Keith Tanner said:

The most important thing is support. Get an ECU that can be tuned by someone who knows what they're doing. This doesn't mean a forum full of 300 people that have each tuned one car, you need one guy who has tuned 300. There is no substitute for that depth of knowledge.

THIS..........

If I may... you keep going back and saying you are worried this will get out of hand...... and keeping this grassroots.... For now, get it going with the stock ECU. Future mods are always there if you want them.... but you want this up and running... so I'd recommend "stage 1" to go with the OEM.

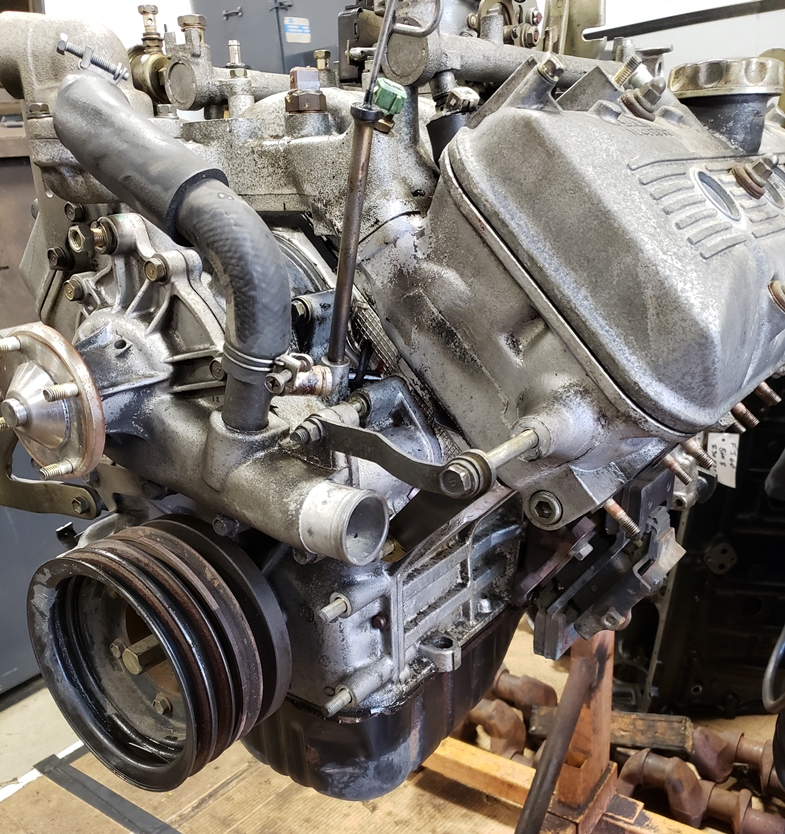

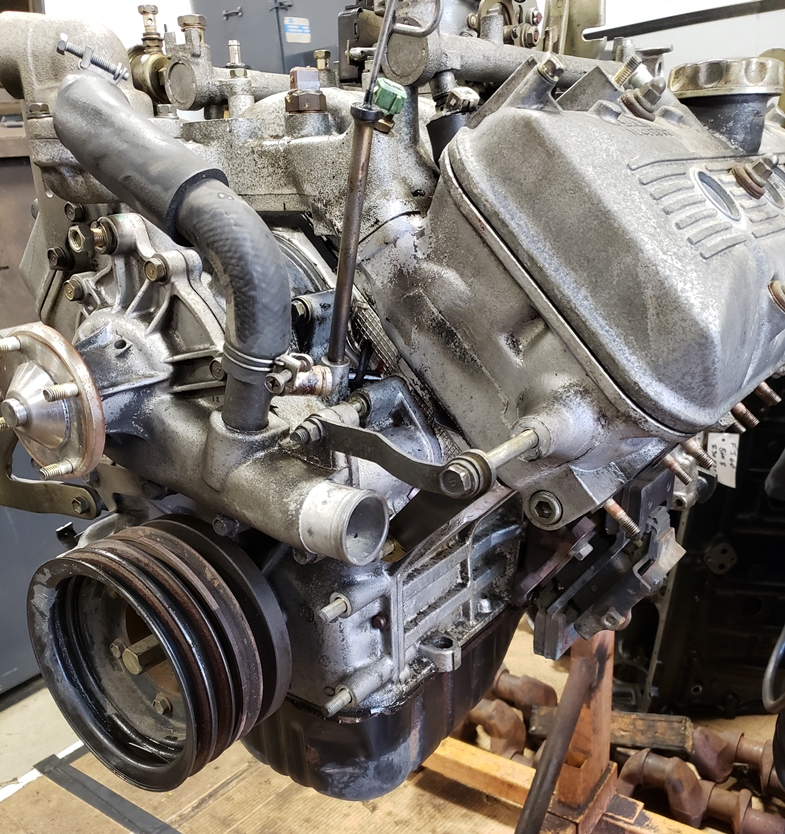

I am glad this thread came up.... as I also am in need of a tuning solution, and while I'm not worried about complex tuning issues like turbos, I AM worried about what system to use as I have a rather unique lump to modernize, and I am slightly hand-cuffed (shattered distributor - made of unicorn horn)

In my case I'm talking about my Japanese Hemi... the 5V-EU. At least it originally came EFI

The shattered distributor is on its way to becoming a cam sensor. As you can see there are also other sensors - I might be able to re-use them once their parameters are known, or at a minimum sensor locations so I can get sensors to match the EFI. Currently there is not a crank pick up - that will need to be made. With a broken distributor, I do believe I've found a way to fire the plugs - 1ZZ COPs appear to fit

I have been shopping tuners, and I have not yet chosen one....... From my POV... this isn't a grassroots project, I'm expecting to pay for quality.

If you already have a cam trigger and aren't too worried about spark scatter a 12-1 or 24-1 or miata/4g cas on the distributor drive tends to work nicely. Bit cleaner than a missing tooth crank wheel +1 on the cam but it really depends on which engine.

We remote tune around the globe as long as we can work out time zones. Current project is an ITB fitted 3.3L 911 in Scotland .. datalogs go a long way these days.

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

The most fun I had was implementing a cam fired EDIS system. Used a 72-2 trigger wheel on the end of the cam shaft adn then used modified pickups from a FC RX7. Worked great. Then later went to batch fired EFI and it worked like a charm. All based on a cam sensor and intake manifold pressure. Everyone wants sequential EFI and the ability to control each individual injector but for 99.9% of the builds a wast spark ignition and batch fire injection will work just fine. Simple is always better with home brew engin management.

