I have the engine out of my F-100. It breaks motor mounts regularly. I think a part of the problem is that the holes on the perches are beat out of shape. I am planning to make these holes the proper shape. Should I weld a piece of 1/8" steel on the top face of the perch? on the bottom side of the perch? or should I do something else entirely? The left side perch is bad(right side of photo) sorry for bad angle on photo, the others are too blurry, I will get better shots.

I have the engine out of my F-100. It breaks motor mounts regularly. I think a part of the problem is that the holes on the perches are beat out of shape. I am planning to make these holes the proper shape. Should I weld a piece of 1/8" steel on the top face of the perch? on the bottom side of the perch? or should I do something else entirely? The left side perch is bad(right side of photo) sorry for bad angle on photo, the others are too blurry, I will get better shots.

I am also replacing the steel and rubber mounts with all steel mounts. I would like opinions on this as well. The mount will be similar to these http://www.summitracing.com/parts/trd-4225

Thanks

Braden

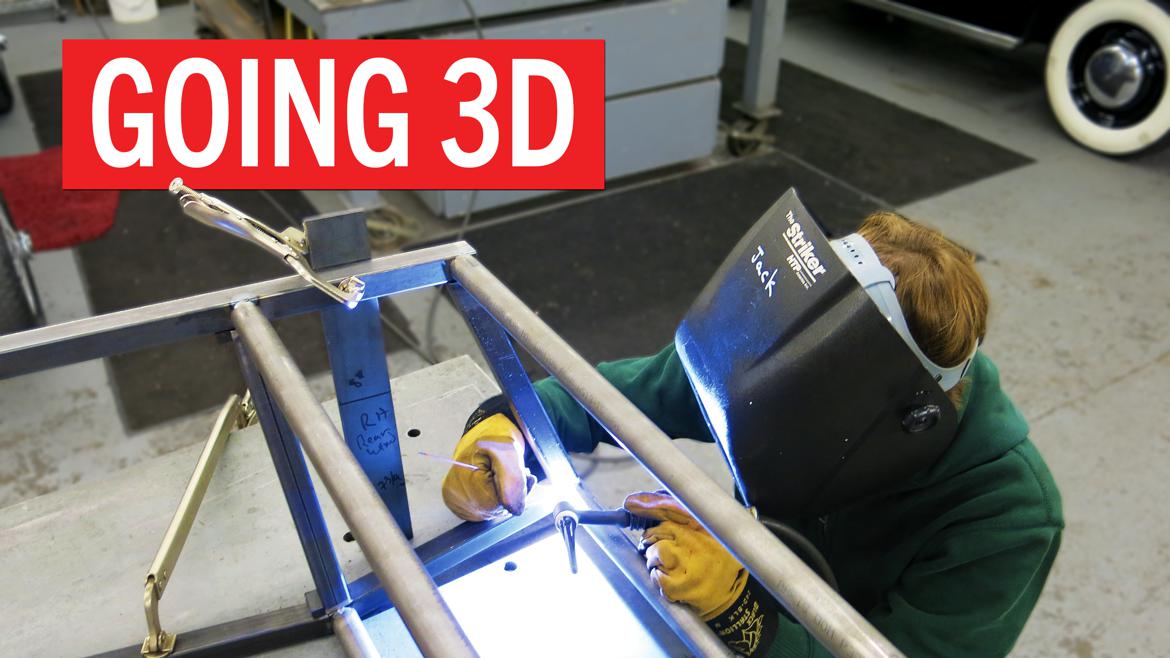

Photo of mounts mentioned above

Photo of mounts mentioned above

It looks like putting them on top will raise the motor which may cause other issues. I would put them underneath or replace the current parts altogether. Remember too that solid mounts will transmit a lot of vibration into the truck. if the engine is rolling over and tearing the mount you may be more comfortable with a rubber or poly mount and a torque limiting strap from the cylinder head to the frame rail to keep it from moving too much.

Wally nailed it. A torque strap is much preferable to solid mounts in anything remotely civilized.

It looks like they came loose and moved around, or weren't tight enough to provide a good clamping load to begin with, tearing up the holes. Make sure they're tight, use washers under the nuts(grade 8 on both), and use blue loctite.

Plate it top and bottom sure it will raise the motor up 1/8 but it will be fine hell a worn mount lets it torque up that much. but I have to ask why fix them at all? thay bolt on find another set and swap'em

Stop buying motor mounts made in India. If you do use the steel fronts, be sure to leave the trans mount rubber or you will torque them out of the bolt holes as the frame twists. And it does twist.

I thank all of you for the advice. The only rubber mounts that I can find are crap, they last about two weeks. The engine perches are not available in my area, they have all rusted away.

I think that I will cut a piece of 1/8" steel to fit under the existing face of the perch. I will cut the proper size slot in this piece and weld it to the bottom of the perch. The face of the perch will have several additional holes drilled in it to plug weld the plate to the perch.

If I strap it down where do I attach the strap to the engine? Do I use a head bolt? Header bolt? Valve cover bolt? What do I use for a strap? A piece of chain or cable have been mentioned to me.

Another thought, you could fabricate new perches (or modify existing ones) to utilize generic suspension bushings, or some readily available ford FE poly mount.

Try Mac's or Dennis Carpenter for real mounts

I have the engine out of my F-100. It breaks motor mounts regularly. I think a part of the problem is that the holes on the perches are beat out of shape. I am planning to make these holes the proper shape. Should I weld a piece of 1/8" steel on the top face of the perch? on the bottom side of the perch? or should I do something else entirely? The left side perch is bad(right side of photo) sorry for bad angle on photo, the others are too blurry, I will get better shots.

I have the engine out of my F-100. It breaks motor mounts regularly. I think a part of the problem is that the holes on the perches are beat out of shape. I am planning to make these holes the proper shape. Should I weld a piece of 1/8" steel on the top face of the perch? on the bottom side of the perch? or should I do something else entirely? The left side perch is bad(right side of photo) sorry for bad angle on photo, the others are too blurry, I will get better shots.

Photo of mounts mentioned above

Photo of mounts mentioned above