I recently "crashed" a KT thread (sorry Keith), and I've been wanting to post more porting work. I've done a search and found a few random threads on porting... many of them are of my individual builds/jobs. There are fair amount of others too...

What I'd like to do with this thread is make this the collection thread for everybodies/anybodies porting work. Kind of make this the box flair thread... but of porting.

So... here goes... some recent work

and a few stills...

A few before and after... this time intake side

1

2

3

4

And finally something new for me....

Please... add to this thread

Sweet!

Still working on the boss to get a head up to you.

I think I might build a camera rig to bolt to my next head. You're a pro compared to me, though. All I have going for me is OCD, knowing how to measure, and a good bit of educated guessing. No pics, FTL.

the results of the castings....

aaaand the engine I built in college.

In reply to fidelity101:

You can tell it's college by all the booze bottles in the background.

In reply to bgkast:

and the fact that the engine is being assembled in the living room...

In reply to bgkast:

Exactly!

In reply to turboswede:

No, I still build them in the living room...

Much easier to carry the engine to the garage instead of carrying it up the stairs first.

I also still use that table to clearance side seals too, that is the pre-assembly coffee table :)

Looks nice and clean... Fidelity101, did you do that free hand, or did you begin with a template?

How were the castings made? Coating the walls with polyurethane? That looks like a very useful tool to visualize where the port needs work.

In reply to oldeskewltoy:

The housings inserts are free hand. The Iron side plates I use a template, but the magic you find is similar to doing cyl heads by changing the short side radius to more flowing. The template just tells you were the boundries are on the surface.

IE: I see port jobs alot like this:

which are sloppy (in my opinion)

which are sloppy (in my opinion)

I don't know if these were the final product (it kinda seemed so) but if there were mine I wouldn't be done. I saw this on an rx7 board's build thread.

Since on those plates it is not where the combustion happens, its meerly where the fuel/air enter it is a little different. Alot of people don't polish the intake side on piston engines for the reason to get better fuel atomization. Everyone has their own thoughts and theories when porting rotaries and nobody is really able to test them to eachother for the most part.

Making the shape itself takes no time but getting the angle right before that is what takes up so much of my time.

- step 1: brush or spray on some marking fluid and let it dry (or force it to dry with some compressed air)

- step 2: use template to scribe line

- step 3: Layers of duct tape (to catch any skips from damaging the running surface)

- step 4: shape and contour

fidelity.... I've come across sloppy jobs as well, in fact OST-017 my one and only O/S valve head was sent to me by my client... from another "head porter" - NOT.

As far as smooth or textured intake runner finish... that is a tiny bit compared to getting the shape fixed... as can be seen in the 4 intake ports I posted above... once the ports are shaped correctly... "we" can argue finish forever......

MadScientistMatt - it was VERY simple... VERY simple. I mixed the catalyst with the silicone, poured it in and let it set up for about 18-24 hours. Then using wooden skewers I pulled the set silicone away from the port walls, and then I ran the corkscrew in and gradually worked the silicone port out of the port.

On cyl heads i like to polish the combustion chamber or the top of the pistons. Reflect some heat energy back into the explosion.

speaking about combustion chambers....

I would polish the rotors and the combustion chambers on them but then I have to re-balance the rotating assembly which is costly. (for the build)

Three ports, one photo.

Existing port is a stock 12A secondary port. Scribed outline is roughly the secondary ports that I had in my old half-bridge Turbo II engine. Port template is my avatar at 100% size, and almost what my actual ports are now. I went a little larger on the eyebrow (closer to water jacket mainly) because bigger is better.

I should have gone even bigger than that. To paraphrase wae, I've never had a ported engine and said to myself "Self, that engine has too much port." I feel the same way about cams, you can't have too big of a cam, just not enough induction or valvespring. Or bottom end strength.

turboswede wrote:

In reply to bgkast:

and the fact that the engine is being assembled in the living room...

I built mine in the kitchen. Where it was also used as a table.

In reply to 16vCorey:

Yes! Polish the E36 M3 out of the exhaust. Good stuff :)

I built a cylinder head for a customer last month who wanted to supply his own parts. One of the things he supplied was an ITB intake manifold that he wanted port matched. It was, without question, the worst casting I have ever seen in my life. It actually turned out OK, but I wish I had taken before and after pics. It would have been good advertising.

Zomby Woof wrote:

I built a cylinder head for a customer last month who wanted to supply his own parts. One of the things he supplied was an ITB intake manifold that he wanted port matched. It was, without question, the worst casting I have ever seen in my life. It actually turned out OK, but I wish I had taken before and after pics. It would have been good advertising.

current client has a similar issue.... the machining and mounting holes don't line up well, so I elongate the mounting holes, drill and install jack screws...

