Blunder

New Reader

5/12/22 4:01 p.m.

There is some shallow pitting. None of the pitted areas seem to be in important areas. Just around the bolt hole and a recessed area that isn't open to the engine. The engine this is going on is N/A if it makes a difference but I suppose it may see a power adder eventually. In case it matters this an explorer intake for a mustang.

That's more than fine. Use a decent Felpro gasket and forget about it. I've seen a bunch of them where I have had to rebuild the pits with JB Weld and a sanding block. You're miles better than that.

Agreed.

I wouldn't think twice about it, if that is the worst area.

Blunder

New Reader

5/12/22 4:16 p.m.

Thanks for the fast replies. That's just what I wanted to hear! Felpro was what I had in mind for gaskets.

Coming from a world where "new" means "after 1970" I can safely say you're all good. You should have seen the intake I put on a Nailhead a few years ago.

Use a good Fel-Pro or similar gasket set with the blue silicone-ish perimeter seals. On the water passages, use a super-thin skim of black RTV. When I say super thin, I mean super thin, as in the gasket should look like you rubbed it with water. Ok, maybe a little thicker than that, but you should be able to see the blue through the RTV. I take a little between my thumb and middle finger and rub it on like I'm cleaning my glasses. There should be enough to be a bit smeary, but not enough that you have excess. This is also one case where you don't want RTV squishing out of the seams since you can't clean it off the inside of the water ports. On the intake ports, don't use a single thing. First, because they don't need it, and secondly, the constant fluttering of vacuum pulses will slowly work the soft RTV back and forth and it can fail.

You probably also know this, but the end "china wall" gaskets they include in the kit fit best when thrown in the trash. There is no real way to predict how any given combo will end up sitting on the block. Heads or block could have been milled, different machining on the intake, core shift in any casting, etc. The chances that the end wall gaskets will fit and seal properly are slim. They also have nothing holding them in place and they can blow/slip out over time. 1/4" bead of black RTV instead.

