VolvoHeretic said:My main recollection besides the toilets was that the trains run through the oldest, most run down parts of the nation.

Last train trip of any length I took was Wilmington, DE > New London, CT. I remember thinking that nothing demonstrates how much previously-expensive stuff human beings will abandon to rot.

NickD said:The #2102 at Tamaqua with Andy Muller at the controls.

That is my (very old) stomping grounds. Both sides of my family are from the general Tamaqua area. Dad's side from Tamaqua proper; mom's side from the Shamokin area.

The MLW FPA era at Grand Canyon Railway continues to draw down towards an inevitable close. When GCRY was first starting out, they acquired a pretty sizable fleet of MLW FPA-4/FPB-4s from VIA Rail who was just then retiring the veteran cab units in 1990. Those, along with the steam locomotives, handled all the traffic for the first nearly 20 years but in the early 2000s, GCRY picked up a trio of ex-NJTransit F40s and the writing for the FPAs was on the wall. The FPAs were rated at only 1800hp, versus an F40PH's 3000hp, and the FPAs lacked HEP generators, requiring them to tow a generator car, and dynamic braking, which is desirable since the line has 3% grades. They ran until around 2009, although increasingly less and often as trailing units, and by that point only two, FPA-4 #6793 and FPB-4 #6880, were still in service, albeit very limited use. The #6793 and #6880, as well as A-unit #6776 on static display, all received the new silver and gold livery, while A-unit #6773 and B-unit #6871 were still operable but were placed in storage, still in the original dark green and gold livery. There were two additional A-units, #6762 and #6768, that never were repainted out of VIA Rail blue and yellow and never ran on the GCRY; they were used as parts donors and were scrapped some time ago.

It now appears that the #6773 and #6871 are leaving the property, as they were spied with the reporting marks for Cuyahoga Valley Scenic Railroad this weekend. That will reduce the number of remaining MLWs on the GCRY property to the operable #6793 and #6880 and the displayed #6776. I'm not sure if the #6776 is parked due to a mechanical issue that prevents it from running, or if it's just not viewed as needed, with more F40PHs on the property. Reports indicate/suggest that release of the other FPA-4s to the Cuyahoga Valley will occur as soon as the GCRY's "new" ex-Larry's Truck & Electric/ex-Amtrak F40FH rebuild is road-tested and certain inspections, payment, etc. occur. That will end the MLW FPA-4's presence on the GCRY entirely.

In the wayback machine, Sunday Best is how we rolled. I have a family picture taken around 1957 at Disneyland and we are all "dressed to the nines." I was only 4 in that photo and even I am wearing a sport jacket.

Lou

The move from GCRY to Cuyahoga Valley Scenic Railroad is kind of a lateral move for railfans. While it's good that they aren't being gutted and/or scrapped (like the FPA-4s at Napa Valley Wine Train) and the plan is for them to run at CSVR, who already has a trio of their own FPA-4s, the CSVR has a bit of a checkered reputation with railfans, as does the GCRY.

First; what's the beef with GCRY? Well, when GCRY started out in 1988 under the ownership of Max and Thelma Biegert, it was a fairly railfan friendly operation and ran a lot of really cool equipment. They started with ex-ATSF GP7us, but those were quickly supplanted by the FPA-4s and then they acquired four ex-Lake Superior & Ishpeming 2-8-0s. Two of the 2-8-0s, #18 and #29, were put in service, followed by the arrival of CB&Q 2-8-2 #4960, and there was steam running pretty much every weekend, with cool old Alco cab units running whenever the steam wasn't. They eventually traded off two of the 2-8-0s, the operational #18 and the static display #20, to get an ex-SP&S 2-8-2 #539 with serious consideration towards getting it running. And then in 2006, the Biegert's sold off the railway to Xanterra Travel Collection. Under Xanterra, the steam program was severely curtailed to just a couple weekends a year, the #539 restoration was aborted and the engine went back to the PNW, the inoperable LS&I 2-8-0, #19, was gotten rid of, and the FPA-4s were largely put out to pasture in favor of the F40s.

