Saturday morning I picked up the stuff to start powdercoating. Sweet!

Then my son showed up with his Venture to track down a coolant leak. The weekend went to hell after that. Blown lower intake manifold gasket again.  I had done these gaskets 100K ago when I owned the van. New and improved gaskets, they said when I did them. BullE36 M3. The factory gaskets lasted 130K.

I had done these gaskets 100K ago when I owned the van. New and improved gaskets, they said when I did them. BullE36 M3. The factory gaskets lasted 130K.

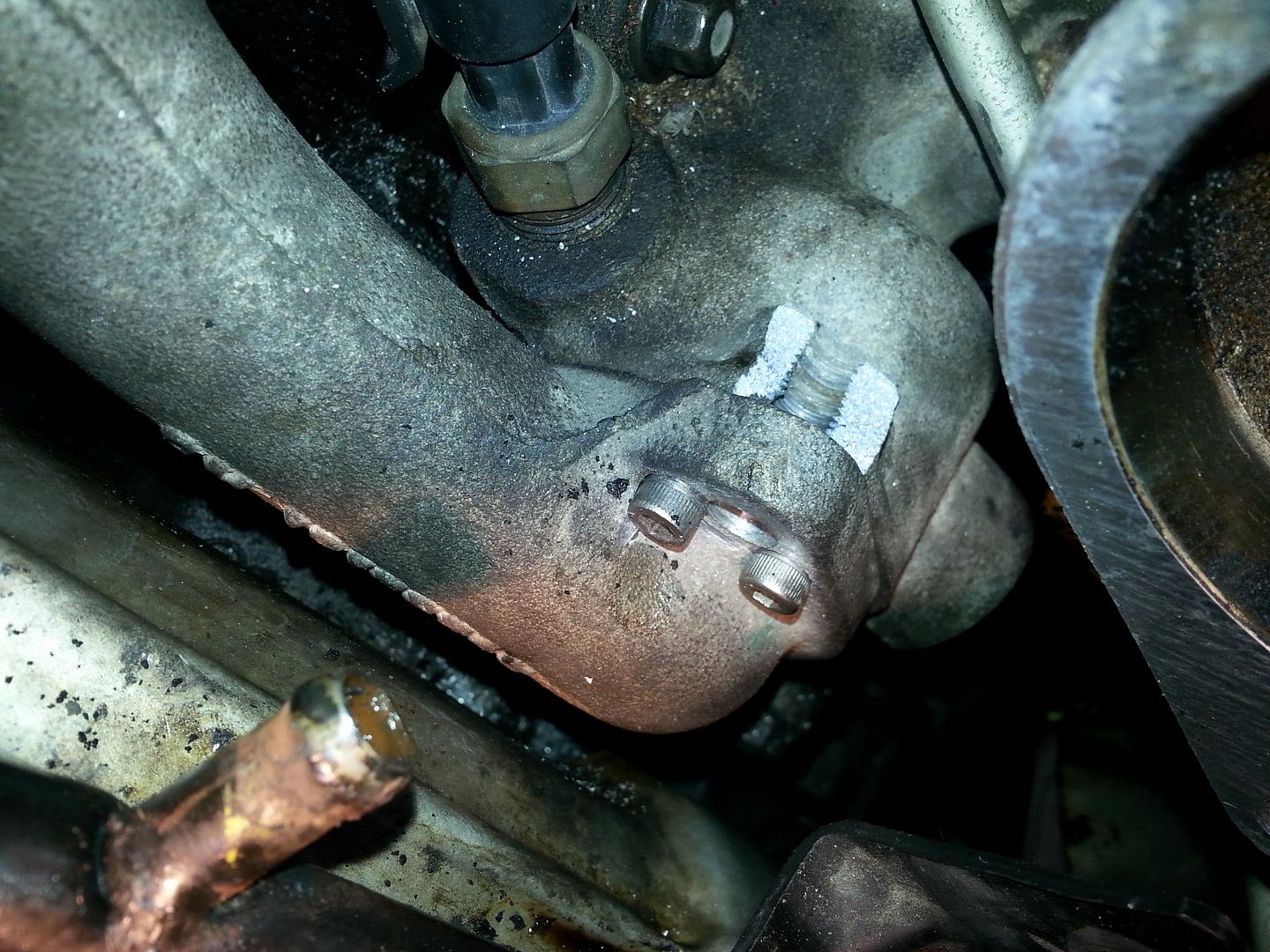

So I let him do most of the tear down. 5 hours later everything was clean and ready to assemble starting Sunday morning. What should have taken another 4-6 hours ended up taking 10. Things really deteriorated when he busted the threads the thermostat housing bolted to. Naturally that was on the lower intake, you know, that part we just spent 8 hours R&Ring.  The first time I did these, it took me 10 hours, start to finish including getting all the baby E36 M3 out of the crankcase. This set was nice enough to fail on the exterior of the engine, but it still ended up being a royal PITA.

