http://jalopnik.com/worlds-first-variable-compression-ratio-engine-could-ki-1785295848

Seems like a very interesting concept. Basically a higher compression engine that will then decrease compression ratio as boost builds. Could be interesting, lots of moving bits to break, but cool none the less.

Worlds first??? Saab was doing it back in the 80s. Jalopnic needs to learn history a little better.

Saab head would move up and down.

In reply to alfadriver:

Yep, i believe the saab head tilted though didn't it? Cool idea either way.

It was more like year 2000, but yeah SAAB had a cylinder bore attached to the head, which could tilt relative to the block. Both designs are pretty cool.

In reply to maschinenbau:

I'll have to check SAE, but I swear I heard it back in the 80's. Not for production, but a research project.

Given that it came out in the 9-5 in 2000, it would be correct timing to have an SAE paper engine in the 80's.

If my Subaru's rings are anything to go by, I think they have prior art on variable compression ratios.

In reply to alfadriver:

After further reading, you're right. They had earlier prototypes and patents in the 80's and 90's. It became famous in 2000 for winning an engine award. Oh and it's a supercharged 1.5L inline-5 making 150 hp per liter

I wonder how they work around the quench distance changing radically. Common consensus is quench distance between .040 and .080 or so actually increases the likelihood of detonation compared to smaller or larger.

Knurled wrote:

I wonder how they work around the quench distance changing radically. Common consensus is quench distance between .040 and .080 or so actually increases the likelihood of detonation compared to smaller or larger.

Im over my head here, but could direct injection help combat this?

that's a bunch of highly critical moving parts...

Wouldn't using a computer controlled bypass system on a positive displacement supercharger achieve the same thing with less re-engineering and less stuff to break?

java230 wrote:

Knurled wrote:

I wonder how they work around the quench distance changing radically. Common consensus is quench distance between .040 and .080 or so actually increases the likelihood of detonation compared to smaller or larger.

Im over my head here, but could direct injection help combat this?

Some, but you would run the compression up to match the DI inclusion anyway.

I think the huge achievement here is that it's going into production. That's 1 too many caveats for a Jalopnik title soooo they of course just ignore it. The audience that can appreciate the achievement of going from functional prototype to production feasible is pretty small. :(

Nissan said:

Nissan engineers said the new engine matches turbodiesels in torque, and is actually cheaper to build than modern turbodiesel engines.

I'm gonna read between the lines here, "VW's cheap(ish) cheating diesel is the only reason we didn't do this years ago".

Trans_Maro wrote:

Wouldn't using a computer controlled bypass system on a positive displacement supercharger achieve the same thing with less re-engineering and less stuff to break?

Or a light pressure turbo on a moderately high compression engine...

44Dwarf

UltraDork

8/15/16 6:50 p.m.

alfadriver wrote:

Worlds first??? Saab was doing it back in the 80s. Jalopnic needs to learn history a little better.

Saab head would move up and down.

It was done very early in WW2 on gas start diesel engines...my brother has a D9(?) ex-military dozer. pull the lever the plate move out of the side of the head. you start it on regular gas as you push the lever in the plate slides into the top of the chamber and it switches to oil burner mode.

Wouldn't a Koneggsigg style fully camshaft-less electro-pnuematic valve train be able to accomplish the same thing (with 99% less Rube Goldberg) by selectively Atkinson cycling the intake valves?

That looks like a mess

In reply to 44Dwarf:

Learn something new. Cool.

In reply to HappyAndy:

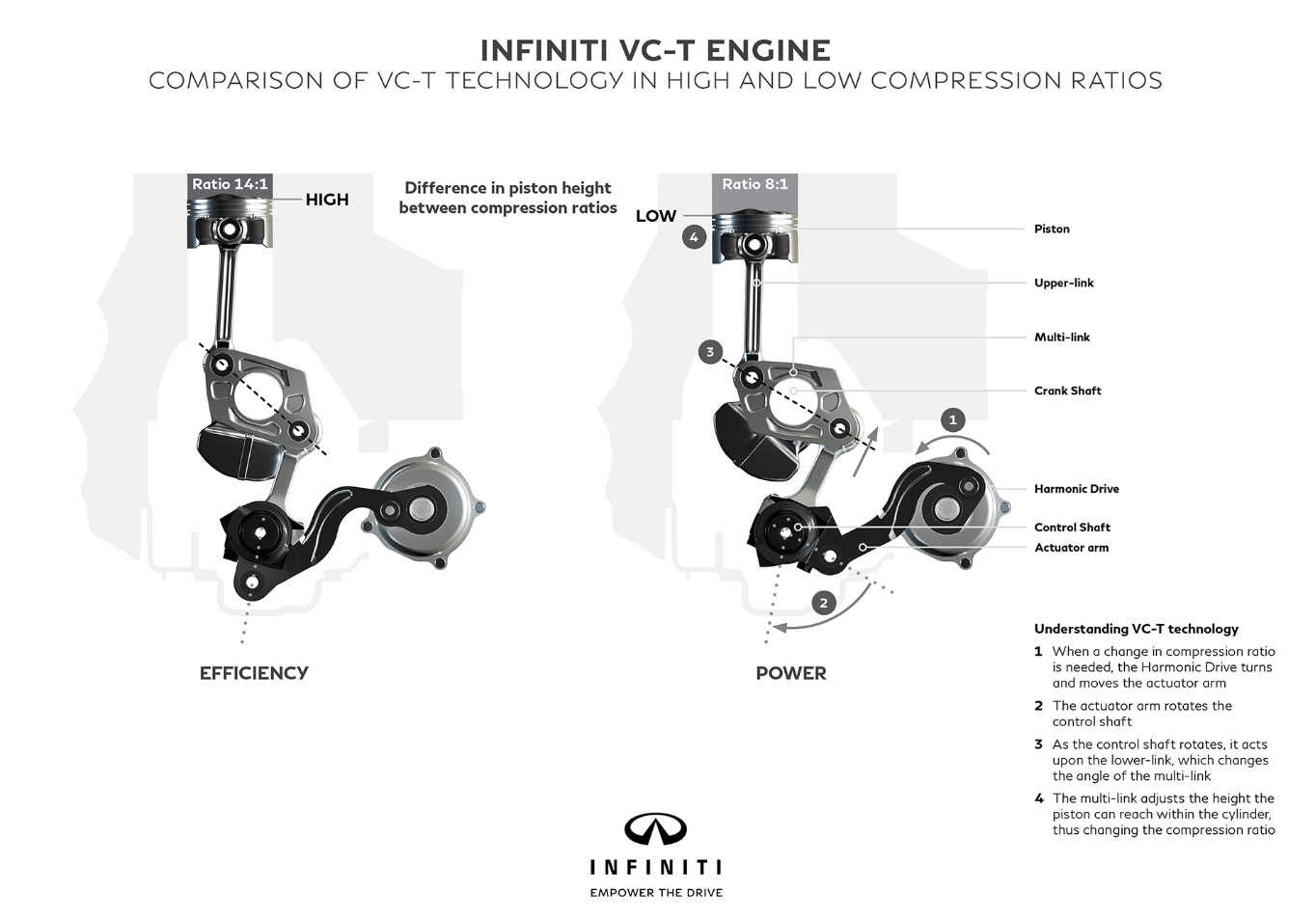

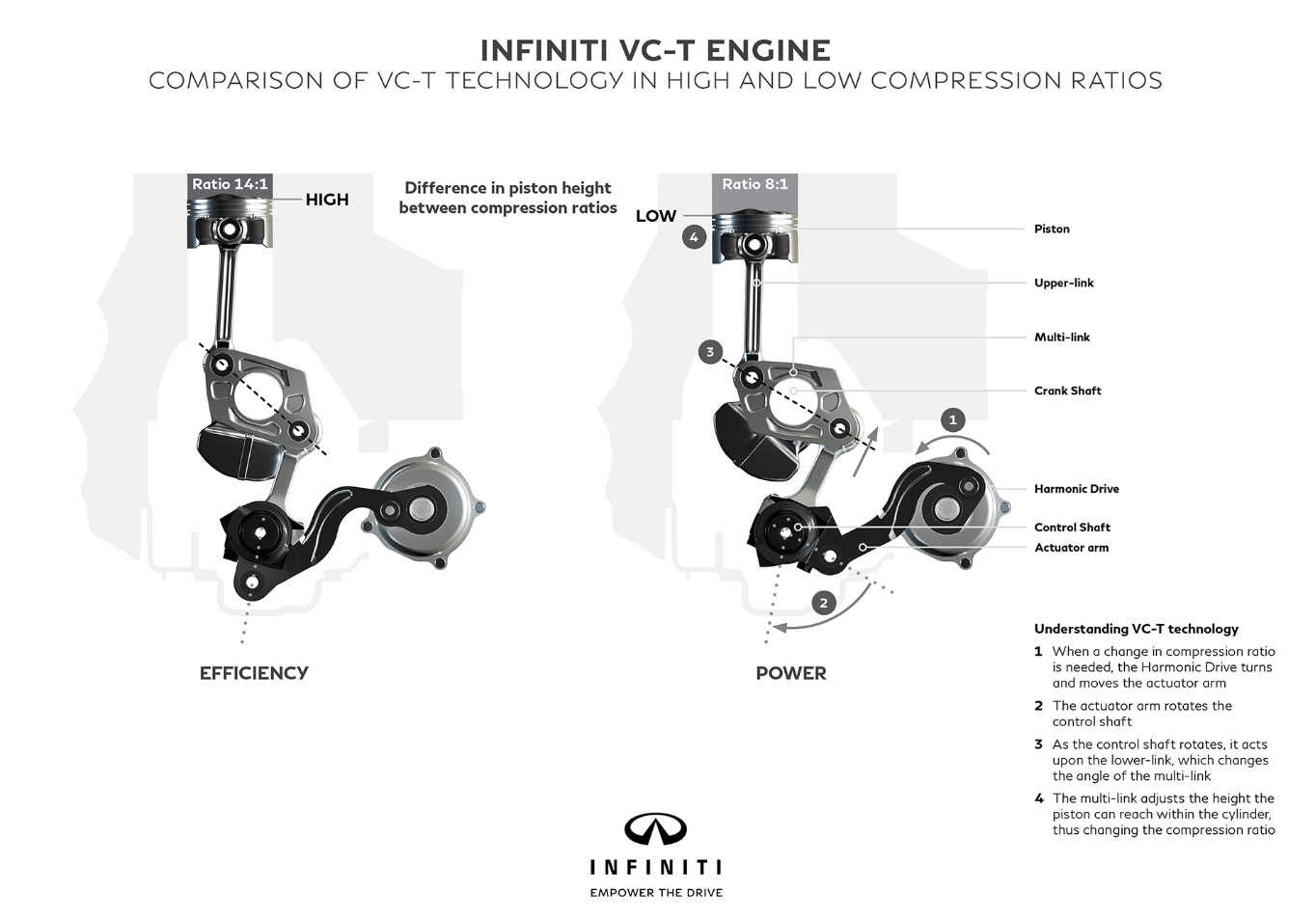

It claims they're already doing Atkinson cycle with VVT, this Rube Goldbergery just lets them push more boost into it when desired.

Ah shoot, mah 22re ah-Ready has varee-uhbel compresshun. Let's see, uh silinder wun gots wun-siggsty, silinder too has, erm.. Fiddy. And the other too has like nine, or nine hunnerd. I furgit.

Gonna swap it inta mah cramit.

(That was so hard to spell out! I fought auto correct the whole time...)

So nissan is going to make the highest horsepower per lb engine (that 3 cylinder 400 hp 80 lb thing) and this. Which will weigh an epic butt ton due to the weight of the variable apparatus and make the LS swap weight savings.

STM317

HalfDork

8/16/16 8:19 a.m.

In reply to Flight Service:

That brings up a good point. I wonder how much weight/size this new tech adds, and if the improvements in fuel efficiency/power will be enough to offset the increased size/weight/complexity.

I bet it doesn't add much weight, probably equivalent to the weight of a few extra con rods. And if you factor in the weight savings from engine downsizing (this 2.0L I4 makes the same power and torque as a 3.5L V6) then the whole package is pretty appealing.

HappyAndy wrote:

Wouldn't a Koneggsigg style fully camshaft-less electro-pnuematic valve train be able to accomplish the same thing (with 99% less Rube Goldberg) by selectively Atkinson cycling the intake valves?

That looks like a mess

Koenigsegg's cam-less valvetrain is electromagnetic, no pneumatics involved.