To keep your drivetrain alive with a manual transmission, its important to pay attention to what happens inside the bellhousing. Engine acceleration and pulldown rates come into play when the car is going down the track, which in-turn have huge effects on the amount of torque that actually gets applied to the transmission's input shaft. The clutch's inertia draw rate is a key factor in determining whether the drivetrain lives or dies, as that inertia draw rate controls the intensity of the torque spike that is created when engine rpm gets pulled down against WOT. It's that spike that actually kills drivetrain components, not some horsepower or torque number from a dyno graph.

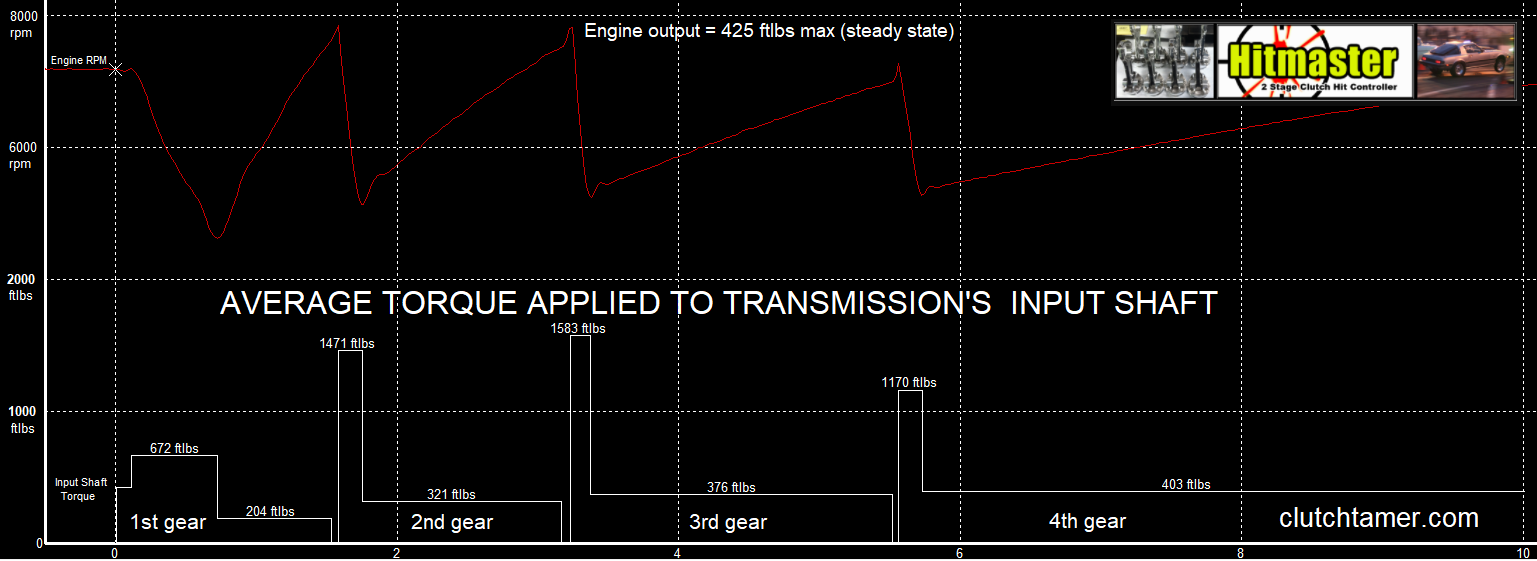

To illustrate the point, let's start with some data from an actual dragstrip pass...

Here's some averaged input shaft torque calculations for the above graph. It shows this example's 425ftlb engine only produces 204ftlbs at it's 1st gear engine acceleration rate, but when that same engine gets pulled down quickly against WOT by the clutch, the input shaft sees the engine's full 425ftlbs + another 1046ftlbs that comes from inertia energy exiting the engine's rotating assy after the 1/2 shift...

