I don't think the extra throttled volume manifests itself as lag so much as it does problems with idle and idle droop. They can be cranky at light throttle openings. WOT, there's enough airflow that it's not an issue.

The ratings are the same - it's the volume of air moved in 1 rotation of the SC, assuming 100% efficiency. Figure that a 2.2l engine will ingest 2.2l in two full crank rotations at ambient pressure, if you push 4.4l of air down its throat you'll get 1 bar of boost. Of course, it's a bit less due to inefficiencies but that'll do for back-of-the-envelope and hopefully I didn't forget something

That'll tell you how fast it needs to be spun. When we were dealing with twin-screws, I think the blower redline was around 15,000 rpm with 18,000 for short bursts. I think we had a 2.1l twin-screw on 1.8 to 2.0 engines, and on the latter we were starting to have bearing troubles at 15 psi. They really woke up at about 12 psi on the 1.8, below that the compressor just wasn't efficient. It was a bit of a narrow operating range, which was a problem for a production item with a range of customers. On a one-off, you could deal with it.

Don't bother with the millenia supercharger. Everything you do to run it will be 100% custom, down to a pulley that lets you run less than like 17psi.

On top of that, when they go bad (and they will) they're not easily rebuildable. Or you can pay $2k to get a rebuilt one.

There's a reason I see so many of these in the junkyards with perfect bodies.

kb58

HalfDork

6/14/13 8:52 p.m.

Until not that long ago turbos didn't have coolant run through them to keep the post-shutdown temperatures from baking the oil, so the goo ended up freezing up the shaft. Nowadays, coolant-cooled units have Greatly increased the reliability of the turbo to the point that they're making a big return.

Do lots of research about turbos. As was mentioned, it's a balancing act between low and high end performance. Unfortunately turbos were given a bad name due to kids building cars that might make 800 hp, but which only attained it in a narrow range. That is, when you zoom in on their OMG I'ma bad-azz dyno graph, yeah, it reaches 800 hp, but 1000 rpm below that, it only makes 400, and 1000 rpm below that, 200. So every time they step on the gas, there's a long delay until the grenade goes off.

However, with careful work and sizing, you can come up with something like this below, something with a very wide and usable torque curve. Yeah it's mine and I'm pretty happy with it.

In reply to kb58:

I guess there are two delayed-response pitfalls to fall into. Apart from only being able to make power in a narrow band of engine speeds, the lag I'm most familiar with and worried about is what you get if you've been off the gas on corner entry and then roll the throttle on at 3000 RPM... With the turbo spooled, you're making 140hp at 3000 RPM, but what would it be if you'd just coasted down from 5000 off the throttle, and how long would it take to spool up and get back to matching your graph?

That is a gloriously flat torque curve, I have to say...

At 3000 rpm, it's not going to matter if you were at 5000 when you entered the corner, and it's not going to spool back up to 5000 rpm. It's going to accelerate to 5000 rpm, just like any engine. Where the lag comes in is how long it takes to get your full 3000 rpm power after getting back on the gas.

We've got a Miata with a big turbo at the shop. 460-ish rwhp out of 2.0l. It's a bit psychotic above 4000 or so. But the thing is, it's still outperforming a smaller turbo below that. It's just that the 4000 rpm hit is so hard, you feel like the car was parked before then. Can take a bit of acclimatization though.

Always considered centrifugal superchargers to be fairly pointless, why not just turbo?

IIRC, the DASC was either an eaton M42 or M62 supercharger

it is M42 but some people have modded the manifold to put a M62 on.

I kind of want a 318ti DASCed.

Twin-screws are more efficient because they ingest and compress the air. Roots blowers just gulp it on one side and push it out the other. If you want proof the twin-screws are more efficient, look at industrial air compressors. Over 95% of new industrial air compressors are twin-screw. I saw an Atlas-Copco with a Detroit 16V96 (16 cylinders at 96 cu.in. each) twin-turbo/single SC, twin-charged 2-stroke diesel engine and two-stage compression deliver 1500CFM at 135psi. See any top fuel dragsters lately? They all run twin-screws now. The down side is that they are precision devices with extremely close tolerances and that adds up to big money for good ones. The latest technology is 3-rotor screw compressors. They have one large one in the middle and a smaller screw on either side. It balances the radial/axial forces and they can run without timing the screw elements.

