bluej

UltraDork

8/17/16 1:23 p.m.

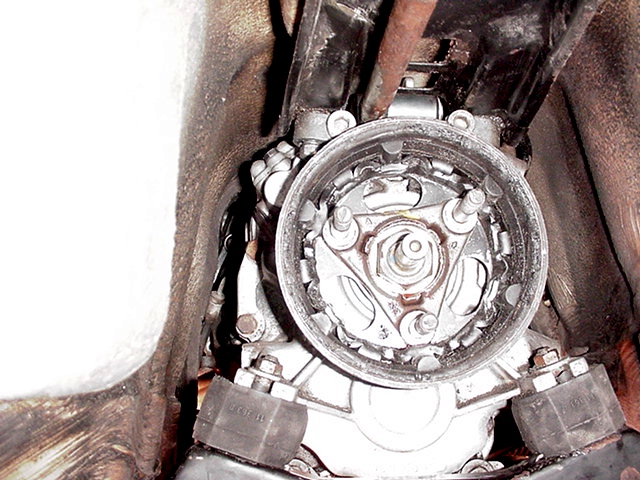

First, carnage pics for the impatient:

no bueno

That bolt is reusable, right?

This happened this weekend in my m52b28 swapped e30. I'd like input on cause.

It is only the second event since the swap. It basically has ~ 2-3 days of rallyx on it and the giubo looked good when I buttoned it up previously. This failed fully on the seventh of nine morning runs, and a handful of runs at the TnT the afternoon before.

Changes between this event and the previous include swapping in a new (used) LSD rear end. I did notice that the diff bushing is suspect.

Other considerations: I fabbed my own engine and trans mounts for the swap, so it's possible the alignment is off. The previous open diff had a much better condition, and stiffer to begin with, diff bushing.

I've already ordered a new, known good quality giubo, bolts/nuts, and a full set of 95A poly bushings for the diff, rear subframe, and trailing arms (and LCA since it was best $$ to get the full kit).

What else should I be looking at/into?

A few pics of the car from the TnT for good measure:

thanks!

Carrier bearing? I'd replace that too. Especially after a failure like that.

And shouldn't there be large washers or a plate on the guibo opposite the shaft? It looks like the bolt heads pulled through the guibo. Mine is an e series so it has the cup shaped disk (like a hole saw for a drill) on it. Not sure if i's had washers or similar plate.

bluej

UltraDork

8/17/16 2:35 p.m.

The CSB seemed good post incident, but they're cheap enough I guess I'll add it to the list.

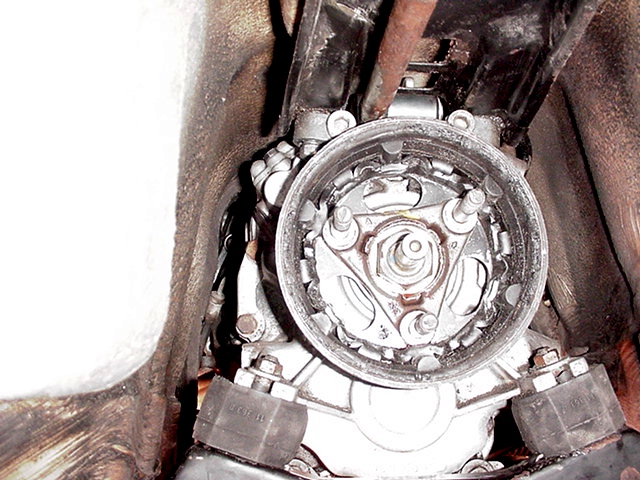

you mean the dampener? it started as an 09/85 build 325e, so it's got one as well like this:

I'm going to remove that guy and not put it back.

Yes, it looked like the nutted end of the bolts from the trans side pulled through the giubo, either taking out the giubo internal metal bushings or taking them with them.

Was it a new guibo? BMW seems to like using rubber that turns into dust after a certain period of time with minimal warning, my e24's guibo and center support bearing went from looking fine to worse than that in only a couple hundred miles of street driving.

You should be able to tell if the alignment is significantly off when you try to install your new stuff.

bluej

UltraDork

8/17/16 3:24 p.m.

guibo was less than a few years old. not a lot of miles, but they were hard ones.

It seems like BMW guibos are good, right up until they're not.  They can look fine, but at some point they just fail.

They can look fine, but at some point they just fail.

If you aren't using the dampener I'd suggest some really big washers or cut the outer ring from the dampener to use the center section as a washer

bluej

UltraDork

8/17/16 4:41 p.m.

the dampener is currently there, but will be removed. why the big washers in its place? I'm not sure I understand the purpose. I did get quality flanged hex head bolts w/ nylock flanged nuts to replace the bent socket head caps.

Was the dampener on when it shredded? It's theoretically about spreading the load. The sleeves can be pulled out of the rubber. They are only there to keep the bolt from Digging in to the rubber from the rotation. Not to keep it from pulling through axially

These have a specific orientation. If you put them backwards, they dont last. Was it installed properly?

just looking at your pics.. I agree with many above. you did not have large enough (or any?) washers to keep the bolts from pulling through the donut. I know that BMW differentials do not move around as much as a solid axle, but there is always going to be some fore and aft movement in the drivetrain. All it takes is a small tear to form where a nut gets pulled into the rubber and that is all she wrote

bluej

UltraDork

8/17/16 8:03 p.m.