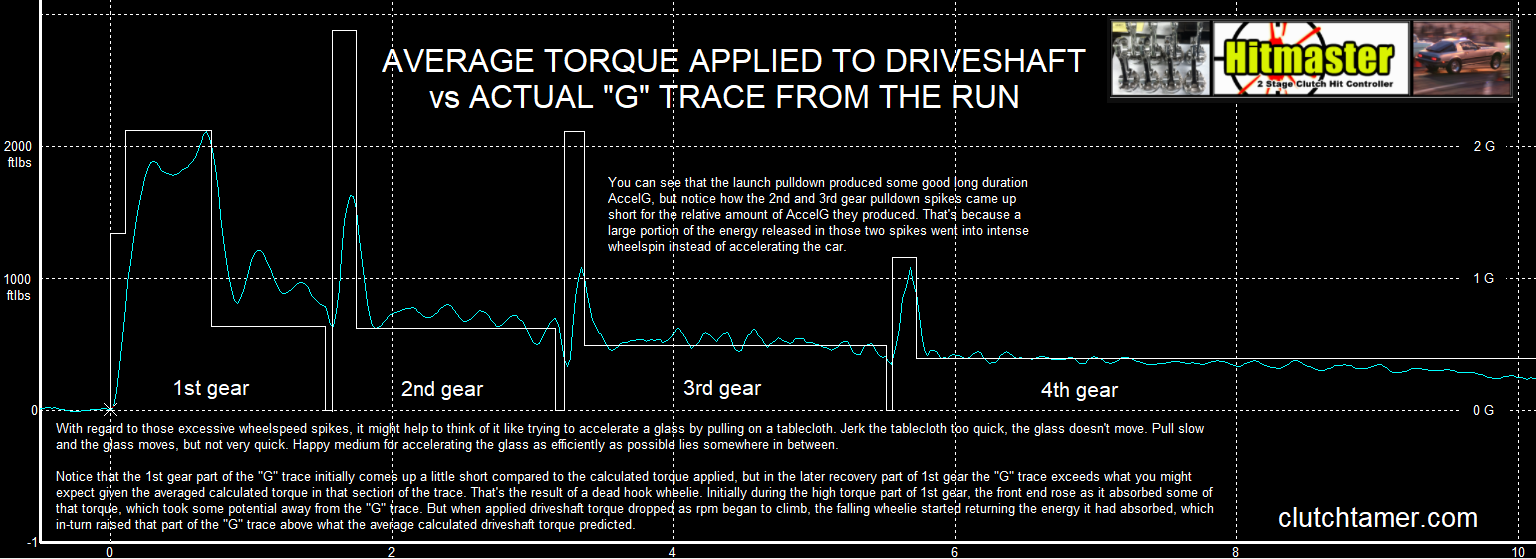

If you are wondering just how accurate those calculated torque numbers might be, here they are multiplied by the transmission's gear ratios, then compared to this run's actual Accel G trace...

