So I have a CNC laser on an old workshop table. It is plenty sturdy but I didn't think about issues with the table not liking x-axis travel. I need to reinforce it to stop movement along the long axis of the table. It needs support in the y-axis as well but that is secondary to the x-axis. My first thoughts are run a stringer along the floor to connect the legs. Then maybe a x brace from the lower stringer to the upper stringer. What says the group mind? Thank you!

I'd spend some time rocking it back and forth and seeing exactly where the pivot points are. It's surprising that beam between the two legs isn't enough to stand up to the laser movements. Probably no need to connect the legs at the base unles they're particularly flexible, I think the X brace is going to be the solution.

The "spine" down the center looks to be about 4" tall. Swap it for a spine of plywood about 18" tall, and secure that plywood to the legs well.

Cool, I will check the rocking and see if I can nail it down.

The plywood spine is promising.

If I had a scrap 2xsomething laying around, I'd make one diagonal from the top stringer to near the bottom of one of the legs. I bet that'd firm it up right quick with little effort.

The other idea if you don't need this to move often is to just tapcon it to the wall...

Pictures of the Laser engraver ?

Thanks

The blue one is a Thunder Nova 24 60w CO2 primarily purchased to do engravings on bottles, cups, wood, etc...

This big fella is a Boss HP3655 150w CO2 laser engraver/cutter. It can engrave but it mainly going to be used to make many, many wine boxes for customers, holiday gifts, etc... This one can have an O2 tank attached to cut up to 20ga stainless. I haven't done this yet as the machine only came in a month ago. My employers picked up both machines for which I am extremely grateful. They are great (and crazy) people for investing in this kind of stuff.

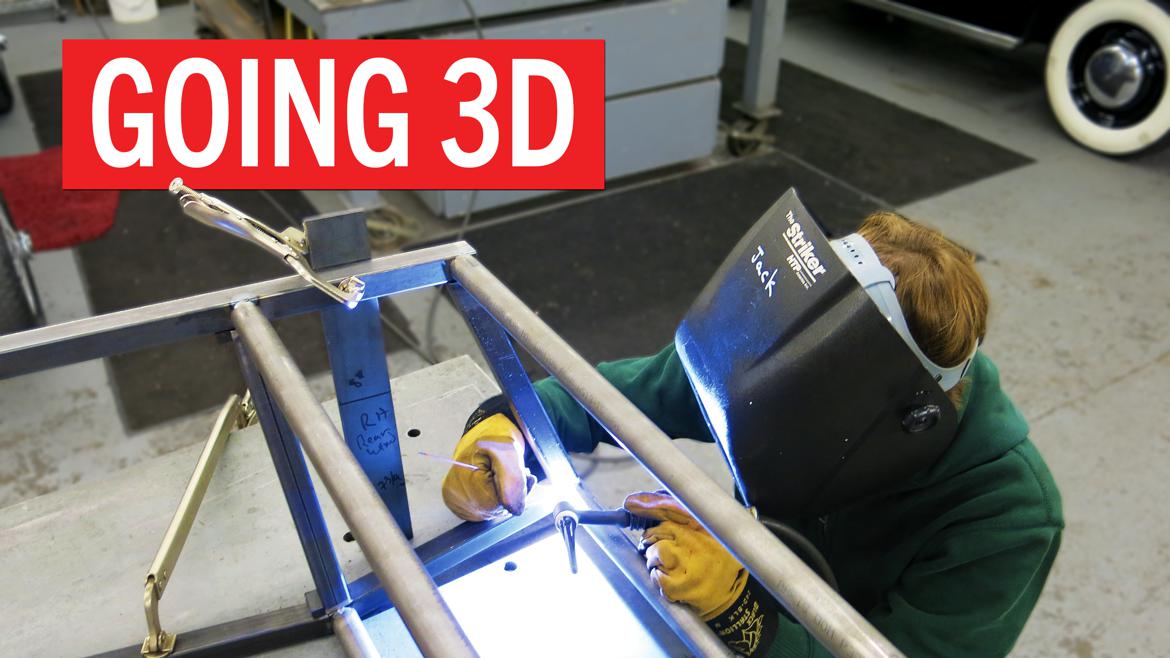

brace installed. Good enough for today but definitely need something else. I'm afraid to see what 1" plywood costs

They are pretty sweet. As long as they aren't running for work I get to use them however I want. They are in my home shop too!

Nice Machines :)

I have one of the K40 blue lasers that are on Ebay for about $400 , only weighs about 60 pounds

I got it at the swap meet for real cheap , its been well used but I have not put any time into figuring out what I need to get it up and running , I know at least an exhaust blower and a water pump and 5 gallon bucket .....

If this is going to be used for years I would built a extra heavy duty table for it ,

cheers

In reply to californiamilleghia :

Yeah, the more I mess with this one makes me think that a purpose built table is in order.

In reply to californiamilleghia :

When you decide to get that K40 up and running, feel free to drop me a line. I've got one that I've been playing with. Definitely a different league than singleslammer's machines :)

https://grassrootsmotorsports.com/forum/build-projects-and-project-cars/fun-with-a-k40-laser-engraver/174139/page1/

singleslammer said:

brace installed. Good enough for today but definitely need something else. I'm afraid to see what 1" plywood costs

You don't need 1" plywood. Total overkill. 1/2" would be fine.

But it looks like you've got it licked.

In reply to SVreX (Forum Supporter) :

The board that is in there is 1" so that was where that came from. I have some 1/2" I can use for this.

Thanks everyone!

In reply to singleslammer :

I'm assuming these machines are quite a bit smaller than the one I gave you.

Since you are postings pics of lasers, feel free to tell the story of the tragic one.

Not one of my finer moments.

I was making a bunch of wine boxes for the holidays last winter and took a break to make some Christmas ornaments for the kids. Long story short, I ran some mirrored acrylic (face down) and wasn't watching the laser close enough and it caught fire. No real damage to me or the house but the laser had some flammable stuff on top that made things worse and it was a total loss.

In reply to singleslammer :

I'm super glad no one was hurt!

What was the learning curve like on that old machine? I know you were struggling with Chinese software issues... what was your solution? Once you got it running, was it a decent machine until the incident? How would you compare the functionality of the 3 machines you've been using? What recommendations would you have for people looking for similar machines?

Wow that went downhill quick , glad no one was hurt

did it hurt any of the wiring ?

In reply to californiamilleghia :

Like home wiring? No, just the drywall above the machine and a fair amount of smoke in the garage.

I'm thinking it would be pretty easy to build a smoke detection system for a laser. Shut down the power, even trigger some sort of extinguisher. "Air quality" sensors are cheap and easy to set up with microcontrollers. That picture has me thinking it would be a good idea. I might play with this.

Asking out of complete ignorance (one of the things I do best...): if the problem is the machine rocking the table, could you mitigate it by absorbing the machine's vibration before it gets to the table? I'm thinking about three or four of something like your basic rubber doorstop, strategically jammed in – I mean, mounted according to precise monitoring and analysis around it.

In reply to Stealthtercel :

The machine needs to not rock to perform correctly.

looks like we have a short term winner. Heavy plywood cabinet with storage and cam over wheels when I need to move it are likely to happen eventually. The arms are required because the machine cannot be flat against the wall.

thanks everyone!