Whereas the GCRY has just kind of lost it's luster under the new owners, CVSR has a reputation of being distinctly unfriendly towards railfans. One example is how they get the park rangers to close off sections of the park that are publicly accessible to keep railfans from taking photos, especially when NKP #765 used to visit. As one person recounted: "I only went once, for the #765 trips. Called and asked when I preferred tickets if they allowed people to ride in the vestibules and they said yes. If they had said no I was going to buy dome car tickets. Conductor made his own rule that day to close the vestibules, and then after riding the first trip, I went to chase the next one and park staff were trying to keep people from photographing the train at public areas." The anti-fan attitude apparently goes back to the early years of Midwest Chapter NRHS providing the train when B&O/Chessie still owned the rails. Their leadership was very anti-railfan and it rubbed off on the Western Reserve Historical Society people who took over from them. And they in-turn got the park service and the local police to make it next to impossible for the photographers to get anything by the end of the #765 trips.

CVSR also just has some weird operational issues. Like Steamtown, CVSR is run by National Park Services, and while they certainly do a better job than at Steamtown and have kept the trains running after previous operators fells apart, it's still not great. They have a lack of management that are railroad people, their leadership is all non-profit foundation people who know how to do fundraising for other things. They also needed to get MoW people who know railroading, not just parks ground staff. They shut down the northern end of the line and have indefinitely cancelled future visits of #765 due to potential erosion along one section of the line. No for-profit railroad would shut down a line because some core samples indicated that the roadbed might at some point washout, they'd set up a work area with someone in-charge when the railroad was operating, and talk them by the problem at reduced speed.

The operating non-profit has gotten rid of experienced people because they told them truths that they didn't want to hear, which is why they are short-handed now. They recently shut down for 2 months to make some safety improvements, and they couched the reason for the complete shutdown as "funding for improvements became available and we needed to do it within a certain timespan". But the rumor mill indicates that there were some serious safety deficits and volunteers blew the whistle (no pun intended) to the FRA and the CVSR had to shut down and do those improvments. It's further reported that CVSR has been kicking out volunteers over that, and if you look through their Facebook page, there's definitely something going on. Every post they make about their volunteers, thanking them or asking for them and such, there are lots of laugh reacts, the comments have been turned off by CVSR and large amounts of comments have been deleted. I also saw another group jokingly offering to take in CVSR volunteer refugees.

They also have suffered from motive power shortages; their motive power consultant is an Alco guy but they don't have the funds or work force to keep them running. Looking through their roster on Wikipedia, they have three FPA-4s, of which one was out of service until major rebuilding for the better part of a decade. They have a C420 that was rebuilt into some sort of MTU-powered "green" power and while they make a big deal of how much cleaner it is, reports indicate it's never really run right since the conversion. Other than that, they have an MLW C424 that's out of service with some sort of catastrophic engine failure, two MLW RS-18s out of service with assorted failures, and four Budd RDCs, also all out of service. Alcos are great and all when you have the expertise and staff to keep them running, but when two or three are the only ones running out of seven, maybe you need to face reality.

The Horizon Rail ex-CSX slug set they had a couple of years ago was nearly perfect for them as the southbound power for the long grade into Akron. Paint the GP40 "mother" for Chessie and the GP30 "slug" in the B&O Sunburst scheme and attract a new generation of fans who think they are the historic finds to have. Engines like those were the last original units to run on the line anyway, and you now have reliable second generation EMD power. Put the Alco cabs on the downhill northbound end of the trains where they don't have to work as hard.

