Useless piece of information for the day. Spruce Goose spark plugs.

So I happened upon an interesting useless piece of information the other day. How many spark plugs did (does I guess, it still exists) the spruce Goose have?

So, it has eight engines. Each one is a 28 cylinder supercharged four row, air cooled radial. That’s 28 cylinders as in four rows of seven cylinders. Btw, each cylinder has 2 spark plugs.

S0, that’s 28 cylinders per engine X 2 plugs per cylinder X 8 engines for a whopping total of 448 spark plugs!!!

Each engine initially made 3,000hp, later ones made 3,500hp. So that meant the Spruce Goose was pumping out up to 28,000hp back in 1947. What a shame it only ever made one flight.

Still the largest wing span ever I think

Neat info.

The layered airplane outline pic is really berkeleying with my head.

Read somewhere that the bottom cylinders in a radial will collect oil and bend rods at startup. This is avoided by removing the plugs and spinning the engine with the magneto grounded. I bet that was a bitch on the Goose.

Love learning random facts like this. Thanks for sharing!

A radial engine will accumulate oil in the lower cylinders but it's more a question of how long it sits and the condition of the piston rings as to how much oil ends up in them. Usually the engines are rotated by hand via the propellers to make sure no cylinders are hydro-locked and to push out any oil that has accumulated into the exhaust. If all is well then they fire them up.

I guess that explains the big puff of smoke on start up from those old timey engines. Neat info.

It must have been fun hand propping those engines 20 feet in the air.

When we could reach the props, we rotated the engine backwards.

In cold weather we diluted the oil with gasoline.

PHeller

PowerDork

3/24/15 9:36 a.m.

It's my understanding that it didn't fly over land, no more than 70 some feet in the air, only for a few minutes. It more or less was just ground effect vehicle.

In reply to Curmudgeon:

When you can reach the props from the ground you pull them through by hand. If there is too much oil you can't move the prop and then pull some plugs. I have assisted on A B-17 and several DC-3s, it takes considerable effort to pull those props.

Video of pulling props on a B-17 https://www.youtube.com/watch?v=Y4pmjZwCEJw

One rather scholarly article I read on that (yeah I have a lot of time on my hands) said that hand spinning won't necessarily clear the cylinders and it's quite possible to develop enough torque by hand to bend a rod. The same article mused that this problem may have contributed to the rather alarming losses of B17's and B29's during WW II.