Honsch

New Reader

7/28/20 11:32 a.m.

If you really want to go grassroots, get a Speeduino.

I put one in the race car a couple of months ago and I'm quite happy with it.

dean1484 said:

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Specifically - knowing where the cam is allows for sequential injection and ignition. If you only know where the crank is you have to run batch because you can't tell the difference between suck and squish or bang and blow.

dean1484 said:

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Not sure if either of these apply to the motor above, but timing belts stretch at high revs so a crank sensor can be worth having even if you've got a high-res cam sensor. Also for any motor with some kind of variable cam phase timing you need both as well.

Keith Tanner said:

dean1484 said:

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Specifically - knowing where the cam is allows for sequential injection and ignition. If you only know where the crank is you have to run batch because you can't tell the difference between suck and squish or bang and blow.

To do that effectively, you need an accurate crank location. BTW, a 72-2 tooth wheel on the cam/distributor is just a 36-1 tooth wheel- telling you where the crank is, and where the cam is +-360 crank deg.

One needs the high tooth count to know specifically where you are WRT the crank angle, you need one tone on the cam to know what stroke you are on.

ZackM

New Reader

7/28/20 12:42 p.m.

This is a great thread.

Here is my viewpoint as someone who owns a shop and deals with EMS on a daily basis. The MS3 is a very powerful ECU, and can do nearly anything you want to do, provided you are willing to put in the time to make it work correctly.

What we see time and time again is people installing this ecu, and either partially getting it going or tuned, and then giving up and bringing it to a shop like ours. We are fully capable of getting it running, but when you are paying 100/hr to get the wiring cleaned up and 200/hr for tuning...your $750 dollar ecu isn't much of a bargain anymore. In fact, I have adopted the policy that if it doesn't already at least start, I won't even schedule tuning time for the car. 90% of the time the car won't make the dyno without a day or more worth the messing around.