Damper was on. Bolts could have loosened. I thought there were washers, maybe not. Either way, definitely will add larger ones. No reason not too. Pretty sure I installed in correct orientation. You can see the tear of compression is through the thicker parts of rubber.

Still not seeing how the damper helps much. It lives on the other (trans) side of the output shaft spider (pic below). Not trying to be argumentative, I just want to understand.

not sure about the damper.. but look at it this way, if it's on the transside, it should help keep a lot of nasty rocks and crud from attacking the replacement guibo

Noodling things through, the damper is there to dampen torsional vibrations, maybe torsional vibrations from the engine could hasten the Guibos' demise.

If you had U-joints, I would DEFINITELY keep the damper since they do an incredible job of cutting down on gear clatter if your joints aren't perfectly at complementary angles to each other. It gets so annoying I wish I could covert TO Guibos.

I don't think it was big bad POOOOWER because CTS-Vs used couplers of about the same size.

mad_machine wrote:

just looking at your pics.. I agree with many above. you did not have large enough (or any?) washers to keep the bolts from pulling through the donut. I know that BMW differentials do not move around as much as a solid axle, but there is always going to be some fore and aft movement in the drivetrain. All it takes is a small tear to form where a nut gets pulled into the rubber and that is all she wrote

e30 guibos don't have washers, IIRC. At least mine doesn't and it's been fine for 4 years of rallycross and stage rally....

bluej

UltraDork

8/17/16 8:35 p.m.

In reply to Knurled:

To clarify, there is the giubo (definitely staying), and another damper that is shaped like a hole saw blade (pics above). The damper is what will go unless someone can can illuminate what benefit it provides to offset the difficulty it creates in servicing the giubo joint.

bluej

UltraDork

8/17/16 8:38 p.m.

mad_machine wrote:

not sure about the damper.. but look at it this way, if it's on the transside, it should help keep a lot of nasty rocks and crud from attacking the replacement guibo

Fair point. Not sure that's worth how much harder it makes it to replace a giubo.

bluej

UltraDork

8/17/16 8:44 p.m.

Knurled wrote:

I don't think it was big bad POOOOWER because CTS-Vs used couplers of about the same size.

Hmm,noted. So very likely other causes as suspected.

I'm really starting to think the entire engine/trans isn't perfectly on center with the diff. Did you quadruple check your engine + trans mounts to ensure they are straight, and to that end, straight to what? It's an e30 of questionable prior ownership, so some chassis shifting would not be totally shocking. I wonder if you picked up measurements that you thought were straight, but weren't in fact. Can you get a dial indicator and mag base on the spider to see if it rotates flat? Guibos are good for drivetrain dampening, but U-joints they certainly are not. I don't know the book spec for misalignment, but I do know that it isn't a lot.

If you weren't dead straight, you'd see the indicator run out. That would put a lot of undo stress at a specific point in rotation, and I could totally see pullouts in that scenario. I'm not questioning your fab skills, but perhaps your reference points were not completely accurate...?

bluej

UltraDork

8/18/16 9:06 a.m.

you can totally question my fab skills, I'm not perfect.

right now the shaft is fully out, so the easiest thing to do is check the angles on the output shaft spider and diff input flange to make sure they're equal, or very close, right?

thinking about it that way, I feel like the shot rear diff bushing is even more to blame. the rear subframe and diff are solid bolted together, then mounted to the frame at the front corners of the subframe and at the rear of the diff by the diff bushing. If that rear bushing fails (I could easily see movement when jacking up the rear by the diff), it'll let the diff rotate under load w/ the compliance in the subframe bushings (lever action helping), changing the effective angle of the diff input axis. Add the rapid loading and unloading of the rough rallyx courses we run, and something is going to fail.

bluej

UltraDork

8/23/16 2:10 p.m.

updates:

-

jacking up the rear via the diff, I can clearly see at least a half inch of movement at the thru-bolt at the bushing. complete garagistic poly bushing set arrived yesterday to correct this and refresh the rest of the control/trailing arms/subframe.

-

once the rear of the car was raised, the "static" angle between diff input and trans output shafts was ~0.4* out. luckily, this is my own stupid fault. I pulled the "spacers" I used to get the harmonic hole saw thing to clear the shift linkage, and there's now a negligible difference in angles as accurately as I can measure them. I think my homebrew motor and trans mounts are "OK" for now.

-

I acquired a 6pt deep 30mm socket, modified it to fit the output shaft nut, and an electric impact took it right off (score!). the bolts on the output shaft flange having bent, ovalled their respective holes and lunched the flange. pics:

acquiring a replacement is proving...challenging. being an early eta (pre 05/86 manufacture), it's a 110mm circle w/ 10mm bolts and rather rare. used only on the early eta manuals (g260) in e30's and e28's. replacements are NLA. the later 12mm bolt ones are available, but that means returning/acquiring a bunch of other parts to match, including a driveshaft.

anyone happen to have one squirreled away? anyone know of a 16 spline output shaft flange from something else that might work?

thanks.

TGMF

Reader

8/23/16 3:28 p.m.

^^^ can you fix what you've got?

Drill holes larger, weld sleeves in place? Use whatever nuts/bolts that will fit your sleeve.

Ghetto fab might even weld a Washer with correct inner hole diameter on outer side?

![]()

![]()