So I am looking at adding a small cargo elevator at our church. Around 4 x 4 being lifted with a 440 pound hammer store hoist. No people, typical load would be under 40 pounds.

The attic access is at the far end of the building down a hole in my thought is to cut a hole at the end of the hallway. Only problem is that the roof trusses are 24 inches apart so I will have to cut one to make this work.

My question is if it is OK to slice through the lower beam of a truss and then just would I need to sister the ones on either side or is that a horrible idea and I should forget about it.

Pictures for general context

under the attic's central storage floor

Yeah as I looked around the internet in general I find that apparently that's a terrible idea and I should never have even considered it. I'm kind of embarrassed that I almost did that, I guess it's a HUGE no-no.

Oh well, glad I didn't start with cutting anything :/

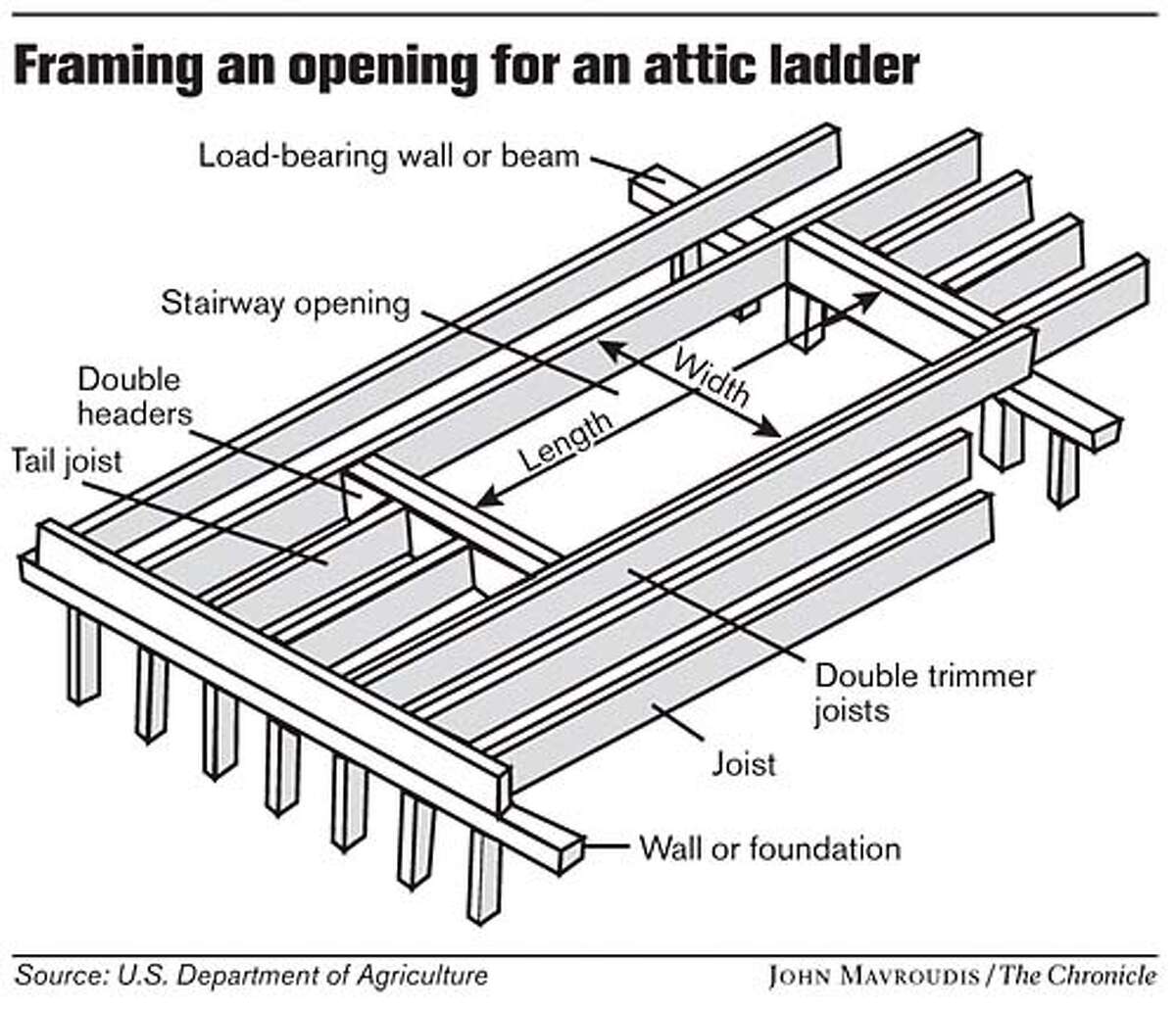