I call it plug and play vs. plug and play around for 10 days.

The best thing said on this thread so far is this, FIND A TUNER YOU ARE COMFORTABLE TRUSTING WITH YOUR CAR, AND BUY WHAT THEY RECOMMEND. ANY, modern system can accomplish nearly anything you want provided that the tuner can make it work. The difference here is how fast they can make it work. You are paying for time.

For us, the LINK and Haltech systems are the way to go. They plug into most cars, fire first try, and we can tune them quickly. Most of the time the total invoice for one of those out the door actually ends up being less than the Megasquirt by the time all the features are added and programmed.

Just my .02...

Zack

alfadriver (Forum Supporter) said:

Keith Tanner said:

dean1484 said:

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Specifically - knowing where the cam is allows for sequential injection and ignition. If you only know where the crank is you have to run batch because you can't tell the difference between suck and squish or bang and blow.

To do that effectively, you need an accurate crank location. BTW, a 72-2 tooth wheel on the cam/distributor is just a 36-1 tooth wheel- telling you where the crank is, and where the cam is +-360 crank deg.

One needs the high tooth count to know specifically where you are WRT the crank angle, you need one tone on the cam to know what stroke you are on.

plan is to add one... pick up mount seems pretty evident in this photo, it had been a mount for a large bracket but will no longer be used

I'm thinking of adding the toothed wheel either at the back of the pulley, or possible in front of the damper section, but behind the pulley drive section

alfadriver (Forum Supporter) said:

Keith Tanner said:

dean1484 said:

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Specifically - knowing where the cam is allows for sequential injection and ignition. If you only know where the crank is you have to run batch because you can't tell the difference between suck and squish or bang and blow.

To do that effectively, you need an accurate crank location. BTW, a 72-2 tooth wheel on the cam/distributor is just a 36-1 tooth wheel- telling you where the crank is, and where the cam is +-360 crank deg.

One needs the high tooth count to know specifically where you are WRT the crank angle, you need one tone on the cam to know what stroke you are on.

A 1993-97 Miata will run sequential injection with just a four-tooth cam signal. It's waste spark so batch ignition, but it can be done there as well. Higher resolution on the crank is nice for sure, but you can do it effectively with less information.

Keith Tanner said:

dean1484 said:

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Specifically - knowing where the cam is allows for sequential injection and ignition. If you only know where the crank is you have to run batch because you can't tell the difference between suck and squish or bang and blow.

Luckily sequential injection and ignition tends to only help with idle quality. VVT and similar is another critical use.

Depending on the application you can find variable returns on your investment on the amount of time and money you spend on your EFI solution.

Converting an old mechanical fuel injection or carb solution to bank-fired EFI via MegaSquirt? You'll see some noticeable gains in drivability and perhaps a little power from the simplification of the intake path and the ability to more closely fine tune the charge mixture. My old 924 typically sees around 12hp gain from simply dropping the air flap and fine tuning the charge. On an engine originally rated for 95-110hp that's quite a bit.

Converting an original implementation of Bosch or similar batch fired injection? Not as much gain, but again you'll have control over the mixture and you can move away from expensive or sometimes difficult to find OE parts. An example would be a friend's Ferrari 328 with the Bosch semi-mechanical fuel injection. $1200 to rebuild the ECU or convert to an aftermarket EFI solution? That was a tough choice, made easier when the rebuild wasn't a guarantee to solve the original problem.

Trying to convert a more modern sequential injection solution gets more and more tricky depending on the application and the implementation of your EFI also is more complex. The gains tend to be much, much smaller as by then the OE's were getting quite good at wringing the most out of their solutions while keeping it emissions legal and survive the expected lifespan.

Adding forced induction to any of those? This is where aftermarket EFI can provide large gains, but you are playing with a lit stick of dynamite in some cases, so you have to be certain of not only your installation and sensors, but also of your safety net.

