bigdaddylee82 said:

In reply to Pete. (l33t FS) :

Other side was still on the ground. The DSG's parking pawl may not have cared for it, but the only popping sounds were from my back.

Edit for photo.

One of these things is not like the other, one of these things just doesn't belong.

Where is the rust on the flange? The chisel marks? The deformed metal from beating it to within an inch of its life with a blacksmiths hammer? None of this seems right.

Streetwiseguy said:

bigdaddylee82 said:

In reply to Pete. (l33t FS) :

Other side was still on the ground. The DSG's parking pawl may not have cared for it, but the only popping sounds were from my back.

Edit for photo.

One of these things is not like the other, one of these things just doesn't belong.

Where is the rust on the flange? The chisel marks? The deformed metal from beating it to within an inch of its life with a blacksmiths hammer? None of this seems right.

When I moved to New Mexico after wrenching on stuff in the rust belt for four decades I was shocked to learn that those are not a tight press fit!

I so wish I had been alive during the board track era!

In reply to Streetwiseguy :

I did 3 winters in Ohio, I served my time, I'm a reformed man, no chance recidivism here.

Thankfully I was dailying an 850 at the time, their bodies are galvanized, but none of their fasteners or hard parts are.

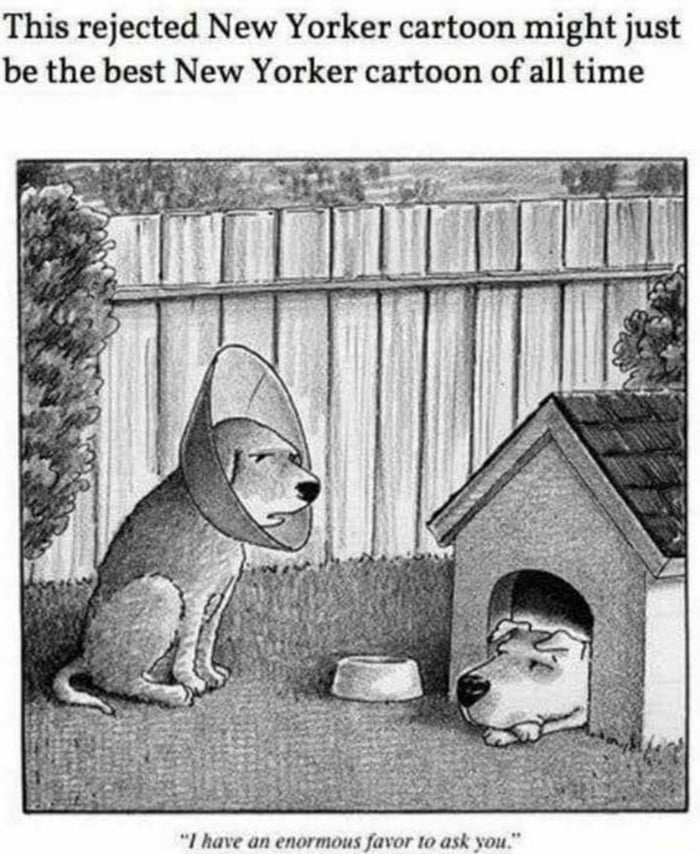

Someone had to try to do this:

Hey, Terry, sup?

Nothing much, just cooking a frozen pizza and rockin hard. Wanna come over?

RossD

MegaDork

1/18/21 2:31 p.m.

Gary

UltraDork

1/18/21 6:09 p.m.

Vanderbilt Cup Race, Long Island, early 20th century

(Balls of the finest brass ... the men, not the cars)

Can someone give me the "for dummies" explanation on chain driven rear axles?

I think it's cool af but I don't understand the reasoning behind this vs. a driveline and regular live axle.

In reply to barefootskater (Shaun) :

You don't have to be able to hob gears or cut splines to make a chain drive. Gears aren't hugely complicated to design, but the machines to make them are.

In reply to travellering :

I would think that a chain drive also means you don't have to figure out how to support the wheels while also sending power through a concentric shaft. That is a non trivial thing to do. A chain drive you would be able to use the same kind of bearings/spindle as on the front, no need to have a hollow spindle to run axles through, and then try to seal the whole mess.

Semi floating axles, like flathead or pushrod engines, is an engineering exercise in simplifying for mass production, not making better.

In reply to travellering :

That makes sense, though I'd argue that they are obviously making the gears already as the drive sprocket is perpendicular to the engine rotation. Engine>trans> 90* turn somewhere.

I was thinking it might be to do with being easier to work around suspension articulation with a chain than with a driveline and slip yoke and u-joints.

Not trying to say you're wrong! I just habitually question mechanical stuff. Almost like "well I didn't design it so it must be inferior and not work well."

In reply to barefootskater (Shaun) :

The U-joint was still a fragile new technology when The Beast of Turin in your photo was built. Not trusted for such a high torque application. Chains had been driving machinery for over a century and were trusted and predictable.

Clean ya dang batteries, people.

That crud is probably conductive.

Mr_Asa

UltraDork

1/19/21 4:42 p.m.

Titanium brake pedals for Ferraris' F1 cars. 30g each

In reply to Peabody :

Photoshop the shop and the house out of the back round and that is quite a picture.

Ok, it's quite a picture now. But the back round is cluttered.