I have about a gallon of various blueings, including two different blues specifically designed for aluminum. I went looking around one day and emailed about a dozen companies and they almost all sent me free samples.

A lot of my grandfathers tools are the cadmium and dull metal plated Duro and Proto tools. I'm not comfortable handling the heavy metals any more than I have to so my plan is to tumble them in the cement mixer with an appropriate agent to mechanically and chemically strip the plating, then blue them all and wax them for moisture resistance. It's actually one of the projects that I am most looking forward to.

This is the product I use for metal blackening

Caswell Metal blackening system

Being able to dunk a part into a large bucket of solution is much better for us than swabbing on a bit at a time.

As someone who just got into MyMechanics a few months ago (and all the similar restoration vids) I love this thread and want to see it continue.

I've used gun blue on a handful of jewelry and small metals projects in college but never thought about it for tools until MyMechanics. This thread is pushing me to do some exploration!

Jumper K Balls (Trent) said:

This is the product I use for metal blackening

Caswell Metal blackening system

Being able to dunk a part into a large bucket of solution is much better for us than swabbing on a bit at a time.

When I run out of my little bottle of Super Blue, I may consider that.

Woody said:

Nice job Keith!

I'm a big fan of Evaporust and MetalRescue. I've used Super Blue for gun parts, but never for tools. I'll have to give that a try.

This 1/2" drive Snap-On ratchet belonged to my grandfather. He was, oddly enough, a toolmaker. I'm guessing it's about 80 years old or more. The ratchet sat in an old broken toolbox (which itself should probably be restored) for many years after he died. It would barely turn. Not long ago, I took it apart and cleaned it up. It was probably before I discovered EvapoRust, so I may have given it a dip in an electrolytic bath for a while. I disassembled it, cleaned and greased everything and put it back together.

It may not be my best ratchet, but it's certainly my favorite. I use it every chance I get. My grandfather has been gone for 35 years, but I think of him every time I use it.

Maybe we should have a "Restore your grandfather's old stuff" thread!

I'd love to see this thing get the full treatment - cleaned and polished, leaving the sunken part of the handle as-is or blued.

I recently picked up a couple of old items from my grandparents house (and axe and a hammer), I'm really looking forward to cleaning them up and getting a new life out of them.

ShinnyGroove said:

I have never seen that guy's page before, and now I'm hopelessly addicted. I restored an old Stanley Jack plane a few years ago and it came out pretty great, at least from a functional standpoint. The hardest part was lapping the bottom flat. I've used it for the last 10 years and it's looking pretty beat up again. My work is not nearly as beautiful as his though.

Plus 100 for the Gary P Nunn shirt!

I might have accidentally looked on eBay for some old tools and there might be some coming this way.

In the meantime, I raided my own stash again. This little guy wasn't too rusty or anything, but as you can see it has seen some use. I'm not sure of the provenance of this one.

I decided to tear it down. This little screw holds the adjuster barrel in place and it was not happy about coming out. I had to work it out - turn it one degree, then back, then two degrees, then back, etc. With lubrication and being very careful not to chew up the slot too badly.

Finally.

Yuk.

Time to get to work. The first thing I did was clean up the handle - filing off some casting marks and cleaning up the jaws.

Same with the lower part of the jaw. I'm sure there's a technical name for this.

I also ran a tap and die over the threads, much better. The adjuster barrel also got a bit of attention with a file to clean up the dings.

After the Envirorust bath (not really necessary), blueing and a stainless steel buff, it's time to reassemble. I thought about trying some polishing, but I think this might have been blued from the factory.

And done! I also gave it a light oiling all over to prevent any rust. It doesn't really look much different, but it's more comfortable and the jaw closes properly. Still looks old.

I also had this big old set of pliers that were covered in surface rust. After the bath and some steel wool attention, they were still a little rough. I think they were actually painted black once.

So I tried the media blaster. Ooooo. As you can see, there's a punch getting the same attention. I discovered in the blaster cabinet that these pliers can actually open much further than I thought, I think they've been gummed up for years.