The first time I did these, it took me 10 hours, start to finish including getting all the baby E36 M3 out of the crankcase. This set was nice enough to fail on the exterior of the engine, but it still ended up being a royal PITA.

I rigged the thermostat housing together. We'll see how long it holds. Anyone want to place bets. It will either fail in the next week, or it will last as long as the engine does.

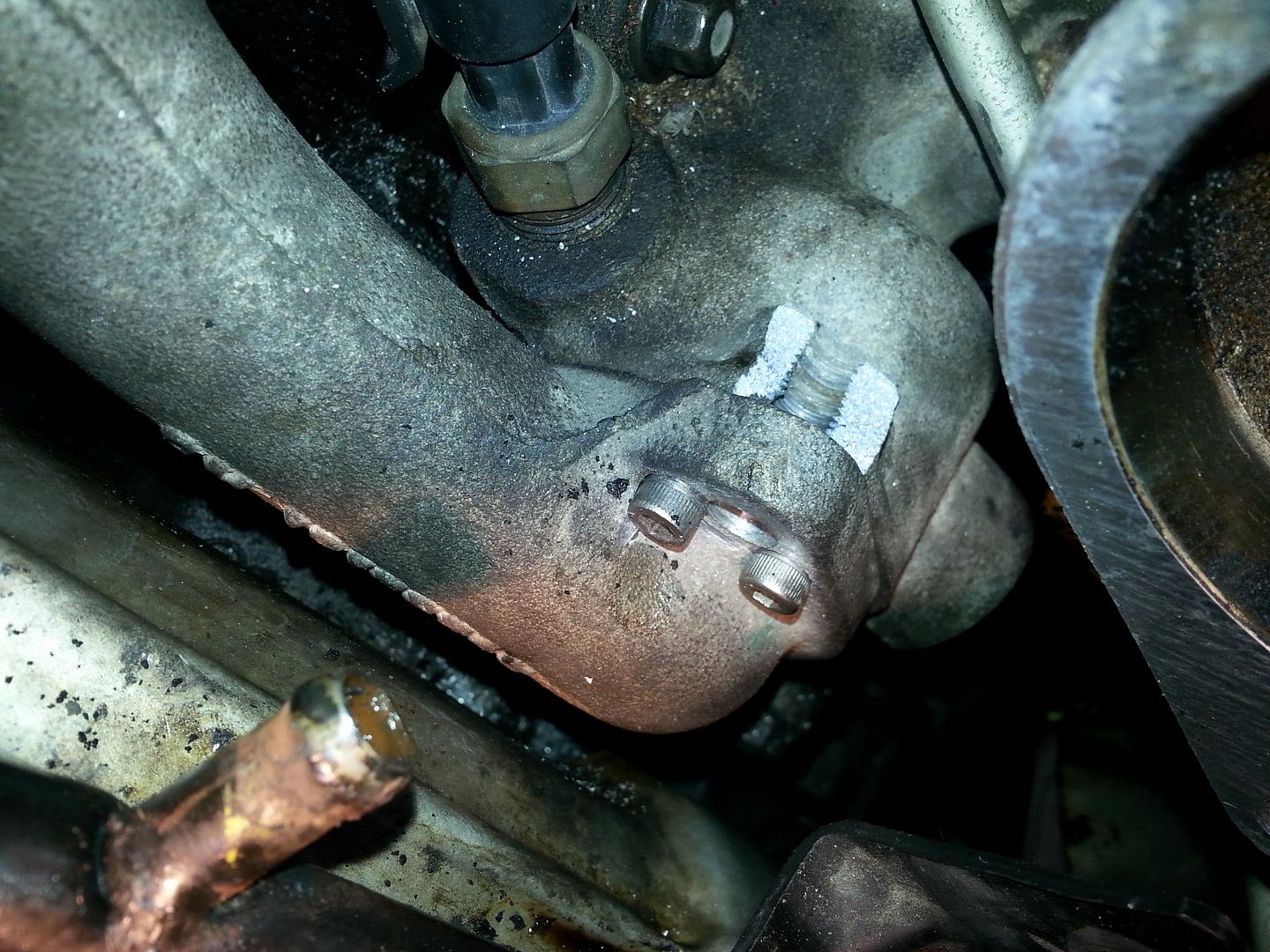

Why GM insisted on making these out of plastic I will never understand. Then again, Felpro's replacements were plastic too. The new ones are steel. I have hopes they will last longer.