The turbo is still more efficient because it uses waste heat from the exhaust to turn the compressor rather than crankshaft power. They're cheaper to install, but the trick comes in sizing the system to match the use of the vehicle. I knew a guy with 3 Supras. His street car still had the twin-turbo setup for flexibility, his drag-car had a massive single turbo for max power and his track car had a medium size single turbo for smoother delivery and simplicity/reliability over the OEM twin-turbo setup.

Keith Tanner wrote:

At 3000 rpm, it's not going to matter if you were at 5000 when you entered the corner, and it's not going to spool back up to 5000 rpm. It's going to accelerate to 5000 rpm, just like any engine. Where the lag comes in is how long it takes to get your full 3000 rpm power after getting back on the gas.

I guess I phrased it poorly, but that was my question. I shouldn't have mentioned any higher RPM specifically, I meant to use 5000 RPM down to 3000 RPM as an example of having been off the gas and decelerating long enough that when you got back on it at 3000 RPM that the turbo would be slowed way down. Since the engine would start accelerating, you wouldn't get back to the WOT dyno chart 'til somewhere above 3000, but the thing I'm curious about is how long that takes.

So the scenario I was attempting to ask about is:

1. Close the throttle from WOT at 5000 RPM

2. Brake or coast down to 3000 RPM

3. Get back to WOT, turbo begins spooling, car is accelerating

4. At x time later and 3000 + y RPM the turbo is fully spooled and power should match the dyno chart, more or less.

Very curious about x, and probably the shape of the curve between getting back on the gas at 3k RPM and arriving at full boost.

Which I have to recognize is an awkward question. I'm not well-calibrated enough to know whether 0.2 seconds or 0.5 seconds or 0.01 seconds from "mostly off boost" to "fully spooled" feels lag-free (or close enough), but since it's my biggest concern with turbos I keep trying to figure out how to quantify it so I have half a chance of knowing whether I'd be happy with the result.

Compounding all this is that you might not go back to WOT at 3k. You might want a short burst of half-throttle, or 3/4 throttle. Depending on the turbo's state, that's going to be a varying amount of power, and the less throttle you give it, the slower it's going to spool back up... Right?

Duke

PowerDork

6/15/13 9:57 a.m.

ransom wrote:

In reply to Keith Tanner:

Very interesting. I wonder whether I'm just thinking wishfully to wonder whether the throttled volume of an intercooler and attendant plumbing on a supercharger setup might introduce temporal effects on the same order of magnitude as lag on a conservatively sized turbo.

The Manic Miata has a post-TB twin-screw Whipple followed by an intercooler. Throttle response is pretty darn direct. Unless you're routing the intercooler piping through Botswana, I don't think you'll induce notable lag.

ransom wrote:

I like the idea of the instantaneous and *predictable* delivery of a positive-displacement, crank-driven supercharger.

I read this comment and can't help but wonder if what you really want is progressive and predictable delivery of power. Instantaneous power isn't always that great for autocross. As the HP limit is raised, the ability to modulate the extra power becomes increasingly more important.

yamaha

UberDork

6/15/13 10:09 a.m.

In reply to djsilver:

You know the roots type blower on the 2 stroke Detroit diesels is only there for scavenging don't you? Otherwise a two stroke diesel will not run.

yamaha wrote:

Turbo and centrifugal can have lag, but make more power up top than they can at the bottom(all depends on size too), and twin screw & roots type make good low-medium power(pending the size again)

"Lag" needs to be defined, here. It's not the powerband, but a response thing. (In a real bad lag situation, the engine outaccelerates the turbo and you don't get much, if any, boost...)

I've driven positive-displacement supercharged cars that had noticeable lag. Easy to figure out why, too. Ford put about 8 feet of plumbing between the supercharger and the intake valves on the Super Coupe, and it takes a bit for it all to pressurize when you open the throttle. Given the sucktastic chassis, an instant hit of power is probably not a good idea anyway.

Keith Tanner wrote:

We've got a Miata with a big turbo at the shop. 460-ish rwhp out of 2.0l. It's a bit psychotic above 4000 or so. But the thing is, it's still outperforming a smaller turbo below that. It's just that the 4000 rpm hit is so hard, you feel like the car was parked before then. Can take a bit of acclimatization though.