Blued, polished and oiled.

I can't capture this in pictures, but I left these three tools sitting on the workbench as I moved on to other things. And they'd catch my eye every time I walked by. They've got a glow to them, a depth to the sheen that makes me just want to pick them up and use them. Although now I'm thinking I need to take apart that adjustable wrench in the middle and clean up the jaws...

Picked up a new, 100+ year old metal shear today. Hoping to get it on the bench this weekend and see what it's really about!

Gallagher mfg co

Lynn Mass

Any ideas for the inside of a 3 gallon gas can? I've got one that sat half full of old gas for a few years, the top half looks like it has barnacles for lack of a better description.

I think evaporust would work, but need to knock the stalactites of the sides to get a good finish, the only two openings are to small to get access for a blaster...ideas?

Thanks

russde said:

Any ideas for the inside of a 3 gallon gas can? I've got one that sat half full of old gas for a few years, the top half looks like it has barnacles for lack of a better description.

I think evaporust would work, but need to knock the stalactites of the sides to get a good finish, the only two openings are to small to get access for a blaster...ideas?

Thanks

Put in a pint of solvent and a handful or two of abrasive media (the stuff you use in a vibratory tumbler) and have fun shaking?

A handful of bolts and vigorous shaking?

I'm hoping we hear more about that shear.

Electroplating is a pretty sweet technique to protect after clean up

In reply to Keith Tanner :

Still kinda figuring it out. Got a few other projects so this one is a bit on the back-burner, but it was under $100 and too cool not to pick up.

The mount fits a 1.5" hole, so last night I cut a hole in a 2x4 and set it on the bench. The handle looks to be fully original. Moves almost all the way, but the blade doesn't close all the way front to back before hitting the stops. Motion is smooth, but the blades didn't cut through a little bit of 20 gauge steel I had around.

Took a quick wire brush to the area around the letters yesterday, and did more today - it looks like that might be an original, or at least old, green paint under all the dust. The only information I can find on Gallagher MFG Co seems to be related to a smaller metal shear with a different action and a patent of 1881. Crazy.

I'll probably just try to clean it up a little bit, maybe sharpen the blades, and see if it will work on any of the metal I work with. If not, I'll look to pass it on!

So, Woody's Snap-On got me looking at eBay, and a couple of $10 purchases later these arrived. The small one is a 6" long 3/8" drive, the big one is 9" long 1/2" drive.