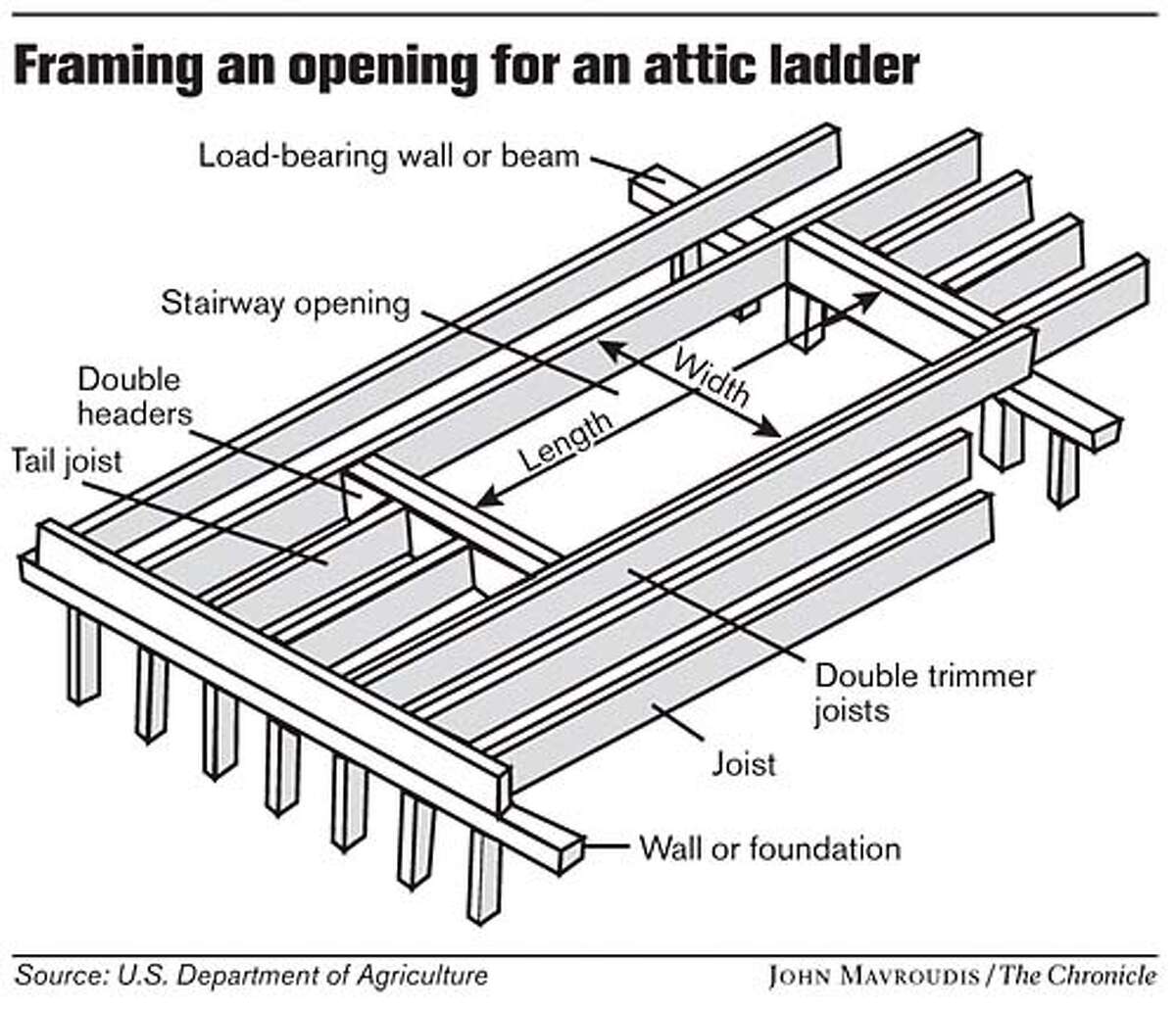

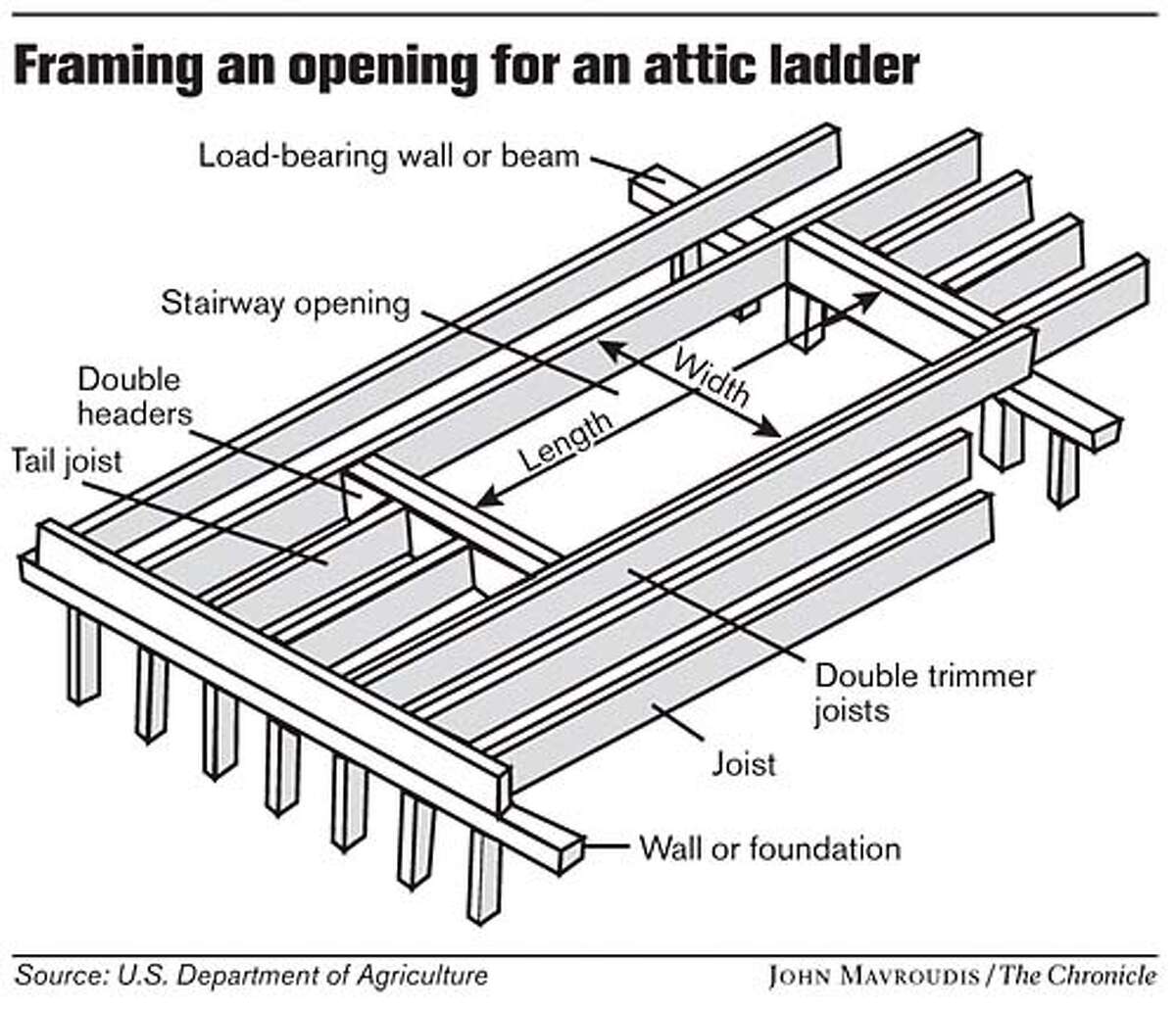

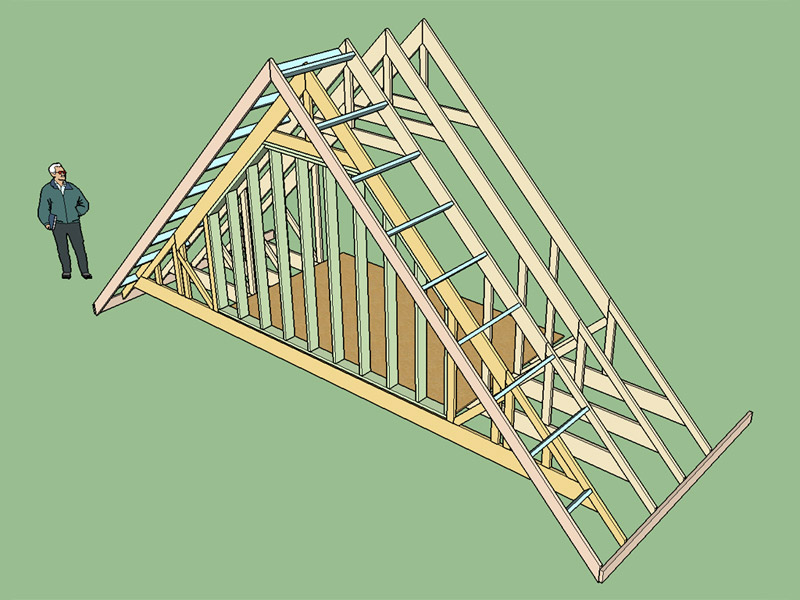

You can probably do it and box the opening to redistribute the loads. Something like this. I have done it before and that is how the attic access in my shop is done.

Most places recommend contacting the truss manufacturer before doing so.

Toyman! said:

You can probably do it and box the opening to redistribute the loads. Something like this. I have done it before and that is how the attic access in my shop is done.

Most places recommend contacting the truss manufacturer before doing so.

I'm *REALLY* excited about this project so in a surfeit of hope I went back up there, found a company label, called, and left a message with Engineering. *crosses fingers*

Duke

MegaDork

2/10/23 3:32 p.m.

In all reality, yes, you should be fine if you do it right. Personally, I would do this:

- Go up in the space next to the truss in question with a BFH and bang up on the sheathing all along the top chord to loosen the sheathing a little.

- Cut the truss in question loose from both the sheathing above and the anchors at the end.

- Slide that truss over against the next truss and spike them together about 12" on center.

- On the back side of the truss opposite, make 16" square 5/8" plywood gussets and plate every panel point where the web members intersect the top and bottom chords. Put them right over the existing metal connection plates. Screw these securely to all members they overlap.

- Put 2x6 cat framing (aka ladder framing) at 24" on center between the top chords spanning your new wider space. This will support the sheathing above. If you can't get down through the roof shingles, maybe put some light gage metal clip angles to secure the sheathing to the new cats.

If that's doable I think you will be fine.

In reply to Duke :

Hmm. Well. Since I don't know what half of those words are, maybe I'm in for trouble?

To be clear, I'm not looking to affect the roof, but go through the attic floor/ceiling. Maybe you knew that and I know nothing.

Duke

MegaDork

2/10/23 3:42 p.m.

In reply to P3PPY :

You should be able to do all that from underneath.

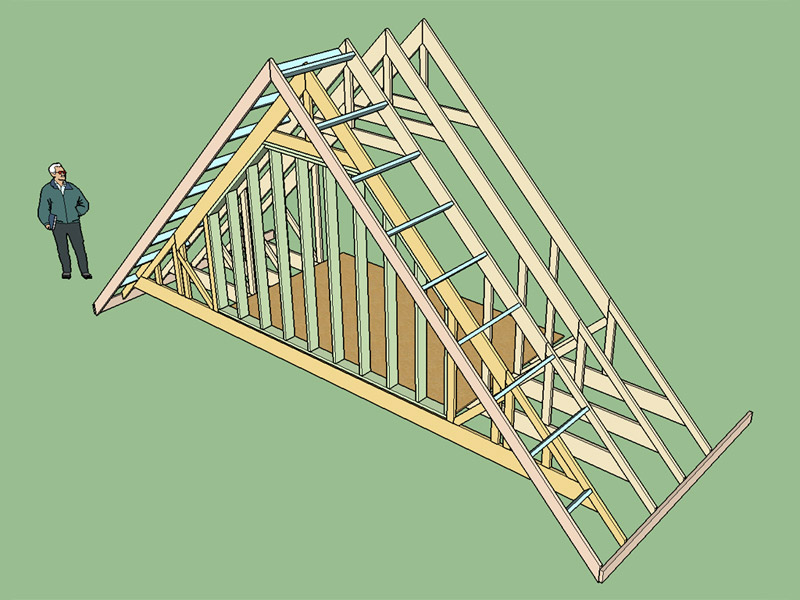

- Top chord is the sloped 2x4 or 2x6 the sheathing is fastened to.

- Bottom chord is the horizontal 2x4 or 2x6 spanning side to side.

- Web members are the internal vertical and diagonal 2xs that connect top and bottom chords.

- Panel points are the the intersections of chords and webs - basically the vertexes of all the triangles in the truss. These are where the flat metal nailing plates are.

- Ladder framing would be similar to the blue lateral pieces in the image below.

What Toyman posted up above. Have done it many times for elevators and such. You can run the structure supports on top of the bottom rail of the truss since its in the attic. Use joist hangers to carry the two cut off ends.