The original set failed in the exact same way.

This is what 230K of very hard miles look like in a GM 3400.

As much as I hate the design of the top half of this engine, with the push rods that run through the intake, the thing is as quiet as the day it left the factory. It's amazing how one cheap part can really screw up a decent motor. Damn bean counters, I bet the original design had a expensive metal gasket in it.

Oh, and that engine was much cleaner when it all went back together.

The steel ones dont fail. I do them in about 2 hours:-p

Over yonder is the tool box. Have at it.

The metal backed ones are the new and improved. The plastic ones are the old and busted. Putting the plastic ones in is almost as dumb as doing an oil change and putting the old oil right back in again. You haven't fixed anything, you just worked on it a bit.

I have never, ever, EVER had to replace a metal-backed gasket on a 3100/3400, only the plastic ones. GM started using the metal ones at the factory with the 3.5 engine. I've seen them with 200k and still the original gaskets. Have never seen one fail, either.

PS - There's a tool for removing the pushrods that makes the job go super fast and you don't have to worry about pulling the rocker threads out of the head from overtightening. Too late for you, now, though, since you'll probably never have to do this job ever again.

I had to do this on my '99 Venture. It's amazing how fast E36 M3 goes down hill when you break something.

(Not looking forward to doing it on my '04 Silhouette)

Overall, I'm very pleased with the vans and I've thrown a ton of abuse at them.

At Knurled: When I did them the first time, the metal ones weren't available, apparently. That was at least 10 years ago.

At TRoglodyte: I did other than advice and help on the harder stuff.

At Jaxmadine: You make me sick.  I'm sure there are all kinds of tricks I don't know that make it much faster.

I'm sure there are all kinds of tricks I don't know that make it much faster.

I did a 3100 intake gasket for 300 plus parts and felt like I didn't charge enough.

At fornetti14: The van has been outstanding. My wife put 130K on it. This is the second set of intake gaskets, it's had one front A-arm replaced, an alternator, (that I replaced while I could get to it easily when I did the first set of intake gaskets) a A/C compressor and that's it. It's hauled kids, boats, trailers, furniture, two GM 4200 I6s, done smokey burnouts, skipped oil changes when the wife forgot, and survived two teenage drivers. What more can you ask of a vehicle.

moparman76_69 wrote:

I did a 3100 intake gasket for 300 plus parts and felt like I didn't charge enough.

NFW!

If you did enough of them, it would might be worth it. It's still an ass load of work.

The problem with the Venture is the entire back side of the motor is under the windshield. Stabbing push rods when you can't see what you are doing isn't fun. I ended up getting out my inspection camera.

There is a ton of stuff you dont really have to take off, like the t.stat housing. Having the pushrod tool is also a godsend. Ive only done about 30 or more of those things. 3.8 is so much easier tho.

mad props tho. The venture does suck.

Buy him a straight six Bel Air, early sixties.

I think we get $700-800 including parts/fluids. The metal gaskets are NOT cheap but we refuse to install the plastic ones. Heck, we had to do an engine in one once (lost a rod...) and we didn't even want to put the replacement engine in until we took it apart and put the metal gaskets in it. Because the plastic ones have a 100% failure rate and it's much cheaper to do it on an engine stand where there's better access and it's already drained of fluids

The pushrods are SUPER EASY if you have The Tool. You just clean everything up, drop the gasket in place, lay the long pushrods against the exhausts and the short pushrods against the intakes, then you put The Tool over the rocker and lift it up high enough that the pushrod falls into place. Done. Takes less time to pop a row of six on than it does to explain it. And you don't risk pulling the #1 exhaust rocker out after you accidentally overtighten the rocker on an '01-up engine with the 8mm thread bolts which was the DUMBEST IDEA EVER, GM, WHAT WERE YOU THINKING.

Srsly. The 10mm thread rockers never had an issue. WTH?

In reply to Jaxmadine:

The only reason we pulled the thermostat housing was to change the thermostat. It had been running cold lately. I've broken housings before, but never the boss off the intake. The thermostat got cocked so he was going to pull the housing back off. The air ratchet was set to tighten. Pop.

TRoglodyte wrote:

Buy him a straight six Bel Air, early sixties.

He would love one, but I doubt his wife would go for it.

We've also seen a near 100% failure rate of the upper manifold at the corners. The runners crack right at the bolt bosses. One fastener per runner is not enough. Oddly enough, while carbon seeps through the crack, it never shows up as a vacuum leak, so we only replace them if the boss actually separates from the manifold.