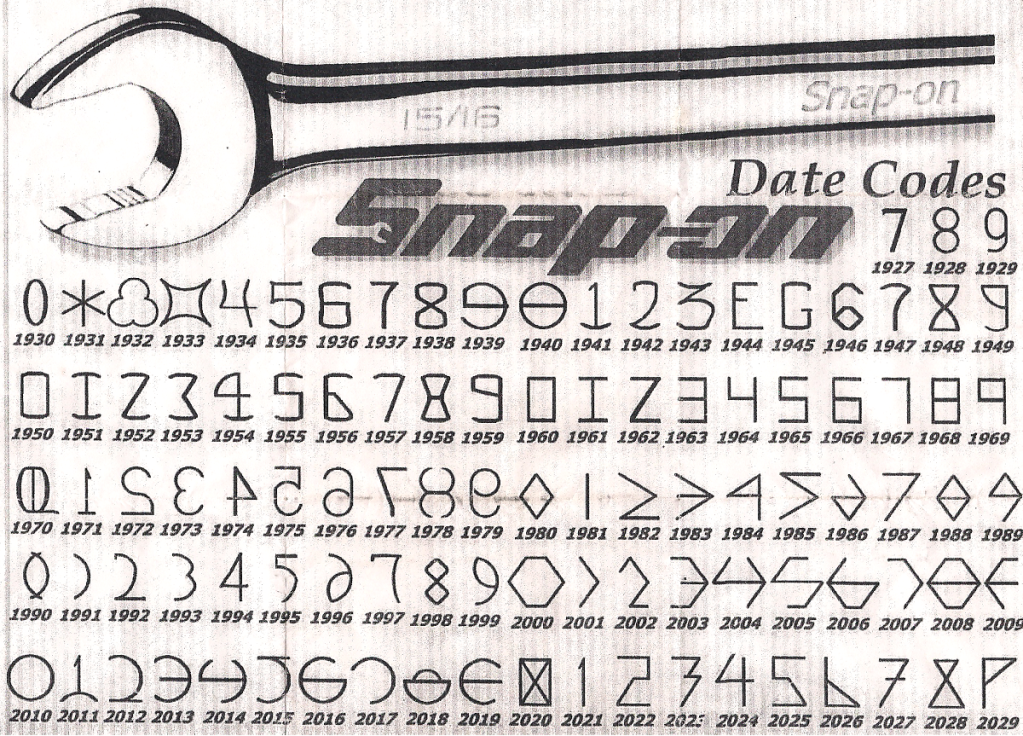

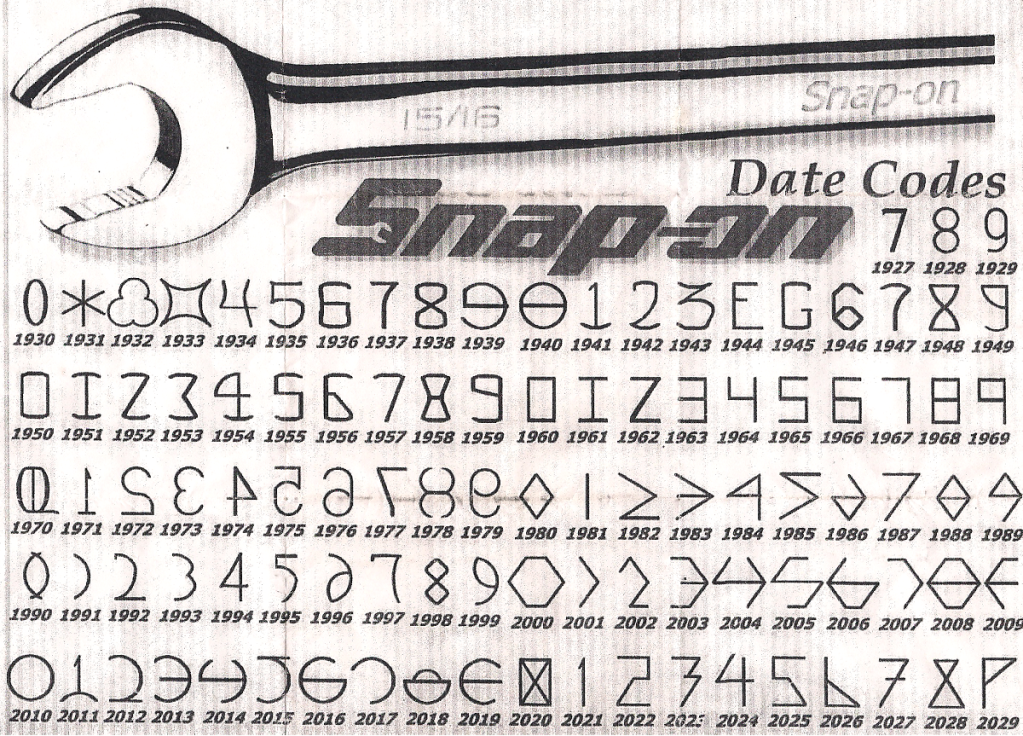

Did you know that you can date most Snap-On tools from a date stamp? That's useful for a 71N because they made them for years. The stamp is between ON and OFF on the selector. Woody, looks like yours is from 1945 if I'm reading it right. Mine big one is 1963. The little one doesn't appear to be stamped.

See the weird little E on the big one? Also, close-up of patina.

These come apart easily with two screws. To get the ratchet out, you need to tap it off with a punch - not yet done here.

Fully disassembled and ready for cleaning.

