BobOfTheFuture wrote:

keep in mind- you dont want it perfectly smooth, you want a "hone" effect. air is Viscous and if the port is mirrior-smooth the air will stick to it like water in a glass (what do they call that again? arg, cant remember) the slight roughness helps break that up and let the air "slip" through easily

This is called laminar flow. It does cause the air to "stick", non-laminar flow on the intake is your friend. It promotes mixing of the a/f mixture. It also causes a bit of a restriction at the flow boundaries due to increased turbulence. On the exhaust side, a mirror polish and laminar flow are preferred because you want to help get as much air out as efficiently as possible. Having a smooth laminar flow helps promote this, because the less turbulence in the exhaust tract the less back pressure you have. I guess if you had a direct injection engine you should have as smooth an intake as you can get, but with port or TB injection the added mixing outweighs the extra restriction of a more turbulent intake.

fifty

New Reader

8/21/09 7:51 p.m.

Check out the forums at http://www.tractorsport.com/cgi-bin/forum/cgi-bin/ikonboard.cgi for DIY flow bench discussions

Brust

Reader

8/21/09 8:04 p.m.

BS on the "no SU/Stromburg" nonsense. Check out a little book called "Tuning BL's A-series engine" by David Vizard. SU's whoop up on webers for mid-range power/torque (which is actually useful). Dyno graphs to boot. Please don't speak nonsense like that without useful graphs to prove it. Also, it's great to have a nice, shiny port, but the point isn't for speed at this point. Use port size to maintain speed, the rougher finish on an intake port is to induce turbulence on the boundary layer in order to more effectively mix the air and fuel. So, Griffin, I guess I'm just re-iterating your point. Sorry dude.

Regardless, for the why's etc, this book is pretty spectacular even if you don't own anything with an a-series.

fifty wrote:

Check out the forums at http://www.tractorsport.com/cgi-bin/forum/cgi-bin/ikonboard.cgi for DIY flow bench discussions

Hey that's my forum!

Just happen to be a member/subscriber here on GRM

Bruce

fifty

New Reader

8/21/09 9:31 p.m.

Thanks for the forum, Bruce! I'll definitely buy some orifice plates and plans when the time comes (probably this winter).

To the original poster, here's a porting / polishing / flow bench book I found helpful:

http://www.amazon.com/Build-Modify-Power-Cylinder-Heads/dp/1903706769/ref=sr_1_1?ie=UTF8&s=books&qid=1250908091&sr=8-1

I have done allot of work porting. Not so much polishing.

My basic porting will involve looking at the following.

-

Try to straiten out the flow from the intake to the valve. This usually can only be improved a little if at all.

-

Accelerating the flow in to the cylinders. I do this by opening up just below the valve to a diameter that is equal to or less then the valve opening (never more) You then want the area below this to neck down a little. Note that I am not giving any exact measurements here as this is very motor specific and motor application specific. High rpm race motor versus street track toy or just street car that you want to work better (where torque is your friend) If you dont understand what I am getting at think hour glass shape or look at the cross section of a jet engine or if you look at the cross section of some carburetors they have the same shape as they are trying to accelerate the air by the jets for better atomization as well as better low rpm functionality. One last thing is to not remove to much around where the valve stem comes out of the head. People tend to hog this out to much crating a big open space here. Just smooth it out and re shape as needed. Try to use it to "aim the air/fuel mixture up in to the chamber,

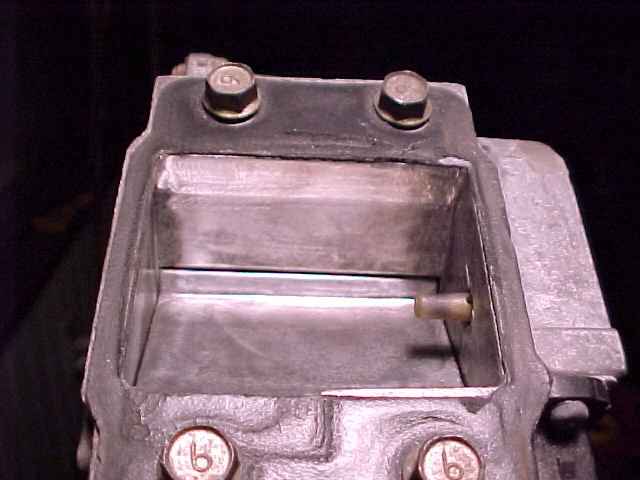

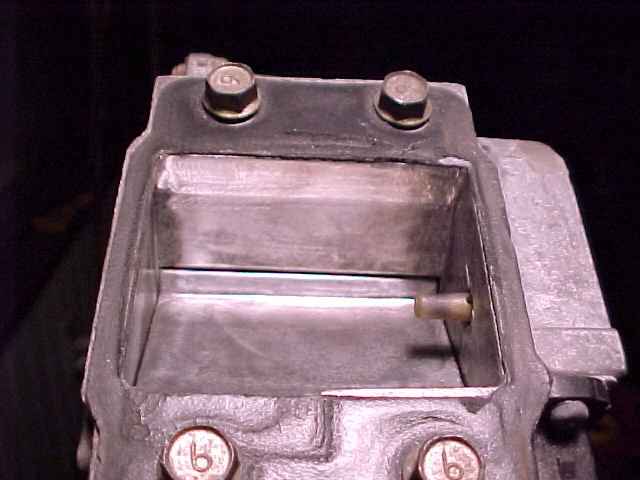

Here is one of my Porsche head intakes.

Lastly in EFI cars muck with your heads as the last part of the puzzle. I have had much more noticeable gains when working on other parts of the intake tract. The biggest has been on the AFM. Especially on my RX7. It made a huge difference on throttle response and a noticeable difference in forward thrust.

Photos

Before

After

After

Before

After

After

Before

After

After

Before

After

After

Before

After

After

More stuff on this on off of my web pages here>>> WARNING Really bad colors on this page. I need to change this!!!!http://www.ehadesign.com/~dsmith/mas.htm

There is allot to this port work especially how to deal with the "barn door" It is a mod that works very well but like all things done wrong and you will bugger up your hardware. The key is to make sure you dont mess with the doors ability to seal top and bottom or you will affect how it is pushed by the air. You want to get more air through but you dont want to change how the door works. Sounds simple but it took me quite some time to figure out what you can and cant do. BE CARFUL!!!!

Other things to look at are all the plastic pieces that make up air box's and what not. Look for restrictions, casting slag and anything else that the manufacturers left behind. In most cases you dont need to change the design you just need to clean up the castings so the actually reflect the original design.

Good luck with it have fun. More is not better and remember that porting a head is just a piece of the whole puzzle that will hopefully net you that little bit more than the other guy . .. . . .

After

After

After

After

After

After

After

After

After

After