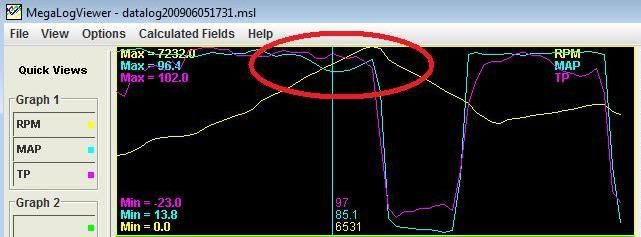

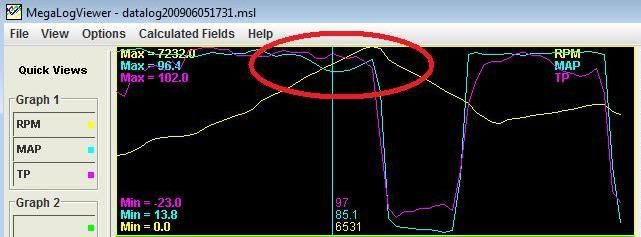

What kinds of things can cause a "dip" in the MAP readings in a specific narrow range of RPM (6000-7000), such as shown below? Map at this altitude is 94.5kPa-ish. The engine runs fine, and I don't think I "feel" this dip, but it's odd.

What kinds of things can cause a "dip" in the MAP readings in a specific narrow range of RPM (6000-7000), such as shown below? Map at this altitude is 94.5kPa-ish. The engine runs fine, and I don't think I "feel" this dip, but it's odd.

Was this on a dyno, or at speed? I'd suspect something somewhere in the intake path is flexing or collapsing at max airflow. Or other aero forces at work (if at speed).

Carter

At speed, but it does not depend on road speed, strictly rpm.

Intake is GSXR600 ITB's on a steel intake manifold with brand new K&N filters on a 4AGE locost.

First, is this a custom intake? If so where is the MAP sensor? Is it on or near a corner or turning section in the intake or in a 'dead spot' for flow? If so you could be in a recirculation zone or separation zone during high flow which simply means the MAP sensor location isn't optimum.

Second, erohslc may be onto something, you could have an issue w/your intake not feeding enough air at higher rpms leading to a venturi effect which would require redesign or the intake track, or some sort of induction to help offset the upstream pressure loss. By your numbers you're looking at a 7% pressure loss in only the highest RPM range. Dyno time would tell you if you're really loosing alot of power up top.

If it's not causing you any major problems though, I wouldn't worry about it...

I'm using the existing ports in the GSXR ITB's for the MAP sensor.

The ITBs taper down slightly - the trumpets continue the same taper. The runners are straight, 1-3/4" exhaust tube - the same area as the original big port blue top 4AGE two runners combined.

I tried trumpets that were 1-1/2" shorter, just to see, but It's still there.

I've tried with the MAP disconnected, and the engine running Alpha-N, and when I get MegaLogViewer to calculate horsepower, it calculates a drop right there, that follows the drop in MAP.

Maybe I have more intake than the engine can actually draw in? Maybe the moving column of air is bouncing off the closed intake valve and heading back out the runner?

It's a stock bluetop 4AGE, stock cams and compression.

can you put a vacuum gauge on and tell me what the reading is, right before the dip, at the dip and after the dip?

Could be a resonance pulse fighting you. Whats the distance from the back of the valve to the end of the trumpet?

I experienced something similar with a Turbo II RX-7 intake manifold. Except, instead of a dip, it was a steady increase in vacuum.

The same exact throttle body on a different intake manifold nets atmospheric pressure all the way out to "Cripes, it was time to shift three minutes ago" so it can't be a restrictive throttle body. My theory is that on the old intake, the manifold pressure source was in a runner, while on the new one the source is on a plenum, so maybe there was some high speed airflow vacuum generation thing happening.

You can thank B&G for more then just MS now..

Bowling's Intake Runner Computator Computation Results:

Your 6400rpm dip is almost exactly between the 3rd and 4th harmonic pulses.

If you tune to constant AFR do you get a VE dip there too? If you tune to a constant VE across there does it go a little rich? If either of those are true, it's most likely resonance.

If not, move the vac port to a dead spot on the manifold, make sure there's little flow across the inside of the port that could pull vacuum on the open end.

Thank you so much for all your help on this. I appreciate it very much.

I used the B&G calculator as well as a few others on line to calculate my runner lengths. I looked for consistency between the calculation results.

I have it tuned for a constant AFR throughout the entire WOT rpm range. The VE table increases as the MAP dips (which I guess tells me the engine wants to go lean). Based on this, I am sure if I set the VE tables all the same, it will go lean through the MAP dip (based on what's happening already).

Should I try that? Think that might be it? Maybe the runners are too large a diameter...... I matched the runner area with the two runners of the TVIS intake, I thought it would have been reasonable....

If I disconnect the MAP sensor (I'm tuning Alpha-N), and have MegaLogViewer calculate horsepower (based strictly on fuel consumption, my guess), there is also a horsepower dip where the MAP shows a dip. Bah.

If your tuned VE for constant afr doesn't follow the same curve as the MAP dip, it's more likely an effect caused by where you're pulling vacuum. I would try moving the vac source for the MAP sensor to somewhere else and checking again for that phenomena.

Not sure if it will help you or not, but here's what my 20 valve does:

It goes to atmo at about half throttle and stays there. Makes tuning with MAP a biatch. Here's the motor:

The "cow bells" are still inside the air box. Perhaps you could do something similar, that is, add a velocity stack to the end of the throttle bodies. That's what the cow bells are, near as I can tell. Something to change the effective length of the intake.

Paul_VR6 wrote: If your tuned VE for constant afr doesn't follow the same curve as the MAP dip, it's more likely an effect caused by where you're pulling vacuum. I would try moving the vac source for the MAP sensor to somewhere else and checking again for that phenomena.

Just so I'm following you, if the VE tables are NOT following the MAP sensor (basically, my MAP is decreasing, but the VE tables are increasing), then the issue could be a fictitious measurement one (move the MAP port(s) and see what happens).

Cool. I may try that. Thank you.

(.... waiting for my Wilwood master to come in so I can drive it.)

You'll need to log in to post.