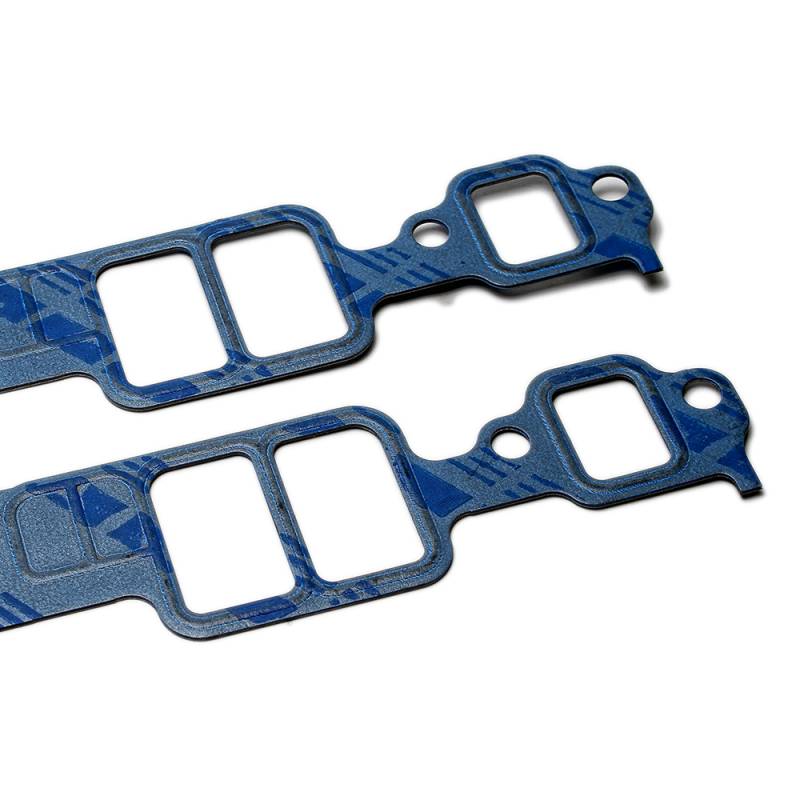

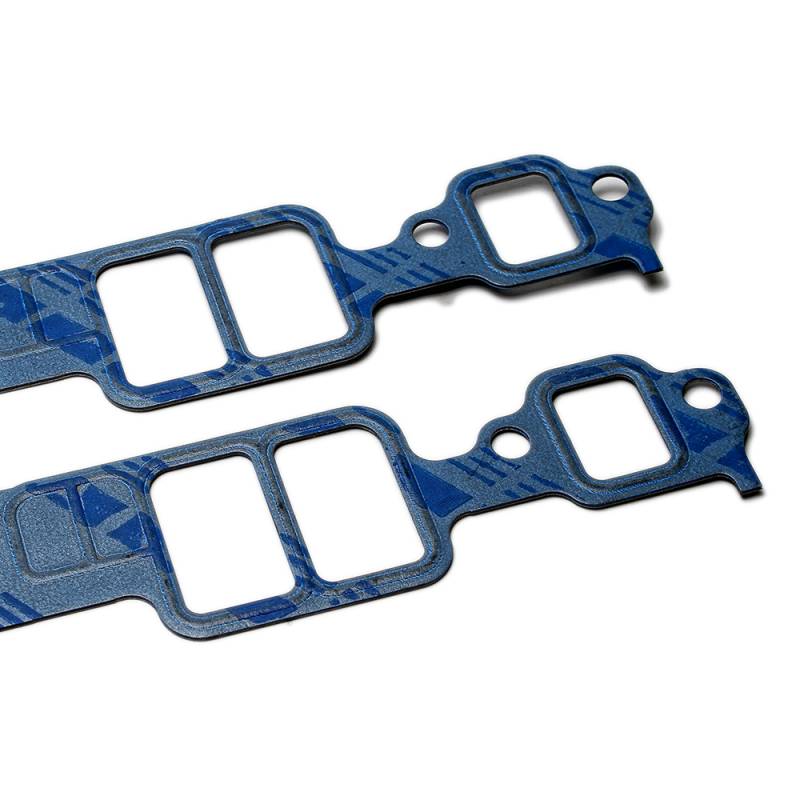

Gaskets should look like this (not exactly that shape, but note the blue seal around ports):

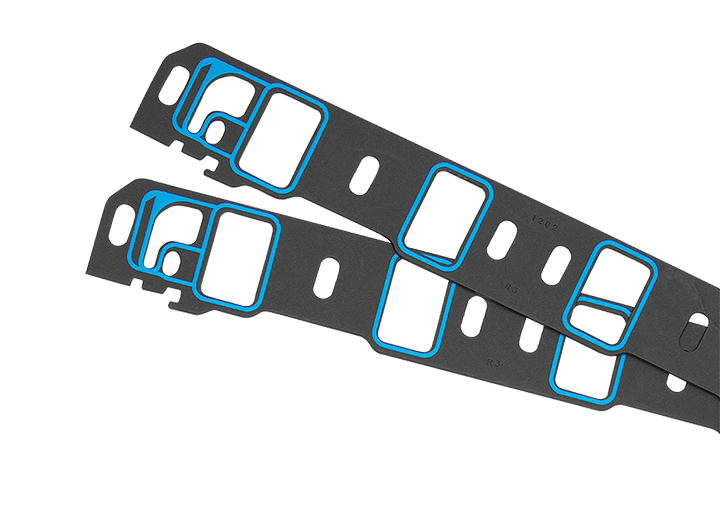

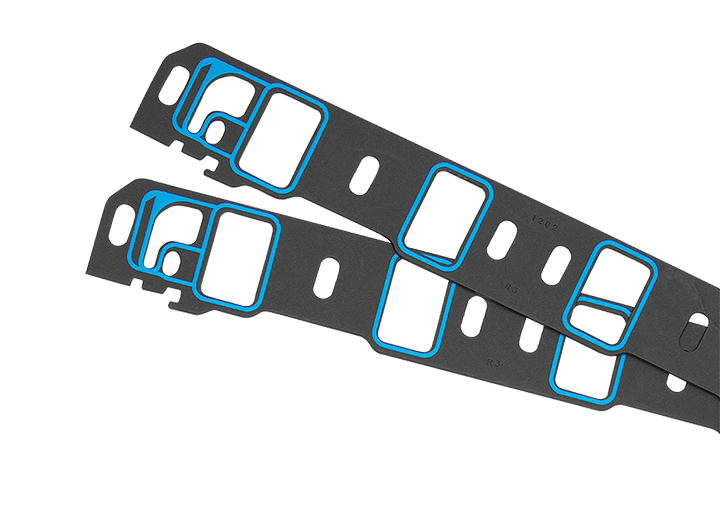

These below are also fine. They are a tried-and-true "printoseal" design... but it's tech from the 70s. Great gaskets, but not as good as the above.