All of the EFI systems essentially work the same. The ECU receives data from the sensors of what is happening in and around the engine. It uses this data to look at a table or a series of tables to determine when and how long to fire the injectors and coil(s). The values in the tables are what your or the tuner adjust. If you control things other than fuel and/or ignition, then you'll need tables for those as well. Cooling fans, turbocharger wastegate solenoids, VVT solenoid, etc. The part that causes the most confusion is the fact that terms used between systems can not line up completely

Keith Tanner said:

alfadriver (Forum Supporter) said:

Keith Tanner said:

dean1484 said:

In reply to oldeskewltoy :

With a cam sensor you don't need a crank sensor. With a crank sensor you sometimes need a cam sensor. It depends on the specific type of system you are implementing.

Specifically - knowing where the cam is allows for sequential injection and ignition. If you only know where the crank is you have to run batch because you can't tell the difference between suck and squish or bang and blow.

To do that effectively, you need an accurate crank location. BTW, a 72-2 tooth wheel on the cam/distributor is just a 36-1 tooth wheel- telling you where the crank is, and where the cam is +-360 crank deg.

One needs the high tooth count to know specifically where you are WRT the crank angle, you need one tone on the cam to know what stroke you are on.

A 1993-97 Miata will run sequential injection with just a four-tooth cam signal. It's waste spark so batch ignition, but it can be done there as well. Higher resolution on the crank is nice for sure, but you can do it effectively with less information.

You were talking SEFI- which does require a high tone wheel count (at least 15 deg crank deg) and a cam position to be really effective.

Yea, a simple batch fire system can do things with less info, but that doesn't need to be all that accurate, too.

SEFI? You mean sequential injection, as used in the 1993-97 Miata?

In reply to Keith Tanner :

Are the 4 teeth even? If they are, you still don't know the stroke, so it's guessing sefi. Which means even if the injectors are independent, they are batch fired or on the wrong stroke sometimes.

alfadriver (Forum Supporter) said:

In reply to Keith Tanner :

Are the 4 teeth even? If they are, you still don't know the stroke, so it's guessing sefi.