I think that's the same perception issue that highly ported rotaries have. At anything over 2000rpm they stomp all over a stock port, but it just keeps building from there. And then there's a surge in torque at 5500 or 7500 or so when it comes up on the pipe and things REALLY get moving... but you can still make more power than stock peak without ever having to go over 5000.

What turbo is on that Miata, if I may ask out of idle curiosity?

petegossett wrote:

ransom wrote:

I like the idea of the instantaneous and *predictable* delivery of a positive-displacement, crank-driven supercharger.

I read this comment and can't help but wonder if what you really want is progressive and *predictable* delivery of power. Instantaneous power isn't always that great for autocross. As the HP limit is raised, the ability to modulate the extra power becomes increasingly more important.

That may well be the case. That said, I can't help but think that it's easier to modulate a car which is consistently instant than one whose torque curve actually needs to be a 3D map and not a simple graph, in order to capture boost, which in turn varies depending on what you were doing a second ago...

I was looking about in hopes of finding a graph of someone overlaying graphs of WOT with graphs including tip-in from off-boost so we could see how quickly the latter catch up with the former (though this would only be in RPM, not time...), and found a related discussion on miata.net with both Keith and Corky Bell (or someone with that username) checking in. No luck finding such a graph, though.

ransom wrote:

No luck finding such a graph, though.

A dyno graph like you described isn't that useful, because the RPM difference is going to vary depending on the load the dyno places on the car.

