I skipped reading a few pages because it seems to be a cycle of the same thing over and over again... did anyone mention the Tata Nano?

I skipped reading a few pages because it seems to be a cycle of the same thing over and over again... did anyone mention the Tata Nano?

This is the strangest conversation. Hypothetical prices and configurations are proposed, real world examples are posted, and the arguing continues about the hypothetical building of what has already been built.

In reply to bearmtnmartin (Forum Supporter) :

You are aware this is totally hypothetical? I hope you weren't convinced that I was going into production. If so I'm sincerely sorry.

I think it's possible. Others disagree. Nobody is wrong, nobody is right.

In reply to AAZCD-Jon (Forum Supporter) :

Yes. . Actually I considered one briefly. My wife has limited mobility and she can no longer walk down to or back from the dock.

I looked at golf carts and they were $6/8000 in reconditioned shape. So at $1400 this would have been a bargain. But shipping was going to be over $4000. Ultimately, Well, my wife wouldn't fit.

frenchyd said:Driven5 said:Even if 3D printed plastics (are we still talking recycled on top of that?) were the structural materials you are looking for, which they're not, 3D printing is FAR too slow per machine to be cost effective for major components at 1M/yr rates. You also just upped the size requirements for your factory, and all of the associated costs, by an order of magnitude.

Could be. Or maybe we could have a massive amount of standard speed printers ;-) on the assembly line?

That's exactly what I meant when I said your factory now needs to be an order of magnitude bigger. At 1M/yr, assuming 24/7/365 with zero downtime and zero disruption (ROFL), you need to be outputting 1 of each and every component every 31.5 seconds. Even a best case fantasy-land scenario, you're talking easily more than 1,000 appropriately sized 3D printers, and everything to support their operation, per significantly sized component. The bigger the component, the larger and fasterand (and much more expensive) each of those 1,000+ printers dedicated to that particular component needs to be to maintain rate. This epically fails at both goals of cheapest possible and highest possible rates.

Nobody in their right mind would consider 3d printing anything used on a product being manufactured in those quantities.

In reply to frenchyd :

Your logic is falling very close to this:

"If an infinite number of monkeys were put in a room with an infinite number of typewriters for an infinite amount of time they would eventually reproduce all the works of Shakespeare."

Untrue. Here's where that logic breaks down..

It fails to recognize that an infinite number of monkeys would repeat the same mistakes an infinite number of times.

There are 104 keys on a U.S. typewriter. That means that your odds of getting the first letter right are stacked against you 103:1. The second letter is also against you 103:1. All the way to the end.

The infinite monkeys would repeat the errors an infinite number of times. They would never finish a single work of Shakespeare.

An infinite number of 3D printers and an infinite number of robots in an infinite amount of space with an infinite amount of time and an infinite amount of free materials and an infinite capital investment budget would never complete a million low cost cars. They would never complete a single car.

Your problem is not a math problem. It's a monkey problem.

Off topic, but: I don't think you are properly grasping infinity.

An infinite number of monkeys would repeat the same errors an infinite number of times. Yes. They would also produce all the works of Shakespeare.

No matter how improbably an event is, if it is greater than zero, multiply it by infinity and it will happen.

SV reX said:In reply to frenchyd :

Your logic is falling very close to this:

"If an infinite number of monkeys were put in a room with an infinite number of typewriters for an infinite amount of time they would eventually reproduce all the works of Shakespeare."

Untrue. Here's where that logic breaks down..

It fails to recognize that an infinite number of monkeys would repeat the same mistakes an infinite number of times.

There are 104 keys on a U.S. typewriter. That means that your odds of getting the first letter right are stacked against you 103:1. The second letter is also against you 103:1. All the way to the end.

The infinite monkeys would repeat the errors an infinite number of times. They would never finish a single work of Shakespeare.

An infinite number of 3D printers and an infinite number of robots in an infinite amount of space with an infinite amount of time and an infinite amount of free materials and an infinite capital investment budget would never complete a million low cost cars. They would never complete a single car.

