http://www.wvstreets.co/showthread.php/43335-85-GLH-Turbo-build?p=637823#post637823

Someone invite that guy here, STAT!

So is he changing the timing by having a roller push on the 'pull' side of the timing belt?

Spoolpigeon wrote: Someone invite that guy here, STAT! So is he changing the timing by having a roller push on the 'pull' side of the timing belt?

Damn that's cool.

Looks to me like his rollers take the place of the tensioner, it moves both sides of the belt at the same time. It's the same idea that VW etc used on the cam chains only it works on the outside of the belt rather than the inside.

I think if he were to put one of those rollers on one of those automatic damped timing belt tensioners like Isuzu, Mazda etc use it would get rid of that rattle noise, the rattle would concern me because that means vibration will quickly fatigue the metal.

Without clicking the link, it sounds like the Variocam system that Porsche used since the 90s, and what VW uses on pretty much everything with a single cam pulley and DOHC. (1.8t primarily)

Wait I don't understand how this works...the belt tooth engagement never changes, so how does the timing change?

I could see it changing a little by changing where the belt stretches, but would it make that much difference?

Edit: NVM figured it out, it makes sense if you picture what it does if the engine's not running. It makes a big difference in how much belt is on each side of the cam wheel.

This is the kind of thing I really want to copy and put on my car even though the power gains aren't huge, it's just so cool, like variable trumpets ![]()

GameboyRMH wrote: This is the kind of thing I really want to copy and put on my car even though the power gains aren't huge, it's just so cool, like variable trumpets

You know the mechanical advance mechanism in a distributor?

There used to be a device like that for VW 8v cam gears. I think it predated the 16v engines, to give an idea of how old it was.

It's been a long time so I don't remember specifics, but I assume it was a retard mechanism. Probably heavily preloaded if it were to work at all, given that normal loading would want to make the cam retard anyway. Then again, it obviously worked so well in practice that nobody else ran with the idea, or made it for other engines...

Knurled wrote: Then again, it obviously worked so well in practice that nobody else ran with the idea, or made it for other engines...

Or the patent hasn't run out yet ![]()

Mr_Estrotica wrote: In reply to Knurled: They were made by Franco Industries. They're a pretty cool piece of kit.

Yeah, I have one on my 924, made a nice difference in power range with the bigger cam and ITB's.

Before I sold the CSX, I thought about adapting it to fit the SOHC 2.2 Chrysler motor.