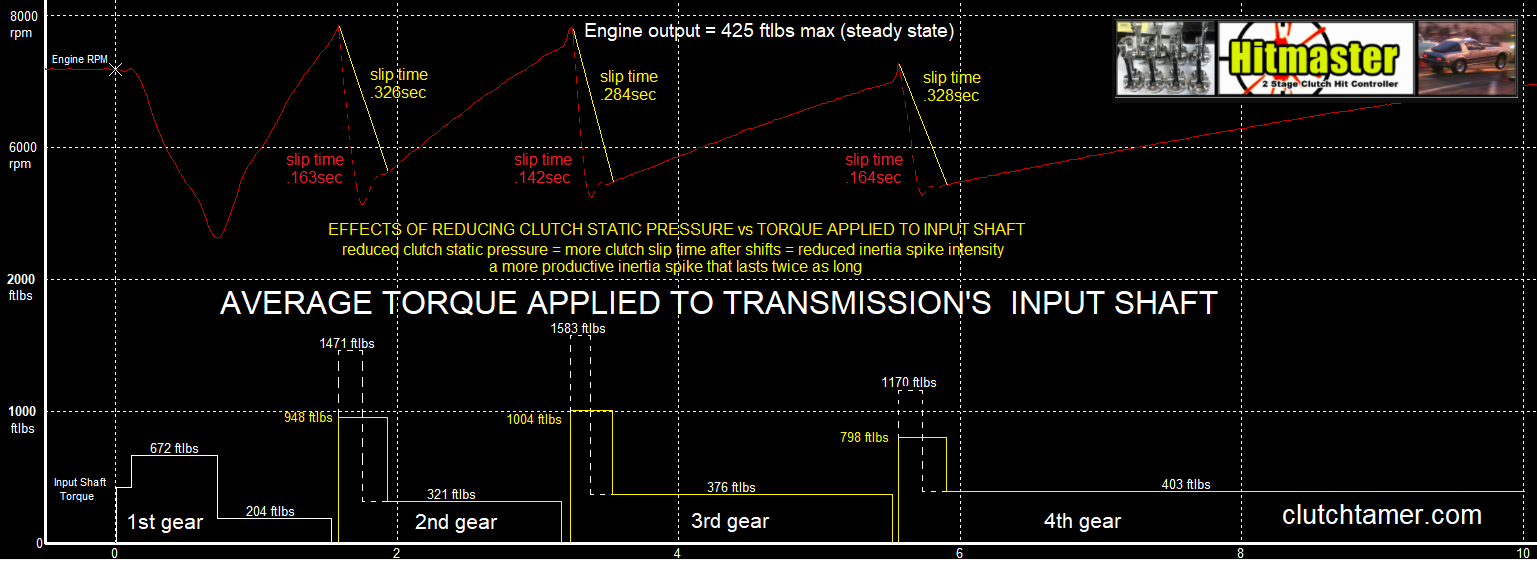

When you reduce clutch clamp pressure, it also reduces the clutch's inertia draw rate. That in-turn reduces the intensity of inertia induced torque spikes sent to the transmission's input shaft. For this example clamp pressure was reduced just enough to double the clutch's slip time, and that change effectively cuts the intensity of the resulting torque spikes roughly in half...

With the torque spike intensities cut in half, they now last twice as long. That in-turn raises those additional areas of the car's accelG trace. Now instead of wasting that energy in a quick blip of wheelspin, it now goes to accelerating the car.

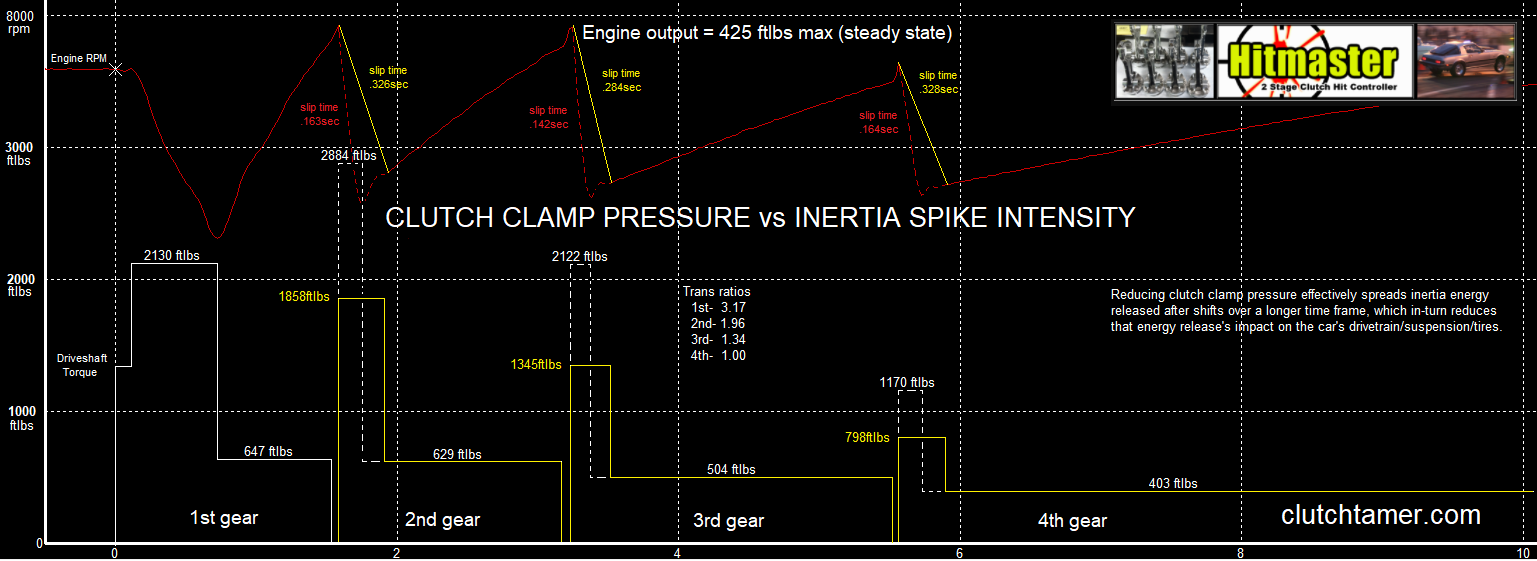

Here's a graph comparing the slower inertia discharge rates and the previous driveshaft torque numbers...

Notice the nice stair-step effect the clamp pressure change had on the torque spikes as it works thru the gears. You could now stick a 400hp shot of n2o between each of those spikes and still not exceed the torque applied to the driveshaft during that dead hooked launch :)

Grant