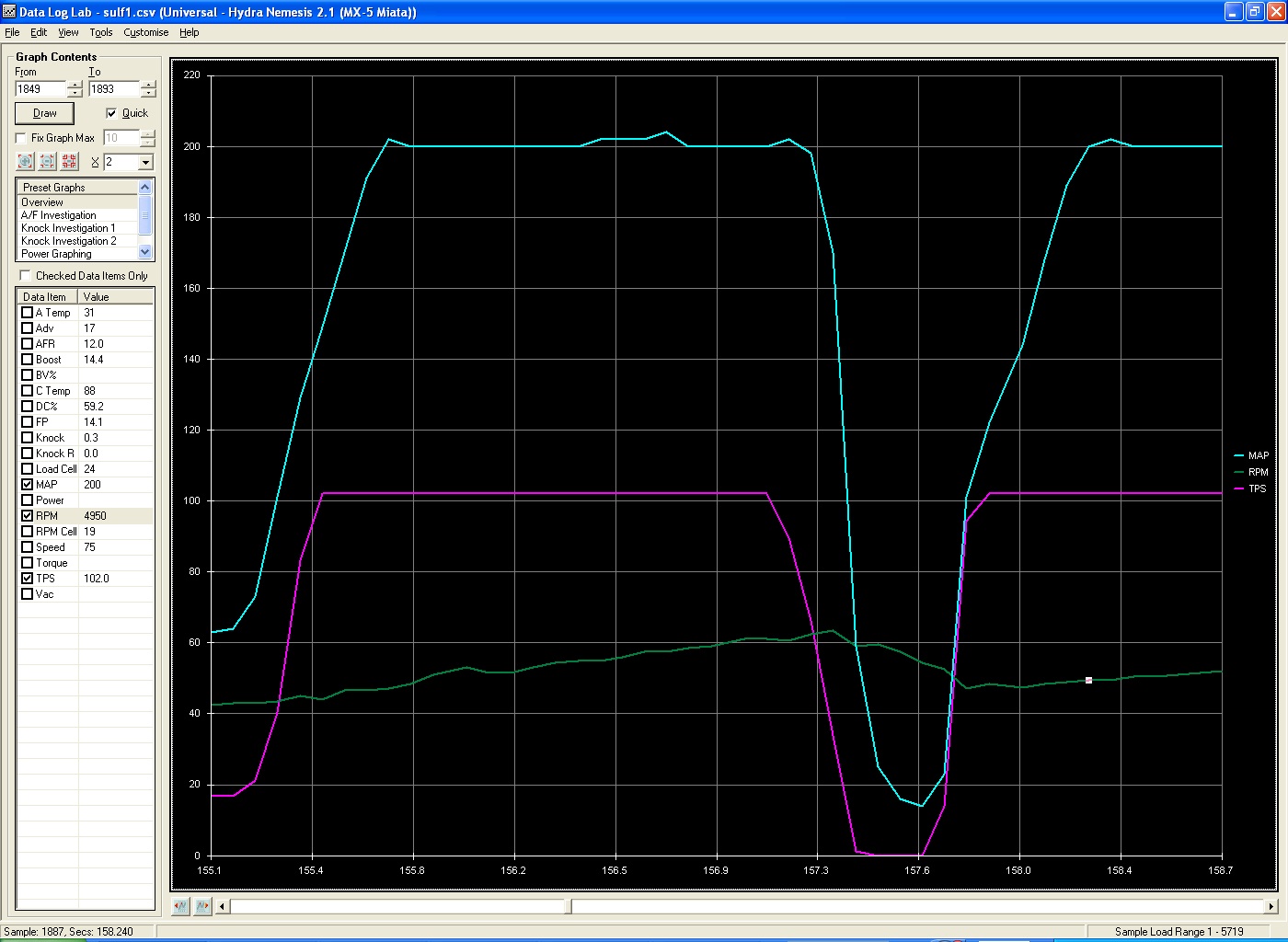

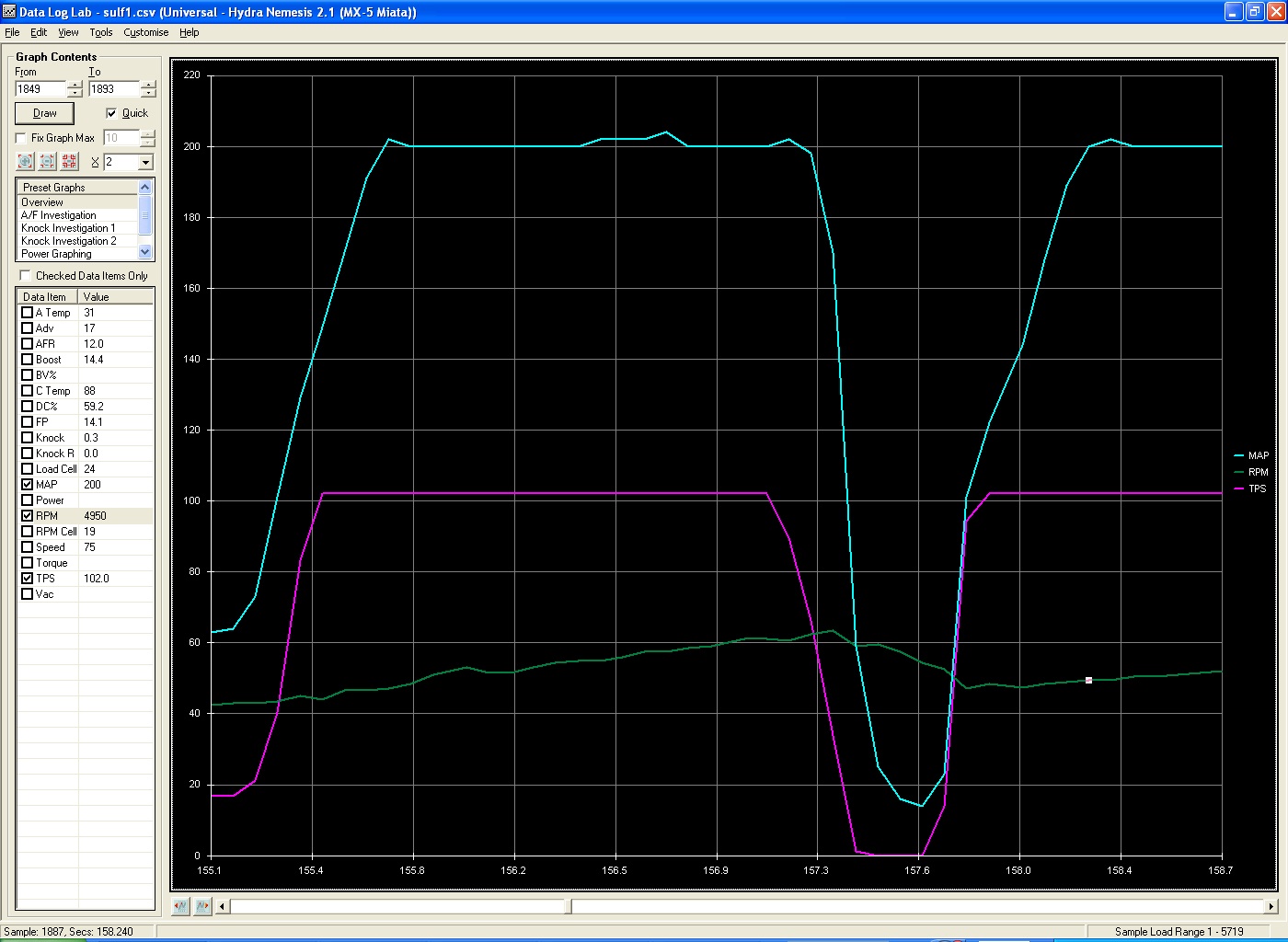

Here's a screen capture of a datalog from my car:

The light blue trace is manifold pressure, and is measured in kpa. The pink trace is throttle position, measured in percent (yes, the Hydra shows full throttle as 102% for some reason) and the light green trace is RPM. The X axis is time, measured in seconds since the start of the datalog, so the graph is only 3.6 seconds long. The main part of the graph is in 3rd gear, the bit on the right is after the shift to 4th.

At the left, the TPS goes from 17% at 155.16 to 102 at 155.48, by which point MAP has gone from 64 kpa to 149. Getting to 200 kpa takes an additional quarter of a second, happening at 155.72.

The shift to 4th is similar, except that the build up to full boost takes one datalog cycle more, so it happens 0.36 seconds after the throttle pedal hits the floor.

yamaha

UberDork

6/15/13 2:14 p.m.

In reply to Knurled:

The super coupe was an oddball as far as positive displacement goes.......idk if any others ever used a similar setup with an A2A intercooler. My redline was torquey as all get out, but that was on the intake manifold with a W2A before the pressurized air reached the engine.

I need to find some good sources for a more complete understanding...

How quickly does a turbo spool down with the throttle shut? Aren't there devices which recirculate or something like that on closed throttle so the inertia isn't doing work for nothing? Crikey, apparently I need to find a complete refresher on the basic plumbing and valves involved in a modern installation...

Codrus, that's some interesting stuff. But that's just short closings of the throttle to shift; how far down does the turbo's speed drop? Or is inertia overwhelmed by drag on that side, making it immaterial whether you're off throttle for 0.5 second or 5 seconds?

You really would need a 3D map to understand the full output of a turbocharged engine. Even fixed at WOT, power is the result of RPM and boost, not just RPM.