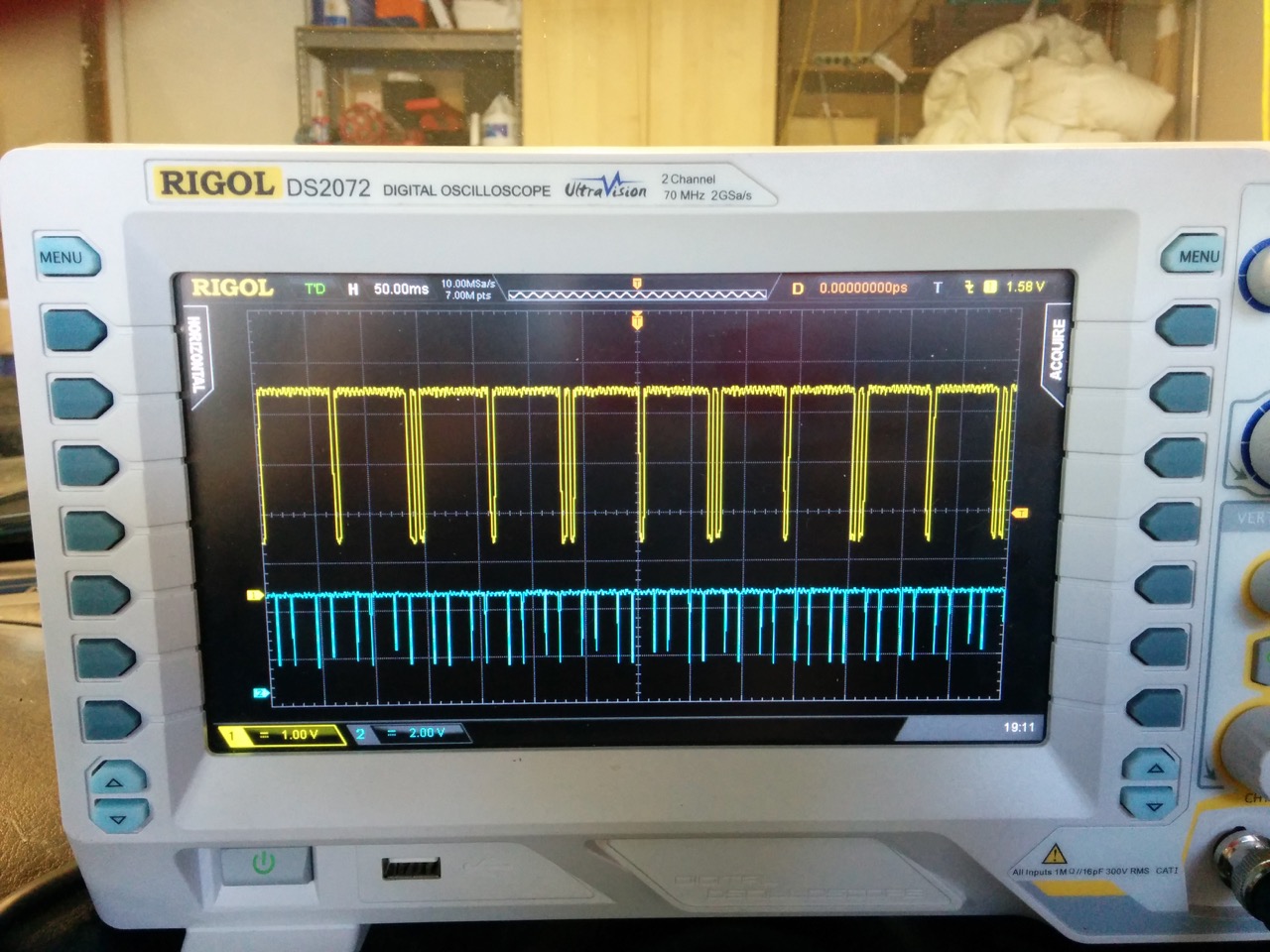

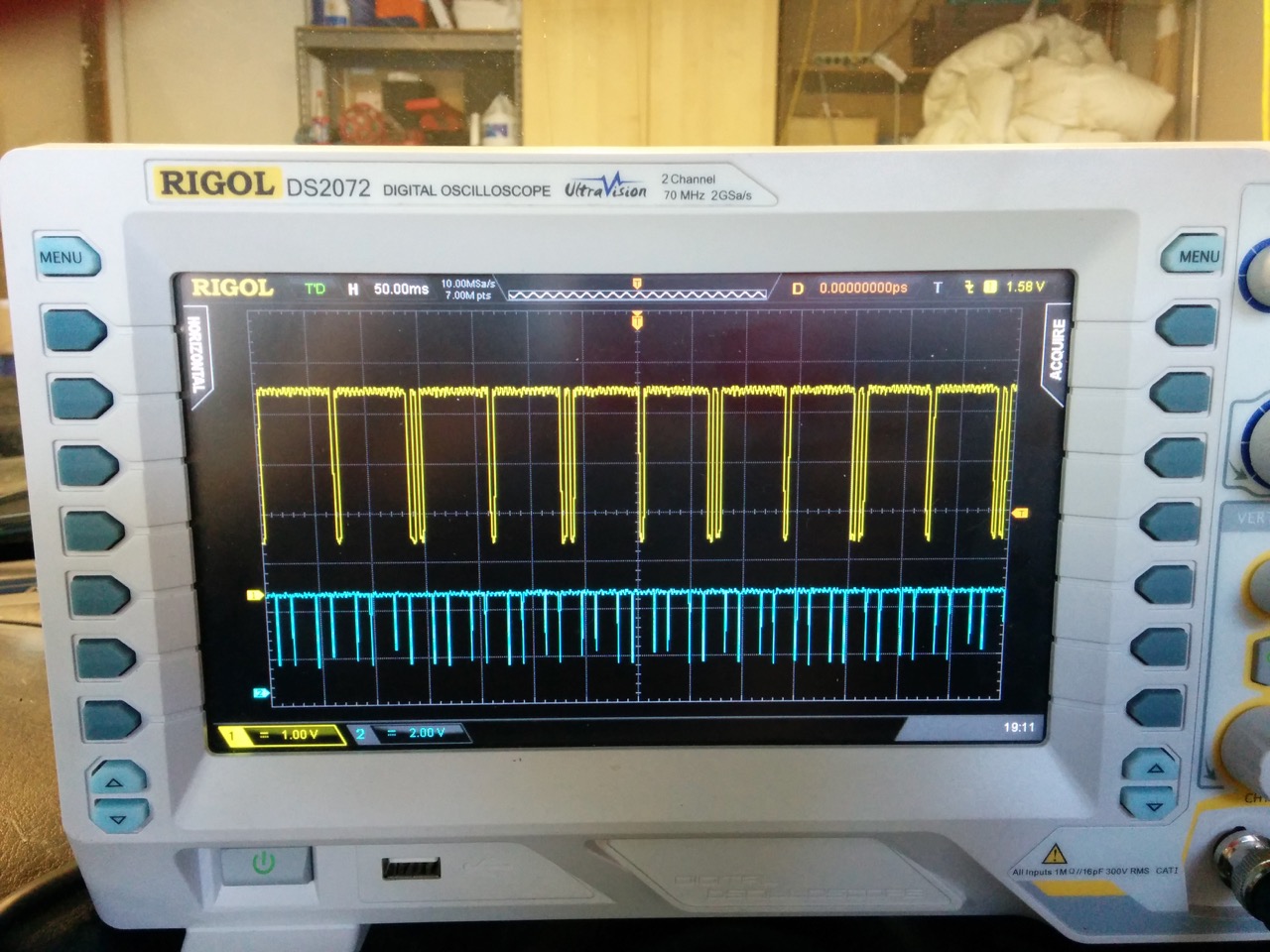

There's four equally spaced teeth and a second sensor reading two irregular teeth. Here's a diagram of the disc they used.

The spark accuracy isn't nearly as accurate as with a 36-1 crank trigger like most Fords used, but it's enough to get cylinder ID and run basic sequential injection.

In reply to MadScientistMatt :

That's not a 4 tooth cam wheel, that's a 2 tooth crank wheel (the 4 evenly spaced even teeth) + 2 tooth cam wheel put together. For sure, that's two different sensors looking at that.

Guilty of oversimplification. There are two signals, and Matt is more familiar with the fine details of them. But it's still just a fairly crude cam signal, so I'm sticking by that! ;)

alfadriver (Forum Supporter) said:

You were talking SEFI- which does require a high tone wheel count (at least 15 deg crank deg) and a cam position to be really effective.

Yea, a simple batch fire system can do things with less info, but that doesn't need to be all that accurate, too.

Even NB Miatas don't run 24 tooth wheels. 4 teeth on the crank (unequally spaced) plus 3 on the cam (so that you get 1 tooth in one phase and 2 teeth in the other). Does sequential injection just fine, either with OEM or megasquirt.

(10 crank revolutions in that image)

In reply to codrus (Forum Supporter) :

That's still two sensors. Not one.

But it is interesting. You can run things much closer to limits when you have more precision in the timing. That's giving away performance to keep it safe.