Your problem is not a math problem. It's a monkey problem.

By your calculation nobody ever wins those lottery's. Because every lottery starts out with odds 324 million to one.

Frenchy, I know of a modern auto manufacturing plant for your car in California once Ellen Muskrat moves his production to Texas. ![]()

In reply to frenchyd :

1.37 million last year. And there are some very interesting production optimization tweaks going on, check out how the Gigapress cars are different. The Gigapress is almost the exact opposite of a 3D printed part.

In reply to frenchyd :

Incorrect. Because there is a guaranteed payout to SOMEONE.

There is not a guaranteed completion to the monkey problem. It's just that everyone thinks there is.

SV reX said:There is not a guaranteed completion to the monkey problem. It's just that everyone thinks there is.

There is because of the statement about infinities. If you have a finite set of states, then running the monkey-on-keyboard process for an infinite amount of time guarantees that every state will be visited. In fact, it guarantees that every state will be visited infinitely many times. Infinity is not an intuitive concept. It's not just "a really big number", it is not actually a number at all.

That's all a digression from the real point though, there are no infinities in car production. Well, aside from the Nissan versions, that is. :)

In reply to codrus (Forum Supporter) :

I didn't say it was exact. I said the logic was getting close (similarly nonsensical)

Keith Tanner said:In reply to frenchyd :

1.37 million last year. And there are some very interesting production optimization tweaks going on, check out how the Gigapress cars are different. The Gigapress is almost the exact opposite of a 3D printed part.

I stand corrected, but not all at one plant in California did he?

I'd really like to understand how the Gigapress works. I'll have to Google that.

Thank you.

In reply to SV reX :

Every once in a while I'll break down and buy a lottery ticket.

Then for a few days I'm like Schrödinger's Cat. Not a winner not a loser.

frenchyd said:Keith Tanner said:In reply to frenchyd :

1.37 million last year. And there are some very interesting production optimization tweaks going on, check out how the Gigapress cars are different. The Gigapress is almost the exact opposite of a 3D printed part.

I stand corrected, but not all at one plant in California did he?

I'd really like to understand how the Gigapress works. I'll have to Google that.

Thank you.

Single factory was not stated as a requirement. But the Fremont Tesla factory makes more vehicles than any other single plant in the US, so it's hard to throw too much shade. Note that this article is a year out of date, I don't how if the Texas plant compares.

https://electrek.co/2022/01/24/tesla-operates-most-productive-car-factory-us/

Gigapress short version. As you might expect from the name, they're the biggest die presses in the world. The exact opposite of painstakingly extruding parts one little wiggle at a time. Wham bam half a car.

Currently, Tesla uses 6000-ton Giga Presses (in Texas) to build the front and rear chassis of the Model Y as single pieces. Using the Giga Press has allowed Tesla to decrease the parts that make up the rear body of the Model Y from 120 to 1.

This enables Tesla to eliminate several welding robots from the production line, decrease the footprint of the factory, and decrease manufacturing time, complexity, and assembly errors.

Having a single-piece rear body as opposed to 120 also makes the Mode Y lighter, stiffer, and simply an overall better product but at a cheaper price.

So, always wanting to be a car designer and engineer, I had to look up "body panels on a Tesla". Here is a Tesla Model 3 body material diagram. How do you attach an aluminum structural chassis assembly to a steel one? I also don't see any Memory Metal anywhere, so just how great can they be? And my favorite pet peeve, why is the rear quarter panel of every metal car ever built a welded on hard to replace structural piece of the unit body? Shouldn't there be a structural sub panel with a finished fender just attached to the sub structure with screws just like the front fenders? ![]()

In reply to VolvoHeretic :