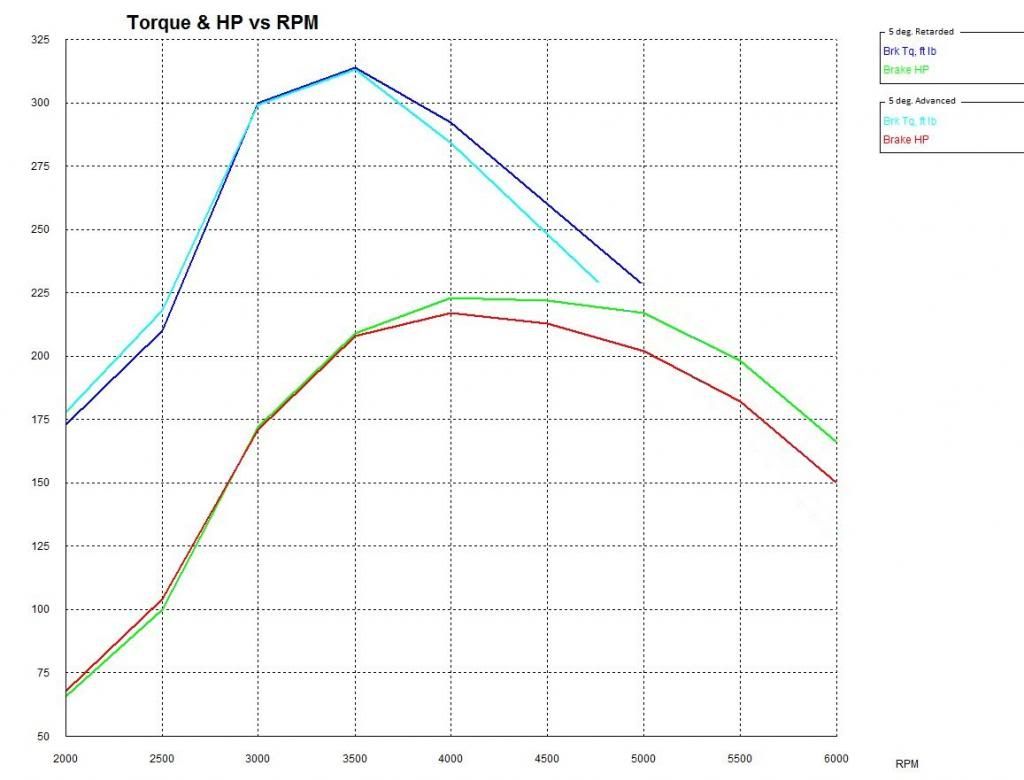

Hi all! Thanks dansxr2 for inviting me. I have a video that shows the basic idea of how this works. http://youtu.be/EsOdmfDA5Rc This mod is mostly just an experiment that I've wanted to do for years and finally got around to trying. It does not make the hp or torque peak any higher but it does add torque under the curve at the low end and a little more horsepower at the top end. I've set the system up for 10 degrees total cam timing change or 20 degrees crank timing. I ran the engine specs through engine analyzer pro and changed the timing from 5 degrees retarded to 5 degrees advanced and overlayed them on the same chart. I am hoping this spring when I get back to a dyno I will see similar results. Torque improves about 5-8 ft lbs and hp shows improvement from 3500 rpm up and by 5000 rpm it gains18-20 hp to the redline.

Hey bud.. I looked over your build thread.. its pretty nice.. I would love to see the pictures of your intercooler set up...

