Mr_Asa

UltimaDork

10/3/23 8:18 a.m.

How common is it for someone to decide to tweak something after a job has been put into production?

Third phase of this one job and on two of the phases either one of my coworkers or I have had to stop forward movement on other projects to get back into tweaking, sometimes literally as stuff gets ordered.

E36 M3 comes in wrong cause of all the hurry-up as we try to get the changes in and then we have to pause forward momentum again to figure out what went wrong and how to fix it.

Its getting frustrating

Happened all the time in my world. The M-256 was a NATO weapon, the US got rights to make them. Using the original German prints, there were descrepancies; interference issues and excess wear problems. So the guy in the manufacturing area is working on print Revision A, you make the correction and now everyone works to Revision B.

There's also an easier route where production shuts down and resumes tomorrow, especially it it's a safety issue.

Your last sentence sounds like management and the budget people are pushing too hard.

That is a really open ended question so there could be a lot of answers. It is a change management deal, question. I used to make custom equipment and it was always on a short timeline so we would regularly start making things before engineering was done. Maybe it was adding holes or weldments, maybe you knew the main frame but were still adding sub assemblies. As the engineer you had to know where manufacturing was in the build cycle, if you were going to make a change that caused pain you better have a good reason why and tell them so they didn't freak out.

Now I am in aerospace so there is a rigorous change management system, some changes are immediate, some are at next batch, some can even be pull everything from the process and implement the change.

So as far as change goes I think you need 1 of 2 things. 1- a strong change management policy that is strictly enforced so everyone knows what is going on at any point, even if that causes pain. 2- engineers that are linked strongly to the manufacturing process so they don't do dumb E36 M3 that screws the people trying to make it.

Mr_Asa said:

How common is it for someone to decide to tweak something after a job has been put into production?

The better question is, "how common is it for something to fly through production with no issues?" It's never, the answer is never.

In reply to Paul_VR6 (Forum Supporter) :

HA! This is a running joke in my house. For years I was in a dysfunctional manufacturing environment where any OPS problem was blamed on Engineering and Engineering blamed OPS for being incompetent and not being able to follow the process. In truth there was probably a little blame for everyone. So when there is a problem like a zip lock bag zipper doesn't work my wife says "engineering", and I say "Ops did it".

In the process of releasing a new product comes a time to kill the engineers and begin production. Engineering changes MUST be managed, some are critical and need to be incorporated.

I'll just say that I've witnessed a number of times where "this is just the prototyping effort" somehow becomes "it's already engineered, just build it that way" when managers start looking for ways to save time/money. And then that situation needs corrected because the prototype wasn't ready to become the full production item. And the result is a lot of on-the-line or post-production corrective work that is much more costly in time/money than redoing the original engineering.

NOHOME

MegaDork

10/3/23 9:18 a.m.

When I was doing this stuff, my sanity was preserved by what is known as the "Phase Gate" system of product development. Each stage of the project was self contained from proposal to final product release as a "phase" of the project. The deliverables for unlocking the "gate" and moving to the next phase were spelled out as quantifiable specifications and requirements. The gatekeepers were not engineering but rather upper management, regulatory department, sales and whoever else saw themselves as stakeholders in the project, sometimes it was the actual client. The goal was to deliver the product that was requested and be able to show that it met the specifications and requirements asked for at the start.

Of course it made no difference to the cluster-berkeley that Mr_Asa or any other project manager is facing because the reality is that nobody knows what they don't know before you start. Every engineer wants a do-over at the end because that is when the best method is obvious. You also have company owners, bosses and clients who don't care that they signed off on something they did not understand. But it did help preserve my sanity because it prevented finger pointing at my team.

Mr_Asa

UltimaDork

10/3/23 9:39 a.m.

Paul_VR6 (Forum Supporter) said:

Mr_Asa said:

How common is it for someone to decide to tweak something after a job has been put into production?

The better question is, "how common is it for something to fly through production with no issues?" It's never, the answer is never.

Less that. I'm well versed with that.

This is more bossman finally realized we are getting ready to get the final orders together and wants to implement an upgrade he has been meaning to tell the engineering and design team about for months

In reply to Mr_Asa :

The hard part is for the management to uphold the update rules/timing. Unless it's operational critical, changes should happen on a fixed schedule. But it's the loudest managers who convince their bosses that minor things like paint hue changes are operational critical. Or worse that they bury the critical issues for many cycles.

In my case amplify all that has been said by the factor of being in a startup company just releasing our first "production". Refinements still happen regularly (mostly in processes) but the product is pretty close.

SV reX

MegaDork

10/3/23 10:38 a.m.

I'm not an engineer, but I work with them every day.

I've never seen a job that didn't have revisions midstream that impacted production. In over 40 years.

Honestly, it's rarely the engineer's fault. It's almost always the dynamic between the owner, CEO, decision makers and the design team. Owners think they have the right to change things if they want to (they do), and they don't expect it to impact their delivery dates (it should) because they have many dependencies in their operations that necessitate the delivery date holding firm. The design team puts a rush on the changes, which leaves bad communication with production (who already put things in motion months ago, and isn't prepared to change direction). It ALWAYS looks like production failed.

Rinse, repeat.

