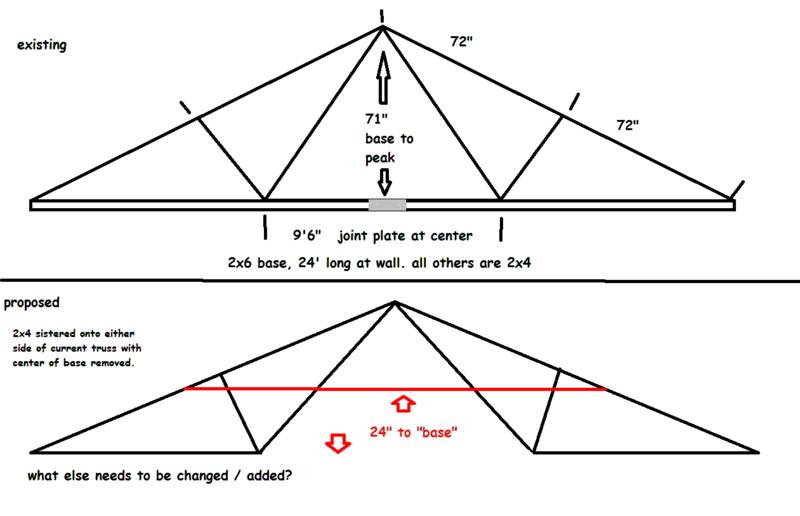

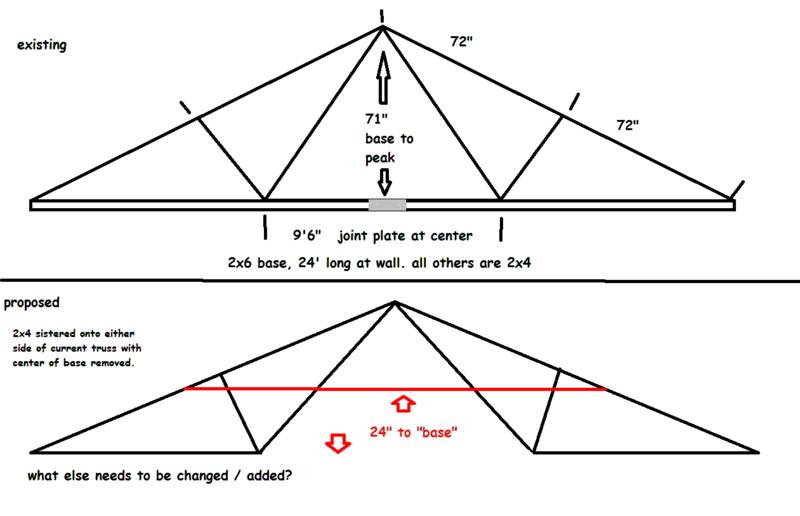

I would like to modify some trusses in my garage to gain extra clearance for a lift. The center section needs to be cut out and raised 24". My first thought is to put a 2x4 (or 2x6) on either side and bolt it together. I assume more would have to be done than just this. Ideas? Haven't been able to get a truss supplier to talk to me so far...

Roof trusses are bad. Modified roof trusses are really bad. Please don't do that.

Duke

MegaDork

12/4/16 8:58 p.m.

A structural engineer can tell you what to do. It may cost a couple hundred bucks for a couple hours of their time.

SVreX

MegaDork

12/4/16 9:09 p.m.

Why would a truss supplier help you and give you free engineering when you are not going to be buying any trusses?

Anything you do will REQUIRE a licensed structural engineer, no matter where you are. No one can answer your question (correctly, or legally) online.

A couple hundred bucks and you'll be done.

Duke wrote:

A structural engineer can tell you what to do. It may cost a couple hundred bucks for a couple hours of their time.

Don't be surprised if they tell you a new truss is needed. Residential roof trusses are a very competitive (cost focused) market. Most wooden truss manufacturers use their own proprietary software to shave every penny out of the design (and their designs take advantage of grey areas, unconservative assumptions, and/or may not technically meet code mandated design requirements, but if sealed by a PE that isn't looked into until something bad happens) so usually there is no excess capacity. Removing the bottom chord is a big deal.

SVreX

MegaDork

12/4/16 9:12 p.m.

BTW, I am confident your idea will not work.

But I am not a structural engineer.

SVreX

MegaDork

12/4/16 9:56 p.m.

In reply to iadr:

Link broken. It links back to this thread.

I'm not a structural engineer but cutting out the center of the bottom cord isn't a great idea, the 2 45 degree uprights have nothing to push against and as someone who has done a decent amount of trusses I can tell you they are alarmingly floppy to begin with.

You could always rebuild the roof stick built if you need the space in the center

If you think about the forces in the truss, he two slanted portions that support the roof are trying to fall downwards, hinge in the center, and push the walls apart. The continuous wooden beam at the bottom of the truss is what's preventing that from happening, and translating the side load into a vertical load. I'm a software guy, not a real engineer, but cutting that beam seems like a really bad idea to me.

I asked around a bit when retrofitting my garage because I had a similar situation. The general consensus I got was that to do it properly required taking the entire roof off the garage and re-engineering the whole thing. That entailed something like the cost of a new M3, so I decided not to pursue it further...

Yeah I don't like that. (warning; not an engineer, the following is my uneducated opinion)A snow load on the roof will push down, trying to flatten the roof by pushing the lower corners outward. The board you want to cut is tying them together not letting them spread.

I am interested in finding out what you come up with and what it costs because I have the exact same situation preventing me from having a lift.

Here is a question. If I wanted to make the wall's two feet taller do I need to completely reframe the garage, or could I make a two foot tall wall to set on top of the existing wall?

Pretty much anything you do outside of a basic triangle involves LOTS more additional wood for.....tada: triangulation. You are proposing something like room in attic with the middle section torn out while you need something more like scissor or vaulted parallel chord. Room in attic has a giant bottom board to make up for the lack of triangulation. You can't cut that board!

Disclaimer-I'm a personal trainer who likes triangles and found a picture on the internet, suing me is pointless.

Duke

MegaDork

12/5/16 8:20 a.m.

SVreX wrote:

BTW, I am confident your idea will not work.

But I am not a structural engineer.

I agree, the truss is under enough load that they have a 2x6 bottom chord for a 24' span, which is a fairly short span for a roof truss. The bottom chord is mostly in tension so cutting it does have some large ramifications of a very negative kind.

I disagree that a structural engineer will tell you you need a new truss. I am confident that they will find a way to reinforce the existing trusses, but it's going to take a lot more than a couple 2x4s. They may want to plate it with plywood. That's why it's worth a couple hours of a professional's time to get a real detail of what needs to be done. They will tell you member sizes, number of fasteners, etc so you can be safe.

Duke

MegaDork

12/5/16 8:28 a.m.

gearheadmb wrote:

Here is a question. If I wanted to make the wall's two feet taller do I need to completely reframe the garage, or could I make a two foot tall wall to set on top of the existing wall?

You could do that, maybe, depending on what's above, but you're introducing a weak knee in the wall. At a minimum you'd need to plate both sides of the studs with 5/8" plywood across the joint - whole sheets oriented horizontally so they span the joint at their centerlines - that are continuously glued and screwed to the framing at something like 12" centers.

Remember this is free internet advice and worth exactly what you're paying for it.

Duke

MegaDork

12/5/16 8:29 a.m.

SVreX wrote:

Duke wrote:

They will tell you member sizes...,

Giggity.

I knew somebody would go there, but I figured it would take more than 4 minutes...

Duke wrote:

They may want to plate it with plywood.

Pretty sure in a codes free environment, I'd do something like this, but not without asking someone to hold my beer.

iadr wrote:

On Garage Journal- one of the major featured garages the guy did this exact thing.

I think how to modify roof trusses is one of the most popular questions on GJ, but that guy was one of the few who actually went about it in the proper manner (even though it was a ton of work.)

iadr wrote:

On Garage Journal- one of the major featured garages the guy did this exact thing. Had to replace the trusses one at a time and the supplying firm did the engineering and signed off on it.

http://www.garagejournal.com/forum/showthread.php?t=263351

I'm not structural engineer either, but looking at that, I can immediately see there's no way your proposal will work.

Fixed link:

http://www.garagejournal.com/forum/showthread.php?t=263351

SVreX

MegaDork

12/5/16 10:44 a.m.

stuart in mn wrote:

iadr wrote:

On Garage Journal- one of the major featured garages the guy did this exact thing.

I think how to modify roof trusses is one of the most popular questions on GJ, but that guy was one of the few who actually went about it in the proper manner (even though it was a ton of work.)

Those are not trusses. That's a stick-framed roof.

He didn't start with trusses, and he didn't install trusses.

The only thing he did was cut out the ceiling beams (not the bottom chord of a truss).

Completely different animal. Stick framed construction can be field modified (often without engineering). Pre-engineered construction (trusses) cannot be field modified without a design by a structural engineer.

SVreX

MegaDork

12/5/16 10:46 a.m.

That guy did a good job. But his solution would not have worked if the roof was trussed.

So, saying he was one of the few who did it in a "proper" manner is a sketchy statement, at best.

i built wooden trusses for 9 years at the biggest truss plant in the upper midwest (and maybe even in the country)... based on all the wooden triangles i built, what you are looking to do would require you to replace the bottom cord completely with boards that angle up from where it meets the top cord like the scissors truss in that pic above, with a flat spot in the middle however wide you want, or just bring them up to a point.. then it's just a matter of adding triangles to tie everything together, at which point you might as well have just done it right and ordered new trusses.

Yeah, scissor truss is what you need. You could probably modify yours into scissors, one at a time. Other option is to run a gluelam beam from gable to gable, then remove all of the truss except the rafter. (Not easy if your door is in the wall with the gable) You would likely have to double up rafters at least. My 20 foot span has a 3x14 beam with 2x10 rafters. (26 by 40 foot building with a support wall in the middle) No bounce in that roof.

SVreX wrote:

Those are not trusses. That's a stick-framed roof.

He didn't start with trusses, and he didn't install trusses.

The only thing he did was cut out the ceiling beams (not the bottom chord of a truss).

Completely different animal. Stick framed construction can be field modified (often without engineering). Pre-engineered construction (trusses) cannot be field modified without a design by a structural engineer.

SVreX wrote:

That guy did a good job. But his solution would not have worked if the roof was trussed.

So, saying he was one of the few who did it in a "proper" manner is a sketchy statement, at best.

My fault...I thought he was referring to a different thread on the GJ, where a guy had actually consulted an engineer on how to modify trusses.

Woody wrote:

Roof trusses are bad. Modified roof trusses are really bad. Please don't do that.

For those who aren't paying attention here, that is the viewpoint of every firefighter I've ever spoken with. Due to how fire burns the connection plates of a truss compared with how it burns a stick built (through nailed) roof system. Truss roofs collapse catastrophically and stick roofs sag more gradually. This is important to the guys who run into burning structures while the rest of us run out.

In a snow-free area, under certain conditions, I MIGHT consider modifying trusses.

If there's ANY chance of a snow load, forget it. Leave them alone.