ransom wrote:

I need to find some good sources for a more complete understanding...

How quickly does a turbo spool down with the throttle shut? Aren't there devices which recirculate or something like that on closed throttle so the inertia isn't doing work for nothing? Crikey, apparently I need to find a complete refresher on the basic plumbing and valves involved in a modern installation...

About as long as it takes for you to hear the blowoff valve make its shooshy sound or the compressor surge to giggle. Then it's effectively spooled down.

I've seen reports from people who have actually measured with a turbo tach that the despool is actually faster with a BOV than without, for the same reason that a hair dryer will speed up if you close the end off. It is an air mover but it's not positive displacement, so you can stall the thing without loading it much. A blowoff valve, so the theory behind the phenomenon goes, keeps load on the turbo since air is still flowing, so it uses up the inertia faster.

Of course, as with anything, you can't take a specific example and call it a generality...

yamaha wrote:

In reply to djsilver:

You know the roots type blower on the 2 stroke Detroit diesels is only there for scavenging don't you? Otherwise a two stroke diesel will not run.

Yes, and the design with the intake valves in the head and the exhaust ports in the cylinder wall is called a "Uniflow" engine because the gases enter the top and exit at the bottom so they don't have to make a U-turn. The term "uniflow" pre-dates diesel engines. Do you know where it originated? ;-)

djsilver wrote:

Yes, and the design with the intake valves in the head and the exhaust ports in the cylinder wall is called a "Uniflow" engine because the gases enter the top and exit at the bottom so they don't have to make a U-turn. The term "uniflow" pre-dates diesel engines. Do you know where it originated? ;-)

Unibrau's efficiently German periods?

