https://youtu.be/UYv0qfhJ1Ho

It would be interesting to see if anyone did a static clearence test.

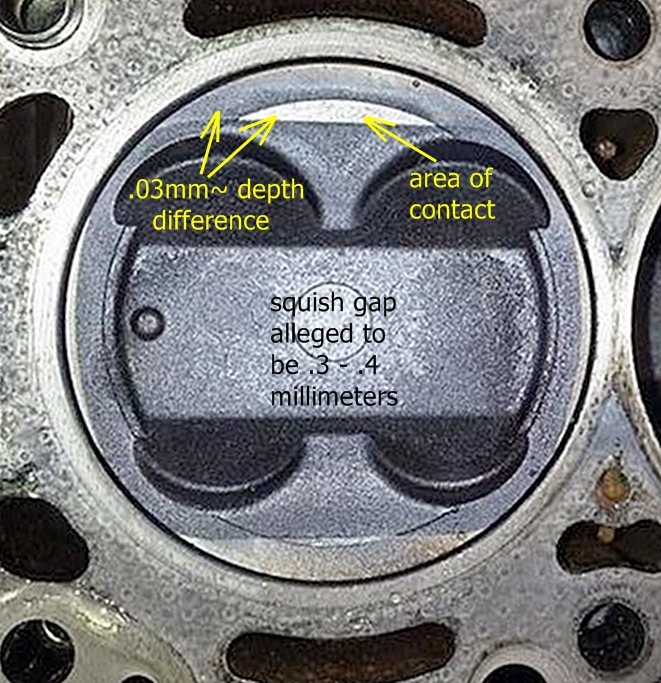

If they are .3mm static... Hmm...

Are people shaving the heads, or special pistons?

Streetwiseguy wrote: Doesn't happen to have standard rod bearings on a .010 cut crank by any chance?

nope... fresh rebuild

alfadriver wrote: It would be interesting to see if anyone did a static clearence test. If they are .3mm static... Hmm... Are people shaving the heads, or special pistons?

Decking, or cutting the block(piston sticks above deck by .045mm), along with running a .8mm head gasket provided a static squish of .35mm.

Target for a snappy 4AG is .040"(1mm) to .032"(.8mm). TRD once offered a .5mm gasket ![]()

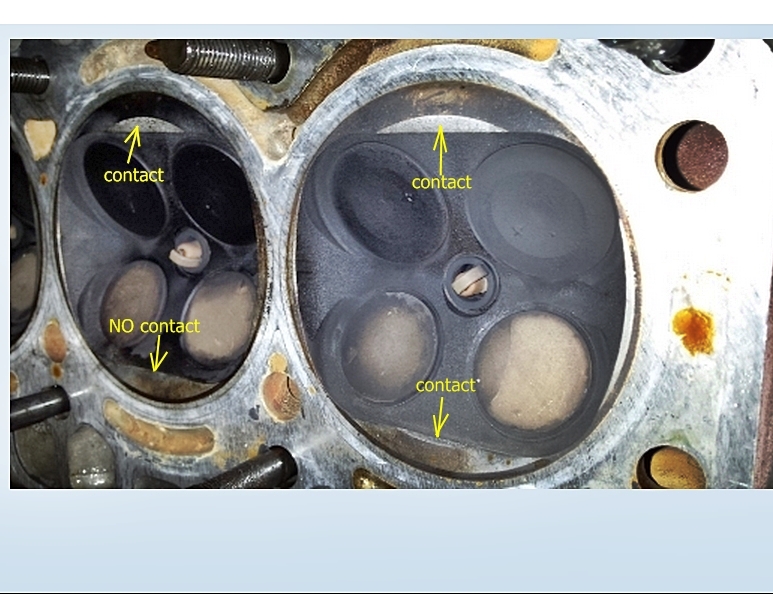

you have a template thanks to the contact... 5 minutes with a die grinder on the chambers and it's clearanced..

oldeskewltoy wrote:Streetwiseguy wrote: Doesn't happen to have standard rod bearings on a .010 cut crank by any chance?nope... fresh rebuildalfadriver wrote: It would be interesting to see if anyone did a static clearence test. If they are .3mm static... Hmm... Are people shaving the heads, or special pistons?Decking, or cutting the block(piston sticks above deck by .045mm), along with running a .8mm head gasket provided a static squish of .35mm. Target for a snappy 4AG is .040"(1mm) to .032"(.8mm). TRD once offered a .5mm gasket

So someone is getting their math wrong- between the machinist (I swear it was only decked a little), the gasket maker (for SURE, .8mm- ignore the +- error_) or....

oops.

oldeskewltoy wrote:Streetwiseguy wrote: Doesn't happen to have standard rod bearings on a .010 cut crank by any chance?nope... fresh rebuild

That's kinda the point of the question. Was it rebuilt using the correct parts and procedures? Obviously not, somewhere...

Streetwiseguy wrote:oldeskewltoy wrote:That's kinda the point of the question. Was it rebuilt using the correct parts and procedures? Obviously not, somewhere...Streetwiseguy wrote: Doesn't happen to have standard rod bearings on a .010 cut crank by any chance?nope... fresh rebuild

agreed.... builder missed the equation.

BUT... from his "accident" we see that he was VERY close. As I pointed out, TRD once offered a .5mm gasket. This squish was about .35mm. So he needed another .15mm (+ or -)???

The thing that has me concerned is that it doesn't rattle till higher rpm. You have about .002" worth of oil film in total between rods and mains, maybe to be generous theres .003". As the piston is going over the top on the exhaust stroke, the oil film thins out a wee bit, and allows the piston to move up a portion of that .003". Rods don't stretch, pistons don't either. If it was a deck height measuring error, it was a damn precise one.

All I'm saying, is don't just get a slightly thicker head gasket and put it back together, check bearing clearances too.

Streetwiseguy wrote: The thing that has me concerned is that it doesn't rattle till higher rpm.

That's NORMAL. Rods stretch under tension, wristpins flex, cranks flex... That is why the general rule of thumb is .035-040 for steel rods and .055-.060 for aluminum. Aluminum rods stretch more so they need more deck clearance.

Can't take measurements made in a static engine at room temperature and assume they will still be there when gigantic forces are stretching and squishing everything and the metal is varying levels of increased temperature.

Call Cometic and order MLS gasket in the thickness you need. Doesn't look like they are hitting very hard .005" thicker gasket should fix?

Since the one piston pictured hit the head around the outside I'd be concerned about the ring getting pinched?

You'll need to log in to post.