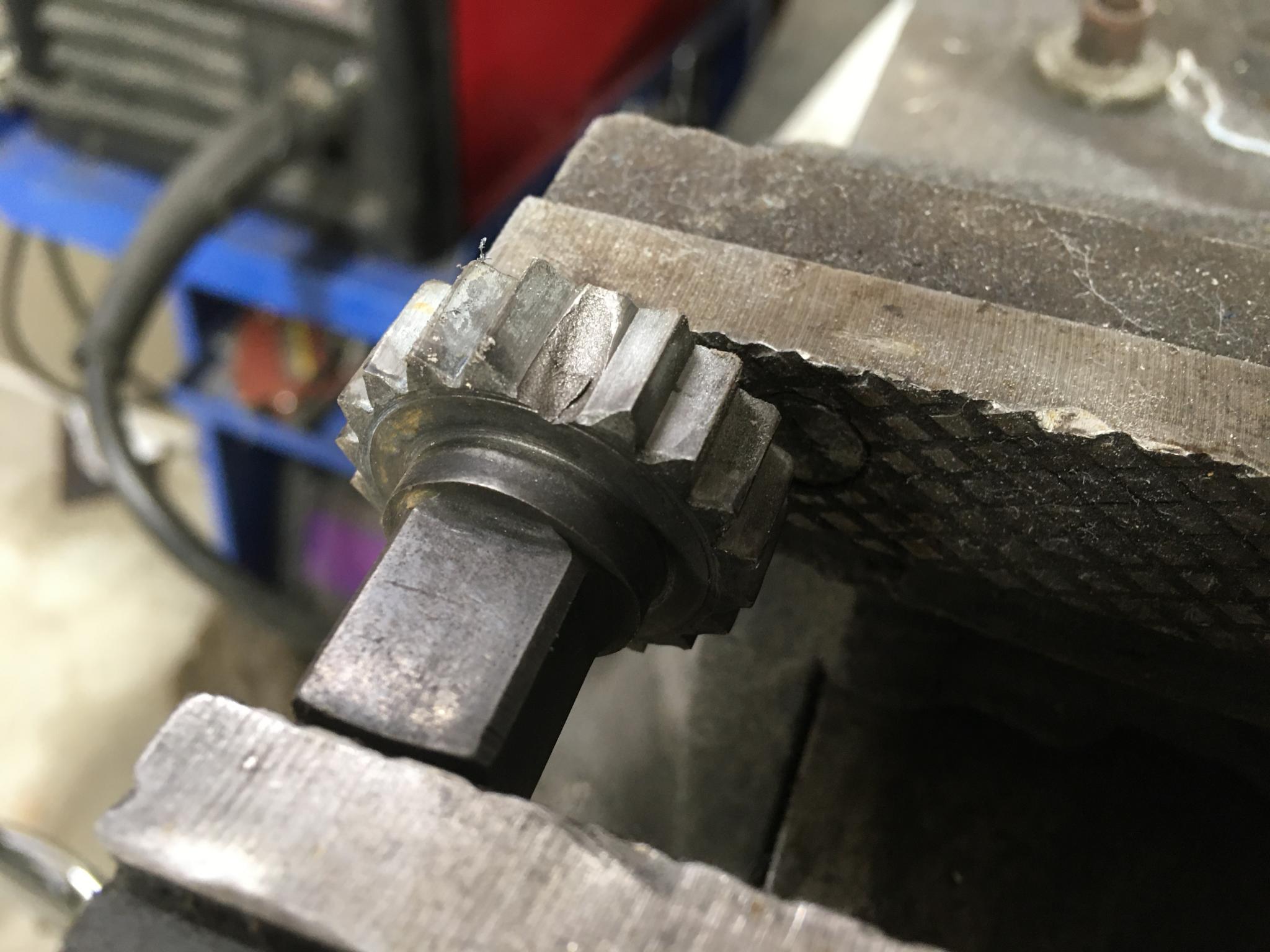

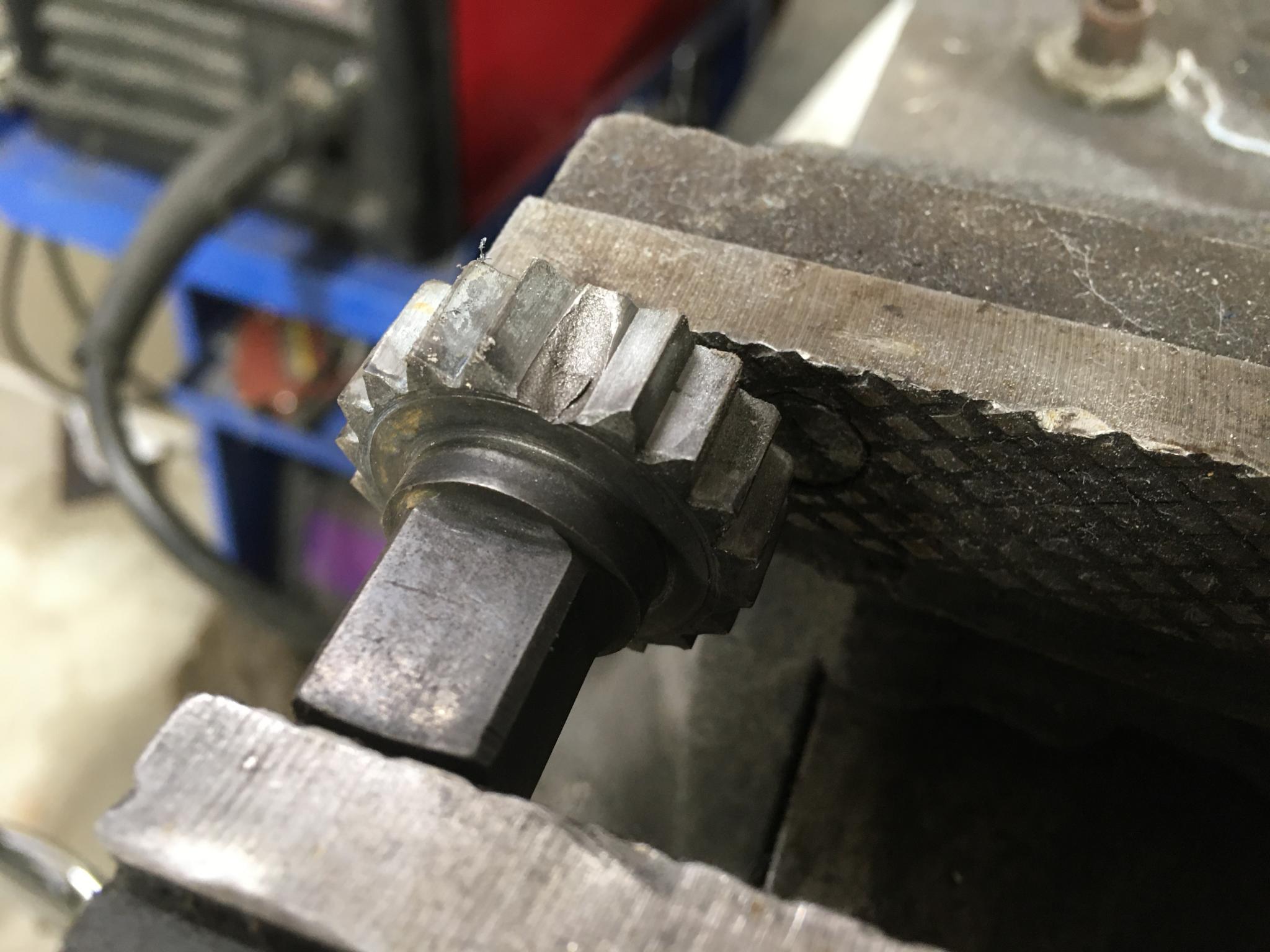

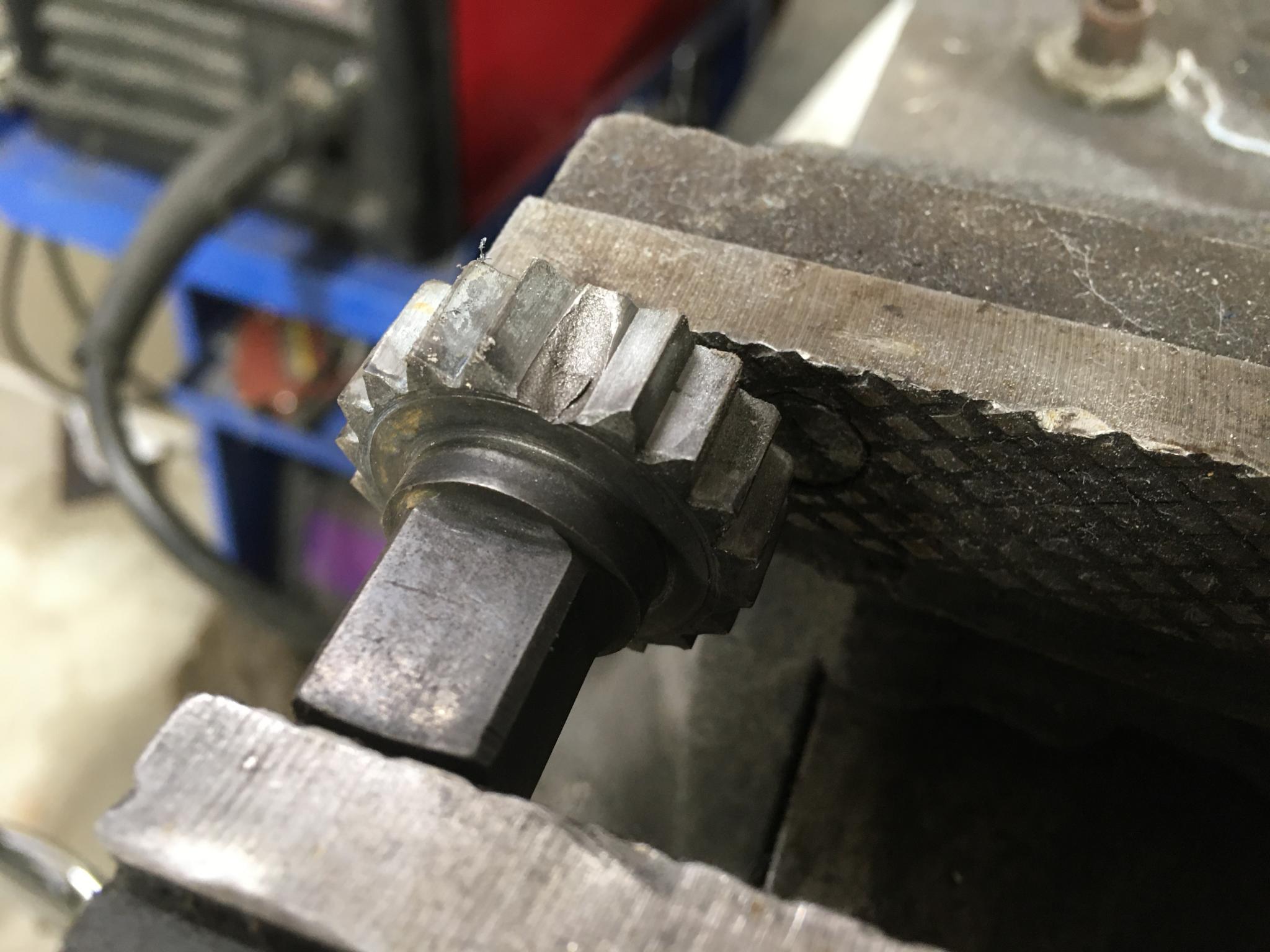

The big one has a problem, though. You can't get rebuild kits for these. It was described as "working", but I guess it would indeed work 95% of the time. I can reassemble as-is, I can find another for parts or I can try to fix this. I'm thinking I can weld some new metal on there and try to shape it. Sounds tedious. But it's not like I NEED a ratchet, I'm doing this for fun...right?

