Merc

New Reader

2/17/12 3:44 p.m.

Anyhow I would like to see what everyone has seen or worked on that has been done improperly or engineered completely wrong. I got this idea from another forum I frequent and thought it'd be great here since GRM is so diverse. I'm sorry my computer crashed and I lost all my pics. I'd love to see what everyone has seen though.

Apparently it starts with the thread title

DrBoost

SuperDork

2/17/12 5:00 p.m.

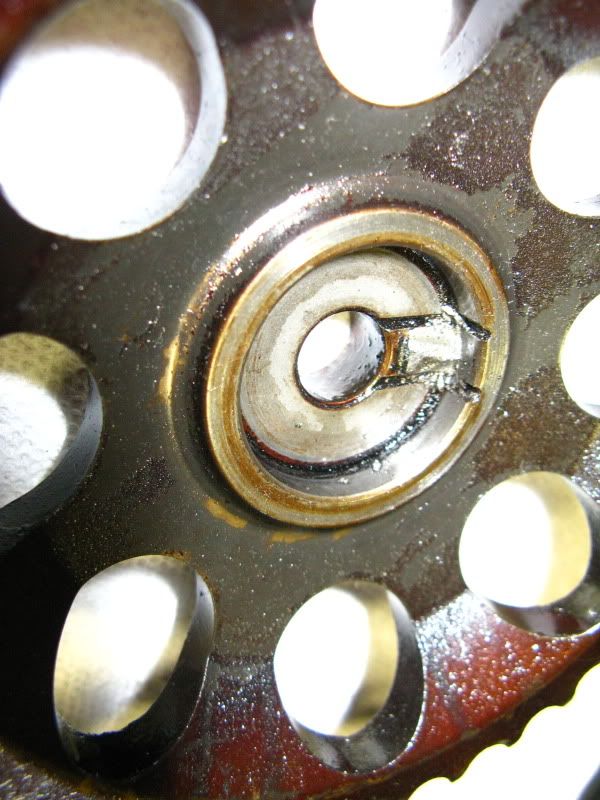

This is the one I posted in the other thread.

Probably one of the most appalling was my 57 Chevy.

Outside:

Inside:

It was a seriously cool car. The appalling part was under the hood and under the dash. Just about every connection was done with wire nuts.

The scary part was the busted U-joint cap on the drive shaft that had been repaired with JB Weld.

With all the quality work on the body and interior, that crap surprised me.

The next owner lucked out. I fixed most of that while I owned it.

Holset turbos have left hand thread turbine shafts. They also cost more than a used complete turbo on ebay.

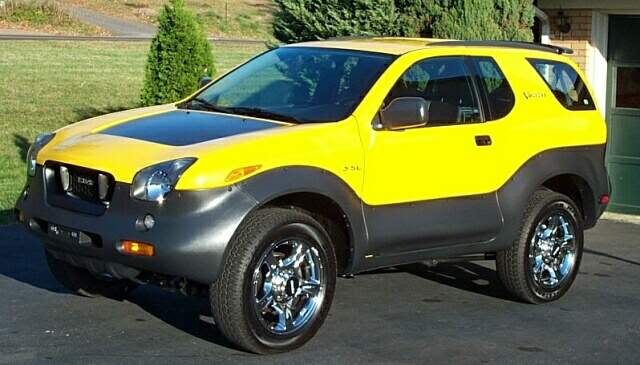

How to NOT lower your car

How to NOT lower your car

I'll post one of my own: How not to load a car on a dolly.

Argh, I left the camera at work.

And I'm not sure if I should even post the pics.

Suffice to say: We received a project that needed finishing. SBC was dropped into the engine bay but nothing was done aside from tinwork and intake manifold. A various comedy of errors later, I stuck our SBC priming tool (gutted distributor) in the thing and went to prime the engine. 1/2" drill loads down, no pressure yet, no pressure yet, no pressure yet... drill speeds up.

"Hey, do I have a large and growing puddle under the car?"

"No.... (walks closer) Oh sh--, yes!"

Those three plugs behind the flywheel? Important!

It was also missing one of the coolant plugs behind the flywheel... and all three plugs behind the timing chain.

Oh well, at least the clutch disk soaked up some of the oil, so that made less mess to clean up. That's good, right?

In reply to Knurled:

I did something similar but not as bad on my first rotary rebuild...You know that threaded plug on the middle iron for the cooling system? I remove that when painting but forgot to put it back. I made a large puddle when I first tried to fill the cooling system.

In reply to JamesMcD:

I left that finger tight once. (PITA to get to with the motor mount in the way) Engine started weeping coolant from that hole about 2000mi later. I thought it was coming from the coolant seal, since i used some really, really badly corroded parts. Hey, I figured it was worth a shot to use them. Dump some stop-leak in there and keep on truckin'.

2000 miles more later, I'm going to a seminar after work, and I'm driving myself instead of carpooling. Car has no heat, and the temp gauge is climbing. Pull off to nearest gas station, find water dripping from the plug. It was two turns loose, and you know how short those things are. That could have been very bad if I would have carpooled and then tried to drive home at 11pm after the seminar was over!

Will

Dork

2/17/12 10:02 p.m.

DrBoost wrote:

This is the one I posted in the other thread.

What happened? Tragic accident involving 3 intercoolers and a buttload of oatmeal?

Is that some sort of tumor? ewwwwww

In reply to stanger_missle:

That's tragic, stage 3 turbo manifold cancer. It's only a matter of time before it metastasizes to other parts of the car. Unfortunately, as long as that car remains with that same owner, it's terminal...

Bolts for cam gears should be more than finger tight when you start the car.

Glad I didn't get a pic of the Celica this morning. Jacked it up at the front cross member to change the wheels for the autocross. Pulled the right wheel then went to pull the left. Hum. That lug is tight. I'll just lower it to the ground and break it with the breaker bar.

Uh, oh. There's no wheel on the other side. Good thing the jack was there or the rotor would have been on the ground. I had to barrow another jack to get the car off of my jack! Oh well. Didn't break anything. Man, need more sleep.

How to NOT lower your car

How to NOT lower your car