Ditto on the two sensors. Ditto ditto?

I have yet to see a cam triggered engine do anything really stupid even at very high power levels. As long as the drift is repeatable, which it usually is with rpm, it can easily be dealt with.

alfadriver (Forum Supporter) said:

That's still two sensors. Not one.

So? That doesn't make it a 15-degree wheel. :) All the timing is driven off the four teeth on the crank wheel, the sensor on the cam is just there so it knows whether TDC is for #1 or #4.

In principle you can use a single sensor on the cam with twice as many teeth on it as the crank has and correct for the belt stretch based on RPM like Paul mentioned. AIUI this isn't good enough for doing proper misfire detection, though, and that's why OEMs use crank sensors instead. Mazda used the diagram above for all the 1.6 cars (90-93) and the first couple years of 1.8 (94-95), but midway through 95 they needed to add OBD2 with misfire detection, and they added a crank trigger just for that (different pattern from the NB cars though).

I suspect it's also easier/cheaper to get the proper resolution on the crank because the pulley is larger.

In reply to codrus (Forum Supporter) :

Which is to say that the small # tooth tone wheel wasn't really effective.... Good enough for some things, but it needed to be better. Having one tone signal every 180 deg makes it very hard to know exactly where you are to be agressive on spark- which matters on many levels.

