My FB RX-7 has a Weber downdraft setup with a Racing Beat intake, and over the last few years of track driving, the fuel would occasionally boil/evaporate from the carb on hot days, making the car hard to start and/or causing a brief bog in the rev range till the fuel was replenished. This is exacerbated by the rotary design having the intake right above the exhaust manifold. This year, I built myself a rudimentary heat shield between the intake and exhaust which seemed to help substantially, but I wanted to further improve things. After reading infernosg's build thread, including the part where he found that a dedicated air box could reduce his intake temps drastically, I think I'd like to build a similar box that shields the velocity stacks from engine bay heat, and also routes cool air toward the carb. So far it doesn't appear that any off the shelf options are available unless I want to pay $400 and hope the box shows up from Australia before next year.

Those of you who have build your own air box, what material did you use, how difficult was it to get right, and did you measure IAT before and after? The only tricky part about the FB will probably be hood clearance, the velocity stacks are already fairly close to the hood when shut. Ideally I could route some cool air their way without disrupting the way they're supposed to draw in the intake charge..

You could try to use the underside of the hood as one side of your feed to the velocity stacks. That gets you as close to the hood as possible for clearance. Some sort of inlet to the duct would be needed, either at the base of the windshield or at the nose of the car. Heat reflective foil on the other three sides (on the engine bay side) to help keep heat out of the inlet. Make any duct at least 2 times larger (cross sectional area) than the inlet area of the intake runners. Other options are a simple box that is fed with air from a high pressure location (nose or base of windshield) and is not connected to the hood, but could seal to the hood surface to keep the velocity stacks working.

For materials: aluminum sheet is easy to form and light, but will transfer heat (that's why you should use the reflective foil). Fold and rivet corners/joints. fiberglass/carbon are the other real options. These require some fairly involved mold building. The cloth is reasonably priced, but the epoxy resin you need to use is not cheap. Still need reflective foil to protect these parts. Stainless sheet is an option, but it's heavy. It does not transfer heat as much as aluminum and is more of a pain to fabricate with. Mild steel splits aluminum and stainless, but only in the worse directions (transfers heat, harder to fab than aluminum, heavy). I am sure there will be other suggestions.

If you have the ability to measure the IAT, then that will be the best measuring stick for the effort.

I was set on making an air box out of fiberglass. It's pretty easy to work with. Just make a form with foam to the shape you want, seal it, apply mold release, then lay up the fiberglass. Once the fiberglass is cured either chisel out the foam or use something like acetone to melt it away. The only reasons I didn't is I realized I could more easily modify the air box EFI Hardware sells, the AUD to USD conversion was favorable and they were in stock

I still have the fiberglass base of the air box I bought from EFI Hardware. If you'd like, you can have it to assist in making your own air box. It shouldn't be too hard to use foam to make a similar upper piece. I see it's out of stock but if you get the opportunity I really would just buy it from EFI Hardware. It's specifically made for Weber IDA carbs on 1st generation RX7s so you shouldn't have any fitment issues. If air horn length is an issue they can always be cut down a bit.

In reply to infernosg :

I might contact them and see how long it'll be out of stock, also a friend send me the pdf to the Mazda competition manual which featured their air box specs:

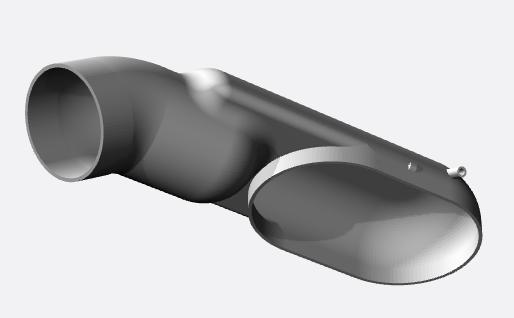

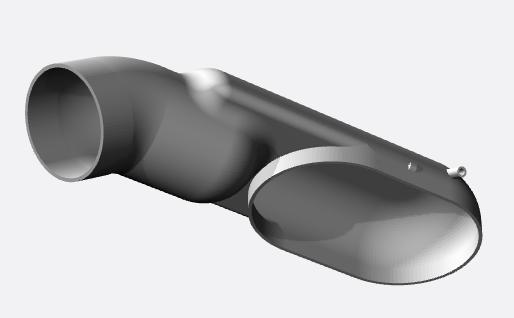

I am using Fiberglass myself, my lower air box so far(still in progress so excuse the mess):

Essentially this bolts to the ITBs on the bottom, stacks bolted down on top, sandwiching the box between them. Of course, my air box is separated into a lower and an upper portion, which makes it more difficult because I had to add this flange in.