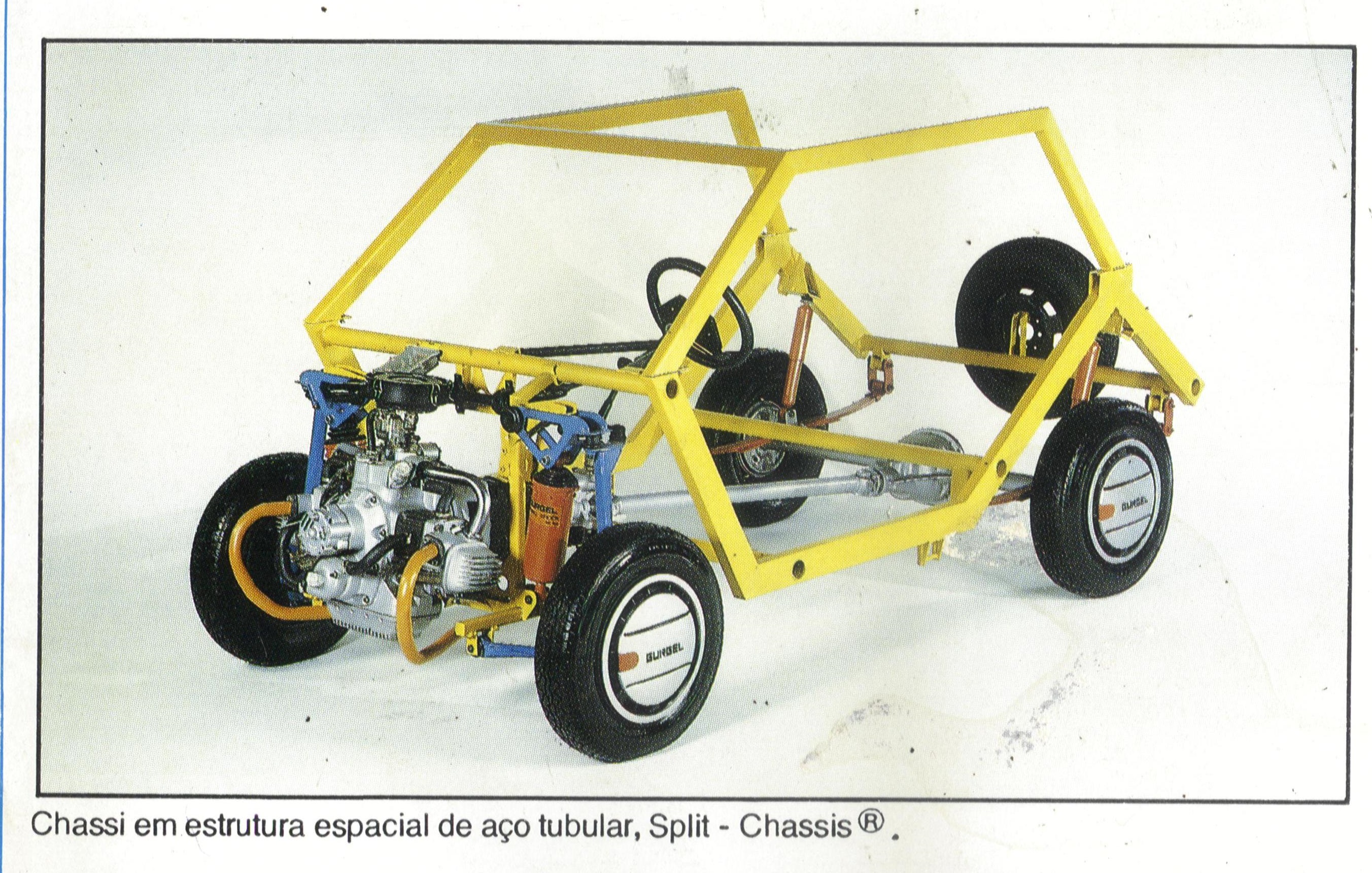

Here's another brightly painted chassis for nonsense-comparison, Gurgel BR-800, "more than 3k" were mfg'd in Brazil from 1988-91. This was the prototype design for the chassis. The front suspension is interesting with extension spring-struts. Triangulation is overrated?

And this was the production version, b/c ROPS (roll-over protection structure) is overrated.

You'll need to log in to post.