Found the article: http://www.avweb.com/news/pilotlounge/182680-1.html

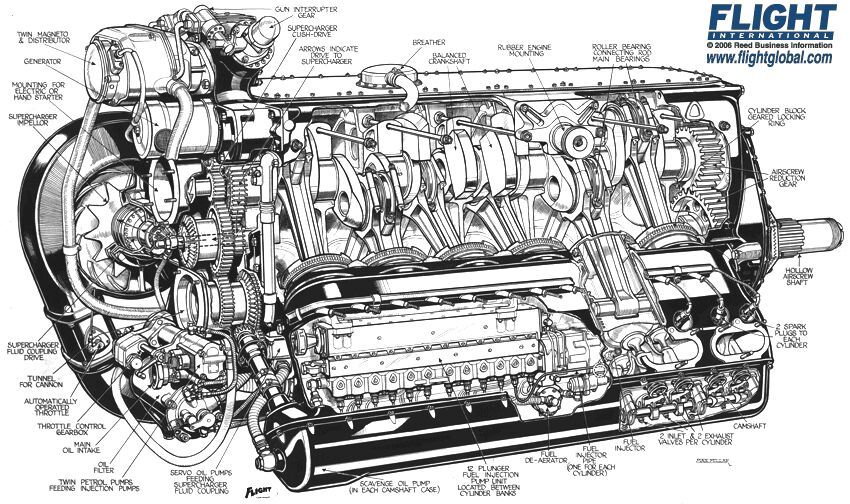

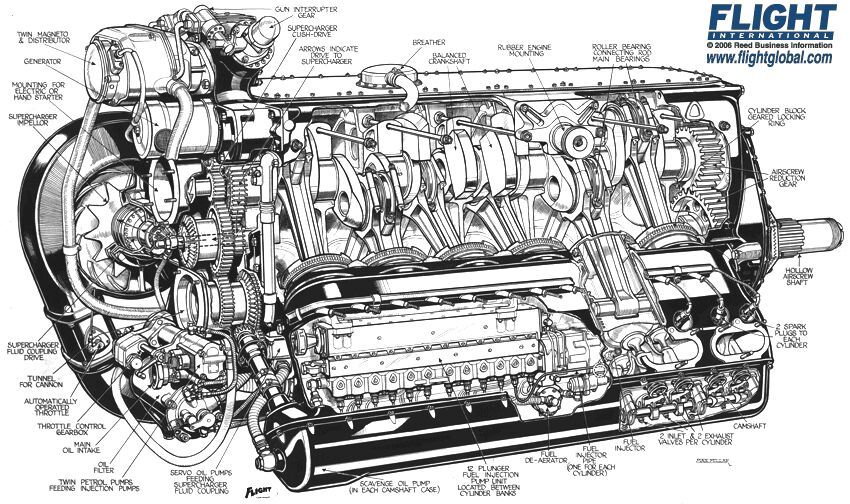

It's also interesting to note that the later Focke Wulf 190 engine was an inverted V12. Think about that for a moment: an upside down engine the size of a Merlin. The first ones were built by Junkers, later Mercedes.

No mention of how to avoid oil collecting in the cylinders.

In reply to Curmudgeon:

I think you mean ME109 engines- the FW190 used a radial engine. Not only were the ME109's inverted 12's, they were also fuel injected- so the inverted G capability was far better than the Spitfire or Hurricane of the time.

alfadriver wrote:

In reply to Curmudgeon:

I think you mean ME109 engines- the FW190 used a radial engine. Not only were the ME109's inverted 12's, they were also fuel injected- so the inverted G capability was far better than the Spitfire or Hurricane of the time.

Good point, how do carbs cope with -Ve G?

Not just the later (D) FW190's, all the 109's had Daimler-Benz inverted V12's

This is also why the Hispano HA1112 (Spanish after war copy of the Me109) had such a different nose then the Me109. The engines also turned different directions, that's a bit of an issue also as you can imagine. Note the location of the exhaust ports:

The HA1112's are best known as being used as Me109's in the movie The Battle of Britain.

In reply to alfadriver:

Most FW-190s had BMW radial engines. The FW-190D and the later TA-152 had Junker Jumo inverted V-12s.

Adrian_Thompson wrote:

alfadriver wrote:

In reply to Curmudgeon:

I think you mean ME109 engines- the FW190 used a radial engine. Not only were the ME109's inverted 12's, they were also fuel injected- so the inverted G capability was far better than the Spitfire or Hurricane of the time.

Good point, how do carbs cope with -Ve G?

They don't. They cut out once the bowl is empty. The 109s would just push over at full power. The Spits either had to roll over and pull or loose all power for a few seconds just when then needed the power (think about following a 109 that pulls into a climb then pushes over once into the climb). Either way, they loose a few seconds at a critical time.

Adrian_Thompson wrote:

...Each engine initially made 3,000hp, later ones made 3,500hp. So that meant the Spruce Goose was pumping out up to 28,000hp back in 1947. What a shame it only ever made one flight....

Guess what happens when you take one of those and put them in a Corsair:

Factory Hot Rod kamikaze chaser (built by Goodyear)

And you thought the Corsair nose was long in stock form!

aircooled wrote:

The HA1112's are best known as being used as Me109's in the movie The Battle of Britain.

The HA1112's are best known as being used as Me109's in the movie The Battle of Britain.

Ditto the CASA 2.111. They were a Spanish version of the Heinkel HE 111 and was used in the Battle of Briatin Film

Adrian_Thompson wrote:

alfadriver wrote:

In reply to Curmudgeon:

I think you mean ME109 engines- the FW190 used a radial engine. Not only were the ME109's inverted 12's, they were also fuel injected- so the inverted G capability was far better than the Spitfire or Hurricane of the time.

Good point, how do carbs cope with -Ve G?