It was a big weekend for PRR fans. For beginners, the T1 Trust held their annual open house, where they show off progress on the construction of all-new 4-4-4-4 Duplex #5550. Last year was held in St. Louis and they brought out the boiler, cab and nose of the engine. This year it was held in Altoona, birthplace of many of the original PRR T1s and where K4s #1361 is also being restored. Instead of the boiler, this year the T1 Trust brought out the completed frame sections and four of the brand-new 80" drivers for display.

And the #1361's tender was also on display inside the museum.

Meanwhile, farther east, another PRR steam locomotive was being moved to a new location and a step towards it PRR B6sa 0-6-0 #60 was moved from a storage siding at Yorklyn, DE on the Wilmington & Western to the railroad's Marshallton Shops for planned cosmetic restoration before movement to Lewes, DE for display by owners Lewes Junction Railroad & Bridge Association with a PRR caboose.

In reply to NickD :

I've been following the T-1 build on Facebook. Very exciting stuff, especially since their stated goal is to take the speed record from the Brits...

The #60 is kind of an interesting case, because it's the PRR engine that seems to have been largely forgotten about. PRR, as a whole, was very good about preserving a lot of motive power (the T1 4-4-4-4 and J1 2-10-4 are notable misses) but the issue has always been that the collection almost entirely went to the Railroad Museum of PA, who doesn't want any of it operationally restored. That's left Pennsy fans with mixed feelings: there's a lot of preserved PRR steam unlike, say, NYC, but it's unlikely to see any of it operate again. That leaves PRR #1361, which has been mired in decades of disputes and a stalled restoration that has only gained momentum in the last few years, PRR 2-10-0 #4483, which is in rough shape and is too big and heavy to really restore to operation, and PRR 0-6-0 #643, an ancient B4 that operates occasionally at the Williams Grove Historical Steam Engine Association and is, for now, the only operational PRR steam engine.

Oh, and then there's #60. The #60, which is an odd piece in that it lacks the typical PRR Belpaire boiler, was built at Altoona in 1913, worked the 30th St. Station/Penn Coach Yards in Philadelphia, PA, and then was retired and sold off by the PRR in 1952. It was purchased by Cemline Corp. at Hamarville, PA for use as a stationary boiler, but that plan never materialized. It was purchased decades later by the Historic Red Clay Valley Inc. in October of 1982. The Wilmington & Western, operated by the HCRV at the time, was going through a phase of acquiring as many steam locomotives as possible. At one point in the mid-80s, the W&W had the largest private collection of steam on the east coast, including an 0-4-0, five 0-6-0s, one 2-6-0, two 2-8-0s (BC&G#14 & leased Southern Railway #722), a 2-8-2, a 4-4-0 , a 4-6-2(#425 of R&N fame), and a 4-6-4 (leased CP#2839). They also had a huge collection of PRR equipment; alongside the 0-6-0, they had a doodlebug, several P70 coaches, and that monster 8-axle coast-to-coast tender that's being restored for PRR #5550.

The #60 sat for years on a siding at the Hercules Research Center in Wilmington, until it was put up for sale in 1995 and purchased by Hockessin businessman and owner of the Wilmington Blue Rocks, Matt Minker and placed next to his office building, which was built to look like a freight house, in the town adjacent to the W&W right of way. Minker passed away and it's sat in Yorklyn Heights for almost three decades out in the weather. It has since been sold to Lewes Junction Railroad & Bridge Association, who already own a PRR caboose, and the plan is to restore the #60 cosmetically and display it with said caboose.

