You have to go to a pick and pull. Be sure to drop them in the mud before going to the cashier.

Someone strips all the LS coils and Toyota COPs out of all the yards locally before i can get to them. Also been trying to find a set in the yards for almost 2 years now. ![]()

I guess we just have more trucks that have been rolled in the snow or just rusted to pieces up in NE.

The EDIS coil and box is cheep enough at the pick and pull. I get them for less than $20. I usually pull 3-4 of them and put it all in a pile and carry it to the counter. They look at it as a pile of wires and just sell it to me for a lot less than if I brought them a single coil and a single EDIS box. Make a trigger wheel from a 72 tooth spur gear (McMaster car sells them for cheep) and remove 2 teeth 180 out from each other (-2) and affix it to where the rotor was on the distributor. You have to use a 72-2 if you are going to mount the trigger wheel to the distributor and or the cam instead of the 36 -1 that is used when mounting to the crank. Then just mount a sensor from a RX7 crank / speed/position sensor on the distributor housing (I would gladly give Dan one as I have 4-5 of them laying around) This is the exact setup I used on my 924s. Has been dead reliable for at least 6 years and close to 120K miles.

I have LS Coils, just never planned on using them just yet. You can have those offered Ben. What mods would I need to adapt to coil over plug???

How much of an increase in Duration & decrease in Dwell should I try?

The coil is effectively saturated on the datalog I looked at. The MS is managing it proportionally with spark duration. Your max spark duration is pretty low. You can try reducing dwell and increasing spark duration. It appears that acceleration dwell addition is active too, probably because of your slightly choppy RPM signal. So, there's another 1ms added.

dansxr2 wrote: I have LS Coils, just never planned on using them just yet. You can have those offered Ben. What mods would I need to adapt to coil over plug???

You can't run COP on these motors.

Well... i shouldn't say "can't."

But i will say that i wouldn't attempt it.

That i don't know.

I'd guess more like... 40, though. These are like BPs. Total timing whores.

Dan, you have the maps from Matt's car, you should be able to look at them and find out.

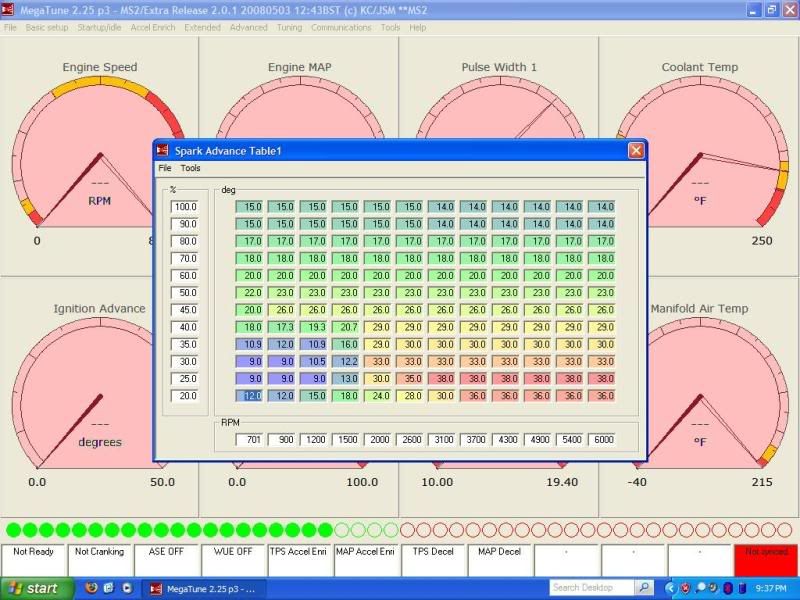

I'm not entirely sure how much this helps, i don't understand the up and down units, myself, but here's this one. This car made 350whp/458wtq.

Also worth mentioning that his car had a stutter you could see in the dyno pull around 4000-4500rpms as well. AND that someone else in his thread mentioned that they had the same thing on Megasquirt.

Here's the thread. Video is on the first page, you can see the stutter on the in-car pull. Comment near top of 2nd page mentions the same stutter on their car.

http://www.mx6.com/forums/1g-mx6-forced-induction/228923-f2t-hp-torque-record-broken.html

I believe this map to be pretty conservative.

Ben I don't get some of this either... I was under the assumption that the Vertical Scale was Fuel Load (which I thought was the same as the MAP reading) and the Horizontal Scale is RPM. what is the % mean of Fuel Load?

Looks somewhat similar i suppose. This is ASSuming that his map is scaled similar, though he would have had to have had a map up to 290ish kpa minimum with the boost he was running.

dansxr2 wrote: Ben I don't get some of this either... I was under the assumption that the Vertical Scale was Fuel Load (which I thought was the same as the MAP reading) and the Horizontal Scale is RPM. what is the % mean of Fuel Load?

Yeah i don't know what his scale was. Doesn't make much sense to me.

Swank Force One wrote:dansxr2 wrote: Ben I don't get some of this either... I was under the assumption that the Vertical Scale was Fuel Load (which I thought was the same as the MAP reading) and the Horizontal Scale is RPM. what is the % mean of Fuel Load?Yeah i don't know what his scale was. Doesn't make much sense to me.

X2

Well, don't let the map trick you into being 100% sure your actual timing out at the motor is not berked somehow. If engine management KNEW something was wrong it would tell you what is was.

If im reading that map right timing at 15psi and 4500 should be 25? Now to figure out what it's ACTUALLY doing.

25ish, yes.... What i don't really like just looking at it is how sharply it starts to drop off under more boost.

Dan, is this Matt's map? I'm guessing that if it is, it's the map from his old VF hybrid?

Well i think he sent two... one for the VF hybrid and one for the huge Holset.

That's gotta be the VF, the Holset had maps to 32psi or something.

Fuel load is the way that TunerStudio interprets the load cells. If you are running Speed Density (MAP only) the fuel load is equal to the MAP reading. If you are running alpha-n (TPS) then this is scaled by how much you put your foot down. If you run a blend, or ITB mode the fuel load is a proportional representation of MAP and TPS loads and whatever weighting or switchpoints you are using.

I'm just running Speed Density. I'll do a new datalog on my way to work and post it up... so your prognosis is timing / setting related, not mechanical?

dansxr2 wrote: How much of an increase in Duration & decrease in Dwell should I try? The coil is effectively saturated on the datalog I looked at. The MS is managing it proportionally with spark duration. Your max spark duration is pretty low. You can try reducing dwell and increasing spark duration. It appears that acceleration dwell addition is active too, probably because of your slightly choppy RPM signal. So, there's another 1ms added.

Well, remember what you paid for this advice!

Based on this:

http://www.msextra.com/doc/ms2extra/MS2-Extra_Gen_Ignition.htm#moreign

I would suggest removing 2ms of dwell (acceleration compensation seems to add 1ms right back), and add 1ms to spark duration.

So, max dwell of 3ish ms, and max spark duration of 1.7ms. This is assuming you still have a smallish plug gap.

But before you do that, can you verify that the rotor is pointing at the cap pin of cylinder 1 when the engine is at about 25deg BTDC? My reasoning here is that your car probably runs at 25deg + or - 15degrees under pretty much all conditions, so there should be a good rotor alignment if it's centered at 25deg.

I'm gonna try this this evening... The detailed info on how to set timing to -0* is also revelent as well. I'll post what I find.

You'll need to log in to post.