STM317 said:

mattm said:

Driven5 said:

mattm said:

I agree that Ford's approach is getting them to market in advance of the Chevy, but even Ford has indicated that this platform is a dead end.

The F150 platform for the Lightning being a dead end really doesn't hurt it (or Ford) at all though. It gets the product to market sooner in a package that is more appealing to the masses that are naturally resistant to change. Then once established it can change over to a new better suited EV platform once the larger market is ready for that next evolution.

GM is either betting on a creating a sudden seismic shift in the market, or targeting it as more of a niche vehicle than the Lightning. Crossbreeding a low sales volume new product with a low sales volume old product is an extremely risky gamble if the goal is creating a high sales volume new product.

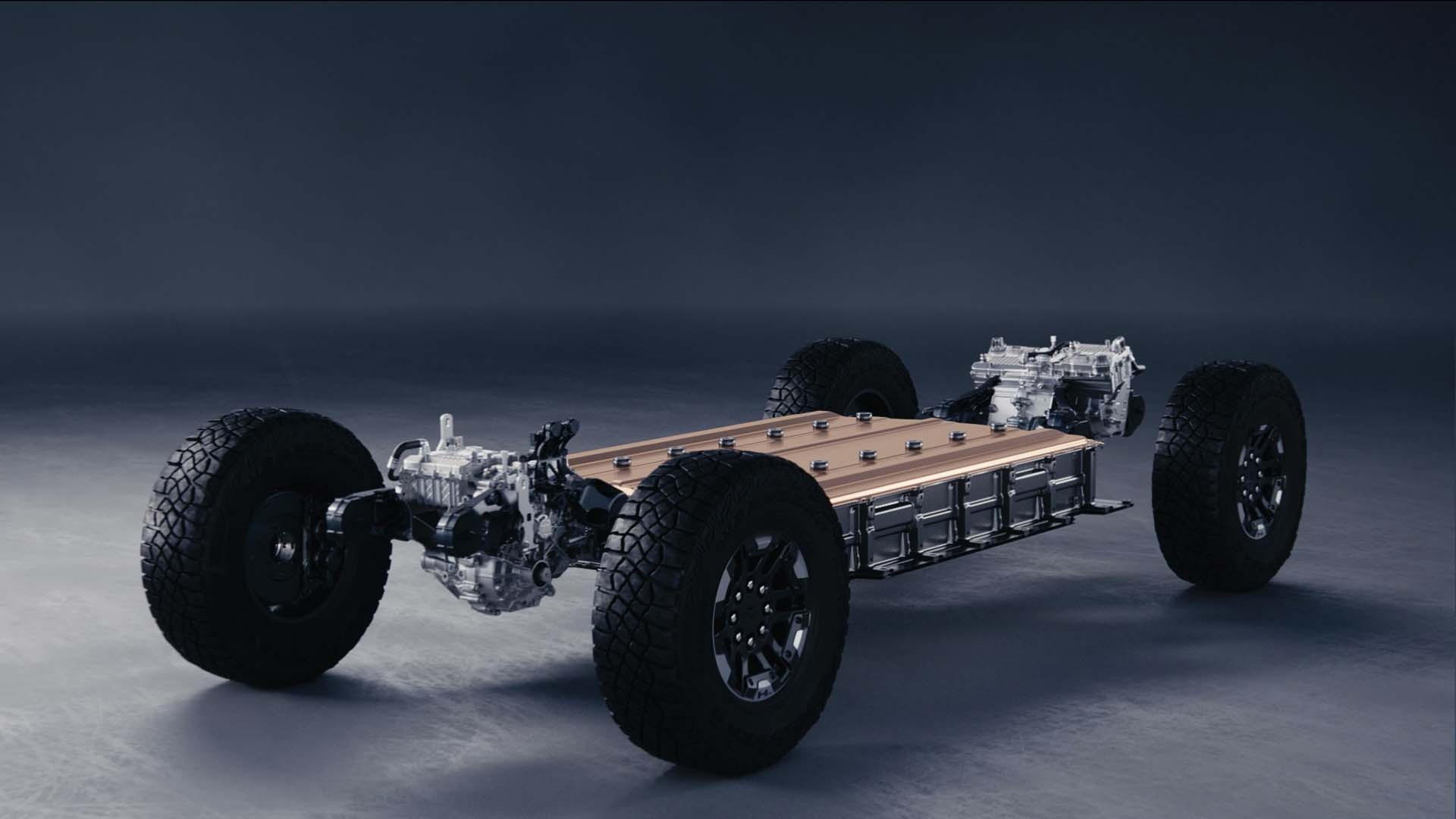

I would say creating a platform that is essentially a one off and will be replaced quickly, costs more than building the correct architecture from the beginning. I would say that the approach Ford took requires more people and time to build vs something like the skateboard type that Tesla went to market with in 2012, to say nothing of the high volume model 3 platform that went into production in 2017. That is the platform that Diess is worried about when he references the 10 hour build time target that Tesla has set for the German plant. Remember it takes VW 30 hours to build the ID.3 or 4 with a hope to bring that down to 20 within a year.

The costs of the batteries right now are such that saving money in production is hugely important to making EVs financially viable along with efficiency. The importance will lessen over time as the cost of batteries comes down.

It can be seen as an unnecessary first step, or as practice that allows them to set the market for EV trucks while ramping production and building battery production capacity so they'll be ready to roll with more widespread production (and more profit) when the next gen Lightnings are rolled out in 3-4 years.

The whole concept with the skateboards that all EVs may eventually be based on is building scale and sharing the platform between models because batteries are expensive. That's essential when you're creating new models from the ground up. But the F150 already has that scale and shared platform in place. Instead of building scale for batteries, Ford has more or less taken the opposite approach and used the existing scale for the non EV parts of the truck. The Lightning and regular F150s may not travel down the same assembly line, but they are built in the same Dearborn/Rouge facility as far as I can tell. That's a lot of frames, body panels, windows, seats, control arms, etc all in the same place already, just waiting to be used. By adding batteries to the current F150, they leverage that existing scale to enter into the market with the first EV truck before the competition, continue to gain engineering/manufacturing/supply chain expertise with EVs and batteries, while battery costs just drop into reasonably profitable range. 3 years from now when the next Lightning is expected (and the Chevy here is still likely to be ramping production), Ford will have made a few hundred thousand Lightnings as practice for the big show in 2025 when batteries are cheaper and they can all actually build these things for real profits.

I'm not sure which strategy will be better, but I can see logic in both.

There is certainly logic to both approaches, but I wonder if Ford is relying too much on the muscle they have already built, vs the new one they need to build for EVs. Tesla, being from Silicon Valley, has internalized the lesson of the post mainframe era of computing, where software is the focus, not hardware. Tesla designs the cars so most functions are accomplished with software that they built. Auto headlights and auto high beams, lane departure warning, auto wipers, infotainment, navigation (with reliance on Google maps data,) blind spot warning etc etc. There are solutions for all of those that all of the manufacturers use, and Tesla sees more value in building those features themselves. Ford can buy ready made hardware solutions for these that certainly include software, but developed by a supplier. Software they cannot improve because it doesn't belong to Ford. This is the biggest difference between Tesla and the traditional manufacturers.

Tesla wants to be vertically integrated so that they can control the experience and build solutions that are driven by software. Ford and the rest certainly build software, but are heavily dependent on suppliers to deliver solutions that are dependent upon specific hardware and include software that Ford and the others have minimal control over. See the current chip shortage. Tesla is suffering much less as they have already rewritten firmware for chips that have better existing supply. This vertical integration gives them an advantage, at least at this point in the transition.