Any hope of the #60 seeing a fire in her firebox? Never say never, but extremely unlikely. The #60 is absolutely terribly condition. She sat for something like thirty years in wet weather, and occasionally being flooded (it was near the Allegheny River) before being "rescued" by HRCV, and thirty years of damp did no good to the boiler shell and rivets/staybolts. Even in her current condition, she's at best a "basket case", the cab was butchered to get her to Delaware on a trailer, and what exists today is a fabrication. The original slopeback tender is long-gone; it was apparently in terrible shape and was swapped out for an engine-less tender that's debated to have come from either a PRR G5 4-6-0 or an H8 2-8-0. Someone said they did an internal investigation a couple years ago and climbed in the smokebox, which is paper thin, to discover a nasty and rusty flue sheet. A few of the tubes are still in there, but it looks as if a few of them are completely rotten out and collapsed, and the firebox is empty; you can climb in from the bottom if you dare, since the grates and ash pans are long gone. Parts of the valve gear are gone, the air compressor is MIA, the fireman's side running board is gone, the backhead has been completely robbed of any jewelry, there's no glass left in the cab or headlight, the cab and tender body have severe rust issues, the boiler jacket returned to the earth long ago.

The #60 as she looked in '76, tucked off in the weeds at Hamarville, PA. This thing is the source of a lot of railfan urban legends. A lot of "I remember seeing a PRR locomotive tucked off in the weeds near Pittsburgh in the '60s/'70s" that are eventually narrowed down to this engine.

Recon1342 said:I've been following the T-1 build on Facebook. Very exciting stuff, especially since their stated goal is to take the speed record from the Brits...

Even if it doesn't take a crack at the speed record (and I'm curious if the FRA will allow it to), it's still a huge accomplishment. Hell, even if it never turns a wheel under it's own power, it's a huge accomplishment, just to rebuild an extinct steam locomotive of such a huge size (With tender, it's only 13 feet shorter than a Big Boy)

I'm just hoping that it runs somewhere out this way. The details of where it will run aren't set in stone, because it's still over 5 years out from being completed (getting that existing "coast-to-coast" tender saved them 3 years and $3.5 million though) and a lot can change in 7 years. I recall hearing that there was a deal for it to maybe come to Steamtown though.

Also, interesting to note that in the photo above, the little access door to the nose cone appears to be falling off. Mechanics used that door to get inside to clean out the smokebox or make minor adjustments, or to remove a number of bolts that would allow the whole nose cone to be removed for bigger jobs, like replacing flues and superheater units.

An interesting note on the T1 reconstruction efforts is that Timken Bearing, who originally supplied the roller bearings for the rods and axles, is a sponsor of the build and has found the cross reference to their modern catalog, and are going to donate the hardware.

Even more fascinating is that Timken is doing something similar with the PRR #1361 restoration. Now, PRR, like SP, was a railroad that never really accepted the use of roller bearings, and the T1s were pretty much the only class of PRR locomotive with usage of roller bearings on axles and rods. But, at one point PRR had Timken draft up a plan to implement roller bearings on the K4s Pacifics. That program never went anywhere, I'm guessing because of the arrival of the T1s, but when the #1361's restoration was rebooted a couple years ago, the decision was made to convert to the #1361 to roller bearings to avoid another axle bearing debacle like it had back in 1988 and to make Class Is a little more receptive to hosting it. Timken dug into their archives and found they still had all the blueprints from that never-used design, and contributed them to the restoration.

In reply to NickD :

Timken are pretty cool folks, for sure. Their catalog cross references are amazing... and not just for railroad parts, either.

Timken actually had their own steam locomotive for a while: 4-8-4 #1111, nicknamed the "Four Aces". Timken wanted to promote the advantages of their roller bearings in use on tender, lead and trailing truck and drive axles, and connecting rod journals, and so in 1930 they had Alco cook up a very attractive 4-8-4 with 73" drivers and liberal use of their roller bearings, and painted the cab, cylinder and boiler jackets and tenders a fetching shade of emerald green and applied big Timken lettering to the tender and hit the road with it. Another 52 different manufacturers also agreed to contribute parts to the locomotive to also serve as advertising for their company, including a Franklin trailing truck booster, American multiple front-end throttle, and a Worthington feedwater heater.

