I tried to change the bolt pattern on my Volvo 1800E 40 years ago from 5x4.25" to 5x4.5" by having the lug holes welded up and the new bolt pattern drilled into my steel front hub and solid rear axle flanges. Unfortunately the machine shop couldn't place the holes in an accurate round circle and they had to shave .05" off of the radius (.10" total diameter) of the shoulder style lug nuts to get them to fit. Needless to say, the wheels are super off center and the shaking is awful.

Instead of shipping everything off to DutchmanAxles.com and start over, I was wondering if it would just be easier to get some used or new Ford Mustang bolt on front hubs and machine off everything else except the wheel flange and then machine the center hole to match a new machined lip on the back sides of my Volvo axle and hub to center them? So, mount the Mustang flanges with wheel studs behind the Volvo flanges with the wheel studs poking through.

The holes for the Volvo studs are a giant 5/8" and I don't think that I can get 3" studs that would fit them anyway. The photos of the Volvo axle and hub are non molested stock spares.

If this where a solution, what should the tolerance between the outer hole and the inner flange be for a (snug) fit?

My 2 decimal place HF digital caliper's battery just died so I don't know what the back of the hubs and axles diameter are. The Volvo flanges are something like .35x" thick. It's amazing just how worthless only 2 decimal places are.

Also, these are the front hubs with vented disk brakes that I want to adapt to my control arms and the rear axle out of the Volvo 164 that I already have on the 1800. I think that the 1031 rear axle is basically a Dana 44 axle with it's axle tubes, outer bearing housings, shafts, and press on bearings with a Dana 35 7-5/8" R&P

It already sounds like too much work just talking about it, but after everything is perfect, just tack weld the Mustang flanges to the Volvo hubs and axles?

Kind of a reverse wheel adapter/spacer.

The earlier Volvo 1800 and 122 Amazons were 4.5" bolt pattern and will bolt on your existing hubs.

In reply to tester (Forum Supporter) :

Thanks, I forgot that volvoclearinghouse put vented 240? front disks onto his 1800ES and will have to reread it tonight although I don't remember the wheel bolt pattern. I had always wanted to replace the complete front suspension and crossmember with a 164's but I'm running out of time plus I probably can barely crawl out and get up from under the car anymore.

The bolt on solution in the front is a hub and rotor from a 122s made after 1963, they are 5X4.5 and fit your calipers. The rear is a different problem. I am sure someone in Sweden has done it, but I have not.

In reply to TurnerX19 :

Sounds great, thanks. Anybody know the stud knurl diameter and if ARP sells a 3" or so long one?

Dorman lists one for 1973 140 on up with a knurl diameter of 0.643" which I'm sure fits the newer 1800 with the crappy 4.25" bolt pattern. Also early Dodge Vans.

DormanProducts.com: 1/2-20 Serrated Wheel Stud - .640 In. Knurl, 1-5/8 In. Length

Jegs seems to indicate that their widest stud knurl diameter is .625".

Well, I found a photo showing that someone found some 3" studs that fit in a front Volvo hub. Since he put a Ford 9" rear end in the back I would have to say he has 5x4.5" bolt pattern but I can't say for sure. I will have to dig deeper and maybe try and reach out to the builder. The web page link is from 2007 and of a 1971 1800 with V8 engine.

build pitures summer 2007 Photo Gallery by james richardson at pbase.com

I keep seeing this hub/rotor assembly on the internet, this one form IPD.com. Is it what the early 5x4.5" bolt pattern hub looks like? Is this a two piece unit and if so, how is the rotor held onto the hub?

Well, looks like I would need a 4" wheel stud to make this works. Probably need one even without the Mustang hub. Bummer, the nice thing about the Mustang hub is that it's a wear item and I could get them for free and have the machine work done locally. This would also have been the solution for the rear axles as well.