Knurled wrote:

djsilver wrote:

Yes, and the design with the intake valves in the head and the exhaust ports in the cylinder wall is called a "Uniflow" engine because the gases enter the top and exit at the bottom so they don't have to make a U-turn. The term "uniflow" pre-dates diesel engines. Do you know where it originated? ;-)

Unibrau's efficiently German periods?

Germany was involved! It was one of the final design stages of piston type steam engines. In the link below, the writer even mentions that Detroit Diesel adapted the design to their 2-stroke diesels.

http://www.classicsteamengineering.com/index.php?topic=281.0

ransom wrote:

So the scenario I was attempting to ask about is:

1. Close the throttle from WOT at 5000 RPM

2. Brake or coast down to 3000 RPM

3. Get back to WOT, turbo begins spooling, car is accelerating

4. At x time later and 3000 + y RPM the turbo is fully spooled and power should match the dyno chart, more or less.

Very curious about x, and probably the shape of the curve between getting back on the gas at 3k RPM and arriving at full boost.

Compounding all this is that you might not go back to WOT at 3k. You might want a short burst of half-throttle, or 3/4 throttle. Depending on the turbo's state, that's going to be a varying amount of power, and the less throttle you give it, the slower it's going to spool back up... Right?

Really, what happens before 3 isn't relevant. The question is: at X rpm, how long does it take the turbo to hit the maximum boost available at X rpm? And codrus gave us a real-world example - you can extract the info from on-road datalogs best, it's not something that lends itself to dyno testing as well. Every time you datalog a shift, you see it.

How long it takes to reach maximum boost (regardless of RPM) is a different matter. Again, going back to a naturally aspirated car, imagine you've got one with an aggressive cam and a problem with a bog on tip-in. The hesitation is your lag and the time it takes to get up to your cam's favored RPM range is the spoolup time.

Turbos don't ever stop spinning, so they don't really "spool down". They spin at idle. When the bypass valve opens, you dump the air that's post-turbo but you don't stop the turbo.

And turbos generate boost according to demand. So no, it won't spool up as fast if you don't give it full throttle. In fact, it won't fully boost at all. If you want full boost, you use full throttle. Seems reasonable enough

Why use a centrifugal? They're easy. They're popular with V8 guys for some reason, probably due to packaging in front of the engine instead of a big bulky PD supercharger. And they don't have such a variety of load/boost/rpm conditions as turbos, so they're easier to tune.

That 450+ hp Miata at FM runs a GT3076R with an external wastegate, I think. It's also on a 2.0 and runs E85 for those power levels. We don't know what the maximum power level is, it maxed out our old dyno

ransom wrote:

I was looking about in hopes of finding a graph of someone overlaying graphs of WOT with graphs including tip-in from off-boost so we could see how quickly the latter catch up with the former (though this would only be in RPM, not time...), and found a related discussion on miata.net with both Keith and Corky Bell (or someone with that username) checking in. No luck finding such a graph, though.

Yes, that is the real Corky Bell who posts there.

Keith Tanner wrote:

Why use a centrifugal? They're easy. They're popular with V8 guys for some reason, probably due to packaging in front of the engine instead of a big bulky PD supercharger. And they don't have such a variety of load/boost/rpm conditions as turbos, so they're easier to tune.

I think a lot of the centrifugals on domestic muscle cars come from a couple factors:

Ease of packaging on a V8 - it's about like hanging an extra alternator off the motor. That also means it doesn't take very much time to install.

Lots of low end torque and not much top end, so a centrifugal's boost delivery helps with the weak points in the existing torque curve.

That 450+ hp Miata at FM runs a GT3076R with an external wastegate, I think. It's also on a 2.0 and runs E85 for those power levels. We don't know what the maximum power level is, it maxed out our old dyno

Was that a Dynapack Evolution 2000 by any chance? Just wondering as we used to have one at DIYAutotune with a similar limit.

The old dyno was a Rototest. They have higher level ones, but at the time we bought the dyno that sort of power level in a Miata was science fiction.

![]()