[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/S_zpswogxgcrf.jpg.html] [/URL]

[/URL]

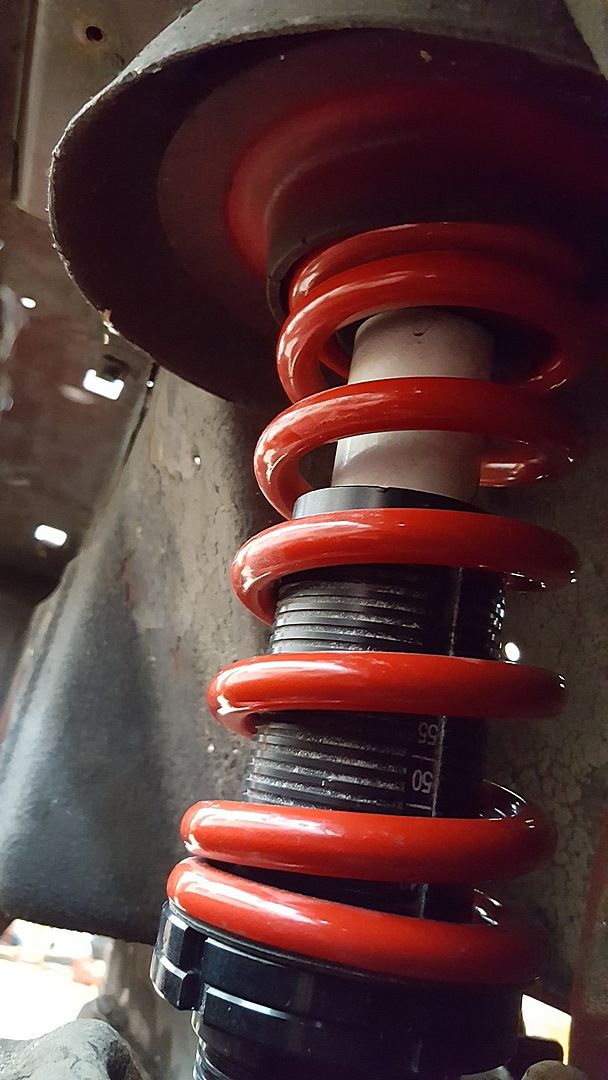

The above picture is my cluster berkeley that is my challenge car front suspension.

It's set to ride height, +/- 1 inch.

Coilovers are needed for rate and Tire clearance.

A-arms must remain. Like they are.

The factory spring saddle is more or less junk. The shocks are essentially bottomed (3/4 inch of travel in compression).

So, I need to adapt different shocks. I've found a few with correct stroke and length, that are readily available in the junkyard in bilstien variety. They are all a different lower mount though. Which means I need to make something.

My best option is a standard eyelet shock. Next best is the gm crossbar style.

My thought was to relocate the spring saddle pin to the underside of the upper control arm, and create a steel block that mounts a roller bearing around the saddle shaft with essentially an u profile to mate to the gm crossbar, or to turn the spring saddle shaft down to fit through the eyelet style shock.

Both of these relocate the shaft to the underside of the upper control arms for more bump travel. This puts the entire Suspension load on 2 3/8 bolts.

The car is an 80 amc spirit. Dedicated race car. Never going back on street. Autocross, hillclimb, hpde.

So, what says the hive? Any other ideas?

What does the top mount look like? Any way of keeping the spring locating pocket but moving the center up so that your current shocks aren't fully compressed?

I don't think it would last long with all the spring force being in tension through those two bolts - the factory setup is designed to support the bolts with the arm. That said, if you added some strength to that part of the arm, it probably isn't anything to worry about.

Stampie's got a better idea though. It would be much easier (though I'm saying this without seeing the upper spring perch) to cut out the center of the spring hat, weld in a tube a few inches long, and weld the center of the spring hat back on to move the upper mount upwards. This also only changes the shock load support, which doesn't need to be anywhere as beefy as something taking spring load (unless you have internal bump stops in the shocks instead of on the arms).

top spring mount rests directly against the strut tower. I cann extend the upper mounting point (stud) for the shouck about an inch, which will help. but that still leaves me with the options of these blown KYB shocks, or parts store monroes. no performance shock for this application, especially one that can cope with 650lb springs.

and more travel is much better in my book. if I can get the inch at top, the half inch to an inch at bottom, and add the 3/4 ive got now, it gives me about 2.5 inches of bump travel, which puts me in the middle of the stroke for the junkyard s10 bilstein.

I'm going to try to snap some more pictures here in a little bit on lunch break so I can show you guys better what we're dealing with. The current pictures are about Craigslist Worthy.

STM317

HalfDork

10/27/16 12:13 p.m.

Could you replace the coilover/shock with a pushrod, and then mount it in the engine bay?

This would give you even more tire clearance than the coilovers would in their current location too.

Okay, so the top of the shock is already uncomfortably close to running into the hood, it looks like, but there may still be enough room to move them up some.

That upper A arm is beefier than it looked in the first pic. Bolts may be fine, but I'd put a nice fat washer on the top of that arm at a minimum just to try to prevent tearing.

There aren't any other shocks that would work up there? Seems like a Chevy F-body, B-body, or A/G-body shock might work a lot better than the (I'm assuming longer) S10 part, and the mounting is the same.

I just want to say that I appreciate the Star Wars reference in the title and didn't want you to think it went unnoticed.

Video: Help me Obi Wan Kanobi you're my only hope

Why not eliminate the saddle the shock is mounting on and use a longer shock with a conventional lower eye? Use the existing cross shaft the weird Y or V thingie is mounted on and just mount the shock directly onto that.