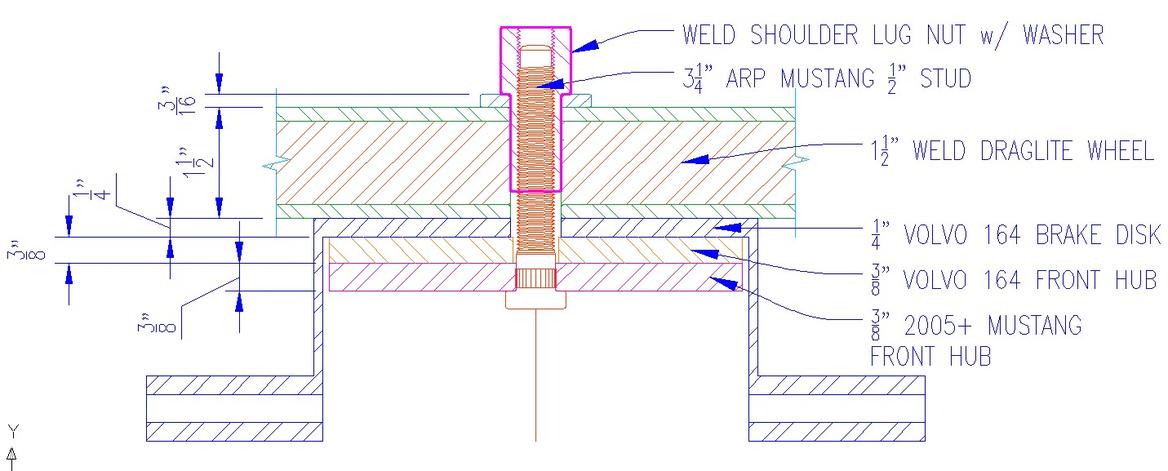

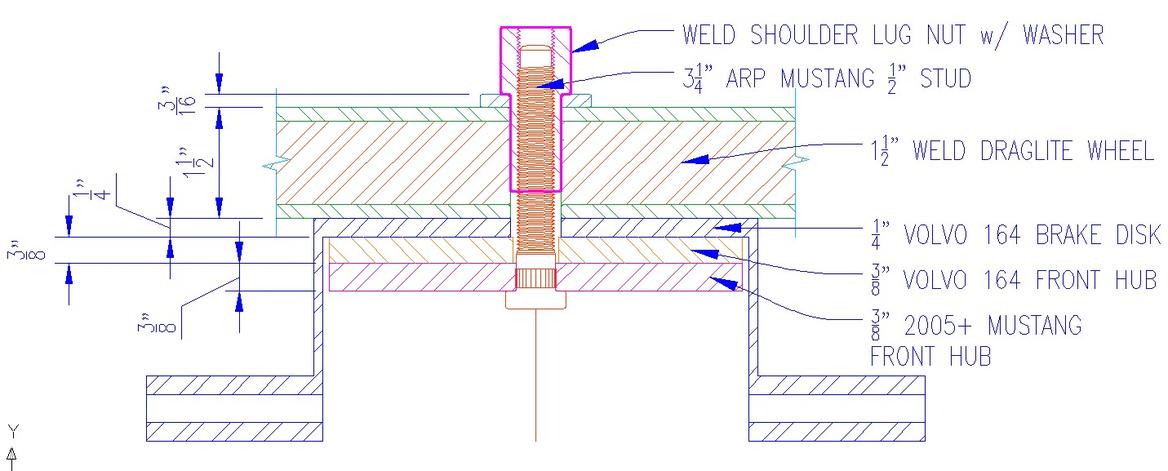

Please note that I have guessed at some of the dimensions such as the true thickness of the hubs and brake disk and the Weld nut's washer. Still pretty close for discussion. I should just get some all thread...

I did a little more measuring and refining my drawings and some research lately. All of the 3" or so wheel studs are too short and don't have enough thread contact. Without finding longer press in wheel studs, machining used solid axle shafts or front wheel hubs won't work. Machining new screw in hubs or axle is too expensive.

How about having Send-Cut-Send machining some 1018 3/8 plate with 1/2-20 threaded holes for McMaster-Carr grade 8 full-threaded 4" bolts for wheel studs? I see that Jegs sells 1/2-20 3" cap head grade 8 wheel studs. Both are supposedly 150,000 psi.

I would need to machine in a small shoulder on the back of the Volvo front hub and rear axle area for the center hole in the 3/8" plate to locate off of. I would need to take the hubs and axles to a machine shop to figure out the hub and axle flange shoulder's true location and I would make all of them the same size.

After cutting the flange shoulders, what do I call out for a location dimension for the Send-Cut-Send 3/8" flanges?

Note: The Volvo's front disk brake would not need to be shaved using a 4" bolt.

