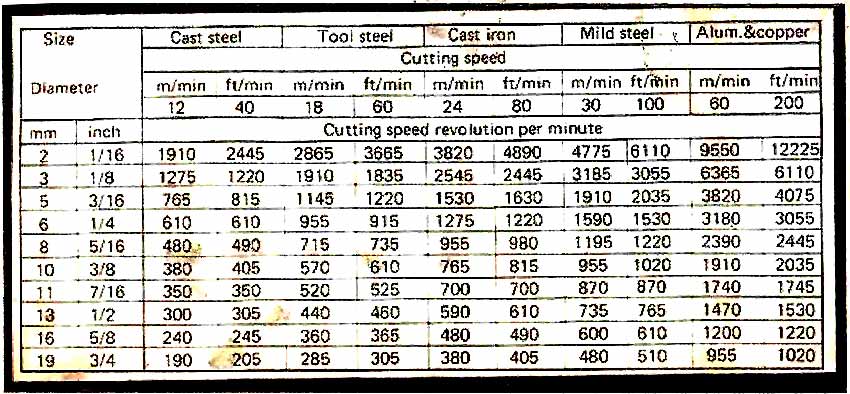

Speeds are measured in "surface feet per minute" and are dependent on drill diameter.

This kind of chart is a handy thing to keep on the side of the drill press

In reply to Robbie (Forum Supporter) :

That's similar to the one I have at my office. It gets the job done.

Buy a good drill vice for it.

Trent said:

AMiataCalledSteve said:

In reply to Trent :

What are appropriate spindle speeds for steel? I got a little bench top drill press for a song a little while ago, but as far as I can tell it will only spin down to about 500 RPM.

500 should keep you in the clear for up to 3/4" drills.

Speeds are measured in "surface feet per minute" and are dependent on drill diameter.

This kind of chart is a handy thing to keep on the side of the drill press

IMHO that chart is very optimistic. A light weight home shop drill press isn't going to turn a 3/4" drill bit at 500 rpm through steel. I use the 250 rpm setting on my DP quite a bit.

On those old Sears drill presses you used to be able to buy an intermediate pulley setup that would drop spindle speeds down considerably.

Our college had a terrific old Rockwell DP that would go down to 100 rpm (IIRC) just by winding a knob/handle on the front. If you could find one of those....it was big enough and strong enough that I drilled out an oil passage in a BMC A series block with it sitting on the platten

Toyman! said:

In reply to Robbie (Forum Supporter) :

That's similar to the one I have at my office. It gets the job done.

Buy a good drill vice for it.

Looks very much like mine.. second getting a drill press Vice. Absolute must.

Trent said:

At some point during your search someone is going to recommend, or you will come across one of those 1940's through 1960's Craftsman drill presses made by King Seeley. They are nicely made, really cool looking and something you should totally avoid.

The spindle speeds are way too high to use with any drill bit over 1/4" in steel. They never have the rack and pinion option so adjusting the height of the table is a pain and will likely need a complete overhaul

This is coming from a person who has had four. They are just terrible for a modern workshop, but man they look cool.

Does that mean I should stay away from this? I'm strangely attracted to it but I'm reading that atlas and craftsman were the same back in 1950 or so when I think this guy was made.

https://www.facebook.com/marketplace/item/8168923936465988

I also want to look at this one but the seller isn't responding to me.

https://www.facebook.com/marketplace/item/979879356323261