I would never attempt to move a truss under a completed roof. YMMV

If you cut a truss chord you have basically created a bunch of dead weight. Any truss that's cut loses its shape holding ability and that ability needs to be replaced with extra framing.

It's entirely possible to strengthen the trusses in either side of one that you need to cut but the reinforcing is not just a simple recipe. It'll require some calcs. Hopefully the truss engineer can help you out.

Ohhh, Duke-- in the midst of not understanding a number of those terms, I didn't catch that you were saying to move the truss itself. I hear how that would be ideal, that makes perfect sense to not break what's there. However, this thing is probably at least 30 or 40 feet across, I can't imagine being able to do that.

It's one thing if you modify a truss on your own house and something goes wrong, it's another if you modify a truss on a church and something goes wrong...yes, it's possible to modify them without any issues, but in this case I'd really want to talk to a structural engineer first.

I worked for a now retired structural engineer and we did things like what you want. You will need the individual data sheet for the truss you want modify including it's exact dimensions and web spacing from the original truss manufacturer. If that information wasn't available, he would send me up into the attic to measure everything including the nailing plate sizes, draw a 3D line drawing model that he would import into his engineering program and annalize the stresses and come up with fix. He would list all of the additional members, brackets, and nailing patterns.

It isn't that hard to fix the truss that you cut up and distribute it's loads to the adjacent trusses, the problem is that you are trying to make the two trusses next to the butchered truss hold up the cut truss and all of its loads which they are not designed to do. You will need posts at the outside of the opening you want to create. It will cost thousands of dollars to engineer and it will be all by the hour. You will definitely need a building permit and they are going to demand you hire an engineer.

Another problem is that truss design firms are pretty guarded about their truss joining plate engineering and they would probably also need to brought into the project.

Is there anyway to put the elevator on the exterior of the building and coming in through the gable end truss?

I always spread the cut truss load over a minimum of two adjoining trusses on each side. Much depends on the distance to any supporting walls. Obviously, if it is possible to put supporting posts on each side of the cut opening, its a no-brainer.

Being a church, scan the congregation for a engineer who may "donate" a solution. Many will tell you how to do it, but not legally sign off on it (wink wink).

Two years ago, with the help of a truss engineer, I cut 5 adjoining trusses apart in the middle of a 50' span so a car collector could get enough height for his cars on a two post lift. Lots of bolts and something like thirty 16' 2x4s made for a happy customer.

Last year I installed a residential elevator for a family and had to do exactly what you need.

YMMV

If the engineering option doesn't work out... What needs to be hauled up to the attic? Maybe you can use a 22.5" wide attic stair instead.

Duke

MegaDork

2/11/23 9:14 a.m.

If it's spanning 40 feet, yeah, get a structural engineer or the manufacturer involved.

Yeah this is sounding increasingly less likely to be kosher.

The idea of going outside wouldn't work, but that sparks a realization that the site of my planned project *is* in a newer addition. I could check the older part of the bldg and see if it had a diff design. Sourcing plywood to make a storage "floor" would then be the big new cost.

Regarding the ladder: we do have one, it's just annoying/sketchy to bring things up that way, esp with older ppl

After rotating your photo, you basically need to infill vertical web pieces between the diagonal web members next to where you want to cut the truss bottom chord and then sandwich everything between large plywood sheet gussets epoxy glued and screwed around the cut area. Maybe something like 2x12s on the outside of all of that. You still need a steel post under each end of the cut out truss extending down to the concrete floor wherever that is and put a pad footing under the post. Is there a basement under the main floor? You would also probably need to brace the truss to the two adjacent trusses.

You should also flip the stairs so that it exits on top at the plywood platform that is there. How much stuff are you going to put up there and how much does it weigh?

How about a winch and a sled on the ladder.

Something like this using the existing stairs. With some careful planning the platform could be as large as your current opening.

In reply to Toyman! :

Hey! Even a rope and pulley...

Most of the stuff is fairly light, just bulky. Think "winter church decor"

That seems like a lot of work, bracing and money for Christmas decorations. Add to that more insurance and liability if it fails. Is there an window that can be widened and a belt elevator installed for each use? Back of the church, open the window to French slider size?

914Driver said:

That seems like a lot of work, bracing and money for Christmas decorations. Add to that more insurance and liability if it fails. Is there an window that can be widened and a belt elevator installed for each use? Back of the church, open the window to French slider size?

Right, man. I'm searching for easier alternatives now. If I were looking to store engines or something that would be one thing...