In reply to VolvoHeretic :

The circled holes are threaded and 2 of them are used to retain the rotor to the hub when the calipers are off. Needless and annoying as they originally locate a single hole in the wheel, so it is always indexed to the hub. They must have been balancing them fully assembled on the production line, tires and all on the car. Having an out of balance brake disc on my present Volvo, I index with paint post balance, and I found someone with the (now illegal..OSHA) machine to do it. I need to watch this, I may have missed a help point

In reply to TurnerX19 :

Sorry, the circle was supposed to show the transition from hub to flange that needs a locating step. To mount my wheels I had to taper the brake disk hat hole with a large drill bit to countersink a tapered bolt so the aluminum wheel could sit flush on the brake hat. Everybody please note that Volvos are lug centric, there is nothing on the hub and axle flanges to locate the wheel's inner base circle. We should all buy lug centric adapters for wheel balancing machines and take them to the tire store every time we mount tires.

Does anybody know what the lower ball joint taper is on these Volvos? How would you go about measuring them? Baked Play-Doh?

Seems like a lot of work to avoid finding a competent shop or buying wheels that fit.

In reply to 93gsxturbo :

LOL Yep, everything with these old Volvos is a pain in the but. Why on earth did they ever change to 5x4.25" wheels? I've been fighting this for 40 years. Should have figured out 4.25 to 4.75 adapters with Vette 9.5 and 11" x 17 wheels and 275 and 315 tires, but here we are.

I have no idea how to find old 5x4.5 front hubs, the only thing I find are one piece hubs and rotors which must be cast iron I guess.

VolvoHeretic said:

....

I have no idea how to find old 5x4.5 front hubs, the only thing I find are one piece hubs and rotors which must be cast iron I guess.

Where are you located? Any where near Birmingham Alabama?

In reply to Indy - Guy :

North Dakota. Those early 1800 hubs would work great but I still need to fix the bolt pattern of my 164 rear axle shafts. Are those yours and want to part with some hubs?

In reply to VolvoHeretic :

The cars pictured have the later small bolt pattern. The only 1800s with 4.5 bolt pattern have drum brakes. All disc brake Volvo rears are the later bolt pattern, damnit! Indyguy might have a pair of early front hubs already with him, not back in Alabama., but probably needs them.

In reply to TurnerX19 :

Ok, thanks for that information. I like the Send-Cut-Send for the rear hub fix but I need someone to say that a grade 8 full thread bolt will work for a wheel stud.

The other alternative is to shorten a Ford Explorer 8.8 rear housing to two short side axle tube lengths and use to short axle shafts. Then transfer the linkage attachment points to bolt it up.

Here is the early Amazon/1800 hubs with ARP 0.625 Knurl 1/2"-20 3.5" studs and 164 vented rotors. I'm not sure there is enough thread engagement with the nut.

That is almost twice the required thread depth for the torque limit on the threads and more than enough regarding the shear and bend loads from the short barrel on the nut. The shorten the Explorer deal is a pretty common thing. I do not like grade 8 bolts or studs on wheels, they are not bend load friendly, and barrel nut wheels can do that when the barrel is shorter than the wheel depth. Grade 5 is better, just don't over torque them.

In reply to VolvoHeretic :

Those cars were left behind in Alabama, waiting for someone to grab them. I'm working with Gariation to get down there. Could grab whatever you next trip down. (If any of it would work)

Reply to TurnerX19:

I have zero need for any Volvo hubs. We are now running Miata suspension/hubs. 😉

In reply to Indy - Guy :

The original hubs from your early build 1800 are what Heretic needs. Check the bolt pattern,

Volvo sucked with this one.

Thanks, guys. Here are my current late hubs and 164 Dana 44 like rear axles re-re-welded up and drilled by DutchmanAxles.com assuming I couldn't find any early 1800 front hubs Still need to re-redo the rear axles nonetheless. I'll make sure to send the studs along with the axles and make them calculate the pilot hole for the knurl and make sure they get them pressed on straight.

Axle flanges (Plug old holes, add $10pr if tapped holes).

Pretty reasonable pricing.

I worked with VCH on the 240 setup. I turned down the Volvo hubs on the lathe so the 240 rotor would fit over the old hub. If I remember correctly, we also drilled the holes out to match the knurl on bigger, longer studs we got from Summit or Jegs. I don't remember the size but they were bigger than the stock Volvo studs, 1/2-20 x 3.75 seems right.

![]()