Which we've seen happen, and it still didn't have a vacuum leak. Maybe 6 bolts really is enough, if five still works well enough to seal.

Then he needs a new wife. Lol

TRoglodyte wrote:

Prefers walking?

Prefers going in debt for a new car. That isn't an option.

In reply to Knurled:

Plastic or aluminum upper?

This is a 99 so it has the bigger rocker studs and the entire intake is aluminum.

Aluminum. (I don't think they ever made a plastic one) The ones with 3 bolts per head will crack, the ones with 6 bolts per head don't.

But the intakes/heads that have 3 bolts per head are also the ones that flow air like little baby hurricanes. The 3.5/3.9 heads are better still, but the geometry is different so you can't put them on an older block to get high airflow and high compression for low dollars.

Not that I've looked into this for a long time or anything...

Vigo

UberDork

9/30/13 9:40 p.m.

This is one of the reasons why i rarely recommend anything with that motor. And it's not JUST the lower intake gaskets. That issue is annoying, sure. But the REAL issue in my mind is that damn never everything on the top of that motor is harder than it should be other than the water pump and the alternator. The design just annoys the hell out of me (it took a while to get to this point).

Maybe i'm spoiled by dodges, but the 3.3 in Caravans is both more reliable AND easier to work on.

I always sort of guffaw when i've seen people here recommend the gm minivans. Maybe you buy a van that has had those gaskets done. Maybe you do them once and figure you'll never have to do them again. Well, fool you twice...

I really like the 3.8 from the same years. The difference between a 3.1/3.4 and a 3.8 is huge in my opinion.

I have had an epiphany!

After a morning of visits to the insurance agent and credit union, I have made an incredible discovery . . . .of course still in the study stages BUTT (and its a big butt) I offer my (ahem) theory.

Each of us is responsible for our own suffering.

I. e. (in example):

you picked her up at the bar,

you didn't pay your bill,

you choose to live in this wonderful democracy (only the best after you've tried the rest),

who purchase that POS????

you didn't vote,

(or worse) you voted for the wrong candidate,

you chose to maintain a power slide for 2 blocks (and hit the power pole),

that is my theory, which is mine and correct.

Let the whining STOP.

Vigo wrote:

Maybe i'm spoiled by dodges, but the 3.3 in Caravans is both more reliable AND easier to work on.

notsureifserious.jpg

I like how they call for 2.5 hours to do the spark plugs. 2.2 of which are for getting at ONE of them. I did find a way to cheat, though - you mangulate the exhaust manifold heat shield and get at it with an open end wrench from underneath. Even removing the wiper cowl (a 3 minute process) gives you no room to work back there.

And the 3.3 eats intake gaskets too, assuming that the rocker shafts stay attached to the head long enough for it to get to that point. You'd probably never know that the intake was leaking given the perpetually failing water pumps prevent the engines from holding coolant long enough to have visible leaks anywhere else.

Of course, it IS understandable that the water pumps fail. It's the lowest point in the cooling system, and all of the crap in the cooling system collects there during the long periods where the minivan is idle while the 4-speed auto is being rebuilt/resealed. Again.

Vigo

UberDork

9/30/13 11:03 p.m.

Well i guess since we've already had a "i do lower intake gaskets in 2hrs on 3.1s" in this thread i'll contribute that i've NEVER had to bend anything to do plugs in a 3.3/3.8, and i've NEVER had to take the cowl off either. Or the intake manifold, for that matter. Guess im just good?

As for the rocker shafts, as far as i've seen that was only an issue on the first couple of years and never since.

The water pumps are easy on the early 3.3s but somewhat annoying on the later ones. Good thing you only have to do them as often as GM intake gaskets.

And which part of the lower intake gasket is failing on 3.3s? The sheetmetal part or the sheetmetal part? Gotta admit i don't know much about that problem. In fact, i had never SEEN a 3.3 lower intake gasket until this past spring, and i've owned at least one 3.3/3.8 car every day since 2001 and worked as a tech most of that time too. Just lucky?

![]() I had done these gaskets 100K ago when I owned the van. New and improved gaskets, they said when I did them. BullE36 M3. The factory gaskets lasted 130K.

I had done these gaskets 100K ago when I owned the van. New and improved gaskets, they said when I did them. BullE36 M3. The factory gaskets lasted 130K. ![]() The first time I did these, it took me 10 hours, start to finish including getting all the baby E36 M3 out of the crankcase. This set was nice enough to fail on the exterior of the engine, but it still ended up being a royal PITA.

The first time I did these, it took me 10 hours, start to finish including getting all the baby E36 M3 out of the crankcase. This set was nice enough to fail on the exterior of the engine, but it still ended up being a royal PITA.