Woody wrote:

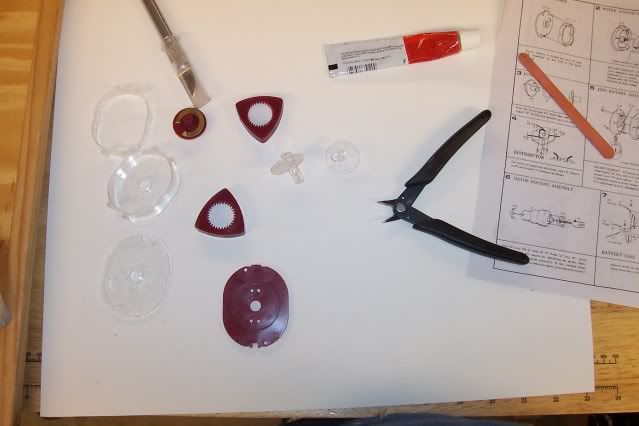

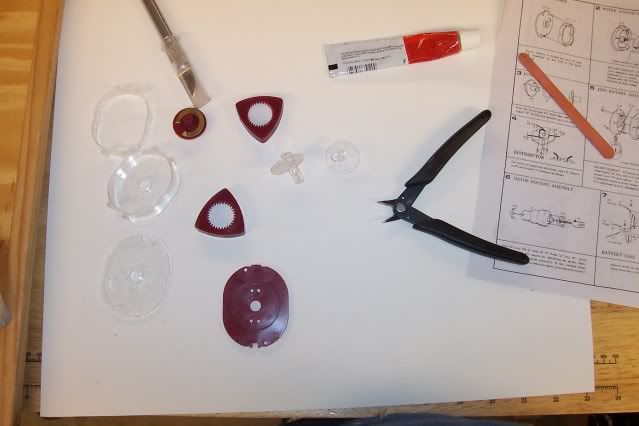

I've run into my first snag, as it seems that my ten year old tube of model glue is no longer working as originally intended. Hopefully, I can still purchase a replacement for this poison without a permit.

I'm an hour into this project and already, I have been able to do what I do best, which is to shower obsessive levels of detail upon tiny parts that few people will ever notice.

Small rotating parts have been chucked into a drill and turned to ensure that they are perfectly round, except, you know, the eccentric stuff.

(plastic model guy mode on)

Ditch the Testors. You're doing some great stuff cleaning up the parts, don't ruin them by using "old school" adhesives. That's the kind of crap that made all the model cars we built as kids look like lumps of bad welding. I can't find any link to the chemical content (googling gives me nothing but 340,572,345 places that want to sell me Testors cement) but old "model cements" like T's stuff actually works by melting the plastic of both pieces to be joined, and letting the pieces fuse together as it dries. Not so good if you want to preserve the details you've carved into the "smaller parts" you've mentioned. I did use it, but kind of like a filler to make the big gaps between the parts solid enough to lay & sand filler putty on a bodywork conversion I was doing. Think of it as "welding". You don't always want to weld pieces together..sometimes you just want to "assemble" them.

For regular assembly, I use CA.

http://en.wikipedia.org/wiki/Cyanoacrylate

Yeah, what's popularly known as "Super Glue". The stuff was originally invented to bond skin on wounds, so you really don't want to get it on your hands. Honestly, it doesn't have much resistance to shear..but I've never worried about how much shear my little model cars will suffer while on their display bases on the shelf.

Only probs I've had with CA:

1.) The stuff binds so quickly that you need to have the parts lined up perfectly the first time. Wasn't a problem for me when I was 30, but now that I'm chasing 50, my hands shake like the San Anrdreas Fault. OTOH, since there's so little shear strength, you can usually separate any mis-aligned pieces with a lil' torque in the joint between them using something like an X-Acto knife.

2.) CA's been around for so long now that there are dozens of different "mixtures" for model making. Slow curing for the R/C airplane guys, fast curing for those of us working polystyrene, "fast flowing" for field repairs to flying models (that stuff was really intended for the R/C airplane guys, but I loved the stuff for my flying model rockets), "slow flowing" for construction of the models in the first damn place, etc. etc. Make sure you find the right one for the job you're trying to do. I just damn near screwed up a rare Tamiya 1/12th scale Matra F1 car (I'm converting it from the kit supplied Matra V-12 to the Ford Cosworth powered car Jackie Stewart won the `Ring with in 68) by using one of the "thinner" CA products out there. Stuff didn't bond quickly enough to hold all of those old warped parts together, and was so thin that it ran off of the parts I was trying to glue together. It seemed like half of it ended up on my fingers. Which brings me to...

3.) Have a debonder close at hand.

http://www.supergluecorp.com/zap/zap-z-7-debonder

The great thing about CA is that since it's a largely chemical bond, you can shoot other chemicals at it to break the molecular structure of the bond. Maybe not what you want on your model, but it's exactly what you want when your thumb and index finger are stuck together.

Sorry I got so long-winded, Woody! I'm just getting back into plastic modeling m'self after about 5yrs, and I'm kinda hyped up right now.