Isn't one of the biggest killers of turbo engines.. shutting them off HOT? Doesn't start/stop technology (for fuel efficiency) break this cardinal rule?

to further muddy the topic.. is purchasing a used Turbo unnecessarily risky? Because I love the idea of a used explorer sport but I don't need another money pit. What can you do in the used market to avoid a buying a thrashed turbski?

The killer is when you shut them off HOT not shutting them off HOT.

What kills them is shutting them off like that and the oil cooking in the bearings. Start/Stop tech in a normal driving situation would keep the flow going fairly normally I would think.

Do they run electric oil pumps or something?

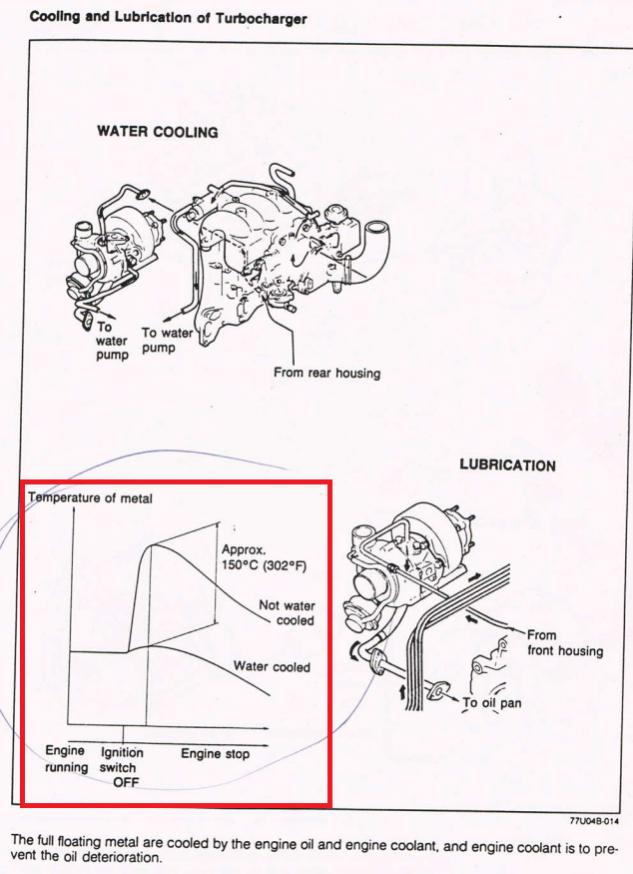

IIRC, that was more of a problem back before water cooled turbos were common. These days I wouldn't worry about it. Oil has gotten better, turbos have gotten better, and cooling systems have gotten better.

OHSCrifle said:

Isn't one of the biggest killers of turbo engines.. shutting them off HOT?

Not since manufacturers started using water jacketed turbos in the 1980s.

Non cooled turbos will get up over 600F in the center housing after shutoff. Ain't no engine oil going to survive that. Water cooled turbos stick right around coolant temp, the coolant will self circulate by thermosiphon.

If the car is factory turbo, you can usually get stock turbos cheap. I have had many turbo cars, and usually find the turbo itself to very rarely be an issue.

In addition to all of the water cooled comments- all modern turbos have natural cooling built into it- so there's water flowing even when the pump is not.

The bigger issue is turning off the oil supply while the turbo is still spinning at high speed. FWIW, I always turn off the auto start-stop.

Which is why the car manufacturers use their computers to monitor a number of things before the auto stop/start engages.

I know on my FoRS, the engine has to be up to temp and the outside needs to be above 50F, the battery voltage needs to be above a certain point, etc.

So they aren't just killing the motor for the hell of it and the turbo/engine does have a bit of residual oil pressure, so it's not as bad as you think.

In reply to OHSCrifle :

When I was searching for good used junkyard turbo's I'd give the blades a spin. Where it stopped I'd mark with a magic marker on the blade and housing.

spin again mark. Spin again mark, a few more spins and as long as the turbo stopped randomly I knew it was good.

By the way more new turbo's failed that simple test than used ones. Not sure what that is saying except maybe usage is good for machinery?

Newer turbos can be ball bearing turbos, but if you want to base this on random rotational inertia?

The true test with journal bearing turbos is to check the side to side play against the spec from the manufacturer. Garret, Mitsubishi, KKK among others manufacturer turbos for OEMs and they all have different specs for their turbos.

triumph7 said:

The bigger issue is turning off the oil supply while the turbo is still spinning at high speed.

If the engine is idlng, the turbo isn't spinning at high speed.

Hell, if the engine ISN'T idling, I'd guess that it takes about as much time for the turbo to stop as it does for oil pressure to bleed away. I've never really checked either, but turbos don't just keep spinning for minutes when there's no exhaust gases to drive them.

In reply to OHSCrifle :

To your original question, if you're worried about the exploder sport, why not just buy one of the zillions of similar vehicles out there? It's not like the exploder is the only CUV.

In reply to frenchyd :

Spinning a dry new turbo can do that. If they have sat on shelf for too long usually there isn't enough oil in the thrust bearings to make up the tolerance and the wheels rub on the end housings.