You do have to be realistic in your expectations of fiberglass though...its good to about 200 degrees F. Not the fiberglass itself, but the resin you use. This means that to avoid heat transfer between the engine surface itself and your airbox you will need some type of insulator. In my case I will have rubber gaskets on either side limiting the heat transfer. The underside of the airbox where it sits above the valve covers and engine I will use heat reflective tape on....which leaves just the ambient air temp under the hood...since I have my headers wrapped(with fiberglass exhaust wrap no less) the temperature should be kept to a reasonable amount.

My goal wasnt to reduce the IATs, but was purely for filtering purposes in an attempt to maximize hood clearance(using a filter like ITG as an example would make it so I would have to run a higher hood scoop) so I can't answer whether IATs would be lower...but the air will be ducted from a source isolated from ambient engine bay temp so in comparison I am willing to bet it will be significantly cooler(warm air intake vs cold air intake)

I see you have the book, so my comments re: sizing are irrelevant

however, they are not foolin' when they say the air must be surgically clean. Any small air leaks bypassing the filter will quickly kill an engine.

In reply to Pete. (l33t FS) :

I have run open velocity stacks for years on the advice that i would be fine if I kept the car off dusty roads.. I have a feeling this is the reason it doesn't make the power it probably should. With the Weber setup and a full exhaust system it made 102 whp and 85 ft lbs on the dyno, I was told the engine might be a bit tired because similar setups have yielded closer to 120 whp. Either way, when my extra 12a that's being bridgeported gets finished I'll be running proper filtration

In reply to bruceman :

That looks doable ! Have you measured IATs after building it ?

In reply to dannyp84 :

All roads are dusty to a rotary. The AIR is dusty if you live within 10 miles of a city or a farm.

Out of the roughly 8 12As that I acquired for parts a few years ago, 100% had trashed side housings. (As well as rotors and rotor housings) You can trash the side housings by removing the air pump from a stock engine and taping over the hole in the air cleaner instead of using a proper hose cap.

That's why I ended up just sending my original engine's bits to Chips for reconditioning.

Oh well, I can send some of my extras out and between them, new GSL-SE rotor housings, and some FC rotating assemblies, I have enough bits to build another bridge ported 13B at least

j_tso

Reader

8/23/21 5:53 p.m.

In reply to dannyp84 :

Is there a fuel return line, or does it dead end at the carb?

If you have access to CAD, a 3D printing service might work. One of my backburner projects is an airbox for my DCOE, Shapeways has a "versatile plastic" (Nylon 12) that looks like it may hold up. This model is estimated to be $150 to print:

In reply to j_tso :

My return line comes off the regulator near the firewall so the only line to the carb is the feed. I might have access to a 3D printer but I don't know if it's large enough for this project

Pete. (l33t FS) said:

In reply to dannyp84 :

All roads are dusty to a rotary. The AIR is dusty if you live within 10 miles of a city or a farm.

Out of the roughly 8 12As that I acquired for parts a few years ago, 100% had trashed side housings. (As well as rotors and rotor housings) You can trash the side housings by removing the air pump from a stock engine and taping over the hole in the air cleaner instead of using a proper hose cap.

That's why I ended up just sending my original engine's bits to Chips for reconditioning.

Oh well, I can send some of my extras out and between them, new GSL-SE rotor housings, and some FC rotating assemblies, I have enough bits to build another bridge ported 13B at least

Who is Chips ? I have some extra housings with the chrome missing in large sections ? Can they be fixed ?

In reply to dannyp84 :

Chips Motorsports in Warren, MI. Close enough that I just drove up there myself to drop them off and pick them up when done.

He only does SIDE housings, not rotor housings. Grinds them, Nitrides them, and laps them smooth. I have about 2000mi on the stock 12A in my '81 and it seems to be great.