I had a job a few months ago where the the CEO walked in to the Accounting suite the DAY BEFORE final inspection and said "I think we should tear out the walls in here and reconfigure this space too". He didn't expect any changes in the scheduled delivery date. We had to pull in a crew to work 24/7, and try to hide the revisions from the inspector while he was inspecting (because the plan review process would have caused months of delays)

It's kinda normal.

In reply to SV reX :

Did anyone try to explain to the CEO in that accounting story the issues that would drive, and ask for a later date to make that change?

In reply to maschinenbau :

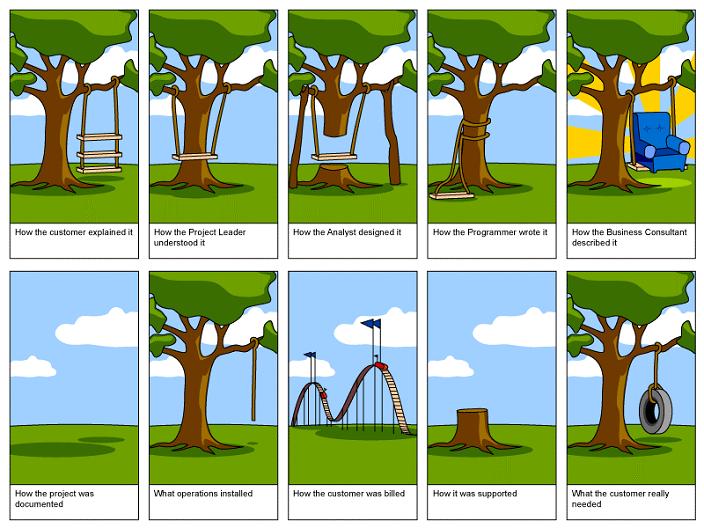

Yes very relevant, I love that one. I have it hanging up on the bulletin board in our office.

I've had projects catch on fire (nothing that I designed, that time) and require design changes.

The longer you're an engineer, the more perspective you get on such things. I was on the phone with a purchasing rep this morning who had some bad news to give. When I asked her why she called me instead of the lead engineer, she told me it was because she knew I could take it.

So now I get to tell him.

SV reX

MegaDork

10/3/23 1:26 p.m.

pres589 (djronnebaum) said:

In reply to SV reX :

Did anyone try to explain to the CEO in that accounting story the issues that would drive, and ask for a later date to make that change?

Sure. But it didn't matter.

CEOs make deadlines on projects for a reason. 2 years before that moment he had made the deadline based on the fact that his primary season for sales was the 4th quarter and he needed his showroom done. 4th quarter sales represent 65% of his annual sales, and he literally needed it done so he could pay for the project. Plus, there were financing deadlines that would expire if the project went any longer.

We could complain about him being unreasonable, or we could figure out a way to get it done and be first in line for the next few projects he had planned.

Makes no sense to bitch about the hand that feeds you, even if he's not that reasonable.

We make things happen. He gives us work.

I worked in the auto industry.......everybody could take a piece of the blame. I went to a meeting with an OEM and I was given a new bumhole for sending preproduction parts that weren't to spec. A couple of our own VPs were admonishing me for letting that happen until I told them the plant had managed to launch the product and we still didn't have a part drawing or written specs. I suggested that they come the the follow up meeting without me just in case that tidbit were to slip out. .....and this happened despite the fact that we had a whole system of phase exit reviews. E36 M3 happens!

SV reX

MegaDork

10/3/23 1:36 p.m.

Every single new project I've done in the past 12 years has been started before plans were complete. Preliminary site plans only- "Not for Construction".

INCLUDING the current one, which is a $5 BILLION project.

volvoclearinghouse said:

I've had projects catch on fire (nothing that I designed, that time) and require design changes.

The longer you're an engineer, the more perspective you get on such things. I was on the phone with a purchasing rep this morning who had some bad news to give. When I asked her why she called me instead of the lead engineer, she told me it was because she knew I could take it.

So now I get to tell him.

Anyone who acts like such a child that people don't want to tell them what is going on should re-evaluate their leadership technique, maybe their life choices all together. Sounds like maybe you should be the lead engineer.

SV reX said:

Every single new project I've done in the past 12 years has been started before plans were complete. Preliminary site plans only- "Not for Construction".

INCLUDING the current one, which is a $5 BILLION project.

This one hurts my soul. But I agree it is 100% how it works. If you only knew what those land development civils went through to get those plans to preliminary. It's 12-14 hour days in front of a computer with everyone pissed off and wondering why you aren't done yet. And then, you get absolutely slaughtered because there is an error. It's a rough world to live in.

What is more frustrating then engineering changes? Getting locked in a room with a pin headed bean counter and interrogated into cost reductions. Result? Never meet the cost target, get beaten up quarterly for this and then going through 2 100% product recalls.

SV reX

MegaDork

10/3/23 4:09 p.m.

In reply to Scotty Con Queso :

I'm sure it is. It's not a job I want.

Im not complaining. I learned a long time ago to swing with it and be flexible. I'm just recognizing that it's pretty normal now.

SV reX

MegaDork

10/3/23 4:16 p.m.

In reply to Scotty Con Queso :

We are working from plans to build the 2000 acres of building pad for over 16 million square feet of buildings which include NO utilities, storm drainage, or building designs.

11 detention ponds, 3 1/2 miles of frontage road, and a rail yard, and it's all gonna have to be redone when they figure out what they want to build and where the buildings are going.

In reply to SV reX :

Okay now that is extreme. I'll give you that one.