The SU carb was developed as a partial solution to that exact problem but yes it would run out of fuel in an inverted position. The Germans developed fuel injection as their solution and it meant the German planes had a tactical advantage.

The valve covers on those inverted V12's were also the engine sump and a scavenge pump pulled oil out to send back to the engine bearings etc. So they were also what we know as 'dry sump' now. Lots of technical improvements which we take for granted now were developed in response to necessity back then.

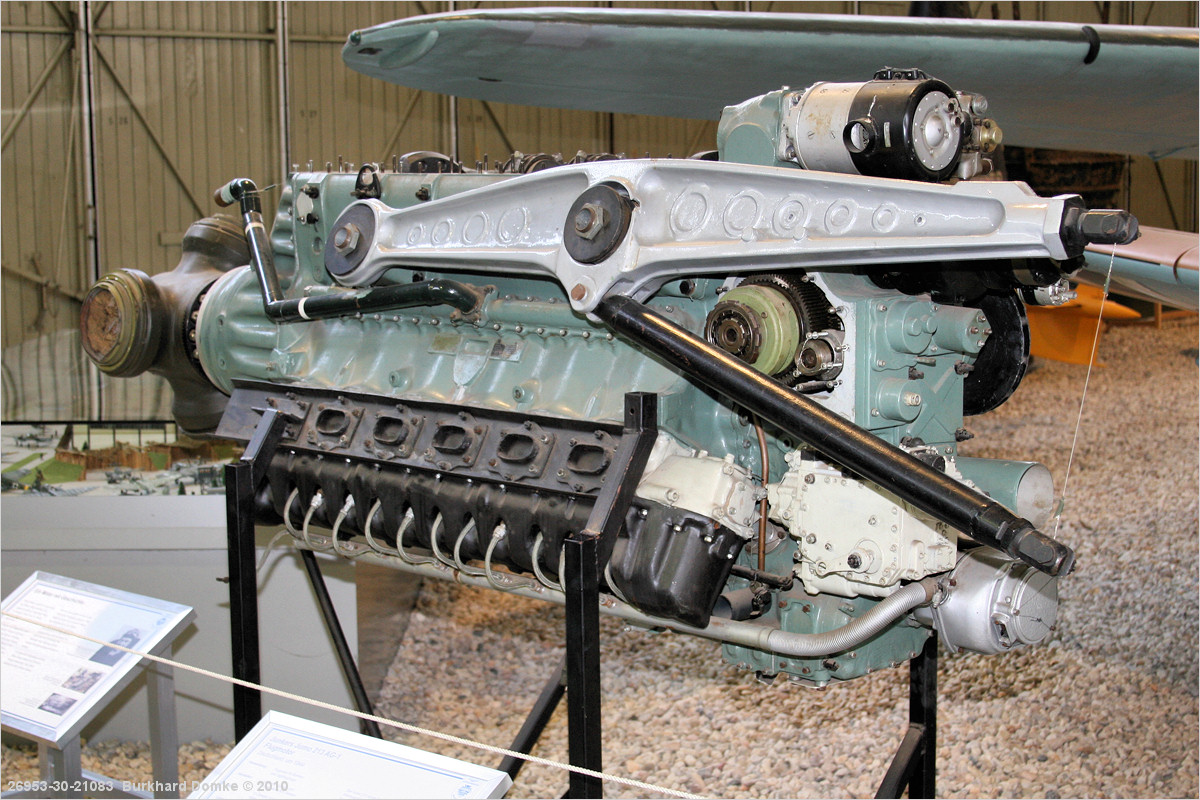

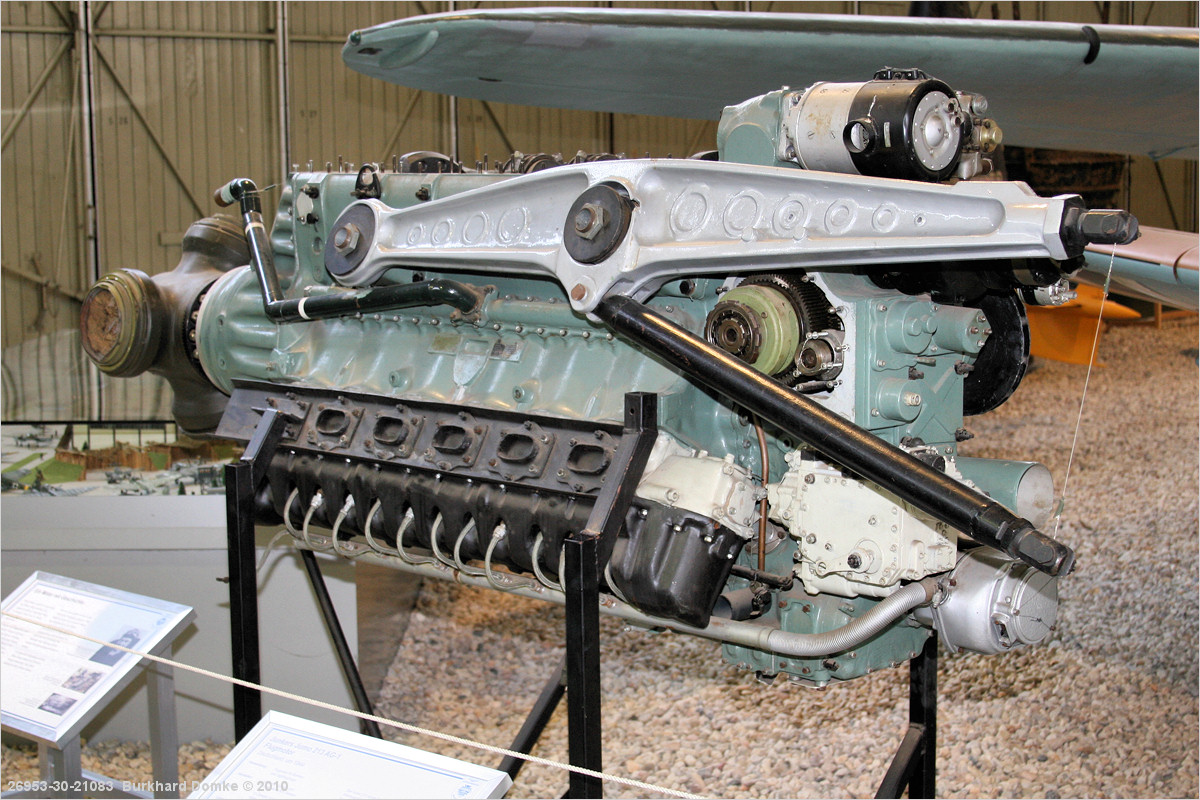

Look what's under the Goose's wing in this pic:

Curmudgeon wrote:

No mention of how to avoid oil collecting in the cylinders.

It is possible to bend a connecting rod by hand. Someone at work managed it a few weeks ago on a modern horizontally opposed engine by forcing it over.

When I worked on radials we would remove the bottom plug on the bottom cylinder if the engine was going to sit for a while. Then screw in a bottle to catch the offending oil.

I don't know about the losses unless the maintainers or pilots were just trying to get the aircraft up and caused the damage but let it go. That would be scary...

Compression releases are common in the motorcycle world. I wonder why the radial engine manufacturers didn't do something similar; on a four stroke the compression release opens the exhaust valve a bit so the engine can be kick started. It seems to me that would have been pretty simple to incorporate into radial engine design, thus negating the need to pull spark plugs etc and would have saved a lot of time.

Toebra

New Reader

3/24/15 11:24 a.m.

Adrian_Thompson wrote:

Good point, how do carbs cope with -Ve G?

Poorly, as described above

They were supercharged and used nitrous oxide too, because ze Germans could not get good high test fuel. They inverted the V-12 to have better weight distribution.

Early radials were known as 'rotaries' because the crankshaft was bolted to the airframe and the crankcase spun around it, thus eliminating the need for a power robbing flywheel. The carburetor fed through the center of the crankshaft.

It is really weird to see one running, it messes with your head.

https://www.youtube.com/watch?v=CYc-H8Wg-MQ