The bridge ported 4 port 13B for my other car, which has had its bits resurfaced by him, is still powering an engine stand, waiting for the weather to break enough for me to wrestle it in without me killing myself from heatstroke in the process. I had to have him fix the housings after the throttle cable wore a small hole in my air filter, which killed the engine quite rapidly. I haven't had the bridge port motor in the car since 2018 or so, when I threw some experimentally ported GSL-SE side housings at my rotating assembly and increasingly warped/cracked rotor housings, just to keep the car mobile.

Allegedly, Goopy can rechrome rotor housings, but they only do business on Facebook and Pete don't do Facebook. I have a huge stack of 12A rotor housings to be refinished if they do, which is a bit absurd because I only have two sets of good rotors and one of them is in my stockport.

In reply to Pete. (l33t FS) :

I always assumed that once a rotor housing lost its chrome, it was done. I'm just waiting on Logan at Defined Autoworks to port my spare side housings, so I can begin my bridgeport build. I bought two used 12a motors a couple years ago and one of them looked good after tear down so the housings from that one went to Logan. The engine in my car is original and is currently at 158k. It runs well and I don't intend to pull it till the bridge motor is fully ready, at which point I will pull the original, clean it up and set it on a shelf till it's needed again.

i also don't do Facebook, but I thought Goopy had a website. It must be a prerequisite with rotary stuff that your business name has to be strange, remember pineapple racing ?

In reply to dannyp84 :

Shallow Pockets was my porting shop name, when I was trying to do porting for people. That's a lot of why my Photobucket account is SPRTUSA. It was a double meaning for both my "less is more" philosophy of keeping velocity up instead of bigger is better, and "shallow" pockets vs. deep-pocket moneyspending.

Logan's good people and he does amazing stuff. He's the one who recommended Chips to me, apparently he has Chips resurface all of their side housings when they aren't just buying new.

(Chips isn't a weird name, the owner's name is Chip, or at least, the Anglicisation of his Eastern European name works out to be Chip.)

In reply to Pete. (l33t FS) :

I dabbled with porting only so far as trying to cut out the racing beat porting template, at which point I felt my skill level was far too inferior to work on good irons, and I don't have any bad ones to practice on, so I drove out to see Logan. He also fired up the 4 rotor for me with no mufflers, which was quite an experience.

The first thought that came to my mind for a sealed Weber downdraft airbox would be an ammo can (.30 or .50 would be a good size). Cut the carb air horn bolt pattern into the bottom, add a tube and flex hose to feed cool air in from a convenient spot.

The problem with metal is it absorbs too much ambient heat. If you are going to make an airbox...your ideal material is going to be Nylon...it shouldn't be difficult to draw up a CAD file for such a simple shape and then get it 3D printed from somewhere like E-Machine Shop, failing that, carbon fiber tends to be made with resins with a higher heat tolerance than most fiberglass resins...you could simply buy some carbon fiber panels, cut to size and then use angle aluminum for the corners, seailing it with RTV

I wouldn't get too caught up on heat as long as you're sticking with what I'll call "automotive grade" materials like fiberglass. Yes, the air box is bolted to the engine and you'll get some conduction but with the engine running you'll always be moving ambient or slightly-more-than-ambient temperature air through it. That should be plenty to counteract any conduction from the engine and since the cooler air is moving it's better at transferring heat than the stagnant, hot air in the engine bay. My air box has survived over a year with no signs of distress and the car mainly gets driven on track. The highest IATs I've seen are around 120F and that's when I'm idling stationary in the paddock in near 100F ambient temperatures. I'd wager the actual fiberglass part of my air box never gets much hotter than that.

In reply to bruceman :

I am very curious about your setup here because I was originally thinking of using the bottom of my hood as the top of my airbox and your setup is very similar to that(airbox top hardmounted to the hood) Do you have any sealing issues? Or is the foam dynamic enough to account for any changes due to engine torquing?(not that a rotary has much of that compared to my engine) I am just wondering how its working for preventing particulates for you.

In reply to Wicked93gs :

It is far from perfect. The base where the air filter seals is too flimsy and no doubt leaks. There is signs of dirt and grit on the insides the velocity stacks. Really this is not going to ever seal well since the hood and engine move independent of each other.

I wanted the air filter and ducting to be easily moved out of the way because initially I was having fuel injector issues. Over the last year or so these are fixed and this winter I intend to redo the whole setup similar to the IPRA Rx7's in Australia. They have high volume air boxes with dual 4 inch ducts to feed them.