ShawnG

UltimaDork

2/7/20 7:35 p.m.

FYI, the really old Snap-On 1/4" drive isn't 1/4", it's 7mm.

ShawnG said:

FYI, the really old Snap-On 1/4" drive isn't 1/4", it's 7mm.

I never heard that before. There were 7/16" drive ratchets and sockets at one time.

Got the Snap-Ons finished. I decided not to polish the big one. But I did repair the broken tooth. I welded a bead on to the broken area and ground it into shape. It's not a perfect match but it's good enough to work without any noticeable difference from the others.

It may not hold up to as much torque as the original but I'm not going to be putting a cheater bar on this thing. The seller gave me $4 off because of the broken wrench (he swears it was working when he shipped it, ummm, no) so that's a $5 Snap-On ratchet then.

Threw the wrenches in the bead blaster, did a little sanding and reassembled with the Nyogel 767A damping grease that someone else here suggested. They feel great, almost a little too damped but as long as the ratchet ratchets it'll be good. The smaller one had been chrome plated but most has worn off by now. I did a bit of sanding and took off some more, then blued it which gives a real patina'd look. Because of the sanding, the surface is very smooth, almost velvety.

JoeyM

Mod Squad

2/15/20 7:31 p.m.

In reply to Keith Tanner :

I need to try this

RossD

MegaDork

2/15/20 7:44 p.m.

Keith Tanner said:

Got the Snap-Ons finished. I decided not to polish the big one. But I did repair the broken tooth. I welded a bead on to the broken area and ground it into shape. It's not a perfect match but it's good enough to work without any noticeable difference from the others.

It may not hold up to as much torque as the original but I'm not going to be putting a cheater bar on this thing. The seller gave me $4 off because of the broken wrench (he swears it was working when he shipped it, ummm, no) so that's a $5 Snap-On ratchet then.

Threw the wrenches in the bead blaster, did a little sanding and reassembled with the Nyogel 767A damping grease that someone else here suggested. They feel great, almost a little too damped but as long as the ratchet ratchets it'll be good. The smaller one had been chrome plated but most has worn off by now. I did a bit of sanding and took off some more, then blued it which gives a real patina'd look. Because of the sanding, the surface is very smooth, almost velvety.

Those look great. The larger ratchet needs to be in a tool kit in an AMC. Both made in Kenosha!

You could try to heat treat that part you welded. I dont recall what to do but maybe someone else does. (Get it just before red hot with a torch and quench in oil?)

My inner smartass thought this would be a thread about Viagra.

Apexcarver said:

I love evaporust, I did a bunch of my grandfathers tools about 5 years ago.

I wonder what the economics of opening a business of dunking car shells would be... Acid sucks to deal with (neutralize), you NEVER get all the sand out of a unibody after blasting...

Imagine if you could do a spray-gel on rust spots on your car...

I have it on good authority (Speaking to the Evaporust reps at a trade show) that they will indeed sell you a train car full of it.

Just in case you want to explore the economics of it.

They have a 58 Chevy that they treated like that and modified afterward.

Probably the wrong thread, but this thread deserves a bump, so here goes:

I have a Husky 1/2" air impact. Prolly 15 years old. It's beefy, has a nice cast aluminum body. I use it now and then, probably don't oil it as much as I should, etc. etc.

Well, one day it worked. One day a few months later it didn't. I pulled it apart a little, wasn't familiar territory and I wanted to be sure I didn't totally bork it. It will still spin, sometimes, but no torque and it seems to be just spilling air at the vents by the trigger.

Anybody know what's wrong with it? Not a whole lot of hours on it, really.

I searched online for parts, but can't really find this model.

Husky H4103 1/2" Impact Wrench Max. 275 ft. lbs. Torque

Looks exactly like this one:

They're not worth anything. Should I just chuck it in the trash and get another one?