Its tour of 88,992 miles on fourteen railroads included turns on elite passenger varnish such as the New Haven's Merchants Limited and the C&O's Sportsman, and on the Pennsylvania it handled twelve passenger cars up the Allegheny mountain grade without a helper and even saved three minutes on the standard schedule. Seems PRR should have taken note and built a 73"-driver Northern instead of wasting time on the S1 and T1 Duplexes. Twelve of the 14 railroads seriously tested the Four Aces. In freight service, the locomotive made 328 freight runs pulling an average of 83+ cars per trip at an average speed 29.8 mph. On the Chesapeake & Ohio, Four Aces started and pulled a 132 car coal train weighing 9,864 tons. In passenger service, Four Aces made 227 runs with an average of almost 11 cars per trip at an average speed of 41.2 mph. Most often remembered from this tour were the publicity shots in which a young women pulled the #1111 along a track to demonstrate the silky smooth, low-friction qualities of the roller-bearing installation.

The engine's demonstration tour ended on the Northern Pacific. The NP was, ironically, not impressed with the Four Aces performance, but that boiled down to the fact that NP burned extremely low-quality lignite coal, also known as "brown coal" or "rosebud coal", and the Four Aces firebox and grate arrangement was not configured to properly burn it. While testing on the NP, they damaged the crownsheet of the firebox, which led to a dispute with Timken; NP said that the locomotive belonged to Timken and was therefore Timken's responsibility to repair, while Timken pointed out that the damage happened on NP property with NP crews at the controls and was NP's responsibility to fix. The ultimate solution was that Timken would sell the #1111 to NP at a bargain and then NP could fix the locomotive.

With the visored headlight removed and replaced with the usual NP garbage can-sized headlight, the green paint replaced with black, and the number changed to #2626, the Four Aces entered NP service as their class A-1. I'm not sure if adjustments were also made to the grate and petticoat to make it perform better on the lignite coal that NP used, but since it lived a career of almost thirty years on the NP without complaint, it seems likely. It was converted to oil-burning in the late '40s as well. NP followed up the #1111/#2626 with additional orders of 4-8-4s that were equipped with Timken roller bearings, so they were clearly impressed by the advantages of roller bearings as well.

The #2626 was retired in 1957, having covered 2.1 million miles while in NP service and consuming 80,000 tons of coal, 9 million gallons of fuel oil, and more than 17.5 million gallons of water. Timken eventually reached out to the NP to express interest in preserving the locomotive and displaying it at their Canton, OH headquarters. Reportedly NP was open to selling the engine back to Timken, but by the time negotiations were concluded it was discovered that the locomotive had been scrapped in the meantime.

One of the demonstrations of the Four Aces low rolling resistance, courtesy of those Timken roller bearings. The New York Central also did something similar with the first of the S-1 Niagaras (also equipped with Timkens) as a publicity stunt.

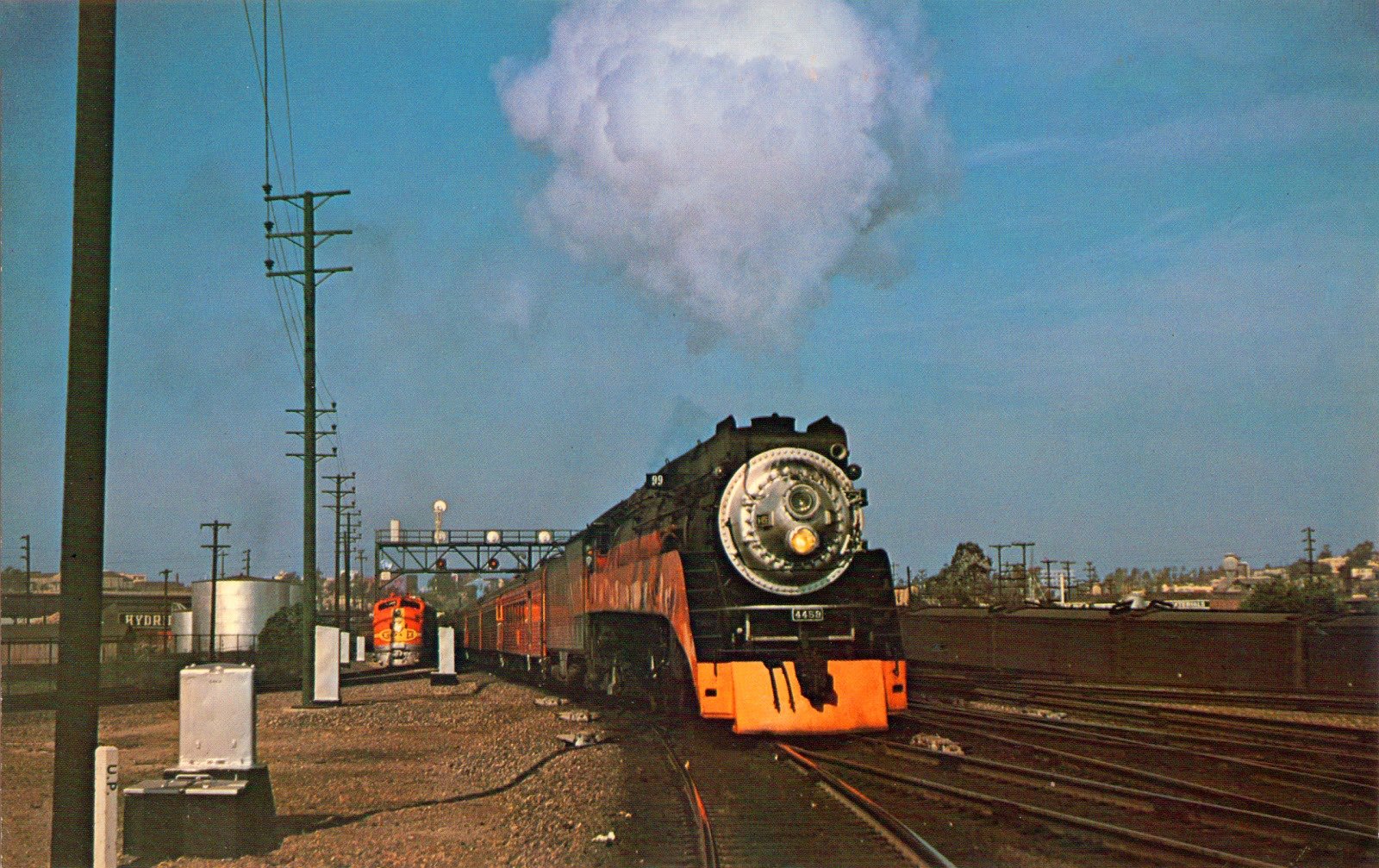

I mentioned how SP was not a proponent of roller bearings, and here's one of the two steam locomotives that were so equipped: SP GS-5 #4458. The GS-5 class was composed of just two locomotives, the #4458 and the #4459. Identical to the GS-4s other than roller bearings on the tender trucks, lead and trailing trucks, drive axles, and side rods, these were considered the high water mark of SP 4-8-4s. The #4458 used Timken bearings, while the #4459 used SKF bearings, presumably to test both company's offerings, and when the pair of GS-5s were retired and scrapped in '58, the bearings were all examined and showed minimal wear.

So, if the roller bearings on the two engines were such a success, how come it didn't warrant widespread adoption? Part of it was timing; when the GS-5s were built in spring of '42. After that, getting roller bearings and lightweight materials became difficult and the War Production Board was cracking down on new designs or passenger-only locomotives, so when the GS-6s (and Western Pacific GS-64s) those were a rehash of the older GS-2/GS-3 designs with 73" drivers and solid bearings. After the war, and those materials became available again, SP was moving on to diesels, not purchasing any large, higher-speed mainline steam locomotives (The last of the 4-8-8-2 cab forwards were also built in '43).

The other issue was that Southern Pacific had developed their own system, the "Spring Pad Lubricator" which consisted of a wool carpet-like oil pad with wicks, resembling large unraveled carpet strands, dangling down into a bronze or aluminum oil sump. The lubricating pad is pressed against the bottom of the axle by an "X" frame and coil springs, and is also fed a stream of pressurized oil as well. Every conventional driver axle at the time used blocks of grease that had a concave surface that kept the axle journals lubricated over the full length of the journal bearing surface. However, the grease block had a steel distribution screen that allowed the full surface of the journal to get even grease application. As a driver journal began to warm-up , the screen 'metered' the grease flow, allowing the axle to return to its operating temp. However, grease blocks tended to wear-thin, at random rates. so after

every trip, when over an inspection pit, a loco could have one or more grease blocks that were in need of replacing. Replacing the thin grease blocks was a labor intensive job that could take 20 minutes per grease block to be replaced. SP was spending a lot of labor hours replacing grease blocks, since every 4-axle engine has 8 grease blocks, spread across a fleet of hundreds of locomotivess, with multiple axles and soon you're talking thousands of grease-blocks needing attention.

So, SP decided to solve the problem on its newer locos like cab-forwards and MT-1 Mountains and GS 4-8-4s. They switched to the oil-lubricated spring pad driver journal boxes. The driver journal boxes were fitted with round sight glasses so the inspectors could check the oil levels. Any that were low, were easily spotted and quickly re-filled, and if you've ever noticed an SP engine with white stars painted at the center of the drive wheels, that's to denote that they are equipped with spring pad journal boxes. However, not every SP loco was oil-cellar equipped, since there was no reason to be retrofitting old switch engines or 2-6-0s that were poking around on branch lines, and so manual labor and a substantial workforce was still required. Because of that large work force, adopting roller bearings for locos would not heavily reduce that labor force. No matter how many new locos they bought, if roller-equipped, they still had thousands of grease-blocks that needed inspecting. Also, the Southern Pacific didn't have the extended 100mph running of, say, UP or NYC, they were a 90mph railroad tops, and only for fairly short spurts, so the advantages of roller bearings weren't as pronounced.

Something that is interesting is that when Oakland requested a large steam locomotive for display, SP just grabbed the first GS off the yard track they were stored on, and that happened to be GS-4 #4449. Reportedly, right behind it was one of the two GS-5s, and someone said that Doyle McCormack has remarked that he wished they would have grabbed a GS-5 instead, since solid bearings have caused grief with hosting railroads. While still FRA legal, some Class Is like to refuse anything with solid bearings. Back in the day, solid bearings were fine, but as steam locomotives went away, a lot of the original manufacturers stopped making grease cakes, or environmental concerns have caused those that still make them to change the formula, and modern grease cakes tend to be troublesome (reminiscent of the flat-tappet camshaft issues of today). They have updated the #4449 with roller bearings on the lead and trailing trucks and the tender axles, since that's fairly easy to unobstrusive do, but haven't undertaken trying to retrofit the drive axles. And to install roller bearings on the rods requires a complete redesign of the rods and would be visually noticeable. Since the #4449 doesn't go out on Class I rails anymore (Or really any rails, since the Oregon Pacific Railroad is no longer allowing the #4449 to run on their tracks anymore), the friction bearing issue isn't an issue

I just saw a news story that our local short-line, the Mississippi Export Railroad, is building a new freight car repair shop & looking to add 35-new jobs.

In reply to Pete Gossett (Forum Supporter) :

Now is really the age of the shortline. Class Is really just want to to handle the city-to-city movements and ditch the actual switching and last-mile delivery to customers. So you find an area with a bunch of industries and get the Class I to sell it to you and handle interchange from the Class Is yard to the customers. which was basically the idea Conrail had with the aborted Conrail Express concept back in the '90s.

You'll need to log in to post.