So one of my jobs, years ago, was working for holset. Part of my job as a product engineer was to review customer returns in the lab and perform tear downs of field returns and also (lots of ands) do testing to identify new failure modes.

I've seen some really coked up turbos. To get them really coked up you'll have to shut them down hot. Very hot. Usually saw this from guys running equipment hard as hell when the engine castatrophically fails. Then you're removing the shaft and wheel with a hammer and looking at scores up siezed sleeve bearings.

rolling element bearings are more tolerant.

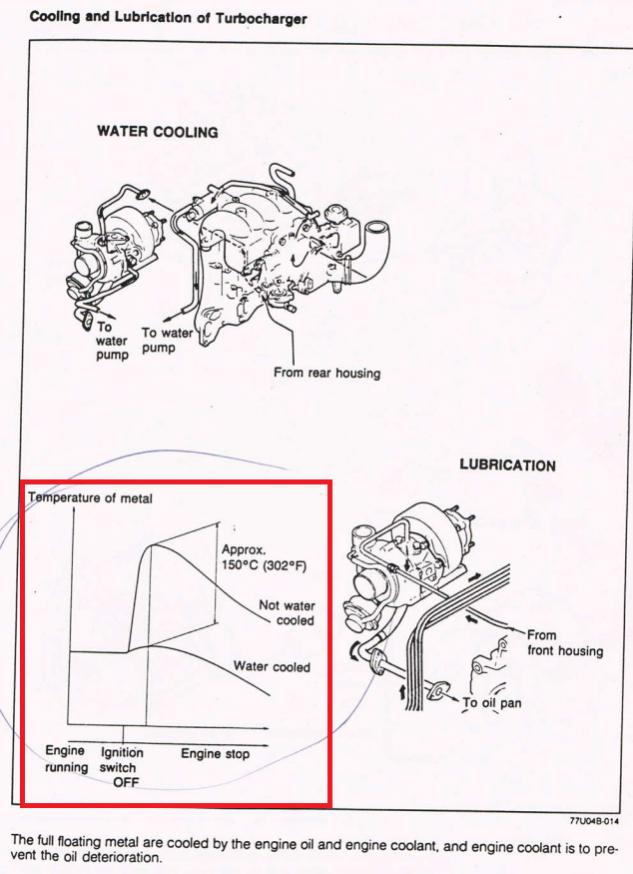

synthitic oil, not shutting it down super hot and just keeping the oil topped up( low oil levels will Kill them faster). That's what you need.

tldr, if it's a conventional turbo without any variable nozzle stuff and a ball bearing one. I'm not worried at all. If it's a sleeve bearing I'd just want to keep the oil topped up.

if you want to test a used turbo put an indicator on the snout of the shaft perpendicular to the main axis of the shaft and measure side play. Ensure the bearings have some oil in them to ensure tolerances.

In reply to Fueled by Caffeine :

Heh... I remember stories of equipment operators holding contests to see how long they could get the turbo to choo-choo-choo after shutdown...

In reply to Pete. (l33t FS) :

The dealer used to send those turbos back to us in a plastic tub. In pieces and ask for warranty.

that's a nope.

Fueled by Caffeine said:

In reply to frenchyd :

Spinning a dry new turbo can do that. If they have sat on shelf for too long usually there isn't enough oil in the thrust bearings to make up the tolerance and the wheels rub on the end housings.

That makes sense but then some of the used turbo's I rejected could have simply sat on the shelf too long. My Saab parts guy had stuff sitting around for decades. I still see the car every once in a while doing smoky burnouts. And that car was built 25 years ago from a 1975 Jag.

It is easy to manage not to have oil cooked in a turbo.

I ran dino oil in my 88 Fiero turbo. First rule - idle it down a bit after a hard acceleration run before shutting off. Second rule - as extra insurance use a 'Turbo-saver' (made by Accusump). It is basically a fire extinguisher that hold a quart of oil, connected to the upstream side of the oil supply to the turbo. It is mounted with the connection down and when you turn the engine on the oil pressure fills the canister part way up.

When you shut down, that oil, still under whatever pressure the oil pump developed, drains out from pressure through a small orifice through the turbo bearing for several minutes after shut down, cooling the bearing down. Very simple, fairly cheap and very effective.

https://treperformance.com/i-133430-canton-accusump-turbo-after-oiler.html

84FSP

UltraDork

9/8/20 1:33 p.m.

I was just going to mention an aftercooler but that is even simpler.

If you are worried about it, you can turn off stop-start every time you start the car.

But knowing the requirements to allow for the shut down, it's not something I worry about. Let alone the actual use vs. what people envision as the extreme that would cause problem. By the time it would allow it to shut down, the turbo is barely even spinning, and there's still water moving through it.

Or just use a water cooled turbo.

Looking for and failing to find the graph Chrysler engineers made during the development of the 2.2/2.5 turbo engines.

I do not know about most turbo cars. I do know the Abarth 500 has a pump that runs if the turbo is above a certain temperature threshold when you shut it down.