Having the crank timing on the crank also lets it be a larger diameter- which improves the signal strength thanks to the higher velocity.

Why they were doing that so late in the decade? No idea- Ford had been doing 36-1 toothed wheels since the early 90's.

codrus (Forum Supporter) said:

In principle you can use a single sensor on the cam with twice as many teeth on it as the crank has and correct for the belt stretch based on RPM like Paul mentioned.

unless you have one missing tooth on that wheel, you can't do sefi. The crank has a missing tooth once every revolution so you know where TDC is, the cam has one every revoluition to tell you if that's compression or exhaust TDC. And knowing both is required to do SEFI.

alfadriver (Forum Supporter) said:

codrus (Forum Supporter) said:

In principle you can use a single sensor on the cam with twice as many teeth on it as the crank has and correct for the belt stretch based on RPM like Paul mentioned.

unless you have one missing tooth on that wheel, you can't do sefi. The crank has a missing tooth once every revolution so you know where TDC is, the cam has one every revoluition to tell you if that's compression or exhaust TDC. And knowing both is required to do SEFI.

You can't do it with all equally-spaced teeth, that's correct. A missing tooth is the most obvious way to make a pattern for finding TDC, but you can also do it using other patterns. One advantage to having multiple teeth unequally spaced is that (with some clever software) it's possible to reduce the minimum time necessary to sync so you don't need as much cranking before the engine fires up. Of the various computers I've used on my Miata, the Hydra required 2 full crank revolutions before it would sync and fire, the MS3 does it in 1, and the OEM ECU usually manages to fire on the very first compression stroke.

Paul_VR6 (Forum Supporter) said:

Ditto on the two sensors. Ditto ditto?

I have yet to see a cam triggered engine do anything really stupid even at very high power levels. As long as the drift is repeatable, which it usually is with rpm, it can easily be dealt with.

I ran the cam triggered system on my 924s for more than 170k miles with no issues with belt stretch or loosing resolution at high speeds. In fact by making the change the timing was more accurate and consistent as compared to the OE set up with a cap and rotor. I also gained multi spark under 2400 rpm from the edis resulting in a much better running car under the curve. Modern timing belts really don't stretch. If they did the OE manufacturers would have issues with it and they don't. I see this as an old wife's tale probably left over from way back in the day. I would have more concern with a gear driven distributor than a belt driven cam. Also a chain driven cam that then turns a gear driven distributor to me would be the setup that would have the most amount of slop and yet this setup works just fine. In many cars.

People get to warped up in these kinds of things. Unless you are running a motor to the absolute limits where a random quarter of a degree of timing will cause your motor to grenade you don't need the precision that people will tell you that you need. Most of those telling you that you need to run multi point injection and batch fire sucks are just wrong. Those that say wast spark sucks and you should be running coil on plug are also wrong. Apply the KISS principal to stand alone engin management and you will always be happier in the end.

my 72-2 on the cam was exactly like a 36-1 on the crank but it was so much easier to fab up and install versus trying to add a trigger wheel to the crank and to mount a sensor down there. I had visions of coil on plugs and separate injector drivers for each injector. Then you look at the wiring needed and the cost of all the components and I came back to earth. Instead of four coils I needed one. Instead of fabbing up four brackets for the coils I re used the coil bracket from the ford contour that I got the coil from. Instead of having to fab up a special wiring harness I used the factor one for the injectors. I even used the factory harness from the countor between the edis modul and the coil and the sensor. I Just added spade connectors for easy replacement. There were countless other little reasons why keeping it simple saved a bunch of other little things that were then eliminated. It really can be a trickledown type situation where every feature you add will exponentially increase the number of thing you need to do to get it running. Oh then there is the tuning. If you add all these features and possible variables in to the system the tuning gets that more complicated.

Getting back to my 72-2 on the cam. To my knowledge I was the first to do it on a stand alone. This was back in 2007 I think maybe 08? It was also really a "let's see if we can make it work" experiment and it ended up working very well. In fact the system is still in my 924s that I offered for sale here a while back. I think I passed on what I learned to Mat at DIY back then as it was a cool experiment. Mat may remember better when it was.