In reply to STM317:

Eyelet shocks would be great for this. Remove the pocket, weld in substantial enough support (thick plate box, or tubing) to the underside of the arm to lower mount, and use said thick plate to make new lower shock mounts with the correct height adjustment. Makes the lower shock mounts as easy as having two parallel plates with a hole through both.

foxtrapper wrote:

Why not eliminate the saddle the shock is mounting on and use a longer shock with a conventional lower eye? Use the existing cross shaft the weird Y or V thingie is mounted on and just mount the shock directly onto that.

That would hardly give any more travel vs. the current setup, it looks like the shock is only sitting about 1/2" above the shaft line right now.

Maybe.... make two brackets shaped like a V with a hole in the middle the same diameter as the bearing/bushing in the bottom of the shock. Probably 3/16 or 1/4" thick and as big as you need.

Weld them on the bottom of the control arm in line so a bolt you would likely have to turn down would go through one bracket, through the coilover and through the other bracket.

You would likely need spacers to fit between the brackets and the coilover and the end against the beating/bush would be turned down to just press against the center.

I would reinforce the bracket with a 1/2" or so lip around the edge. You could make the brackets out of one piece and bend them or just weld them on.

Clear as mud?

Any way to go through the upper arm and connect to the lower arm? Don't know anything about AMC Spirit suspension layout and just thinking outside of the box here.

In reply to jfryjfry:

I'm having trouble seeing what you are saying.

In reply to tomtomgt356:

That thought crossed my mind, but the lower control arms would need to be completely redesign to deal with the load.

GameboyRMH wrote:

foxtrapper wrote:

Why not eliminate the saddle the shock is mounting on and use a longer shock with a conventional lower eye? Use the existing cross shaft the weird Y or V thingie is mounted on and just mount the shock directly onto that.

That would hardly give any more travel vs. the current setup, it looks like the shock is only sitting about 1/2" above the shaft line right now.

That is one of my leading ideas, with the coilover sleeve rising on the shaft as well. But there is some reason I can't put my finger on that it seems like a bad idea.

gearheadE30 wrote:

Okay, so the top of the shock is already uncomfortably close to running into the hood, it looks like, but there may still be enough room to move them up some.

That upper A arm is beefier than it looked in the first pic. Bolts may be fine, but I'd put a nice fat washer on the top of that arm at a minimum just to try to prevent tearing.

There aren't any other shocks that would work up there? Seems like a Chevy F-body, B-body, or A/G-body shock might work a lot better than the (I'm assuming longer) S10 part, and the mounting is the same.

I've got about 1.5-2 inches before it hits the hood. So I can go up there.

The s10 shock is actually a half inch shorter than g-body, and 1 inch short term than f body. And s10 blazers used a similar spring rate and a bilstien from the factory.

STM317 wrote:

Could you replace the coilover/shock with a pushrod, and then mount it in the engine bay?

This would give you even more tire clearance than the coilovers would in their current location too.

Do you by any chance have some write ups or links to doing this? Seems like a great idea, but I have no idea how it actually works or how I would implement it.

Only downsides are that it's (relatively) costly and difficult.

Trim them ears off the lower spring mount. Move the shaft to the bottom of the upper arm. Maybe some spacer plates to keep lowering the shaft until you have the length you need! Grind for clearance.

Bruce

In reply to egnorant:

Won't that overload the two 3/8 bolt that hold the saddle and shaft? Either in shear or tension?

I have nothing useful to add other than the thread title makes me smile every time I see it.

Another outside of the box thought: Any way to decouple the spring and shock? Keep the spring supported by the top of the A-arm and have the shock bolt below the a-arm? That way the two bolts are only holding the force of the shock (not much) and not having to support the weight of the car.

STM317

HalfDork

10/27/16 4:30 p.m.

GameboyRMH wrote:

Only downsides are that it's (relatively) costly and difficult.

Only downsides are that it's (relatively) costly and difficult.

Basically this, but the shock doesn't have to end up in a position like this, since in your case you'd probably run into issues with steering shaft and exhaust stuff. Based on your pics, I'd consider running the shock horizontally either in front of the shock tower down the inner fender, or back into the firewall. I suppose you might be able to fab a strut tower brace that you could mount the shocks too as well, but that might be more complex.

If it were me (and I say this with nothing to go on but the pics you've posted), I'd unbolt the upper part of the shock towers, install a plate with a slot for the pushrods to pass through and a mount for the bellcrank pivot there, and then run the coilover down the inner fender toward the front of the car. Or remove the inner fender completely and weld up some tube in whatever fashion suits it (I don't know how this would fit into your skill set or budget). You can make the bellcranks pretty easily using some bearings and sheet metal, or you might be able to find motorcycle rear shock mounts that would work as an off the shelf option. Cut the top of the fenders or hood (for clearance as necessary, and to show off your trick suspension like a BAC Mono).

Kind of like this: http://www.jmeenterprises.com/JME%20New%20Suspension.shtml

[/URL]

[/URL]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121607_zpsycvle5to.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121607_zpsycvle5to.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121534_zps2uyujpgs.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121534_zps2uyujpgs.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121551_zpsl44sxgmg.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121551_zpsl44sxgmg.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121528_zpsaekvsxap.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121528_zpsaekvsxap.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121547_zpsfbqt2umh.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121547_zpsfbqt2umh.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121521_zpszmq6y4nt.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161027_121521_zpszmq6y4nt.jpg.html] [/URL]

[/URL]