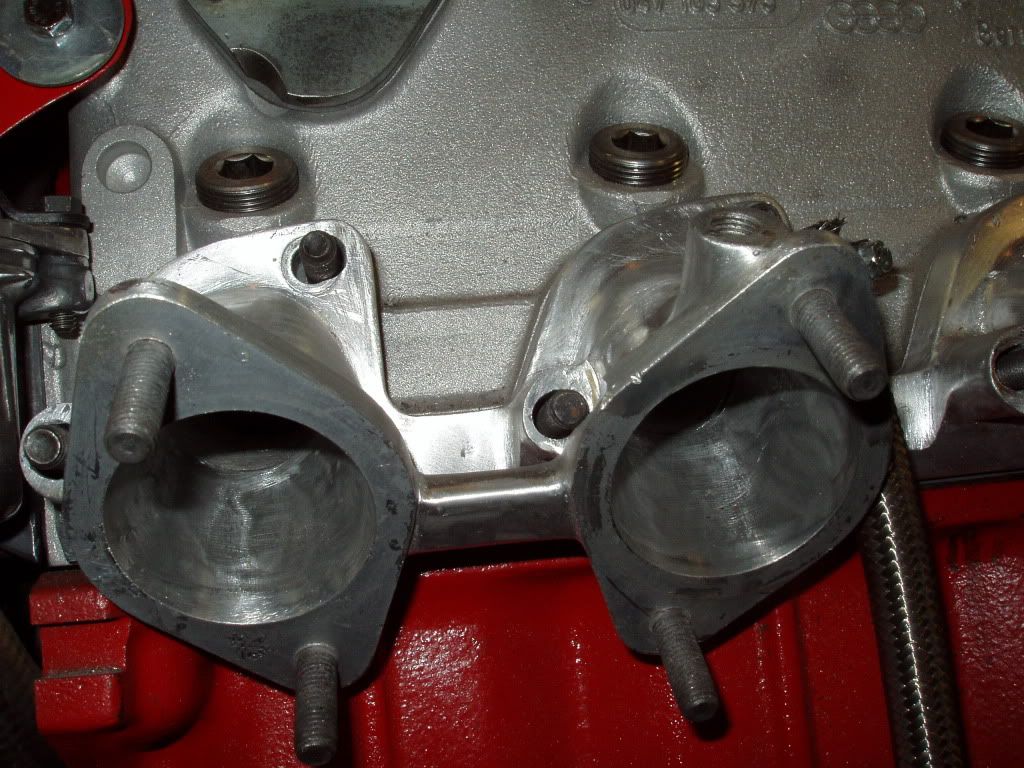

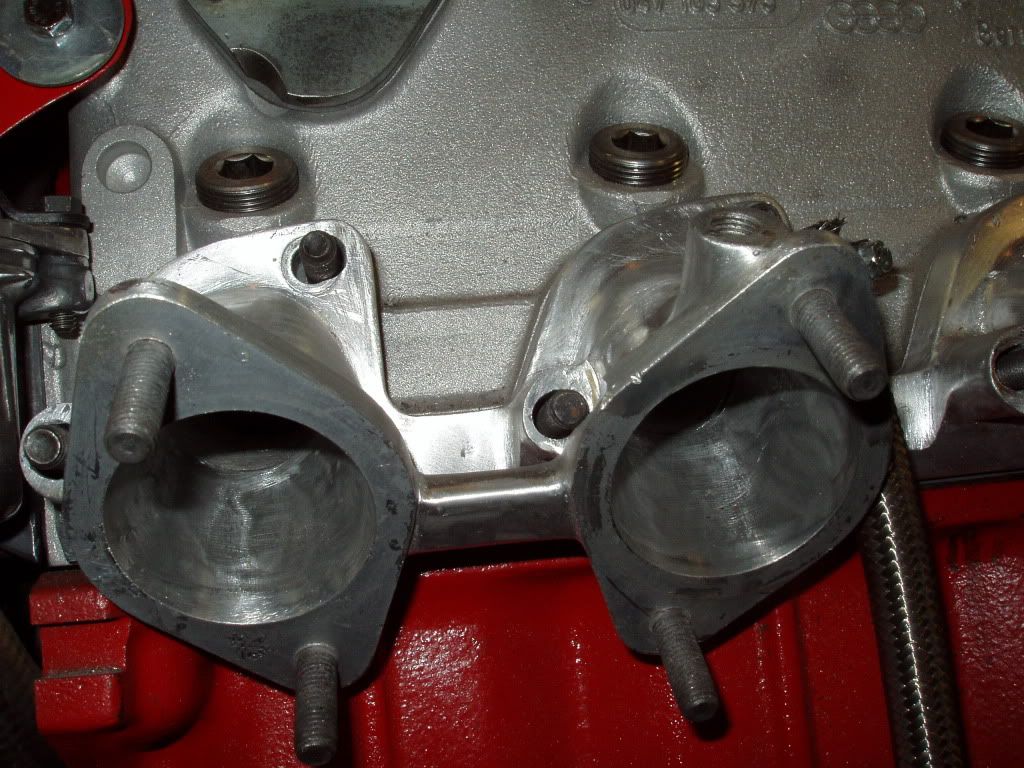

as in this adapter from a couple years back

Oh... and as far as the exhaust... (different client/head)

I had to do similar work to the DCOE manifold for my 924. It was a PITA to elongate the holes to shift it sideways enough to get it close enough to try and port match it to the head.

Good times.

The final polish was a royal PITA, btw.

I've got a VW counter flow 8v, a BMW M20 head, and a 944 head that I'll be building soon. I'll try to get pics. I'm bad about getting caught up in what I'm doing and not taking any.

(very) mild porting on an Audi NG cylinder head.

It would have taken days to get an older 38mm head nearly this nice. And all I did was basically knock off the sharp edges in the casting, and a little casting flash. Didn't bother touching the guide area because I kinda want some mass there for longevity, and that part of the casting was already pretty good. So no pictures.

![]()

![]()

![]()

which are sloppy (in my opinion)

which are sloppy (in my opinion)

Intake port:

Intake port: