Its getting to be that time.... new boat floor. I posted on my favorite trusty baja forum and it seems like its dead over there.

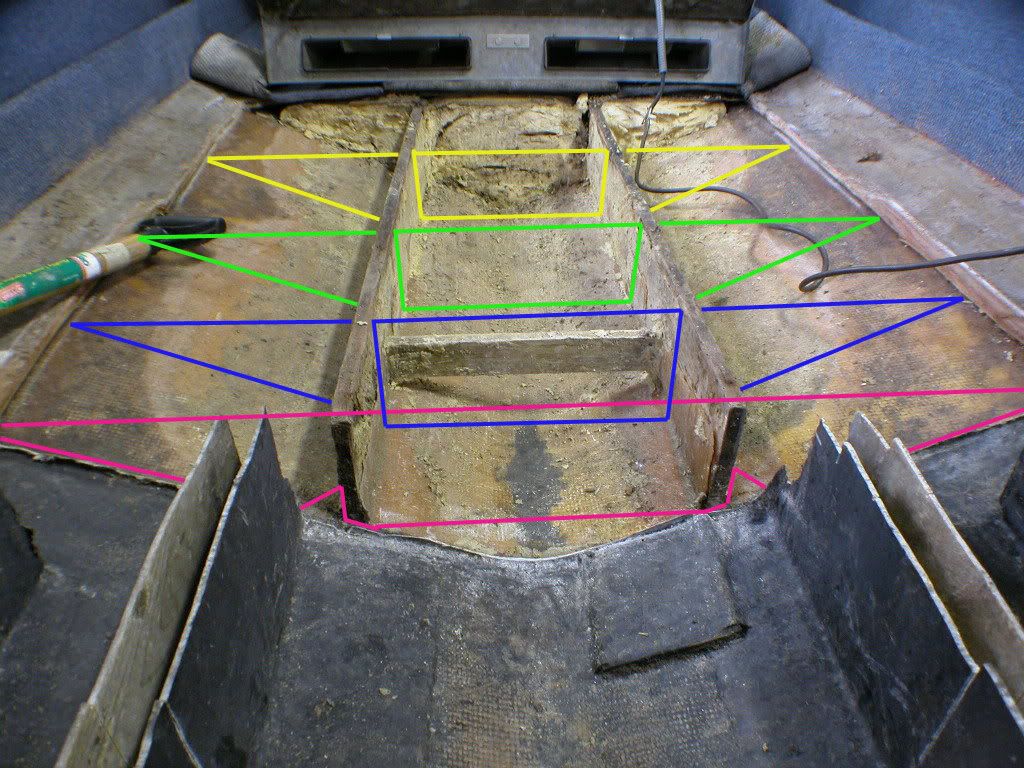

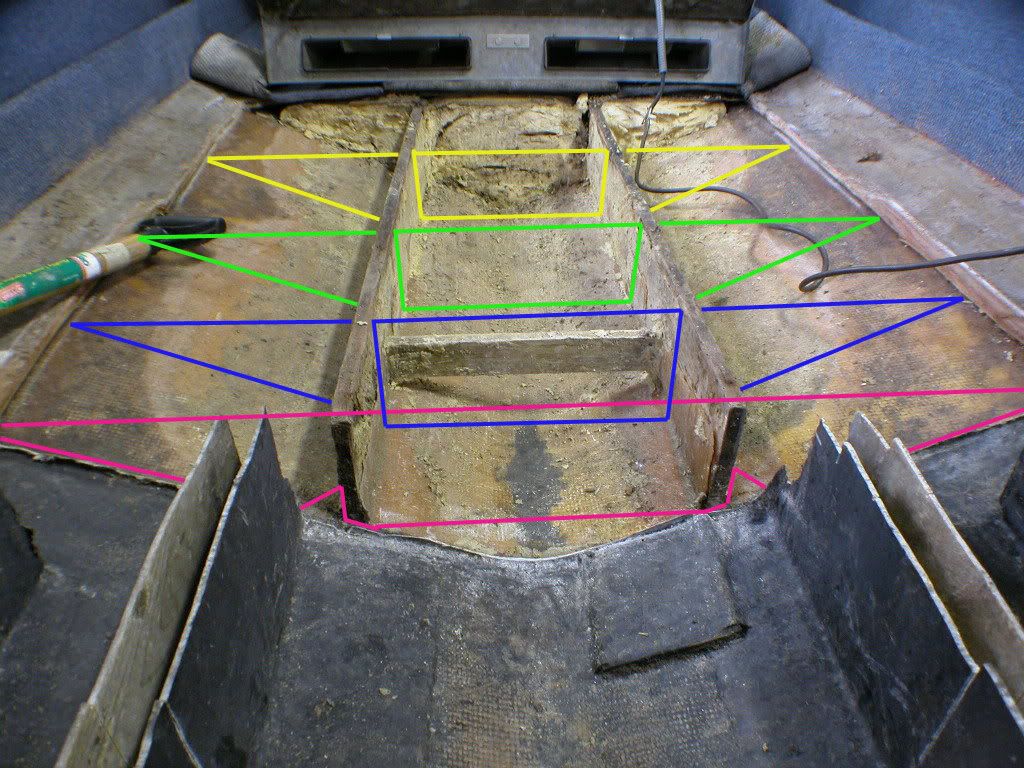

I know about the product "starboard" which is a marine lumber replacement, but there are two problems with it: 1) its heavy and 2) its not load-bearing. So, until I get enough thickness to it it will be too heavy. Here is the floor as it is now and I drew in an idea for supports. I can do the framework with the starboard stuff so it won't rot, but I need ideas for the flooring itself.

Picture:

First thought was plain old marine plywood. That would be great if I was going to carpet it; when it rotted I could just pull up the carpet and replace the plywood. But I plan on doing something different with the floor, maybe colored rhino liner. Since sprayed-on liners are so expensive I don't want to have to do it every time.

So - if I do that starboard type stuff for the framework, what can I put on it for flooring that A) won't rot, B) is stiff enough to mount things like pedestal seats, and C) doesn't weigh a ton. I gotta think there is some extruded structural foam or plastic out there that would do the job. I don't mind paying a bit more. I'm not talking about $4000 worth of carbon fiber matrix, but assuming that regular lumber would be about $150 I don't mind dropping $400 or so on a good floor that I don't have to worry about.

McNichols sells a ton of fiberglass decking. They are generally expensive on their products, but quality.

This is sort of a random link of what I'm thinking, but they have more options.

http://www.mcnichols.com/products/trade-name/safplank-99/?pageCode=contentproducts

You might go with some sort of hybrid floor with wood/carpet around the edges and the main part being some of the above...just a thought.

-James

My father has been using Advantech with good results. It's a water resistant impregnated fiber board.

Strizzo

SuperDork

5/2/11 10:08 p.m.

Is starboard the same thing as seaboard? We have a table on the upper helm made of the stiff I think, with no problems. I'll ask what the thing is made of, but iirc its like a heavy duty nylon stock that can be worked like wood

Strizzo wrote:

Is starboard the same thing as seaboard? We have a table on the upper helm made of the stiff I think, with no problems. I'll ask what the thing is made of, but iirc its like a heavy duty nylon stock that can be worked like wood

yeah, there are several trade names for that stuff. Its like a white plastic stuff. Its great stuff, but according to the website it requires about 20-30% more thickness and supports have to be spaced about 20-30% closer when compared to plywood.

Strizzo

SuperDork

5/3/11 12:54 a.m.

hmm, i'll have to find out what our table is made of. it looks just like the cheesy plastic tables that set into the floor in the bow of a lot of runabouts, but it was all machined out of a single piece of delrin or nylon type material, so its solid and sturdy. even better, the piece was scrap from a dash install or something, so all it cost was the machining time.

KATYB

Reader

5/3/11 5:20 a.m.

all i have done in past was plywood wrapped in fiberglass

GregW

New Reader

5/3/11 6:05 a.m.

Wrap some paper honeycomb in a couple of sheets of fiberglass filled with epoxy resin. Light and strong.

KATYB wrote:

all i have done in past was plywood wrapped in fiberglass

I know nothing about boats and marine stuff, but this is what I was thinking about. The right epoxy should seal the plywood pretty well, and you can call it carbon/glass composite.

EricM

Dork

5/3/11 8:06 a.m.

I have always just put in Marine Grade Plywood and then glassed in in place. shrugs

OK sometimes we used Kevlar, but that was for the 70 Foot offshore racing boat.

YaNi

Reader

5/3/11 10:10 a.m.

GregW wrote:

Wrap some paper honeycomb in a couple of sheets of fiberglass filled with epoxy resin. Light and strong.

You can bond aluminum honeycomb panels together to form a rigid structure and then cover it all in fiberglass.

aluminum monocoque

I've always used plywood as well, but 5 years later you're just doing it all over again.

Keep in mind this boat gets used about twice a week in Texas between March and October and then is on the water for a solid two months used 4-5 times a day in Canada for July and August.

Plywood in fiberglass is great, but all it takes is one anchor dropped on it or the flexing of the pedestal seat mounts to make little fissures in the epoxy and then its just a matter of months until its rotten.

I was thinking there has to be some form of 1" structural foam stressed-skin material. Sorta like an interior house door that is filled with a stiff foam and skinned with some kind of nylon laminate or something.

MadScientistMatt wrote:

Diamond tread aluminum?

Good idea, but even coated it gets screaming hot. Not pleasant on bare feet.

YaNi wrote:

GregW wrote:

Wrap some paper honeycomb in a couple of sheets of fiberglass filled with epoxy resin. Light and strong.

You can bond aluminum honeycomb panels together to form a rigid structure and then cover it all in fiberglass.

aluminum monocoque

I LOVE it. I've already contacted the Ayres company in that last link. I'm going to get their recommendations on which type of panel to use.

... now watch... it's probably $4000 for a 4x8 sheet of the stuff

They quoted $400 AUD for a 1200mm x 2400mm sheet. That's about 4x8ft.

That's not too bad. They have all kinds of construction, too... aluminum, plywood, fiberglass... which one were you looking at? If its strong enough, I'd like to go with the fiberglass since its so light.

Any ideas on DIY foam core panels? GregW, I read your paper idea and it got me thinking. Paper won't work since its only a matter of time until a fissure or crack in the epoxy lets water in, and then its done. I need the substrate to be non-rotting.

My first thought was do some trial and error on some of those pink styrofoam sheets at home depot, but their strength is pretty wimpy. Also, when little cracks do appear, the foam will start deteriorating quickly.

Any ideas for DIY structural panels that are non-rottable, hydrocarbon resistant, and won't hold water?

Curtis,

What you want is closed cell foam board. You should be able to pick it up in sheets at your local hardware store, it's blue. Won't absorb water and you can laminate it in fiberglass. Make sure to get a resin that won't dissolve it. You can use this for your grid. NOT FOR THE MOTOR STRINGERS. Make sure you leave room at the bottom for water drainage. I can't tell by your drawing but it looks like you are sealing the bottom of the hull with the stringer grid. Bad idea. You will hold water and thus weight and future corrosion. Fiberglass will absorb water. Then cause delamination.

As far as the stringers where the motor will sit you will need to go marine grade plywood. Marine grade stuff should last you a good long time as long as you seal it in fiberglass. If you want to get fancy and real strong on top of those use a piece of steel so you have metal to bolt your engine mounts. That is how MasterCraft is building theirs (they actually run the entire rear engine bearing stringer upper of steel in the back, since their boats deal with incredible forces from skiing/wake boarding.)

You starboard is good for the physical floor. That is what that product is made for so if you want and you have built a nice level grid you can use it. Just remember it is pricey. Then again the word boat is actually not a word but an anagram. Bring Out Another Thousand. Good luck with the project.

FlightService wrote:

Curtis,

What you want is closed cell foam board. You should be able to pick it up in sheets at your local hardware store, it's blue. Won't absorb water and you can laminate it in fiberglass. Make sure to get a resin that won't dissolve it. You can use this for your grid. NOT FOR THE MOTOR STRINGERS. Make sure you leave room at the bottom for water drainage. I can't tell by your drawing but it looks like you are sealing the bottom of the hull with the stringer grid. Bad idea. You will hold water and thus weight and future corrosion. Fiberglass will absorb water. Then cause delamination.

Motor stringers were done a few years ago. That photo was from 2007 when I was re-doing the boat. For now I just laid some scrap ply over floor but now I'm back to do it properly.

No worries about the drainage... Notice how the center supports are rectangular, but the floor is angled. There will be about 3" of space under the framework. the triangular side supports will also have about a 2" triangle cut out of where it meets the stringers. I didn't draw it in because its hidden in that perspective. Notice how I drew the bulkhead closest to you in the picture? I have cutouts to let them drain

You starboard is good for the physical floor. That is what that product is made for so if you want and you have built a nice level grid you can use it. Just remember it is pricey. Then again the word boat is actually not a word but an anagram. Bring Out Another Thousand. Good luck with the project.

My concern with the starboard is A) weight, B) lack of self-supporting over spans, and C) cost. Its great for some things, but spans are not one of them. It says so right on the website

Maybe what I'll do is find some of that foam and experiement with some bonded skins.

In reply to curtis73:

Yeah if weight is a concern would avoid it. If you are good a laying glass then the laminated foam would be your best bet.

Tn Tech made a subamarine out of that construction method.

I googled some FRP manufacturers and emailed some of them. I found one that looks promising. They can take any of their FRP grating or bar grating and bond a sheet of 1/8" or 1/4" FRP or fiberglass sheet on to it. I need to get span ratings and calculate some weights but it looks like I can do a completely synthetic floor for the same or less weight than ply/epoxy. If my initial calculations are correct (translated: if the grate/sheet that I think will be right) I can do the whole floor with about 80 lbs of material compared to the 100+ lbs that it would take for ply/epoxy.

I wouldn't say I'm GOOD at laying glass, but fair. I don't suck anyway.