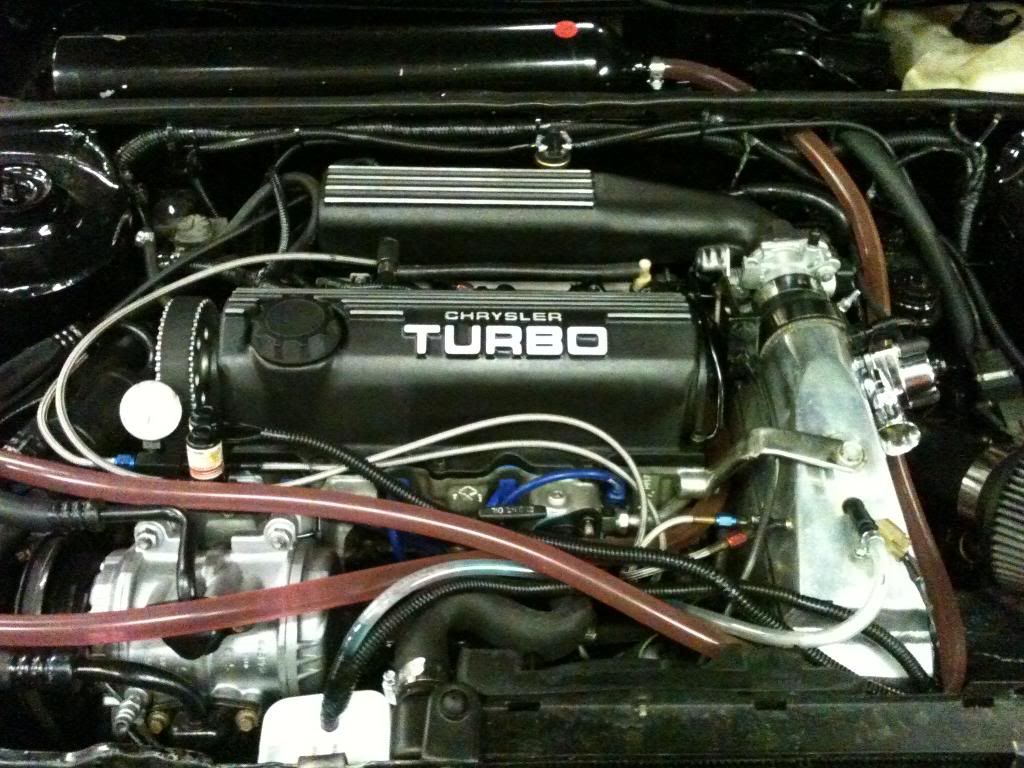

I try to do everything as cheap as possible but also as dependable as I can. This water to air intercooler was built for less than 350 dollars. I used an ebay intercooler and bov. The pump is a used 02 Dodge Durango rear heater boost pump. The reservoir is an old portable oxygen tank. Dodge Omnis have no room under the hood. If you add a large after market intercooler you pretty well have to do away with the a/c system. I can't live without a/c so I use it to pre-cool my water for the intercooler. The a/c compressor runs normally cooling the water through the heat exhanger that I also bought off ebay. Over two gallons of water can be cooled down to below freezing even during the hottest summer days. I run a mix of antifreeze in the coolant to keep if from freezing. Anytime the throttle is pushed beyond 70 percent the compressor kicks off but the water pump stays running. This keeps the intercooler very cold. As soon as you let off the gas the compressor kicks back in and starts cooling the water down for the next run. The system is efficient beyond belief. I've seen underhood temps at 105+ but the output of the intercooler under 20 psi boost is in the 80's and 90's. With my old air to air I hardly every saw anything less than 150 under that kind of boost. Needless to say I can run a much better advance curve with this setup.

Intercooler with bov installed. I have no intercooler piping so everything gets mounted on the top of the intercooler, Bov, nitrous fogger and methanol injector.

Heat exchanger installed into the a/c low pressure hose.

Durango rear water pump and oxygen tank.

Beta testing the heat exchanger. Minus 3.5 degrees on the outside of the exhanger. Of course this is without water so its colder than when its actually transfering heat. This was in the middle of summer on a rainy day. The rain water froze instantly when it hit the outside of the exchanger. I've seen 14 below after it runs 4 to 5 minutes, that is why I run a mix of water and antifreeze.

Complete system with red Toyota antifreeze mixed in the coolant just for looks. Nitrous and methanol added to make the coldest air charge possible on my budget lol.

We need to chat sometime! I'm in Sutton and would love to see this thing in person. I like you have a vendetta to show some of the local Camaro/Mustang fanboys a shot of something different ;-)

I'm sure there are a couple of them here locally that could beat me in the quarter but they really don't want to take the chance lol. The Omni is just fast enough that if they make one mistake it will be a loss they will never live down.

FINALLY! Someone that has used the car's A/C system to provide cooling to their intercooler! I've thought about this soooooo many times but have never found anyone that has done it! ![]()

Welcome!

Not much to tell really. The system is very simple. If you have any questions I will try to answer them. I just cut the low pressure - suction hose between the evaporator and compressor and put the heat exchanger in. Any a/c shop that can make hoses can do it. The freon that is returning to the compressor can still absorb a lot of heat even after it cools the interior of the car. It does strain the condenser somewhat so I run two fans on mine, one pusher and one puller. The car has no heat soak problem like most intercoolers, the longer it idles the better the intercooler works! On a 70 degree day I've measured the intercooler water tank at 25 degrees. I don't think any other kind of intercooler can match an a/c cooled system.

RossD wrote: FINALLY! Someone that has used the car's A/C system to provide cooling to their intercooler! I've thought about this soooooo many times but have never found anyone that has done it!Welcome!

There was a kit for the cobalt SS/SC, made less power than the stock air to water intercooler. The small gain from having colder air didn't offset the power draw from the compressor.

The VVT is interesting.

You'll need to log in to post.